Precision CNC Machining for Small Parts: What You Need to Know

By:Admin

{Company Name} is a world-class precision machining company that has been in the business for over 20 years. With state-of-the-art facilities and a team of highly skilled machinists, they have built a reputation for delivering high-quality products to a wide range of industries, including aerospace, automotive, medical, and more.

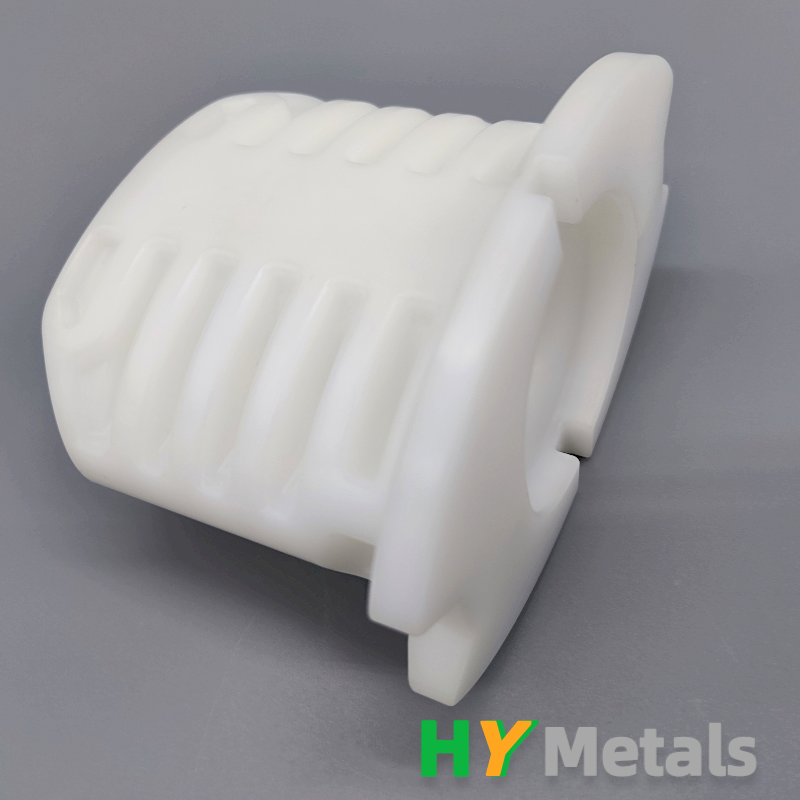

One of the key services offered by {Company Name} is CNC machining of small parts. This process involves using computer-controlled machines to remove material from a workpiece, resulting in the production of intricate and precise components. With their advanced CNC equipment and expertise, {Company Name} has the capability to machine a wide variety of small parts, from prototypes to high-volume production runs.

The company's CNC machining capabilities are particularly well-suited for producing small parts that require tight tolerances and complex geometries. This includes components such as gears, bushings, connectors, and many others. Their ability to work with a wide range of materials, including metals, plastics, and composites, further expands the possibilities for small part machining.

In addition to their technical capabilities, {Company Name} also focuses on providing exceptional customer service. They work closely with their clients to understand their specific needs and requirements, ensuring that the machined parts meet the highest standards of quality and accuracy. This collaborative approach has allowed them to build long-standing relationships with their customers, who rely on {Company Name} for their precision machining needs.

With the increasing demand for small, intricate parts across various industries, {Company Name} continues to invest in the latest CNC machining technologies to stay ahead of the curve. Their commitment to innovation and continuous improvement has made them a trusted partner for companies seeking high-quality small parts for their products.

In a recent development, {Company Name} has made significant investments in their CNC machining capabilities, including the acquisition of new equipment and the implementation of advanced software solutions. This has further enhanced their ability to produce small parts with unmatched precision and efficiency, reinforcing their position as a leader in the precision machining industry.

One of the key advantages of working with {Company Name} for CNC machining of small parts is their ability to handle complex projects with quick turnaround times. Their advanced equipment and experienced machinists allow them to optimize production processes, minimizing lead times and ensuring timely delivery of machined parts to their customers.

Overall, {Company Name} has solidified its position as a top-tier provider of CNC machining services for small parts, catering to the diverse needs of industries that demand precision and reliability. With their unwavering commitment to quality and customer satisfaction, they continue to be the go-to choice for businesses looking for a trusted partner in precision machining.

