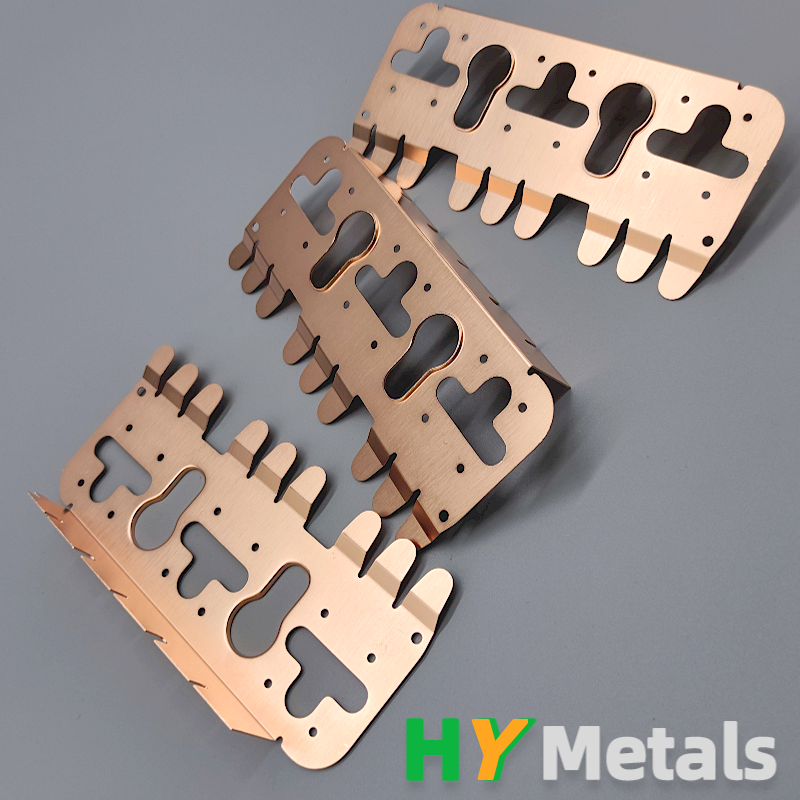

High-Quality Custom Sheet Metal Parts for Different Applications

By:Admin

{Company Name}, a leading manufacturer and supplier of custom sheet metal parts, has been at the forefront of the industry for over 20 years. The company specializes in providing high-quality, precision-engineered sheet metal parts to a wide range of clients across different sectors. With a strong focus on innovation and technological advancements, {Company Name} has gained a reputation for delivering top-notch solutions that meet the highest standards of quality and performance.

In a recent development, {Company Name} has announced the launch of a new line of custom sheet metal parts that are designed to offer enhanced durability, functionality, and efficiency. These parts are meticulously crafted using advanced manufacturing techniques and state-of-the-art equipment to ensure unmatched precision and performance. The company's team of skilled engineers and technicians work closely with clients to understand their specific requirements and deliver customized solutions that perfectly align with their needs.

"We are thrilled to introduce our new range of custom sheet metal parts that are engineered to deliver exceptional performance and reliability. At {Company Name}, we have always been committed to pushing the boundaries of innovation and excellence, and this new line of products is a testament to that commitment," said {Spokesperson Name}, the CEO of {Company Name}.

The new custom sheet metal parts offered by {Company Name} are available in a variety of materials including steel, aluminum, and copper, and can be customized in different shapes, sizes, and finishes to meet the unique needs of each client. The parts are designed to withstand harsh operating conditions and demanding applications, making them a perfect choice for industries where precision and quality are of utmost importance.

In addition to their exceptional quality, the custom sheet metal parts manufactured by {Company Name} are also known for their cost-effectiveness and quick turnaround times. The company employs efficient production processes and leverages its extensive industry expertise to deliver parts that not only meet the highest standards but also help clients optimize their operational costs and timelines.

{Spokesperson Name} further added, "We understand the critical role that custom sheet metal parts play in the smooth functioning of various industrial processes, and we are dedicated to providing our clients with solutions that exceed their expectations. With our new line of parts, we aim to set new benchmarks in terms of quality, performance, and reliability."

With a strong emphasis on continuous improvement and customer satisfaction, {Company Name} has established itself as a trusted partner for businesses looking for top-of-the-line custom sheet metal parts. The company's unwavering commitment to excellence, coupled with its dedication to staying ahead of industry trends, has helped it build a loyal customer base and earn accolades for its cutting-edge solutions.

