A Guide to Heat Sink Extrusion: What You Need to Know

By:Admin

In today's fast-paced world of technology, electronic devices are becoming more powerful and compact, which inevitably leads to an increase in heat generation. This rise in temperature can have detrimental effects on the performance and longevity of electronic components. To combat this issue, the use of heat sinks has become indispensable in the field of thermal management. Among various types of heat sinks available in the market, heat sink extrusions have proven to be a superior solution for effective heat dissipation.

{Company name}, a leading manufacturer of heat sink extrusions, has been at the forefront of developing innovative thermal management solutions for a wide range of applications. With a strong focus on research and development, the company has continuously pushed the boundaries of heat sink technology to meet the evolving needs of the electronics industry.

Heat sink extrusions are aluminum-based heat sinks that are created through an extrusion process, which involves pushing a solid aluminum billet through a die to produce the desired shape. This method allows for the creation of complex and efficient heat sink designs that are both lightweight and cost-effective. The extrusion process also enables the incorporation of various features such as fins, channels, and mounting holes, providing flexibility in design and performance.

One of the key advantages of heat sink extrusions is their superior thermal conductivity. Aluminum, the most commonly used material for heat sink extrusions, offers excellent thermal conductivity, allowing for efficient heat transfer from the electronic components to the surrounding environment. This property is crucial in preventing the overheating of electronic devices and ensuring their reliable operation.

In addition to thermal conductivity, the lightweight nature of aluminum makes heat sink extrusions an ideal choice for applications where weight reduction is a consideration. The ease of machining and surface treatment further enhances the versatility of aluminum heat sink extrusions, allowing for customized solutions to meet specific thermal management requirements.

{Company name} has been instrumental in optimizing the design and manufacturing processes of heat sink extrusions to deliver top-quality solutions to its customers. By leveraging advanced simulation and analysis tools, the company can accurately predict the thermal performance of its heat sink designs, ensuring that they meet the stringent requirements of modern electronics.

Furthermore, {Company name} has established stringent quality control measures to guarantee the consistency and reliability of its heat sink extrusions. The company's state-of-the-art manufacturing facilities are equipped with the latest machinery and technology, allowing for precise and efficient production of heat sink extrusions that adhere to the highest industry standards.

The applications of heat sink extrusions are diverse, ranging from consumer electronics and telecommunications to automotive and industrial equipment. Their ability to effectively dissipate heat makes them essential components in electronic devices such as power supplies, LED lighting, computer systems, and motor drives, among others. With the increasing demand for high-performance electronics, the need for efficient thermal management solutions has never been greater, making heat sink extrusions an indispensable technology.

As the electronics industry continues to advance, the role of heat sink extrusions in thermal management will become even more critical. {Company name} is committed to staying at the forefront of heat sink technology, continuously innovating and refining its products to meet the evolving demands of the market.

In conclusion, heat sink extrusions have emerged as a game-changing solution for thermal management, with their superior thermal conductivity, lightweight nature, and design flexibility. {Company name} has been a driving force in the development and manufacturing of high-quality heat sink extrusions, catering to a wide range of industries. With a focus on innovation and excellence, {Company name} is well-positioned to address the evolving thermal management needs of the electronics industry.

