Custom Prototype Tooling: Key Considerations for Efficient Manufacturing

By:Admin

Headquartered in [location], Prototype Tooling has been at the forefront of the tooling industry for over [number] years. The company’s dedication to innovation and customer satisfaction has made it a preferred partner for a wide range of industries, including automotive, aerospace, medical, and consumer goods.

As a pioneer in the field of prototype tooling, Prototype Tooling has always been focused on leveraging the latest technologies to push the boundaries of what is possible. The company’s team of skilled engineers and technicians work tirelessly to develop cutting-edge solutions that meet the unique needs of each customer.

The latest advancement from Prototype Tooling is set to revolutionize the way companies approach prototype development. By combining state-of-the-art technology with unparalleled expertise, the new [product name] promises to deliver unmatched precision and efficiency in the prototyping process.

“We are very excited to introduce our latest innovation to the market,” said [Spokesperson], CEO of Prototype Tooling. “The [product name] represents a significant leap forward in prototype tooling technology, and we believe it will have a profound impact on the way companies bring their products to market.”

The [product name] is designed to streamline the prototyping process, allowing companies to bring their ideas to life faster and more cost-effectively than ever before. With its advanced features and user-friendly interface, the [product name] is poised to become an essential tool for companies looking to stay ahead of the competition.

In addition to its groundbreaking capabilities, the [product name] also reflects Prototype Tooling’s commitment to sustainability. By optimizing the prototyping process and reducing waste, the [product name] helps companies minimize their environmental impact while achieving their business goals.

“Our team has worked tirelessly to develop a tool that not only delivers exceptional performance but also aligns with our values as a company,” said [Spokesperson]. “We believe that the [product name] will not only benefit our customers but also contribute to a more sustainable future for the industry as a whole.”

With its unmatched combination of innovation, performance, and sustainability, the [product name] is set to redefine the prototyping landscape. As companies continue to seek ways to bring their products to market faster and more efficiently, Prototype Tooling’s latest offering is poised to become an essential asset in their arsenal.

“For over [number] years, Prototype Tooling has been dedicated to pushing the boundaries of what is possible in the field of prototype tooling,” said [Spokesperson]. “With the introduction of the [product name], we are proud to continue that legacy and support our customers in achieving their goals.”

As Prototype Tooling prepares to roll out the [product name] to the market, the company remains committed to its mission of empowering companies with the tools they need to succeed. With a track record of excellence and a relentless pursuit of innovation, Prototype Tooling is well-positioned to lead the way in the rapidly evolving world of prototype tooling technology.

For companies looking to gain a competitive edge in their respective industries, the [product name] represents a game-changing solution that has the potential to transform the way they approach prototyping. With its unrivaled performance, sustainability, and user-friendly design, the [product name] is set to become the go-to tool for companies seeking to bring their ideas to life with speed and precision.

As Prototype Tooling gears up for the launch of the [product name], industry leaders and customers alike are eagerly anticipating the arrival of this groundbreaking new tool. With its potential to reshape the prototyping landscape, the [product name] is well-positioned to solidify Prototype Tooling’s reputation as an industry leader and trusted partner for companies worldwide.