As the demand for custom sheet metal parts continues to grow across diverse industries, {Company Name} is well-positioned to meet the evolving needs of its clients and deliver innovative solutions that drive operational efficiency and productivity. With its latest offering, the company is set to reinforce its leadership in the market and make a significant impact on the future of custom sheet metal fabrication.

In conclusion, the launch of the new line of custom sheet metal parts by {Company Name} underscores the company's relentless pursuit of excellence and innovation in the field of sheet metal fabrication. By combining superior quality, precision engineering, and customized solutions, the company is poised to redefine industry standards and solidify its position as a frontrunner in the global market for custom sheet metal parts.

Company News & Blog

Top Trends in Industry Design and Development: What You Need to Know

Industry Design And Development Part (IDDP) is a rapidly growing sector in the manufacturing industry, with a focus on creating innovative and cutting-edge designs for various products and components. It plays a crucial role in enhancing the functionality and aesthetics of products, ultimately contributing to the success of businesses in today’s competitive market.One company that is making waves in the IDDP sector is {}. Committed to excellence and innovation, {} has established itself as a leading player in the industry, delivering top-notch design and development services to a wide range of clients across different sectors.{}’s approach to IDDP is driven by a combination of creativity, technology, and a deep understanding of market trends. The company’s team of experienced designers and engineers work closely with clients to conceptualize, design, and develop products that not only meet but exceed their expectations. By leveraging the latest software and tools, {} is able to bring concepts to life and create prototypes that can be tested and refined before production.One of the key strengths of {} is its ability to tailor its IDDP services to the specific needs of each client. Whether it’s developing a new product from scratch or improving an existing design, the company’s multidisciplinary team has the expertise to take on projects of any scale or complexity. This client-centric approach has earned {} a strong reputation for delivering high-quality solutions that drive innovation and growth.In addition to its design and development capabilities, {} also places a strong emphasis on staying ahead of the curve when it comes to emerging technologies and industry trends. This forward-thinking mindset allows the company to anticipate the evolving needs of clients and adapt its services to meet those demands. Whether it’s incorporating sustainable materials into designs, embracing the principles of Industry 4.0, or exploring new manufacturing techniques, {} is always looking for ways to push the boundaries of IDDP.Furthermore, {} is dedicated to fostering collaboration and partnerships within the industry. By working with other manufacturers, suppliers, and technology providers, the company is able to tap into a network of expertise and resources that ultimately benefit its clients. This collaborative approach not only enhances the quality of its services but also drives value for all stakeholders involved.Looking ahead, the future of IDDP is bright, with continued advancements in technology and an increasing demand for innovative products across various sectors. As such, companies like {} are well-positioned to play a pivotal role in shaping the industry landscape and driving meaningful change through their design and development expertise.In conclusion, the IDDP sector is a critical component of the manufacturing industry, and {} is at the forefront of delivering exceptional design and development services. With a focus on creativity, innovation, and collaboration, the company is poised to continue making significant contributions to the success of its clients and the industry as a whole. As the market continues to evolve, it’s clear that {} will remain a key player in driving the future of IDDP.

High-Quality CNC Lathe Turning Parts for Precision Machining Needs

CNC Lathe Turning Parts - An Essential Component of Precision MachiningIn the world of precision machining, CNC lathe turning parts play a crucial role in the production of high-quality components. These parts are used in a wide range of industries, including aerospace, automotive, medical, and more. They are essential for creating precise and intricate components that meet the strict tolerances and specifications required by these industries.CNC lathe turning parts are manufactured using computer numerical control (CNC) technology, which allows for highly accurate and precise machining. This technology enables manufacturers to produce complex parts with tight tolerances and intricate geometries, ensuring that the finished components meet the exact specifications of their intended application.One company that specializes in the production of CNC lathe turning parts is {}. With over 20 years of experience in the precision machining industry, {} has established itself as a leading manufacturer of high-quality CNC lathe turning parts. The company has a proven track record of delivering precision machined components to a wide range of industries, and is known for its commitment to quality, innovation, and customer satisfaction.{} offers a wide range of CNC lathe turning parts, including shafts, bushings, fittings, connectors, and more. The company utilizes state-of-the-art CNC lathes and advanced machining techniques to produce parts that meet the highest standards of quality and precision. With a team of highly skilled engineers and machinists, {} is able to produce even the most complex and challenging parts with utmost precision and accuracy.In addition to its precision machining capabilities, {} is also committed to providing exceptional customer service. The company works closely with its customers to understand their specific needs and requirements, and strives to deliver tailored solutions that meet or exceed their expectations. {} is known for its quick turnaround times, competitive pricing, and dedication to customer satisfaction, making it a trusted partner for businesses in need of high-quality CNC lathe turning parts.With a focus on quality, innovation, and customer satisfaction, {} has positioned itself as a leader in the precision machining industry. The company's CNC lathe turning parts are used in a wide range of critical applications, and are known for their exceptional quality, precision, and reliability.In conclusion, CNC lathe turning parts are an essential component of precision machining, and play a crucial role in the production of high-quality components for a wide range of industries. With its commitment to quality, innovation, and customer satisfaction, {} has established itself as a leading manufacturer of high-quality CNC lathe turning parts, and is a trusted partner for businesses in need of precision machined components.