Company News & Blog

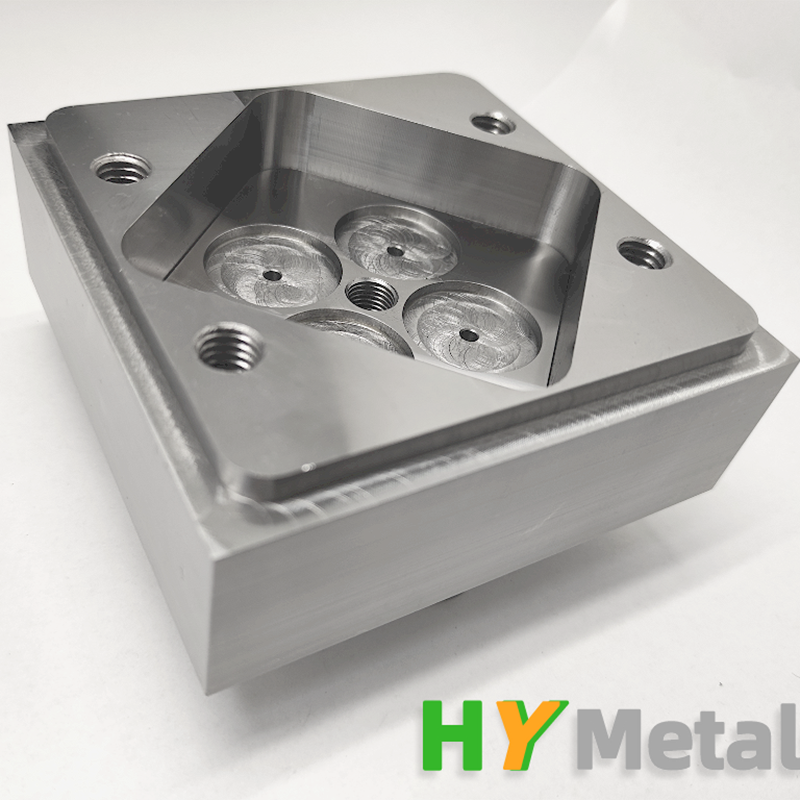

High-Quality Aluminum CNC Parts for Custom Projects

Custom CNC Aluminum Part Innovation Drives {} Growth{} is continuing to drive innovation in the manufacturing industry through the development of custom CNC aluminum parts. The company has become known for its expertise in precision machining and has established itself as a leader in the production of specialized components for a wide range of industries.The company's commitment to excellence and a customer-centric approach have been the driving forces behind its success. By leveraging advanced manufacturing technologies and a highly skilled workforce, {} has been able to meet the unique needs of its clients and deliver high-quality products that exceed expectations.One of the key factors that sets {} apart from its competitors is its investment in cutting-edge CNC machining capabilities. CNC (computer numerical control) machining allows for the precise and efficient production of complex parts, including those made from aluminum. With the ability to accurately shape and manufacture intricate components, {} has been able to provide its customers with tailored solutions that are essential for their operations.The custom CNC aluminum parts produced by {} are widely used in a variety of applications. From aerospace and automotive to medical and electronics, these components play a crucial role in ensuring the performance and reliability of different systems and machinery. By leveraging their expertise in CNC machining, {} has been able to cater to the diverse needs of these industries and contribute to their advancements.In addition to the exceptional quality of its products, {} has also earned a reputation for its ability to deliver on a wide range of specifications. The company's engineering team works closely with clients to understand their unique requirements and develop customized solutions that are tailored to their exact needs. This collaborative approach has allowed {} to establish strong partnerships with its customers and become a trusted provider of custom CNC aluminum parts.Furthermore, {}'s commitment to continuous improvement and investment in the latest manufacturing technologies has enabled the company to streamline its production processes. By utilizing state-of-the-art CNC machining equipment, {} has been able to increase efficiency, reduce lead times, and maintain cost-effectiveness for its clients. This has not only improved the company's overall performance but has also allowed it to stay at the forefront of the industry.Looking ahead, {} remains focused on further expanding its capabilities and enhancing its offerings. The company continues to explore new opportunities for growth and diversification, including the development of advanced CNC machining techniques and the expansion of its product portfolio. By staying ahead of the curve, {} aims to continue serving as a reliable partner for its clients and a driving force in the manufacturing sector.In conclusion, {}'s dedication to innovation and its expertise in custom CNC aluminum parts have been instrumental in its continued success. By prioritizing quality, precision, and customer satisfaction, the company has solidified its position as a leading provider of specialized components. With a strong foundation and a forward-looking mindset, {} is well-positioned to make a lasting impact in the industry and contribute to the advancement of manufacturing.