Company News & Blog

High-Quality, Durable L-Shaped Bracket for Various Applications

L Shaped Bracket: A Versatile and Reliable Solution for Various ApplicationsL shaped brackets are simple yet versatile components that find application in a wide range of industries, from construction and manufacturing to DIY projects at home. These brackets, as the name suggests, are shaped like the letter "L" and are designed to provide support, reinforcement, and structural stability to various structures and assemblies. They can be found in different materials such as steel, aluminum, and plastic, each offering unique properties that cater to specific needs.One company that has been at the forefront of producing high-quality L shaped brackets is [Company Name]. They have established themselves as a leading manufacturer and supplier of brackets and other industrial components, known for their commitment to quality, precision engineering, and customer satisfaction.[Company Name] has a diverse range of L shaped brackets that cater to different industries and applications. Their brackets are designed and manufactured to meet the highest standards of quality and durability, ensuring that they can withstand the rigors of various environments and use cases. Whether it's for structural support in construction projects, mounting of shelves and furniture, or reinforcement of machinery and equipment, [Company Name] offers a solution for every need.One of the key advantages of [Company Name]'s L shaped brackets is their versatility. They come in a variety of sizes, shapes, and finishes, allowing customers to find the perfect bracket for their specific requirements. Additionally, the company also provides custom manufacturing services, enabling customers to order brackets that are tailored to their exact specifications.Furthermore, [Company Name] prides itself on its commitment to innovation and continuous improvement. They invest in state-of-the-art manufacturing technologies and processes to ensure that their brackets are produced with utmost precision and efficiency. This dedication to excellence has earned them a reputation for reliability and consistency in delivering top-notch products to their customers.In addition to their product offerings, [Company Name] places a strong emphasis on customer service and satisfaction. They have a team of knowledgeable and experienced professionals who are dedicated to providing expert advice and guidance to customers, helping them find the right L shaped bracket for their application. This personalized approach sets them apart from their competitors and has made them a trusted partner for businesses and individuals alike.As a company that is committed to sustainability, [Company Name] also ensures that their manufacturing processes are environmentally friendly and compliant with industry standards. They prioritize the use of sustainable materials and resource-efficient practices, aligning with their goal of minimizing their environmental impact and contributing to a greener future.In conclusion, L shaped brackets are indispensable components that play a crucial role in providing support and stability to a wide variety of structures and assemblies. With [Company Name]'s dedication to excellence, innovation, and customer satisfaction, their range of L shaped brackets stands out as a versatile and reliable solution for various applications. Whether it's for industrial, commercial, or personal use, customers can trust [Company Name] to deliver high-quality brackets that meet their needs and exceed their expectations.

Unlocking the Potential of Precision CNC Turning Services for Optimal Results

Precision CNC turning is a highly advanced manufacturing process used to create complex and intricate parts for various industries such as automotive, aerospace, and medical. It is a crucial component of the manufacturing sector, and its demand is only increasing. {Company Name}, a leading provider of precision CNC turning services, has been at the forefront of this technology, providing high-quality solutions to meet the diverse needs of its clients.With state-of-the-art facilities and a team of experienced professionals, {Company Name} has been delivering exceptional results in the precision CNC turning industry. Their commitment to quality and innovation has allowed them to develop cutting-edge solutions that have set new industry standards.Precision CNC turning involves the use of computer-controlled machines to manufacture parts with a high level of accuracy and precision. These machines can perform a wide range of complex machining operations, including turning, boring, facing, threading, and grooving. The process involves the removal of material from a workpiece to create the desired shape and finish.One of the key advantages of using precision CNC turning is the ability to produce parts with consistent quality and dimensional accuracy. The computer-controlled machines ensure that each part is manufactured to the exact specifications, resulting in enhanced efficiency and reduced waste. This level of precision is critical in industries where even small deviations can have a significant impact on performance and safety.{Company Name} has established itself as a trusted partner in the precision CNC turning industry by leveraging its expertise and capabilities. They employ a comprehensive approach that ensures every project is handled with utmost care, from initial design and prototyping to final production. Their team of engineers works closely with clients to understand their specific requirements and develop customized solutions tailored to their needs.In addition to their advanced machining capabilities, {Company Name} also offers a wide range of materials to choose from, including aluminum, stainless steel, titanium, and various alloys. This diversity allows them to cater to a wide range of industries and applications, providing clients with the flexibility to select the most suitable material for their project.Furthermore, {Company Name}'s commitment to continuous improvement and investment in cutting-edge technologies has allowed them to stay ahead of the competition. They regularly upgrade their machinery and software systems, ensuring that they are always equipped with the latest tools and techniques. This dedication to staying at the forefront of technological advancements enables {Company Name} to deliver superior results consistently.In the fast-paced and evolving world of precision manufacturing, {Company Name}'s ability to adapt and innovate has been instrumental in their success. Their commitment to ongoing research and development has enabled them to explore new materials, techniques, and processes, resulting in greater efficiency and cost-effectiveness for their clients.Furthermore, {Company Name} places a strong emphasis on quality control, adhering to rigorous inspection procedures throughout each stage of the manufacturing process. This dedication to quality assurance has earned them various certifications and accreditations, further solidifying their position as a reliable and trusted CNC turning provider.As industries become increasingly reliant on precision engineering, the demand for high-quality CNC turning services continues to grow. {Company Name} continues to spearhead the industry by delivering exceptional results that meet and exceed customer expectations. With their state-of-the-art facilities, highly skilled workforce, and unwavering commitment to excellence, they are well-positioned to remain a leader in the precision CNC turning sector for years to come.In conclusion, precision CNC turning is a critical component of modern manufacturing, and {Company Name} has proven itself to be a leading provider in this field. Their commitment to quality, innovation, and customer satisfaction sets them apart from their competitors. With their advanced capabilities, comprehensive solutions, and dedication to continuous improvement, {Company Name} continues to be the go-to choice for precision CNC turning services.