As the manufacturing industry continues to evolve, the demand for high-quality small parts will only increase. With {Company Name}'s dedication to excellence and continuous investment in CNC machining technologies, they are well-positioned to meet the evolving needs of their customers and maintain their leadership in the precision machining sector.

Company News & Blog

High-Quality CNC Prototype Parts: Your Ultimate Guide

CNC Prototype Parts: Precision Engineering at Its FinestIn the world of manufacturing, precision is key. Every part and component must be engineered with the utmost accuracy to ensure the smooth operation of the final product. This is where CNC prototype parts come into play. CNC, or computer numerical control, machining is a process that uses computer-aided design (CAD) software to create precise and intricate parts from raw materials. {Company} is a leading provider of CNC prototype parts, specializing in the production of high-quality components for a wide range of industries. With state-of-the-art equipment and a team of experienced engineers, {Company} is dedicated to delivering top-notch prototype parts that meet the exact specifications of their clients.CNC machining allows for the production of complex parts with incredible precision. Using computer-controlled cutting tools, {Company} is able to create intricate designs and shapes that would be impossible to achieve through traditional machining methods. This level of precision is crucial for industries such as aerospace, automotive, medical, and electronics, where even the smallest deviation can have a significant impact on the performance of the final product.One of the key advantages of CNC machining is its ability to produce prototype parts quickly and efficiently. {Company}'s advanced machinery and streamlined production process allow them to rapidly turn around prototype parts, reducing lead times and enabling their clients to bring new products to market faster. This speed and efficiency are crucial for companies looking to stay ahead of the competition and capitalize on new opportunities.In addition to speed and precision, {Company} also places a strong emphasis on quality. Their team of skilled engineers and machinists meticulously inspects every part to ensure it meets the highest standards. This commitment to quality has earned {Company} a reputation for excellence, making them a trusted partner for companies seeking reliable prototype parts.{Company} offers a wide range of materials for CNC prototype parts, including aluminum, steel, titanium, and various plastics. This versatility allows them to accommodate the diverse needs of their clients and produce parts for a wide variety of applications. Whether it's a small, intricate component or a large, complex part, {Company} has the capability to deliver.Furthermore, {Company}'s dedication to customer service sets them apart from the competition. Their team works closely with clients throughout the prototyping process, providing valuable insights and expertise to help optimize designs and improve manufacturability. This collaborative approach ensures that the final parts not only meet the client's specifications but also exceed their expectations.With the demand for precision-engineered parts on the rise, {Company} is well-positioned to meet the needs of a wide range of industries. Their commitment to quality, speed, and customer service has solidified their reputation as a premier provider of CNC prototype parts. As they continue to innovate and expand their capabilities, {Company} is poised to play a crucial role in the advancement of manufacturing and engineering.In conclusion, CNC prototype parts are an essential component of modern manufacturing, and {Company} is at the forefront of delivering high-quality, precision-engineered components. With their advanced machinery, skilled team, and dedication to customer service, {Company} is a trusted partner for companies looking to bring innovative products to market.

Discover the Latest Aluminum Extrusion Profiles

Aluminum Extrusion Profiles are an essential component in various industries such as construction, automotive, aerospace, and manufacturing. These profiles are manufactured using a process called aluminum extrusion, wherein the aluminum is forced through a die to create a specific cross-sectional profile.One of the leading manufacturers of aluminum extrusion profiles is {company name}. With over 20 years of experience in the industry, {company name} has established itself as a trusted supplier of high-quality aluminum extrusion profiles to a wide range of customers worldwide.{Company name} offers a diverse range of aluminum extrusion profiles, including standard profiles, custom profiles, and specialty profiles for specific applications. These profiles are available in various alloys, including 6061, 6063, and 7075, with different surface finishes such as anodized, powder-coated, and mill finish.One of the key advantages of aluminum extrusion profiles is their lightweight yet strong characteristics, making them ideal for structural applications in the construction and automotive industries. The versatility of aluminum extrusion profiles also allows for complex shapes and designs, making them suitable for architectural and decorative purposes.In addition to standard profiles, {company name} also specializes in custom aluminum extrusion profiles, tailored to meet the unique requirements of their customers. With a team of experienced engineers and designers, {company name} can assist customers in developing custom profiles to exact specifications, ensuring a perfect fit for their specific needs.Furthermore, {company name} is committed to sustainability and environmental responsibility in their manufacturing processes. Aluminum is a highly recyclable material, and the extrusion process itself generates minimal waste, making it a sustainable choice for customers seeking eco-friendly solutions.With a state-of-the-art manufacturing facility and a dedicated team of experts, {company name} has the capability to produce high-volume orders with precision and efficiency, ensuring on-time delivery to their customers.The quality of {company name}’s aluminum extrusion profiles is upheld through stringent quality control measures and rigorous testing procedures, ensuring that each profile meets the highest standards for performance and durability.Having established a strong reputation for reliability and excellence, {company name} has built long-standing relationships with customers across various industries, serving as a trusted partner in providing top-quality aluminum extrusion profiles.As the demand for aluminum extrusion profiles continues to grow, {company name} remains poised to meet the evolving needs of the market, leveraging their expertise and capabilities to deliver innovative solutions to their customers.In conclusion, {company name} is a leading manufacturer of aluminum extrusion profiles, offering a comprehensive range of standard, custom, and specialty profiles to a diverse customer base. With a focus on quality, sustainability, and customer satisfaction, {company name} continues to set the benchmark for excellence in the industry, solidifying its position as a preferred supplier of aluminum extrusion profiles globally.