Precision Machined Parts for Aerospace Industry

Machined Aerospace Parts plays a critical role in the aviation industry. The leading company has a longstanding reputation for providing high-quality aviation components to airlines and aircraft manufacturers. It boasts a significant market share in the aerospace industry and prides itself on a variety of CNC machining capabilities to deliver exceptional results.The company's proven track record of delivering parts that meet military and commercial aviation standards has made it a trusted supplier in the aviation industry. Customers who partner with Machined Aerospace Parts appreciate the company's focus on innovation, quality, and superior customer service. These are the essential qualities that have propelled the company to the top of the industry.Machined Aerospace Parts' capabilities are vast and diversified to meet the constantly evolving needs of the industry. The company has an array of precision equipment and utilizes the latest tools and technologies to produce a range of components. Whether it's machining parts from solid materials, producing small or large components, or creating complex structures, Machined Aerospace Parts has the expertise to get the job done.The company has a team of highly skilled professionals who are experts in the field of aviation. From engineers to production managers, all staff members are deeply passionate about the industry and take pride in their work. The team is focused on creating efficient, cost-effective solutions that meet customers' unique needs.One of the reasons Machined Aerospace Parts is a preferred supplier in the aviation industry is due to its exceptional quality control process. The company ensures that every component is subject to rigorous testing to meet the strict standards of the industry. The quality control process begins with design reviews and ends with a final inspection of finished products. These stringent checks ensure that all parts meet exacting requirements, and nothing leaves the factory until it meets the company's high standards.Machined Aerospace Parts is committed to continuous improvement, and that includes investing in cutting-edge technology and equipment. The company recently added several new machines to its assembly line, expanding its CNC machining capabilities. The machines allow the company to operate faster, which ensures quicker lead times for customers.Despite the challenges posed by the COVID-19 pandemic, Machined Aerospace Parts has continued to thrive. It has remained committed to serving its customers' needs and has adapted well to the changing landscape. The company maintains safe working conditions and adheres to all regulations and health guidelines to ensure the safety of employees and customers.As a company committed to excellence, Machined Aerospace Parts invests significantly in its people. The company has a rigorous training program that ensures all staff members are up-to-date on the latest industry developments and are equipped with the skills necessary to meet customers' needs. The company also offers training and apprenticeships to young people who want to learn about the aviation industry. By investing in young talent, the company is securing the future of the industry.In conclusion, Machined Aerospace Parts is a well-established, reputable, and innovative aviation company. With its advanced technology, highly skilled workforce, and exceptional quality control, it is no surprise that it continues to succeed in the industry. The company's commitment to providing cost-effective, efficient solutions to customers has propelled it to the top of the industry, and it remains a preferred supplier for many airlines and aircraft manufacturers. In a constantly evolving industry, Machined Aerospace Parts is poised for growth, and its future looks exceedingly bright.