High-Quality Aluminum CNC Parts for Custom Projects

Custom CNC Aluminum Part Innovation Drives {} Growth{} is continuing to drive innovation in the manufacturing industry through the development of custom CNC aluminum parts. The company has become known for its expertise in precision machining and has established itself as a leader in the production of specialized components for a wide range of industries.The company's commitment to excellence and a customer-centric approach have been the driving forces behind its success. By leveraging advanced manufacturing technologies and a highly skilled workforce, {} has been able to meet the unique needs of its clients and deliver high-quality products that exceed expectations.One of the key factors that sets {} apart from its competitors is its investment in cutting-edge CNC machining capabilities. CNC (computer numerical control) machining allows for the precise and efficient production of complex parts, including those made from aluminum. With the ability to accurately shape and manufacture intricate components, {} has been able to provide its customers with tailored solutions that are essential for their operations.The custom CNC aluminum parts produced by {} are widely used in a variety of applications. From aerospace and automotive to medical and electronics, these components play a crucial role in ensuring the performance and reliability of different systems and machinery. By leveraging their expertise in CNC machining, {} has been able to cater to the diverse needs of these industries and contribute to their advancements.In addition to the exceptional quality of its products, {} has also earned a reputation for its ability to deliver on a wide range of specifications. The company's engineering team works closely with clients to understand their unique requirements and develop customized solutions that are tailored to their exact needs. This collaborative approach has allowed {} to establish strong partnerships with its customers and become a trusted provider of custom CNC aluminum parts.Furthermore, {}'s commitment to continuous improvement and investment in the latest manufacturing technologies has enabled the company to streamline its production processes. By utilizing state-of-the-art CNC machining equipment, {} has been able to increase efficiency, reduce lead times, and maintain cost-effectiveness for its clients. This has not only improved the company's overall performance but has also allowed it to stay at the forefront of the industry.Looking ahead, {} remains focused on further expanding its capabilities and enhancing its offerings. The company continues to explore new opportunities for growth and diversification, including the development of advanced CNC machining techniques and the expansion of its product portfolio. By staying ahead of the curve, {} aims to continue serving as a reliable partner for its clients and a driving force in the manufacturing sector.In conclusion, {}'s dedication to innovation and its expertise in custom CNC aluminum parts have been instrumental in its continued success. By prioritizing quality, precision, and customer satisfaction, the company has solidified its position as a leading provider of specialized components. With a strong foundation and a forward-looking mindset, {} is well-positioned to make a lasting impact in the industry and contribute to the advancement of manufacturing.