Best Tips for Aluminum Welding: Techniques, Tools, and Safety Precautions

Aluminum welding is a crucial process in various industries, such as automotive, aerospace, and manufacturing. The ability to efficiently and effectively weld aluminum is essential for creating strong and durable products. One company that has gained recognition for its expertise in aluminum welding is {}.{} is a leading manufacturer of welding equipment and solutions. With over 50 years of experience in the industry, the company has established itself as a reliable and innovative provider of welding technology. {} offers a wide range of welding equipment, including advanced machines for aluminum welding, as well as comprehensive training and support services.The company's advanced aluminum welding equipment is designed to meet the specific needs of various industries. Whether it's automotive components, aerospace parts, or architectural structures, {}'s welding solutions are capable of delivering high-quality welds on aluminum materials. The company's commitment to research and development has led to the creation of cutting-edge welding technology that ensures precision and efficiency in aluminum welding processes.One of the key advantages of {}'s aluminum welding equipment is its ability to produce welds with superior strength and integrity. Aluminum is known for its lightweight and corrosion-resistant properties, making it a preferred material in many applications. However, welding aluminum can be challenging due to its high thermal conductivity and low melting point. {}'s welding technology is specially designed to overcome these challenges and produce high-quality welds that meet industry standards.In addition to its advanced equipment, {} also provides comprehensive training and support services to ensure that customers are able to maximize the potential of their welding technology. The company's team of experts offers training programs and workshops on aluminum welding techniques, as well as on-site support for troubleshooting and optimization of welding processes. This level of support is crucial for industries that rely on aluminum welding for the production of critical components and structures.Furthermore, {} is dedicated to sustainability and environmental responsibility. The company's aluminum welding technology is designed to minimize energy consumption and waste generation, contributing to a more sustainable manufacturing process. By investing in {}'s welding solutions, companies can reduce their environmental impact while maintaining high standards of quality and efficiency.{}'s commitment to excellence in aluminum welding has earned the company a strong reputation in the industry. Its innovative technology, comprehensive support services, and dedication to sustainability make {} a trusted partner for businesses seeking reliable aluminum welding solutions. With a focus on continuous improvement and customer satisfaction, {} is well-positioned to meet the evolving needs of the welding industry.As the demand for aluminum welding continues to grow across various sectors, {} remains at the forefront of innovation, offering state-of-the-art solutions for the most challenging welding applications. The company's dedication to quality, reliability, and sustainability makes {} a go-to provider for businesses looking to elevate their aluminum welding capabilities.In conclusion, {}'s expertise in aluminum welding, combined with its advanced technology and comprehensive support services, makes it a key player in the welding industry. With a focus on innovation, sustainability, and customer satisfaction, {} is well-equipped to address the diverse needs of industries that rely on aluminum welding for their manufacturing processes. By choosing {} as a partner, businesses can ensure that their aluminum welding operations are efficient, cost-effective, and of the highest quality.

High-Quality Aluminum Casting Services: What You Need to Know

Aluminum Casting Company Leads the Industry with Innovative SolutionsAluminum has long been recognized as a highly versatile metal, offering a wide range of applications due to its lightweight and durable properties. As the demand for aluminum products continues to grow, companies such as [Company Name] have stepped up to provide innovative casting solutions to meet the needs of various industries.[Company Name] is a leading aluminum casting company that has been at the forefront of the industry for over 20 years. With a strong dedication to quality, innovation, and customer satisfaction, [Company Name] has firmly established itself as a go-to provider for precision aluminum casting solutions.The company's state-of-the-art facilities are equipped with advanced technology and machinery, allowing for the production of high-quality aluminum castings that meet the strictest industry standards. From complex geometries to intricate designs, [Company Name] has the expertise and capabilities to deliver a wide range of custom aluminum casting solutions to its customers.One of the key factors that set [Company Name] apart from its competitors is its commitment to continuous improvement and innovation. The company's team of experienced engineers and technicians are constantly exploring new techniques and processes to enhance the quality and efficiency of its casting operations. This dedication to innovation has led to the development of cutting-edge casting solutions that have earned [Company Name] a reputation for excellence in the industry.In addition to its technical capabilities, [Company Name] prides itself on its customer-centric approach to business. The company works closely with its clients to understand their specific casting requirements, offering personalized solutions that are tailored to meet their exact needs. Whether it's a prototype for a new product or a large-scale production run, [Company Name] is committed to delivering superior aluminum castings that exceed expectations.Furthermore, [Company Name] places a strong emphasis on sustainability and environmental responsibility. The company has implemented various eco-friendly practices in its operations, including the use of recycled aluminum and energy-efficient processes. By reducing its environmental footprint, [Company Name] is helping to promote a more sustainable future for the industry and the planet.Despite the challenges posed by the global pandemic, [Company Name] has continued to demonstrate resilience and adaptability. The company has implemented strict health and safety protocols to protect its employees and maintain uninterrupted operations. This proactive approach has allowed [Company Name] to fulfill its commitments to customers and uphold its reputation as a reliable and trustworthy partner.Looking ahead, [Company Name] is poised to further strengthen its position in the aluminum casting industry. The company is actively investing in new technologies and expanding its production capabilities to meet the evolving demands of its customers. By remaining at the forefront of innovation and customer satisfaction, [Company Name] is well-equipped to lead the industry and continue providing superior aluminum casting solutions for years to come.