High-Quality CNC Machined Parts for Precision Engineering

CNC Machined Parts are at the heart of the manufacturing industry, and they play a crucial role in the production of a wide range of products. From automotive components to aerospace parts, CNC machined parts are essential in creating precision-engineered products. One company that is at the forefront of providing top-quality CNC machined parts is {}. With a strong focus on precision and quality, {} has become a trusted partner for many leading companies in various industries.{} specializes in the production of CNC machined parts using the latest technology and advanced machining techniques. The company's state-of-the-art facilities are equipped with high-precision CNC machines that can produce complex and intricate parts with exceptional accuracy. Whether it's a simple prototype or a high-volume production run, {} has the capabilities to meet the most demanding requirements.The company prides itself on its ability to deliver precision-engineered parts with quick turnaround times. By utilizing advanced CAD/CAM software and highly skilled machinists, {} can efficiently program and manufacture CNC machined parts to meet tight deadlines. This rapid production capability has made {} a preferred supplier for companies that require fast and reliable machining services.In addition to its cutting-edge manufacturing capabilities, {} places a strong emphasis on quality control. The company follows strict quality assurance protocols to ensure that each part meets the highest standards of accuracy and consistency. By employing advanced inspection equipment and rigorous quality checks, {} ensures that its CNC machined parts are of the highest quality before they are delivered to customers.As a customer-centric company, {} is committed to providing exceptional customer service and support. The company works closely with its clients to understand their specific needs and requirements, and it offers customized solutions to meet their unique challenges. Whether it's providing design assistance, optimizing manufacturing processes, or offering technical advice, {} goes above and beyond to ensure that its customers receive the best possible service.In addition to its focus on precision and quality, {} is also dedicated to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its manufacturing processes to reduce its environmental impact. By using efficient machining techniques and minimizing waste, {} strives to operate in an environmentally conscious manner.With its unwavering commitment to excellence, {} has established itself as a leading provider of CNC machined parts. The company's dedication to precision, quality, and customer satisfaction has earned it a stellar reputation in the manufacturing industry. Whether it's producing intricate components for the aerospace industry or creating custom parts for the automotive sector, {} continues to set the standard for excellence in CNC machining.In conclusion, CNC machined parts are an integral part of modern manufacturing, and {} is a standout leader in the industry. With its advanced capabilities, stringent quality control, and unwavering commitment to customer satisfaction, {} has become the go-to partner for companies seeking top-quality CNC machined parts. As the manufacturing sector continues to evolve, {} remains at the forefront, delivering precision-engineered parts that meet the highest standards of excellence.