Customized Heatsink Part for Optimal Thermal Performance

customized Heatsink part, combined with the company introductionNowadays, with the rapid development of technology, electronic devices are becoming more and more powerful and efficient. However, as electronic components generate heat during operation, it becomes crucial to efficiently dissipate this heat to maintain the reliability and performance of the devices. This is where customized Heatsink parts come into play.One company that has been leading the way in manufacturing customized Heatsink parts is {}. They have been providing high-quality customized Heatsink solutions to their customers for many years and have built a strong reputation in the industry.The customized Heatsink parts provided by {} are designed to meet the specific requirements of their customers. They understand that each electronic device has its unique thermal management needs, and they work closely with their clients to develop customized Heatsink solutions that perfectly fit their applications.{} has a team of experienced engineers and designers who are highly skilled in the field of thermal management. They utilize the latest technologies and tools to design and manufacture customized Heatsink parts that not only effectively dissipate heat but also minimize the overall size and weight of the heat dissipation system.In addition, {} has a state-of-the-art manufacturing facility that is equipped with advanced machinery and equipment. This enables them to produce customized Heatsink parts with high precision and consistency, ensuring that they meet the stringent quality standards of their clients.Furthermore, {} is committed to using the highest quality materials in the manufacturing of their customized Heatsink parts. They understand that the performance and reliability of the Heatsink depend heavily on the materials used, and they source materials from trusted suppliers to guarantee the quality of their products.One of the key advantages of choosing customized Heatsink parts from {} is the flexibility they offer. They can produce Heatsink parts in various shapes, sizes, and configurations, allowing their customers to have complete control over the thermal management of their electronic devices.Moreover, {} offers comprehensive support and services to their customers from the initial design phase to the final product delivery. They understand the importance of timely delivery and work tirelessly to ensure that their customers receive their customized Heatsink parts on schedule.With the increasing demand for high-performance electronic devices, the need for efficient thermal management solutions has never been greater. The customized Heatsink parts provided by {} are a testament to their commitment to meeting this demand and helping their customers achieve optimal thermal performance in their electronic devices.In conclusion, {} is a leading manufacturer of customized Heatsink parts that are designed to meet the specific thermal management needs of their customers. With their expertise, advanced manufacturing capabilities, and commitment to quality, they continue to be a trusted partner for companies looking to enhance the thermal performance of their electronic devices.

Expert Thermal Management Consulting for High Performance Electronics

In the world of electronics, thermal management is one of the most important factors that can make or break the success of a product. When electronic circuits run, they generate heat, and if this heat is not properly dissipated, it can cause a range of problems, from degraded performance to component failure. This is where thermal management solutions come in, and Q ATS is a leading provider of such solutions.Founded with the aim of helping electronic product manufacturers bring their products to market faster, safer, and at a lower cost, Q ATS has established itself as a trusted partner for companies in a variety of industries. Whether it's designing a custom heatsink for a high-power LED light or analyzing the thermal performance of a data center, Q ATS has the expertise and experience to help clients solve their thermal management challenges.One of the key advantages of working with Q ATS is their comprehensive approach to thermal management analysis and design. Rather than simply offering off-the-shelf solutions, their team of engineers work closely with clients to understand the unique requirements of their products and design custom solutions that meet those needs. This ensures that clients get the best possible thermal performance for their products, while minimizing costs and time-to-market.Some of the services offered by Q ATS include thermal modeling and simulation, which allows them to predict the thermal performance of a product before it's even built. This can be especially valuable in applications where thermal management is critical, such as aerospace and defense. Q ATS also offers design and prototyping services, allowing clients to test and iterate on their thermal management solutions before committing to production.Another key area of expertise for Q ATS is the design and manufacture of heatsinks, which are a critical component in many electronic products. Heatsinks are used to dissipate heat from a component or circuit board to the surrounding air, and Q ATS can design heatsinks that are optimized for a specific application, providing maximum performance while minimizing weight and cost.In addition to their technical expertise, Q ATS is also committed to providing exceptional customer service. They work closely with clients throughout every stage of the project, from initial consultation to final delivery, ensuring that their needs are fully understood and met. Their team is highly responsive, with quick turnaround times and a willingness to go the extra mile to ensure client satisfaction.Overall, Q ATS is a valuable partner for any company looking to improve the thermal performance of their electronic products. With their comprehensive approach, technical expertise, and commitment to customer service, they can help clients get their products to market faster, safer, and more cost-effectively than ever before.