Discover the Latest Trends in Metal Forming Technology

Metal Forming, a renowned leader in the metal manufacturing industry, has continued to gain recognition for its innovative and high-quality products. The company, which has been in business for over 50 years, has established itself as a reliable and trusted supplier of metal components for a wide range of industries. With a focus on precision and excellence, Metal Forming has positioned itself as a top choice for businesses seeking custom metal solutions.Metal Forming specializes in a variety of metal forming processes, including stamping, forging, and machining. The company's state-of-the-art facilities are equipped with the latest technology, allowing for the production of complex and intricate metal parts with tight tolerances. This capability has made Metal Forming a preferred partner for companies in the automotive, aerospace, and defense industries, among others.One of Metal Forming's core strengths is its ability to work closely with customers to develop custom solutions that meet their specific needs. The company's team of experienced engineers and technicians collaborate with clients to understand their requirements and provide tailored solutions that deliver exceptional results. Metal Forming's commitment to customer satisfaction has earned it a reputation for reliability and excellence in the metal manufacturing industry.In addition to its dedication to quality and precision, Metal Forming also places a strong emphasis on innovation and continuous improvement. The company invests in research and development to stay ahead of industry trends and technological advancements. This proactive approach allows Metal Forming to offer cutting-edge solutions that meet the evolving needs of its customers, keeping it at the forefront of the metal forming industry.Furthermore, Metal Forming is committed to sustainability and environmental responsibility in its operations. The company has implemented eco-friendly practices and processes to reduce its environmental impact, in line with its commitment to corporate social responsibility. This focus on sustainability not only benefits the environment but also positions Metal Forming as a responsible and ethical partner for businesses seeking environmentally conscious suppliers.As Metal Forming continues to grow and expand its capabilities, the company remains dedicated to maintaining the highest standards of quality and excellence in all aspects of its operations. With a focus on precision, innovation, and sustainability, Metal Forming is poised to continue its leadership in the metal manufacturing industry and provide superior solutions to its customers.In recent news, Metal Forming has announced the launch of a new line of advanced metal forming products that are designed to cater to the evolving needs of the automotive industry. These products are specifically tailored to meet the industry's increasing demand for lightweight and high-strength metal components, driven by the growing trend towards electric and autonomous vehicles. With its expertise in precision and custom solutions, Metal Forming is well-positioned to be a key supplier for automotive manufacturers looking to stay competitive in this rapidly changing market.Furthermore, Metal Forming has also unveiled its plans to expand its operations with the construction of a new, state-of-the-art manufacturing facility. This expansion is aimed at increasing the company's production capacity and further enhancing its capabilities to serve a broader range of industries. With this strategic move, Metal Forming is set to solidify its position as a top-tier provider of metal forming solutions for diverse applications.As Metal Forming continues to make strides in the metal manufacturing industry, its commitment to quality, innovation, and customer satisfaction remains unwavering. The company's dedication to excellence and its proactive approach to meeting the evolving needs of its customers make it a preferred partner for businesses seeking top-notch metal forming solutions. With its track record of success and its vision for the future, Metal Forming is set to continue leading the way in the metal manufacturing industry for years to come.