Listen to a New Track called Spinning by an Artist on SoundCloud

article about a new sound dynamic software and its benefits for music producers.In today's music industry, the need to innovate and explore new ways of creating sounds has never been greater. While traditional software and hardware tools have their advantages, they can sometimes fall short when it comes to creating complex and dynamic sounds that stand out in today's crowded market. That's where the new sound dynamic software, developed by a leading audio software company, comes in.The new software, which has been in development for over two years, introduces a new way of creating soundscapes that is different from anything else on the market. Unlike traditional software which is linear, the new software is spherical in nature, allowing for a much greater degree of freedom when it comes to creating and manipulating sound.So how does it work? The software uses a series of spherical coordinates to create a three-dimensional soundscape. Sound sources can be added in any position, and the software allows for complete control over the distance, direction and intensity of each source. This means that music producers can create complex and dynamic soundscapes that are not limited by traditional linear software.The benefits of this new software are numerous. For one, it allows producers to create truly unique and immersive soundscapes that can help their music stand out in a crowded market. The spherical nature of the software also makes it much easier to work with than traditional linear software, as it allows producers to work with sounds in a more intuitive and natural way.Perhaps the biggest benefit of this new software, however, is in its ability to create truly dynamic soundscapes. Traditional software can sometimes struggle when it comes to creating sounds that change in intensity or direction over time. The new software, however, allows for complete control over every aspect of the soundscape, which means that producers can create sounds that evolve and change in ways that were simply not possible with traditional software.The development of this new software has been a long and arduous process, but the results speak for themselves. Industry insiders have been raving about the software, with many calling it a game-changer for the industry. Music producers who have had the chance to use the software have been equally impressed, with many saying that it has revolutionized the way they create sound.The new software is also highly customizable, allowing producers to tailor it to their specific needs. This means that it can be used in a wide variety of genres, from electronic dance music to classical orchestration. The software is also compatible with a wide range of hardware and software setups, making it a valuable addition to any producer's toolbox."It's amazing to think that just a few years ago, this kind of technology was simply not possible," said one industry insider. "But now, thanks to the hard work of this software company, we have a game-changing tool that is going to change the face of music production."Overall, the new sound dynamic software is a must-have for any music producer looking to create unique and dynamic soundscapes. It represents a significant leap forward in technology and is sure to be a game-changer for the industry.

How to Build a Heavy CNC Milling Machine: 18 Steps with Pictures

Machine, Instructables, heavy CNC milling, epoxy granite, linear guides, building processCNC Milling Machine: A Comprehensive Guide to Building Your OwnBuilding a heavy-duty CNC milling machine is not a task for the faint-hearted. It requires a lot of different working steps and careful planning to ensure that you end up with a machine that can deliver precise and accurate results. In this blog post, we will take a closer look at the steps involved in building a big CNC machine with good milling performance, as well as the materials and equipment needed for the project.Step 1: Design and PlanningThe first step in building a CNC milling machine is to design and plan the machine. This involves deciding on the size of the machine, the materials to be used, the type of milling machine to be used, and the features and capabilities that the machine should have. It is important to have a clear understanding of the requirements before starting the project to avoid any costly mistakes down the line.Step 2: Building the MoldThe next step is to build a big and accurate mold for casting the epoxy granite. Epoxy granite is a popular material for building milling machines due to its sturdiness and vibration damping properties. The mold should be designed to ensure that it is rigid and can create a smooth surface finish. The casting process should be done carefully to avoid any air bubbles or voids that can cause inaccuracies in the finished cast.Step 3: Aligning the Linear GuidesThe linear guides play a crucial role in the accuracy and precision of the milling machine. They are responsible for guiding the cutting tool along a straight and consistent path. The linear guides should be aligned carefully to ensure that they are in perfect alignment with the cutting tool. This requires careful attention to detail and the use of precision measuring tools.Step 4: Building the Machine FrameThe frame of the milling machine should be built to be strong and rigid. The use of high-quality materials such as aluminum or steel is recommended. The frame should be designed with sufficient clearance to accommodate the linear guides and other machine components.Step 5: Assembling the MachineOnce all the components of the milling machine have been prepared, it is time to start assembling the machine. This requires careful attention to detail and a lot of patience. Each component should be installed carefully and securely to ensure that the machine is stable and can deliver precise and accurate results.ConclusionBuilding a heavy CNC milling machine is a challenging task that requires a lot of time and effort. However, with careful planning and attention to detail, it is possible to build a machine that can deliver precise and accurate results. The use of high-quality materials and precision measuring tools is essential to ensure that the machine is built to the required specifications. With the right approach, anyone can build their own CNC milling machine and take their machining capabilities to the next level.