Discover the Best Stamping Tools and Beading Courses Online

and Bead Art’. Bead art has become increasingly popular over the past decade, reaching new levels of creativity and elegance. From bracelets, necklaces, and earrings to stunning home decor, beads offer a vast range of possibilities when it comes to crafting. There are numerous types of beads available in the market, each having its unique charm and quality. But, you may ask, how can you add that extra flavor to your bead art? Stamping tools can help!Stamping tools have been around for a long time and are usually used in leathercraft and metal stamping. However, they can be effectively used in creating bead art too. The technique brings out a new dimension in bead art and allows for a stylish and personalized touch.So, how do you use stamping tools in your bead art? For starters, you will need a few things: a set of stamping tools, a hammer, a workbench, and the beads that you want to stamp on. Once all these are in place, you can go ahead and start!First, you need to determine which stamping tool you want to use. There are various types of stamping tools available, including letters, numbers, and shapes. You can choose the alphabet stamping tool if you want to add a name or message onto your beads, or you could choose a pattern stamping tool to create a unique design on your beads.Once you have chosen the stamping tool, you can proceed to stamp the beads. Place the bead onto the workbench and position the stamping tool where you want it to be stamped. Then, gently tap the stamping tool with the hammer. Remember to be gentle as too much force could break the bead.Voila! You have added a personalized touch to your bead art. The possibilities are endless with stamping tools, and you can mix and match them to create unique designs on your beads.Bead It! iBEADS.com is an online store that offers classes in bead art and information about their two stores located in the island of Oahu. They have a vast range of beads and bead accessories available, including stamping tools. If you're a beginner or an experienced bead artist looking for inspiration, they offer classes catered to all levels.In conclusion, using stamping tools in bead art is an excellent way to add a personal flair to your jewelry pieces or home decor. With a little bit of creativity, you can come up with unique and stunning designs. Don't be afraid to experiment with different stamping tools and bead combinations – who knows, you might just discover your next masterpiece!

High-Quality Aluminum CNC Parts for Custom Projects

Custom CNC Aluminum Part Innovation Drives {} Growth{} is continuing to drive innovation in the manufacturing industry through the development of custom CNC aluminum parts. The company has become known for its expertise in precision machining and has established itself as a leader in the production of specialized components for a wide range of industries.The company's commitment to excellence and a customer-centric approach have been the driving forces behind its success. By leveraging advanced manufacturing technologies and a highly skilled workforce, {} has been able to meet the unique needs of its clients and deliver high-quality products that exceed expectations.One of the key factors that sets {} apart from its competitors is its investment in cutting-edge CNC machining capabilities. CNC (computer numerical control) machining allows for the precise and efficient production of complex parts, including those made from aluminum. With the ability to accurately shape and manufacture intricate components, {} has been able to provide its customers with tailored solutions that are essential for their operations.The custom CNC aluminum parts produced by {} are widely used in a variety of applications. From aerospace and automotive to medical and electronics, these components play a crucial role in ensuring the performance and reliability of different systems and machinery. By leveraging their expertise in CNC machining, {} has been able to cater to the diverse needs of these industries and contribute to their advancements.In addition to the exceptional quality of its products, {} has also earned a reputation for its ability to deliver on a wide range of specifications. The company's engineering team works closely with clients to understand their unique requirements and develop customized solutions that are tailored to their exact needs. This collaborative approach has allowed {} to establish strong partnerships with its customers and become a trusted provider of custom CNC aluminum parts.Furthermore, {}'s commitment to continuous improvement and investment in the latest manufacturing technologies has enabled the company to streamline its production processes. By utilizing state-of-the-art CNC machining equipment, {} has been able to increase efficiency, reduce lead times, and maintain cost-effectiveness for its clients. This has not only improved the company's overall performance but has also allowed it to stay at the forefront of the industry.Looking ahead, {} remains focused on further expanding its capabilities and enhancing its offerings. The company continues to explore new opportunities for growth and diversification, including the development of advanced CNC machining techniques and the expansion of its product portfolio. By staying ahead of the curve, {} aims to continue serving as a reliable partner for its clients and a driving force in the manufacturing sector.In conclusion, {}'s dedication to innovation and its expertise in custom CNC aluminum parts have been instrumental in its continued success. By prioritizing quality, precision, and customer satisfaction, the company has solidified its position as a leading provider of specialized components. With a strong foundation and a forward-looking mindset, {} is well-positioned to make a lasting impact in the industry and contribute to the advancement of manufacturing.