High-Quality Machined Parts for Your Needs: Find Out More Here

Machined Parts Leader Continues to Innovate and Thrive in the IndustryIn an age where manufacturing and engineering industries continue to grow at a rapid pace, one company has managed to stay ahead of the curve by continuously innovating and providing high-quality machined parts to its clients. With a rich history and a commitment to excellence, {Company Name} has solidified its position as a leader in the industry.Established in {year}, {Company Name} has built a strong reputation for delivering precision machined parts to a wide range of industries, including aerospace, automotive, medical, and defense. The company's state-of-the-art facilities and cutting-edge technologies allow them to consistently meet the demands of their clients and deliver parts that meet the strictest quality standards.One of the key factors that set {Company Name} apart from the competition is their dedication to continuous improvement and innovation. The company invests heavily in research and development, constantly seeking new and more efficient ways to manufacture machined parts. This commitment to innovation has allowed {Company Name} to stay ahead of the curve and provide their clients with the latest and most advanced solutions available in the industry.In addition to their technological advancements, {Company Name} is also dedicated to maintaining a skilled and experienced workforce. The company's team of engineers, machinists, and quality control experts are highly trained and dedicated to upholding the highest standards of precision and quality. This emphasis on human capital ensures that {Company Name} is able to consistently deliver machined parts that meet or exceed their clients' expectations.As a result of their commitment to innovation and quality, {Company Name} has experienced continued growth and success in the industry. The company has proudly served a diverse client base, providing essential machined parts that are integral to the operation of various critical systems and equipment. With a track record of reliability and excellence, {Company Name} has become a trusted partner for their clients, who rely on the company's expertise to keep their operations running smoothly.Looking ahead, {Company Name} is poised to continue its success and growth in the industry. The company remains dedicated to staying at the forefront of technological advancements and maintaining the highest standards of quality. By doing so, {Company Name} is committed to meeting the evolving needs of their clients and remaining a leader in the manufacturing and engineering industries.In conclusion, {Company Name} has established itself as a leader in the manufacturing and engineering industries by consistently providing high-quality and innovative machined parts. Through a commitment to technological advancements, a skilled and experienced workforce, and a dedication to quality, the company has earned the trust and loyalty of their clients. As they continue to grow and thrive in the industry, {Company Name} is well-positioned to remain a top choice for those in need of precision machined parts.

Quick and Efficient Prototype Machining Techniques in the News

Rapid Prototype Machining Plays a Vital Role in Transforming the Manufacturing IndustryThe manufacturing industry is constantly evolving, with new technologies and tools emerging every day. The introduction of rapid prototype machining is one such development that has revolutionized the manufacturing industry in recent years. Rapid prototype machining is a technique that’s characterized by quick production of prototypes, meaning that companies can accelerate their product development processes significantly.Today, several companies are exploring the benefits of rapid prototype machining to build flawless products, reduce their time to market, decrease development costs, and increase overall productivity. One such company that has been at the forefront of rapid prototype machining technology is a leading manufacturer of cutting-edge products.With its state-of-the-art facility, the company has been able to leverage rapid prototype machining techniques to deliver innovative products to its customers. From electronics to medical devices, the company has explored every industry and is a go-to resource for anyone looking to develop a prototype of a product they’ve been working on.The benefits of rapid prototype machining are numerous. First, by allowing users to create prototypes using computer-aided design (CAD) software, it reduces lead times in the product development process by several weeks. Second, the process ensures the accuracy of the product by providing users with several iterations of the prototype before final production. And finally, rapid prototype machining helps businesses to make informed decisions about their products, which helps them bring new and better products to the market faster than their competition.At the company, the focus is always on the customer. The company’s in-house experts guide customers through the rapid prototype machining process, providing them with the tools and resources they need to get the job done right. With an unwavering commitment to quality, the company works tirelessly to ensure that every prototype that leaves the facility meets the most demanding standards of excellence.The company’s facility features some of the most advanced tools and equipment in the industry, including full-scale 5-axis CNC machines, state-of-the-art 3D printers, and a variety of CAD software. These resources enable users to create prototypes in a variety of materials, including plastics, metals, and composites.The company’s expertise in rapid prototype machining technology is not limited to the manufacturing of physical products. It’s also a leader in the creation of virtual prototypes, including advanced simulations, test models, and digital replicas. This aspect is critical to the manufacturing industry as it enables customers to test virtual prototypes and refine them before printing the final product. By exploring both virtual and physical prototypes, customers can save money, reduce time to market, and create better final products.The company is a prime example of what businesses can do to leverage the benefits of rapid prototype machining in the manufacturing industry. With its commitment to innovation and excellence, it’s rapidly transforming the way businesses approach product development and manufacturing. And as technologies become increasingly sophisticated, it’s clear that companies that aren’t embracing rapid prototype machining will be left behind.In conclusion, rapid prototype machining is a game-changer for the manufacturing industry. With its ability to reduce lead times, increase productivity, and deliver better products, it’s becoming an increasingly important tool for businesses looking to adapt and thrive in an ever-evolving marketplace. And as companies look to the future, it’s clear that investing in rapid prototype machining technology will be critical to their success. The leading manufacturer has shown the way, and by following their example, others can transform their businesses and establish themselves as industry leaders in the years to come.