Ultimate Guide to 5-Axis Technology: Everything You Need to Know

5-Axis, a cutting-edge technology that revolutionizes manufacturing processes, has been making waves in the industry with its innovative capabilities. This technology, which allows for the simultaneous movement of a workpiece along five different axes, provides a level of precision and flexibility that was previously unattainable. With its ability to produce complex and intricate parts with incredible speed and accuracy, 5-Axis has become an essential tool for companies looking to stay ahead of the competition.One company that has fully embraced the power of 5-Axis technology is []. Founded in [], the company has always been at the forefront of innovation and has continuously invested in the latest manufacturing technologies to ensure the highest quality products for its customers. With the integration of 5-Axis technology into its production processes, [] has been able to greatly enhance its capabilities and efficiency, leading to a significant improvement in its overall productivity.The versatility of 5-Axis technology allows for the machining of intricate geometries and tight tolerances with ease, resulting in parts that are not only of superior quality but also produced in a fraction of the time compared to traditional methods. This has allowed [] to take on a wider range of projects, from simple parts to complex components, all with the same level of precision and consistency. Furthermore, the ability to position the workpiece at virtually any angle without the need for repositioning or reclamping has greatly reduced setup times and increased overall throughput.In addition to its production advantages, the integration of 5-Axis technology has also enabled [] to explore new design possibilities and push the boundaries of what is achievable. The flexibility of the system has allowed the company to manufacture parts with intricate features and intricate contours that were previously impossible to produce, opening up new opportunities in industries such as aerospace, automotive, and medical devices.Despite the initial investment required to adopt 5-Axis technology, the benefits that [] has experienced have far outweighed the costs. The increased efficiency and precision have led to significant cost savings, while the expanded capabilities have allowed the company to take on more lucrative projects, ultimately resulting in a positive impact on its bottom line. In addition, the improved quality of the parts produced has elevated the company's reputation in the industry, leading to new business opportunities and partnerships.Looking ahead, [] is committed to further leveraging the power of 5-Axis technology to drive continuous improvement and innovation in its manufacturing processes. By staying at the forefront of technological advancements, the company aims to solidify its position as a leader in the industry and continue to provide its customers with the highest quality products and services.As 5-Axis technology continues to evolve and advance, more companies are expected to recognize its potential and embrace it as a critical component of their manufacturing operations. With its ability to significantly improve productivity, efficiency, and quality, 5-Axis technology is poised to revolutionize the way parts and components are produced across a wide range of industries. With [] leading the way, it is clear that the future of manufacturing is firmly rooted in the power of 5-Axis technology.

High-Quality Precision Turning Parts for Your Manufacturing Needs

Precision Turning Parts (PTP), a leading manufacturer of high-quality precision machined components, has once again proven their commitment to excellence by delivering top-notch products to their customers. With a solid reputation for producing precision turning parts that meet the highest industry standards, PTP has established itself as a trusted partner for companies in a wide range of industries.Established over 20 years ago, PTP has continuously invested in cutting-edge technology and state-of-the-art manufacturing facilities to ensure that they are always at the forefront of the industry. Their team of highly skilled engineers and technicians are dedicated to producing components that not only meet the exact specifications of their customers, but also exceed their expectations in terms of quality and performance.One of the key factors that sets PTP apart from other precision turning parts manufacturers is their unwavering commitment to quality. Every component that comes off their production line undergoes rigorous quality control checks to ensure that it meets the strictest standards. This dedication to quality has earned PTP numerous certifications and accolades, as well as the trust and loyalty of their customers.In addition to their commitment to quality, PTP also places a strong emphasis on innovation. They are constantly exploring new materials, processes, and techniques to improve their products and stay ahead of the competition. This dedication to innovation has allowed PTP to offer their customers the latest advancements in precision turning parts, giving them a competitive edge in their respective industries.Furthermore, PTP prides themselves on their ability to provide custom solutions to their customers' unique needs. Their team of engineers work closely with each customer to understand their requirements and develop tailored solutions that meet their specific needs. This personalized approach has allowed PTP to build long-lasting relationships with their customers, many of whom have been with the company for years.In addition to their commitment to quality and innovation, PTP also places a strong emphasis on sustainability. They have implemented various initiatives to reduce their environmental impact, including the use of energy-efficient equipment and the recycling of materials. This commitment to sustainability not only benefits the environment, but also helps PTP's customers meet their own sustainability goals.As PTP continues to grow and expand their capabilities, they remain committed to providing the highest level of service to their customers. Whether it's producing complex components for the aerospace industry or critical parts for the medical field, PTP is dedicated to delivering the quality and precision that their customers have come to expect.With a solid track record of success and a dedication to excellence, Precision Turning Parts (PTP) stands out as a leader in the precision turning parts industry. Their commitment to quality, innovation, and sustainability sets them apart from the competition and makes them a trusted partner for companies in a wide range of industries. As they continue to push the boundaries of what is possible in precision machining, PTP is poised to remain at the forefront of the industry for years to come.