High-quality Turning Parts for Industrial Machinery at Competitive Prices

Turning Parts is a leading manufacturer of precision components serving a variety of industries, including automotive, aerospace, and medical. The company specializes in the production of high-quality turning parts that are essential for the functioning of mechanical systems in various applications.Founded in 1985, Turning Parts has established itself as a trusted provider of precision components for a wide range of industries. With a dedicated team of experienced engineers and a state-of-the-art manufacturing facility, the company has the capability to produce turning parts with tight tolerances and complex geometries to meet the specific requirements of its customers.The company's dedication to quality and precision has earned it a reputation for excellence in the industry. Turning Parts is committed to investing in the latest technology and equipment to ensure that it remains at the forefront of innovation and can provide its customers with the highest quality turning parts.In addition to its commitment to excellence, Turning Parts places a strong emphasis on customer satisfaction. The company works closely with its customers to understand their unique needs and provide them with tailored solutions that meet their specific requirements. Whether it's a small batch of turning parts for a prototype or a large-scale production run, Turning Parts has the flexibility and expertise to deliver on time and within budget.Turning Parts' comprehensive range of turning parts includes shafts, bushings, couplings, and other components that are crucial for the smooth operation of various mechanical systems. The company's expertise in turning parts manufacturing allows it to offer a diverse portfolio of products that can be customized to meet the most demanding specifications.With a global customer base, Turning Parts has built a strong network of partners and suppliers to support its operations. The company has a well-established supply chain that ensures it can source the highest quality materials and components for its turning parts, allowing it to maintain its high standards of quality and reliability.Moreover, Turning Parts is committed to sustainable and responsible manufacturing practices. The company adheres to stringent environmental regulations and invests in eco-friendly technologies to minimize its impact on the environment. By prioritizing sustainability, Turning Parts aims to contribute to a more sustainable future for the industry and the planet.As a forward-thinking company, Turning Parts is continually looking for new opportunities to expand its range of products and services. The company is dedicated to staying ahead of the curve in terms of technological advancements and market trends, ensuring that it can continue to meet the evolving needs of its customers.In conclusion, Turning Parts is a reputable manufacturer of precision turning parts with a strong commitment to quality, innovation, and customer satisfaction. With its extensive experience, technical expertise, and dedication to excellence, the company is well-positioned to continue serving as a trusted partner for industries that rely on high-quality turning parts.

UK Supplier of Diverse Electronic Components: Serving Commercial, Industrial, and Military Sectors

in the proper context.Electronic Components | Discover the Best Components for Your NeedsThe electronic revolution has transformed the world, creating unprecedented levels of connectivity and enabling powerful digital technologies. However, all of these technologies are built on the foundation of electronic components. These are the building blocks that make up all of the electronic devices around us, from our smartphones and computers, to our cars and homes.Electronic components come in a wide range of shapes and forms, and they are used to perform all sorts of functions, from storing and processing information, to converting signals and powering devices. As such, they are an essential requirement for all industries, including commercial, industrial, and military.Choosing the right electronic components can be challenging, as there is a vast array of options available. However, it is crucial to select the right components to ensure that your product performs optimally, lasts longer, and operates reliably, no matter what industry you are in.At Electronic Components, we offer a one-stop-shop for all your electronic component needs. We are a UK source for all types of components, and we have extensive experience supplying parts across a range of sectors. Whatever your requirements, we have the expertise and resources to deliver.Our range of electronic components covers everything from passive components like resistors and capacitors, to active components like semiconductors and microcontrollers. We also offer a wide range of sensors, transducers, and power components, as well as connectors, switches, and relays.We pride ourselves on the quality of our products, and we work with the world's leading manufacturers to ensure that our products are of the highest quality. We also offer competitive pricing and quick turnaround times, enabling you to get the components you need when you need them.At Electronic Components, we are committed to providing outstanding customer service, and we are always striving to exceed our customers' expectations. We work closely with our customers to understand their requirements and find the best solutions for their needs. We also offer technical support and advice, so you can be confident that you are making the right choices for your project.Whether you are in the commercial, industrial, or military sector, Electronic Components is your go-to source for all your electronic component needs. We have the experience, expertise, and resources to deliver the best products and services on the market, ensuring that your projects run smoothly and meet your expectations.So if you are looking for the best electronic components on the market, look no further than Electronic Components. We are here to help you achieve your goals and take your projects to the next level. Contact us today to learn more about our products and services, and discover how we can help you succeed.