Wire Bending Techniques: Exploring the Art of Precision and Versatility

Wire Bending Innovations Revolutionize Manufacturing ProcessesWire bending is an essential technique used in various industries such as automotive, aerospace, and electronics to shape wires into precise designs. The traditional process involves manual labor and is often time-consuming and prone to human errors. However, recent advancements in wire bending technology have presented a new era of efficiency and accuracy. Companies like {} are at the forefront of this revolution, introducing state-of-the-art wire bending machines that are transforming manufacturing processes.Wire bending machines developed by {} utilize cutting-edge technology to automate the wire shaping process. By incorporating computer numerical control (CNC) systems, these machines can precisely determine and execute complex wire bending patterns. This level of automation significantly reduces the need for manual labor, minimizing operational costs and increasing production efficiency.One of the key advantages of {}'s wire bending machines is their versatility. The machines can work with wires of various materials and diameters, allowing manufacturers to produce a wide range of products. Whether it is small intricate components for electronics or larger structural parts for automobiles, these machines can handle the task with utmost precision.The accuracy achieved by these wire bending machines is truly remarkable. They can consistently produce wire shapes that adhere to strict tolerances, ensuring repeatable quality in mass production. This level of precision is crucial in industries where even a minor dimensional variation can lead to defective products or compromised safety.Apart from the accuracy, one of the notable features of {}'s wire bending machines is their speed. By automating the wire bending process, these machines can operate at higher speeds compared to manual labor. This leads to shorter production cycles, enabling manufacturers to meet growing market demands effectively.Additionally, {}'s wire bending machines integrate advanced software that allows for seamless programming and control. Manufacturers can design wire patterns through intuitive computer-aided design (CAD) software and transfer the instructions to the wire bending machine. The ease of programming ensures quicker setup times and reduces the likelihood of errors. As a result, manufacturers can achieve faster time-to-market while maintaining the highest quality standards.Another positive aspect of {}'s wire bending machines is their user-friendly interface. The machines are designed to be easily operated by technicians with minimal training. Intuitive controls and clear visual feedback make it convenient for operators to monitor and adjust the wire bending process as needed. This simplicity provides manufacturers with the flexibility to quickly adapt to changing production requirements.The adoption of {}'s wire bending machines has had significant impacts on manufacturing businesses. Manufacturers have reported increased productivity, reduced production costs, and improved product quality. By automating wire bending processes, companies can achieve higher volumes of production while minimizing human errors and associated costly rework.Moreover, {}'s wire bending machines have also opened up opportunities for innovative designs. With the ability to produce intricate wire shapes effortlessly, manufacturers can explore new product possibilities that were previously limited by manual wire bending. This level of flexibility empowers companies to stay ahead of the competition and cater to evolving customer demands.In conclusion, the advancements in wire bending technology, as exemplified by {}'s innovative machines, have revolutionized manufacturing processes. By automating wire bending, manufacturers can now achieve higher productivity, superior product quality, and faster time-to-market. With the ability to work with different wire materials and diameters, these machines provide unparalleled versatility. As manufacturers continue to embrace these cutting-edge technologies, the future of efficient and precise wire bending looks promising.