Get the Best Wire Forming Machines for Sale in Melbourne - Top-notch Jigs and Templates Available!

Wire forming is a process that involves the shaping and molding of metal wires into different shapes. This process is used in a variety of industries from manufacturing to construction, and it plays an important role in the production of many different products. In this blog post, we will explore wire forming and why it's an essential process in many industries.Wire forming machinesWire forming machines are a critical tool in the wire forming process. These machines are designed to produce wire forms quickly and efficiently with precision. There are several types of wire forming machines available, including hydraulic and mechanical machines. These machines are capable of forming a range of materials, including brass, aluminum, and steel.The best wire forming machines should be easy to use, have precision controls, and offer versatility. They should also have a compact construction, making them suitable for use in small manufacturing facilities. Additionally, they should be built with durable materials that can withstand the constant wear and tear of the manufacturing process.In addition to wire forming machines, jigs and templates are commonly used in the wire forming process. These tools offer consistent and accurate wire forming results, which can increase production efficiency. They also help maintain product conformity, which is essential in industries where safety and quality are major concerns.Wire forming applicationsWire forming is a versatile process that can be used to create a vast array of products. Some of the most common applications of wire forming include:- Springs- Hooks- Wire baskets- Shelving- Clips- Hangers- Wire formsWire forming is also used in the creation of more complex products, such as automotive parts, medical devices, and electrical components. Wire forming is an important process that contributes to the safety, durability, and functionality of many everyday products.Finding a wire forming providerWhen selecting a wire forming provider, it's essential to consider several factors. Firstly, you should evaluate the provider's experience in wire forming and their track record in producing quality products. A provider that has been in the wire forming industry for many years will have a wealth of knowledge and experience. They will also have a proven track record of producing high-quality wire forms.Secondly, you should consider the provider's equipment and manufacturing facilities. Do they use the latest wire forming technology? Do they have the capacity to produce large volumes of wire forms? Choosing a provider with modern equipment and state-of-the-art facilities can help ensure that your wire forms are produced efficiently and accurately.Finally, you should consider the provider's customer service. Are they responsive and easy to work with? Do they offer technical support and guidance throughout the wire forming process? A wire forming provider with excellent customer service can make a significant difference in the success of your project.ConclusionWire forming is a crucial process in many industries, from manufacturing to construction. It allows manufacturers to create complex wire forms for use in a variety of different applications. Choosing the right wire forming provider is essential to ensure that your wire forms are produced accurately, efficiently, and to meet your specific needs. When selecting a wire forming provider, consider their experience, equipment, facilities, and customer service to ensure that you receive high-quality wire forms that meet your expectations.