Durable Custom Metal Parts for Various Industries

Custom Metal Parts Supplier {Company} Celebrates Expansion and Growth{City, Date}--Custom metal parts supplier {Company} is celebrating its expansion and growth as it continues to meet the needs of its diverse customer base. With a focus on precision and quality, {Company} has been able to provide custom metal parts for a wide range of industries, including automotive, aerospace, and medical.Founded in {year}, {Company} has built a reputation for excellence in the custom metal parts industry. With a team of highly skilled engineers and technicians, the company is able to create custom metal parts that meet the exact specifications of its customers. Whether it is a complex metal component for an aerospace application or a precision part for a medical device, {Company} has the expertise and capabilities to deliver high-quality products.In recent years, {Company} has seen significant growth in its customer base, as more companies recognize the value of custom metal parts that are tailored to their specific needs. This increased demand has led to the expansion of {Company}'s manufacturing facilities, allowing the company to increase its production capacity and offer a wider range of custom metal parts to its customers."We are thrilled to see the continued success and growth of {Company}," said {Spokesperson}, a representative of the company. "Our team has worked hard to build a reputation for excellence in the custom metal parts industry, and it is rewarding to see the positive impact that we are having on our customers and the industries we serve."{Company} is committed to staying at the forefront of technology and innovation in the custom metal parts industry. The company has invested in state-of-the-art manufacturing equipment and advanced quality control processes to ensure that its products meet the highest standards. Additionally, {Company} continues to invest in research and development to explore new materials and techniques that can further enhance the quality and performance of its custom metal parts.The expansion of {Company}'s manufacturing facilities is an exciting development for the company and its customers. With increased production capacity, {Company} is now able to take on larger orders and offer shorter lead times, allowing it to better meet the needs of its customers. In addition, the company has expanded its product line to include a wider range of custom metal parts, giving customers even more options to choose from."We are proud of the growth and expansion that {Company} has experienced in recent years," said {Spokesperson}. "Our dedicated team has been the driving force behind our success, and we are excited to continue serving our customers with the highest quality custom metal parts."As {Company} celebrates its expansion and growth, the company is also looking ahead to the future. With a strong focus on innovation and customer satisfaction, {Company} is poised to continue its leadership in the custom metal parts industry, providing high-quality products and exceptional service to its customers.For more information about {Company} and its custom metal parts, visit {website} or contact {contact information}.About {Company}:{Company} is a leading supplier of custom metal parts for a wide range of industries. With a focus on precision and quality, the company has built a reputation for excellence in the custom metal parts industry. Through its commitment to innovation and customer satisfaction, {Company} continues to provide high-quality products and exceptional service to its customers.

High-quality precision components for CNC machining.

CNC Precision Components, a leading manufacturer in the field of precision machining, has recently announced its expansion plans to meet the growing demand for its products. The company, known for its high-quality components and superior customer service, is set to increase its production capacity and expand its global reach to better serve its customers.With over [number of years] of experience in the industry, CNC Precision Components has built a solid reputation for its ability to deliver precision-engineered parts to a wide range of industries including aerospace, automotive, medical, and defense. The company’s state-of-the-art facility is equipped with the latest CNC machines and advanced manufacturing technologies, allowing it to produce complex components with tight tolerances and exacting specifications.As part of its expansion plans, CNC Precision Components will be adding new machining centers, hiring additional skilled personnel, and implementing advanced quality control measures to ensure that its products meet the highest standards. This investment in new technology and talent will enable the company to increase its production capacity and reduce lead times, allowing it to better support its customers’ growing needs.In addition to expanding its production capabilities, CNC Precision Components is also focusing on strengthening its global presence. The company plans to establish strategic partnerships and distribution channels in key international markets to better serve its growing customer base. By building relationships with local partners, CNC Precision Components aims to provide localized support and faster turnaround times for its customers around the world.“We are excited about the opportunities that lie ahead for CNC Precision Components,” said [Spokesperson Name], [Job Title] of the company. “Our expansion plans will enable us to better meet the needs of our customers while solidifying our position as a leader in the precision machining industry. We are committed to maintaining the high quality and reliability that our customers have come to expect from us.”In addition to its expansion plans, CNC Precision Components is also dedicated to maintaining its commitment to sustainability and environmental responsibility. The company is continuously looking for ways to reduce its environmental footprint, minimize waste, and optimize its manufacturing processes to operate in an environmentally friendly manner.CNC Precision Components takes great pride in its ability to deliver high-quality precision components while maintaining a focus on sustainable and responsible business practices. By investing in the latest technology, expanding its production capacity, and enhancing its global reach, the company is well-positioned to continue meeting the evolving needs of its customers while maintaining its dedication to excellence.About CNC Precision Components:CNC Precision Components is a leading manufacturer specializing in the production of high-quality precision components for a wide range of industries. With a focus on quality, reliability, and customer satisfaction, the company has established itself as a trusted partner for businesses in need of precision-engineered parts. With its commitment to excellence and continuous improvement, CNC Precision Components is dedicated to meeting the evolving needs of its customers while upholding the highest standards of quality and service. For more information, please visit [company website].