High-Quality Precision Turning Parts for Your Manufacturing Needs

Precision Turning Parts (PTP), a leading manufacturer of high-quality precision machined components, has once again proven their commitment to excellence by delivering top-notch products to their customers. With a solid reputation for producing precision turning parts that meet the highest industry standards, PTP has established itself as a trusted partner for companies in a wide range of industries.Established over 20 years ago, PTP has continuously invested in cutting-edge technology and state-of-the-art manufacturing facilities to ensure that they are always at the forefront of the industry. Their team of highly skilled engineers and technicians are dedicated to producing components that not only meet the exact specifications of their customers, but also exceed their expectations in terms of quality and performance.One of the key factors that sets PTP apart from other precision turning parts manufacturers is their unwavering commitment to quality. Every component that comes off their production line undergoes rigorous quality control checks to ensure that it meets the strictest standards. This dedication to quality has earned PTP numerous certifications and accolades, as well as the trust and loyalty of their customers.In addition to their commitment to quality, PTP also places a strong emphasis on innovation. They are constantly exploring new materials, processes, and techniques to improve their products and stay ahead of the competition. This dedication to innovation has allowed PTP to offer their customers the latest advancements in precision turning parts, giving them a competitive edge in their respective industries.Furthermore, PTP prides themselves on their ability to provide custom solutions to their customers' unique needs. Their team of engineers work closely with each customer to understand their requirements and develop tailored solutions that meet their specific needs. This personalized approach has allowed PTP to build long-lasting relationships with their customers, many of whom have been with the company for years.In addition to their commitment to quality and innovation, PTP also places a strong emphasis on sustainability. They have implemented various initiatives to reduce their environmental impact, including the use of energy-efficient equipment and the recycling of materials. This commitment to sustainability not only benefits the environment, but also helps PTP's customers meet their own sustainability goals.As PTP continues to grow and expand their capabilities, they remain committed to providing the highest level of service to their customers. Whether it's producing complex components for the aerospace industry or critical parts for the medical field, PTP is dedicated to delivering the quality and precision that their customers have come to expect.With a solid track record of success and a dedication to excellence, Precision Turning Parts (PTP) stands out as a leader in the precision turning parts industry. Their commitment to quality, innovation, and sustainability sets them apart from the competition and makes them a trusted partner for companies in a wide range of industries. As they continue to push the boundaries of what is possible in precision machining, PTP is poised to remain at the forefront of the industry for years to come.

High Aspect Ratio BGA Heat Sinks: Perfect for Small PCB Spaces

article on the benefits of using BGA High Aspect Ratio Extruded heat sinks in thermal management applications.As electronic devices continue to become more compact, thermal management becomes a crucial aspect to ensure their continuous and reliable operation. To address this challenge, BGA High Aspect Ratio Extruded heat sinks have emerged as a reliable thermal management solution that delivers high performance in compact PCB environments.BGA High Aspect Ratio Extruded heat sinks are designed with a high aspect ratio or length-to-width ratio, which allows for optimal placement of fins, maximizing heat dissipation while maintaining a small footprint. The fins also provide an increased surface area, allowing for more efficient heat transfer, resulting in improved thermal performance.The use of BGA High Aspect Ratio Extruded heat sinks has many benefits. These heat sinks are ideal for compact PCB environments where space is at a premium and traditional heat sinks cannot fit without compromising other critical components. They are suitable for use in a wide range of electronic devices, including routers, switches, amplifiers, power supplies, and more.One of the main advantages of using BGA High Aspect Ratio Extruded heat sinks is their ability to dissipate heat efficiently. These heat sinks have a high aspect ratio, which means that they have a longer distance or length than the width, allowing more fins to be accommodated, providing greater surface area for heat dissipation. The more fins a heat sink has, the more efficient it is in dissipating heat.Moreover, the fins of the BGA High Aspect Ratio Extruded heat sinks are designed in such a way that they promote convective heat transfer, which results in faster and more efficient heat dissipation. With convective heat transfer, hot air moves away from the heat sink and cool air moves in, leading to a continuous cycle of thermal management.Another benefit of BGA High Aspect Ratio Extruded heat sinks is their ability to accommodate a wide range of thermal requirements. These heat sinks are available in different shapes, sizes, and configurations to suit various thermal performance requirements.In addition to their versatile size range, BGA High Aspect Ratio Extruded heat sinks are also available in different materials. Aluminum is a common material used in the fabrication of heat sinks as it is lightweight, durable, and has excellent thermal conductivity. Other materials, such as copper, can also be used for specific applications.BGA High Aspect Ratio Extruded heat sinks also have a longer lifespan when compared to other thermal management solutions. They are designed to withstand high temperatures and thermal cycles, ensuring that they can deliver optimal heat dissipation for extended periods. Overall, the use of BGA High Aspect Ratio Extruded heat sinks provides several advantages over traditional thermal management solutions. They are efficient, versatile, and reliable, making them an ideal choice for various applications where optimizing thermal performance in compact spaces is critical.In summary, BGA High Aspect Ratio Extruded heat sinks offer many benefits in thermal management applications. They maximize heat dissipation through convective heat transfer, accommodate a wide range of thermal requirements, and have a longer lifespan, and provide an optimal solution for compact spaces. As such, they are an excellent choice for electronic devices that require reliable and efficient thermal management.