The Benefits of 3D Printing and Rapid Prototyping in Manufacturing

In recent years, 3D printing and rapid prototyping have revolutionized the manufacturing industry by allowing companies to quickly and cost-effectively create prototypes and products. With the advancement of technology, companies like {Company Name}, are leading the way in utilizing this innovative process to streamline their production and design processes.{Company Name} is a pioneering company that specializes in 3D printing and rapid prototyping services. By leveraging cutting-edge technology, they are able to provide their clients with high-quality prototypes and products in a fraction of the time compared to traditional manufacturing methods. Their expertise in additive manufacturing has enabled them to work with a wide range of industries, including aerospace, automotive, healthcare, and consumer goods.One of the key advantages of 3D printing and rapid prototyping is the ability to quickly iterate and refine designs. This allows companies like {Company Name} to work closely with their clients to bring their ideas to life and make necessary adjustments in a timely manner. Furthermore, this process significantly reduces the time and cost associated with traditional prototype development, ultimately giving companies a competitive edge in the market.Another benefit of 3D printing is the ability to create complex and intricate designs that would be nearly impossible with traditional manufacturing methods. {Company Name} has been able to push the boundaries of what is possible with their state-of-the-art 3D printers, producing highly detailed and functional prototypes for their clients. This level of precision and customization is unparalleled in the industry, making {Company Name} a go-to partner for companies looking to bring their innovative ideas to fruition.In addition to rapid prototyping, {Company Name} also offers end-to-end manufacturing solutions, including batch production and on-demand manufacturing. This full-service approach sets them apart from other 3D printing companies and allows their clients to seamlessly transition from prototype to production, all under one roof. By offering a comprehensive suite of services, {Company Name} is able to meet their clients' needs at every stage of their product development process.With the growing demand for customized and on-demand manufacturing, 3D printing and rapid prototyping are poised to play an even larger role in the future of the industry. {Company Name} is at the forefront of this movement, continually investing in new technologies and processes to stay ahead of the curve. They have recently expanded their production facilities and added new, cutting-edge 3D printers to their lineup, further solidifying their position as a leader in the industry.As the industry continues to evolve, {Company Name} remains committed to providing their clients with the highest quality 3D printed products and prototypes. Their dedication to innovation and customer satisfaction has earned them a reputation as a trusted partner for companies looking to leverage the power of 3D printing in their product development and manufacturing processes.In conclusion, the combination of {Company Name}'s expertise in 3D printing and rapid prototyping, along with their full-service approach to manufacturing, has positioned them as a driving force in the industry. With their commitment to innovation and excellence, {Company Name} is well-equipped to meet the diverse needs of their clients and lead the way in the exciting world of additive manufacturing.