How to Safely Hang Shelves - Tips from Interior Design Experts

[Company Introduction][Company Name] is a leading industry player in the technology and manufacturing sector. Established in [year], the company has amassed a reputation for innovative products and solutions that cater to a wide range of consumer needs. With a team of highly skilled professionals and state-of-the-art manufacturing facilities, [Company Name] constantly strives to deliver excellence and meet the ever-evolving demands of the market.Known for its commitment to quality and customer satisfaction, [Company Name] has established a strong presence both locally and internationally. Their expansive product portfolio includes a variety of cutting-edge technological solutions, from consumer electronics to industrial equipment, with a focus on creating seamless integration in an increasingly connected world.[Company Name] prides itself on its research and development efforts, investing a significant portion of its resources to stay at the forefront of technological advancements. By fostering a culture of innovation and collaboration, the company has been able to consistently introduce pioneering products that have helped reshape the industry.[Company Name]'s dedication to sustainability is another cornerstone of its operations. By implementing eco-friendly manufacturing processes and incorporating sustainable materials into its products, the company actively contributes to the global efforts in preserving the environment. This commitment to sustainability has not only earned [Company Name] accolades within the industry but also resonated with consumers seeking environmentally responsible choices.With a global presence, [Company Name] has established a robust distribution network that ensures their products reach consumers in various regions. By partnering with leading retailers and e-commerce platforms, the company has successfully expanded its market reach and diversified its sales channels, ensuring easy access to its products for consumers worldwide.[Negotiations with U bracket]Despite facing stiff competition within the technology sector, [Company Name] has continued to thrive by actively seeking mutually beneficial business partnerships. Recently, the company has engaged in negotiations with a reputed U bracket manufacturer to explore collaboration opportunities.The U bracket, an integral component in various industries, serves as a support or fastening device. By partnering with the U bracket manufacturer, [Company Name] aims to enhance its existing product lineup and expand its offerings in sectors such as construction, manufacturing, and automotive.The negotiations between the two entities have progressed positively, with both parties recognizing the potential synergies that can be achieved through collaboration. An agreement between [Company Name] and the U bracket manufacturer would result in the mutual exchange of knowledge, resources, and expertise, ultimately benefiting consumers and helping both companies capture a larger market share.Moreover, [Company Name]'s established distribution network can help streamline the U bracket manufacturer's access to markets it previously struggled to enter. This partnership would provide the U bracket manufacturer with an opportunity to expand its global reach and increase its market presence significantly.The U bracket manufacturer, renowned for its precision engineering and superior quality, aligns well with [Company Name]'s commitment to delivering excellence. By combining their respective strengths, both companies can leverage their expertise to develop innovative U bracket solutions that cater to diverse industry needs and ensure customer satisfaction.The potential collaboration between [Company Name] and the U bracket manufacturer not only promises growth and innovation but also exemplifies the power of strategic partnerships within the industry. As negotiations progress and terms are finalized, the joint efforts of these two industry leaders are expected to open new avenues for expansion and market dominance.In conclusion, [Company Name] continues to demonstrate its commitment to excellence, innovation, and sustainability within the technology and manufacturing sector. The ongoing negotiations with the U bracket manufacturer represent an exciting opportunity for both companies to leverage their respective strengths and explore new avenues of growth. With their combined expertise, [Company Name] and the U bracket manufacturer are well-positioned to bring forth cutting-edge solutions that cater to a wide range of industry needs and further their success in the global market.