Discover the Latest News on Precision CNC Machining Parts

article:CNC Machining Parts Proves to be an Essential Resource for Precision EngineeringFor many decades, the manufacturing industry has relied on CNC machines to produce high-quality end products with a precision-level of accuracy. Among these machines, CNC Machining Parts have become a fundamental resource to aid in the production of high-performance products that meet strict manufacturing specifications. In today's competitive market, achieving success in precision engineering depends on having access to the latest cutting-edge technology. This is where CNC Machining Parts come in, proving to be an essential resource that has transformed the manufacturing industry, providing a step up in the production of the highest-grade products.CNC Machining Parts are CNC-machined components that have been specifically designed to meet the stringent demands of various industries. They are produced to the most exacting standards of quality and durability, ensuring that they offer the best performance under tough and demanding circumstances. These parts are made from high-quality materials like metals, plastics, and composites that ensure that they can withstand the pressures of modern production environments.CNC Machining Parts have been designed to operate with a high degree of precision, accuracy, and reliability. CNC machines, which produce these parts, are run by computers, delivering the highest level of control and accuracy over the manufacturing process. They are programmed to perform a series of highly precise movements that create the desired end product, guaranteeing the highest levels of quality in every component produced. The CNC production process is incredibly fast and efficient, allowing for the manufacturing of large quantities of parts in a short amount of time.The CNC Machining Parts produced by {} are some of the most sophisticated and advanced in the industry. Featuring cutting-edge technology and materials, these parts have been developed to withstand the most demanding of conditions and environments. The company's production process involves the use of state-of-the-art computer-controlled machinery. The automation of this manufacturing process ensures that each part produced is a high-quality, durable component that meets the strictest demands of the manufacturing industry.CNC Machining Parts have a broad scope of applications across a range of industries. They are used in many diverse fields such as aerospace, electronics, automotive, marine, and medical industries, to mention a few. In the aerospace industry, for instance, these parts are used in the manufacture of aircraft parts, ensuring that they are highly durable and can withstand the rigors of high-altitude flight. In the automotive industry, CNC Machining Parts are used in the production of engine components, ensuring that they are efficient and can withstand high temperatures and robust driving conditions.In the medical industry, CNC Machining Parts have become instrumental in the production of high-quality medical devices and equipment. These machines produce precision components for use in surgical instruments, prosthetics, hearing aids, and other medical devices that require precise measurements. The efficiency of CNC Machining Parts has made the production of these components more accessible, cheaper, and faster, thereby improving the medical industry's level of quality.CNC Machining Parts have become essential in modern-day manufacturing. They have transformed the way manufacturing is done, offering higher levels of precision, reliability, and consistency, resulting in better-performing products. The CNC Machining Parts produced by {} are some of the best in the business and come highly recommended by satisfied customers. The company's emphasis on quality, value, and customer service has made them a leader in the industry. By utilizing cutting-edge technology, top-quality materials, and a team of skilled engineers, the company has set itself apart from its competitors, providing superior CNC Machining Parts that meet the stringent demands of various industries.In conclusion, CNC Machining Parts have become an essential resource for precision engineering. They have revolutionized the manufacturing industry by offering the highest level of precision, accuracy, and consistency, thereby producing the highest quality products. The CNC Machining Parts produced by {} are among the best on the market, utilizing state-of-the-art technology, efficient production processes, and high-quality materials. The company's focus on quality, customer service, and innovation has made it a standout performer in the industry, providing the best products and services that meet the needs of customers around the world.