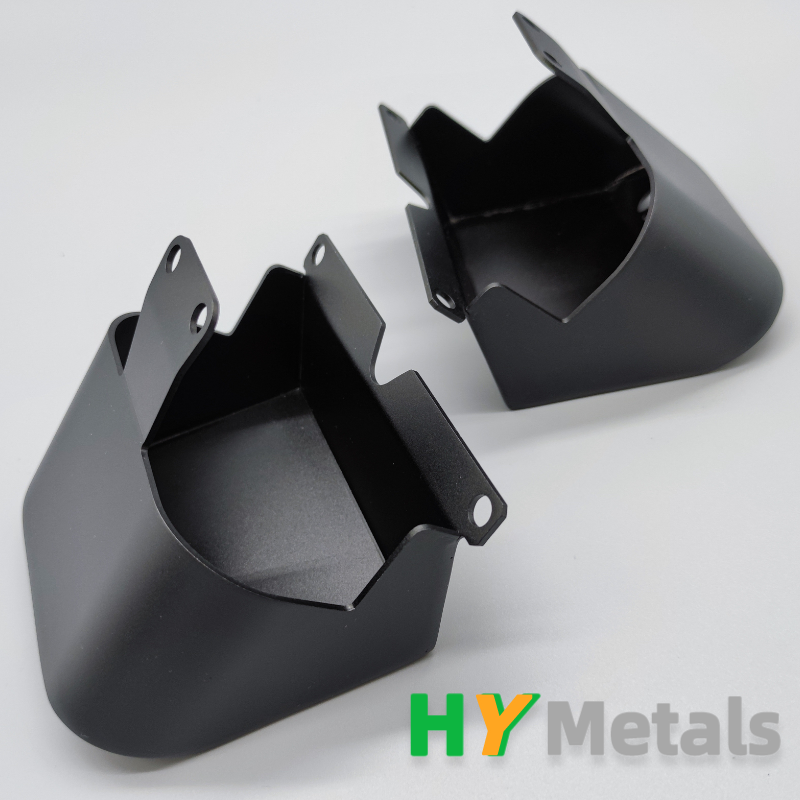

Sheet Metal Box Fabrication: A Complete Guide to Manufacturing

Title: Sheet Metal Box Fabrication Revolutionizing Industrial Manufacturing ProcessesIntroduction:In today's rapidly evolving industrial landscape, companies are increasingly seeking innovative and efficient solutions to enhance their manufacturing processes. One such groundbreaking solution is the sheet metal box fabrication technique, which is revolutionizing how industries design and manufacture enclosures for various applications. By eliminating the need for traditional welding techniques, sheet metal box fabrication offers unmatched precision, cost-effectiveness, and durability. This method is rapidly gaining popularity among industries worldwide, propelling them to enhance productivity and create cutting-edge products.Body:1. The Rise of Sheet Metal Box Fabrication: The demand for sheet metal box fabrication has soared in recent years due to its numerous advantages over traditional manufacturing techniques. This process involves using advanced machinery and computer-aided design (CAD) software to convert flat metal sheets into enclosures or boxes with intricate designs. By utilizing laser cutting, bending, and assembling technologies, manufacturers can create precisely engineered box structures while minimizing material waste and time-consuming setup processes.2. Unmatched Precision and Customization: Sheet metal box fabrication allows for unparalleled precision and customization options. With CAD software, manufacturers can design intricate and complex box structures, ensuring a perfect fit for the intended application. Every cut, bend, and joint is precisely calculated and executed by state-of-the-art machinery. This high degree of accuracy eliminates any potential human errors and ensures consistent quality throughout the manufacturing process.3. Cost-Effective Manufacturing: Traditional welding techniques often require extensive labor and time, leading to a significant increase in production costs. In contrast, sheet metal box fabrication significantly reduces labor costs by automating most of the manufacturing processes. With advanced machinery handling the bulk of the work, manufacturers can achieve higher production volumes in shorter time frames while minimizing human errors. Additionally, the efficiency of this technique greatly reduces material waste, contributing to more sustainable manufacturing practices.4. Enhanced Durability and Strength: The sheet metal box fabrication technique guarantees exceptionally strong and durable enclosures. By utilizing a combination of laser cutting and precision bending, these boxes provide optimal structural integrity. The metal sheets used are carefully selected based on the intended application, ensuring the highest level of strength and resistance against external factors such as impacts, pressure, and environmental conditions. This reliability makes sheet metal box fabrication highly sought after in industries that require robust enclosures.5. Wide Range of Applications: Sheet metal box fabrication finds applications across various industries due to its versatility and flexibility. From telecommunication enclosures to electrical panels, this technique caters to the diverse needs of industries, promoting seamless integration into existing systems. Furthermore, sheet metal boxes can be customized to include additional functionalities such as cable management solutions, heat dissipation mechanisms, and mounting options for internal components. This adaptability ensures that manufacturers can meet the specific requirements of their clients with utmost efficiency.6. Advancements and Innovations: The continuous advancement in sheet metal box fabrication technology is driving further innovation in industrial manufacturing processes. Integration with Artificial Intelligence (AI) and Machine Learning (ML) allows for real-time monitoring and optimization of production parameters. This ensures higher accuracy, reduced downtime, and enhanced productivity. Additionally, the integration of robotics and automation enables manufacturers to achieve even faster production cycles while maintaining precise quality control.Conclusion:Sheet metal box fabrication is revolutionizing the way industries design and manufacture enclosures, offering unparalleled precision, cost-effectiveness, and durability. By adopting this advanced technique, manufacturers can streamline their manufacturing processes, increase productivity, and deliver high-quality products to meet the demands of an ever-evolving market. With continuous advancements and innovations, sheet metal box fabrication is set to become the industry standard, revolutionizing industrial manufacturing processes worldwide.