Exploring the Revolutionary World of 3D Printing and Rapid Prototyping

[Company Name] Revolutionizes the World of Manufacturing through 3D Printing and Rapid Prototyping[City, State] - The world of manufacturing is undergoing a revolution, thanks to the revolutionary technologies of 3D printing and rapid prototyping. One company leading this charge is [Company Name], a groundbreaking organization that is pushing the boundaries of what is possible in the manufacturing industry.With its cutting-edge facilities and state-of-the-art equipment, [Company Name] has become a leader in the field of 3D printing and rapid prototyping. By harnessing the power of these technologies, the company has been able to transform the way products are designed, prototyped, and manufactured.Traditionally, the manufacturing process involved a series of time-consuming steps, including the creation of molds and tooling. These steps often resulted in significant costs and delays, making it difficult for companies to bring their ideas to life quickly and efficiently. However, the advent of 3D printing and rapid prototyping has changed the game completely.One of the key advantages of 3D printing is its ability to quickly create physical objects directly from digital designs. This eliminates the need for molds or tooling, thereby reducing costs and speeding up the production process. By using state-of-the-art 3D printers, [Company Name] is able to produce highly detailed and accurate prototypes in a fraction of the time it would take using traditional manufacturing methods.Furthermore, rapid prototyping allows companies to iterate and refine their designs at an unprecedented speed. In the past, making changes to a design required extensive retooling or starting from scratch. With rapid prototyping, [Company Name] can quickly produce multiple iterations of a design, allowing for rapid feedback and improvement. This iterative process ensures that products are of the highest quality, meeting the exact specifications of the clients.[Company Name] caters to a wide range of industries, including automotive, aerospace, medical, and consumer goods. Its advanced capabilities have allowed companies from these sectors to streamline their product development processes and bring innovative products to market faster than ever before.Beyond rapid prototyping, [Company Name] also offers a range of value-added services to its clients. These include product design and engineering, 3D scanning, and low-volume production. By providing a comprehensive suite of services, the company aims to support clients throughout the entire product development lifecycle, from concept to production.Furthermore, [Company Name] places a strong emphasis on sustainability and environmental responsibility. 3D printing significantly reduces waste compared to traditional manufacturing processes, as it only uses the exact amount of materials needed to print an object. This, coupled with the ability to recycle and reuse materials, makes 3D printing a more eco-friendly option. By leveraging these technologies, [Company Name] is contributing to the global effort to reduce carbon footprints and minimize environmental impact.Looking to the future, [Company Name] has plans to continue pushing the boundaries of what is possible in the world of manufacturing. With ongoing investments in research and development, the company aims to stay at the forefront of technological advancements. By embracing new materials, improving print speeds, and expanding its capabilities, [Company Name] is set to shape the future of manufacturing.As the manufacturing industry continues to evolve, companies like [Company Name] will play a crucial role in driving innovation and efficiency. By harnessing the power of 3D printing and rapid prototyping, they are empowering businesses to bring their ideas to life in a faster, more cost-effective manner. With [Company Name]'s cutting-edge technology and commitment to excellence, the possibilities for the future of manufacturing are truly limitless.

UK Supplier of Diverse Electronic Components: Serving Commercial, Industrial, and Military Sectors

in the proper context.Electronic Components | Discover the Best Components for Your NeedsThe electronic revolution has transformed the world, creating unprecedented levels of connectivity and enabling powerful digital technologies. However, all of these technologies are built on the foundation of electronic components. These are the building blocks that make up all of the electronic devices around us, from our smartphones and computers, to our cars and homes.Electronic components come in a wide range of shapes and forms, and they are used to perform all sorts of functions, from storing and processing information, to converting signals and powering devices. As such, they are an essential requirement for all industries, including commercial, industrial, and military.Choosing the right electronic components can be challenging, as there is a vast array of options available. However, it is crucial to select the right components to ensure that your product performs optimally, lasts longer, and operates reliably, no matter what industry you are in.At Electronic Components, we offer a one-stop-shop for all your electronic component needs. We are a UK source for all types of components, and we have extensive experience supplying parts across a range of sectors. Whatever your requirements, we have the expertise and resources to deliver.Our range of electronic components covers everything from passive components like resistors and capacitors, to active components like semiconductors and microcontrollers. We also offer a wide range of sensors, transducers, and power components, as well as connectors, switches, and relays.We pride ourselves on the quality of our products, and we work with the world's leading manufacturers to ensure that our products are of the highest quality. We also offer competitive pricing and quick turnaround times, enabling you to get the components you need when you need them.At Electronic Components, we are committed to providing outstanding customer service, and we are always striving to exceed our customers' expectations. We work closely with our customers to understand their requirements and find the best solutions for their needs. We also offer technical support and advice, so you can be confident that you are making the right choices for your project.Whether you are in the commercial, industrial, or military sector, Electronic Components is your go-to source for all your electronic component needs. We have the experience, expertise, and resources to deliver the best products and services on the market, ensuring that your projects run smoothly and meet your expectations.So if you are looking for the best electronic components on the market, look no further than Electronic Components. We are here to help you achieve your goals and take your projects to the next level. Contact us today to learn more about our products and services, and discover how we can help you succeed.