New Study Finds Metal Frames Are More Durable than Plastic for Glasses

article.Metal Frames - A Strong and Reliable Solution for Your Home As a homeowner, ensuring the safety and security of your family is a top priority. Furniture and fittings play a pivotal role in making your home safe and comfortable for living. Among the many types of furniture, metal frames stand out as a strong and reliable solution for your home.At Metal Frames (brand name removed), we offer a range of metal furniture that cater to a variety of needs. Our metal frames are durable, stylish, and versatile, and can be used for different settings, from dining rooms to bedrooms. Metal frames come with many benefits. Firstly, they can withstand wear and tear better than other materials. Metal is a strong and sturdy material, making it an ideal choice for furniture that needs to withstand daily use. This means they are not only durable but also require less maintenance in the long run. Secondly, metal frames offer excellent support and stability. They can support more weight than other materials, about four to five times more than wood or plastic. This makes them an ideal choice for furniture that demands more strength, such as bed frames. Additionally, metal frames come in a variety of finishes - from high-gloss polished metal to brushed steel - that can match any home interior design. This not only ensures the strength of the piece, but also adds a sleek and elegant touch to the home.At Metal Frames (brand name removed), our metal frames are crafted with precision and care. Our skilled craftsmen use high-quality material and advanced techniques to create furniture that is both functional and beautiful. Using top-grade metals, we ensure that each product is strong and long-lasting. Metal Frames offers a range of products, from bed frames to dining chairs, all made with a commitment to quality and function. Our bed frames feature robust and intricate designs that can take on more weight without compromising on comfort. They are easy to assemble and maintain, making them an excellent investment in the long run.Our dining chairs are a must-have for your next dinner party or family gathering. Available in different styles, they are comfortable, long-lasting, and stylish. They require minimal maintenance and can be customized to fit your unique needs. With considerable experience in the market, we understand the demands of the consumers and strive to provide high-quality products that cater to their needs. We use a customer-centric approach, ensuring that our products align with customer requirements. Our commitment to quality and customer satisfaction has earned us a loyal customer base. We are continuously growing and improving as a company, and we are dedicated to providing high-quality metal furniture for years to come. In conclusion, metal frames offer an ideal solution for those seeking durable and stylish furniture that can withstand daily use. At Metal Frames (brand name removed), we provide a range of products with a commitment to quality and function, crafted with precision and care. Our metal furniture is sturdy, easy to assemble, and customizable to meet your needs. Whether you need a bed frame or a dining chair, Metal Frames has you covered. Visit our website today to shop our high-quality metal furniture and to discover why we are a top choice for many homeowners.

The Ultimate Guide to Sheet Metal Forming Techniques and Processes

Sheetmetal Forming, a leading provider of metal fabrication services, has recently expanded its operations to meet the growing demand for custom metal parts in various industries. With over [number] years of experience in the industry, Sheetmetal Forming has solidified its reputation as a reliable and innovative company that delivers high-quality products.The company offers a wide range of metal fabrication services, including laser cutting, CNC punching, bending, welding, and assembly. Its state-of-the-art facility is equipped with the latest technology and machinery, allowing the company to handle projects of all sizes and complexities. From simple brackets to complex enclosures, Sheetmetal Forming has the capabilities to meet the diverse needs of its customers.One of the key factors that sets Sheetmetal Forming apart from its competitors is its commitment to quality. The company adheres to strict quality control measures at every stage of the fabrication process, ensuring that the final products meet the highest standards. Additionally, Sheetmetal Forming is dedicated to continuous improvement, regularly investing in training and technology to stay ahead of the curve.In response to the increasing demand for custom metal parts, Sheetmetal Forming has recently expanded its facility and added new equipment to its arsenal. This expansion allows the company to take on more projects and deliver results in a timely manner. With a team of highly skilled and experienced professionals, Sheetmetal Forming is well-positioned to handle the growing needs of its customers.“We are excited about the expansion of our operations and the opportunities it brings,” said [Spokesperson], President of Sheetmetal Forming. “Our goal is to provide our customers with the best possible solutions for their metal fabrication needs. With our expanded capabilities, we are confident that we can continue to exceed our customers’ expectations and maintain our position as a leader in the industry.”Sheetmetal Forming serves a wide range of industries, including automotive, aerospace, electronics, and telecommunications. The company has established strong partnerships with leading companies in these sectors, providing them with reliable and cost-effective metal fabrication solutions. Whether it’s prototyping, low-volume production, or high-volume manufacturing, Sheetmetal Forming has the expertise to deliver results that meet the unique requirements of each industry.In addition to its commitment to quality and innovation, Sheetmetal Forming is also dedicated to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its operations, minimizing waste and reducing its carbon footprint. By utilizing efficient manufacturing processes and sustainable materials, Sheetmetal Forming contributes to a greener and more sustainable future.With its expanded operations and a continued focus on excellence, Sheetmetal Forming is well-positioned to meet the evolving needs of its customers and maintain its position as a leader in the metal fabrication industry. The company’s dedication to quality, innovation, and sustainability sets it apart and makes it a preferred partner for companies seeking reliable and high-quality metal fabrication services.About Sheetmetal Forming: Sheetmetal Forming is a leading provider of metal fabrication services, serving a wide range of industries with custom solutions for their metal parts needs. With over [number] years of experience, the company has established a solid reputation for its commitment to quality, innovation, and sustainability. Sheetmetal Forming is dedicated to exceeding its customers’ expectations and delivering results that meet the unique requirements of each industry. For more information, visit [company website].

Top Aircraft Sheet Metal Fabrication Techniques for Superior Quality

Aircraft Sheet Metal Fabrication Company Leads the Industry with Innovative SolutionsWith the rapid advancement in aviation technology, the demand for high-quality aircraft components is at an all-time high. Recognizing this need, {Company Name} has emerged as a leader in the aircraft sheet metal fabrication industry, providing innovative solutions to meet the complex requirements of the aerospace sector.Founded in {year}, {Company Name} has established itself as a trusted and reliable partner for major aircraft manufacturers and airlines around the world. The company's commitment to excellence and continuous improvement has set it apart in a highly competitive market.Specializing in the fabrication of complex sheet metal components for aircraft, {Company Name} utilizes state-of-the-art technology and cutting-edge manufacturing processes to deliver products that meet the highest standards of quality and precision. The company's team of skilled engineers and technicians are experts in working with a variety of materials, including aluminum, titanium, and high-performance alloys, ensuring that they are able to meet the diverse needs of their clients.One of {Company Name}'s key strengths is its ability to provide customized solutions for its clients. By working closely with aircraft manufacturers and airlines, the company is able to understand their specific requirements and develop tailor-made products that meet their exact needs. This collaborative approach has allowed {Company Name} to build long-lasting partnerships with its clients, who value the company's dedication to delivering high-quality, reliable components.In addition to its focus on quality and customization, {Company Name} also prioritizes sustainability and environmental responsibility in its manufacturing processes. The company has implemented eco-friendly practices and invested in energy-efficient equipment to minimize its environmental impact. This commitment to sustainability has not only earned {Company Name} the trust of its clients but has also established the company as a responsible and forward-thinking industry leader.One of the key factors driving {Company Name}'s success is its relentless pursuit of innovation. The company is constantly investing in research and development to push the boundaries of what is possible in aircraft sheet metal fabrication. By staying ahead of the curve and embracing new technologies, {Company Name} is able to offer its clients cutting-edge solutions that improve the performance, efficiency, and safety of their aircraft.The company's dedication to innovation is best exemplified by its recent development of a revolutionary new manufacturing process that significantly reduces lead times and production costs while maintaining the highest standards of quality. This breakthrough has positioned {Company Name} as an industry trailblazer, setting a new standard for aircraft sheet metal fabrication and solidifying its reputation as a leader in the field.Looking ahead, {Company Name} remains committed to shaping the future of aircraft sheet metal fabrication. By continuing to invest in research and development and collaborating closely with its clients, the company is well-positioned to address the evolving needs of the aviation industry and remain at the forefront of innovation and excellence.As the aviation industry continues to grow and evolve, the demand for high-quality aircraft components will only increase. With its unwavering dedication to quality, innovation, and sustainability, {Company Name} is poised to play a pivotal role in meeting this demand, solidifying its position as the go-to partner for aircraft sheet metal fabrication.