Discover the Advantages of Working with Curved Sheet Metal

By:Admin

Curved Sheet Metal offers a wide range of capabilities in curved sheet metal fabrication, including cutting, bending, welding, and finishing. By utilizing advanced technologies and a team of experienced professionals, the company is able to deliver superior curved sheet metal products that exceed industry standards.

One of the key differentiators for Curved Sheet Metal is its commitment to quality. The company follows strict quality control processes throughout every stage of production to ensure that each curved sheet metal component meets the highest standards. This dedication to quality has earned Curved Sheet Metal a solid reputation for reliability and excellence within the industry.

In addition to its focus on quality, Curved Sheet Metal also places a strong emphasis on customer satisfaction. The company works closely with each client to understand their specific requirements and to provide tailored solutions that meet their individual needs. This collaborative approach has led to long-standing partnerships with a diverse array of customers, from small businesses to large corporations.

Recent developments at Curved Sheet Metal have further enhanced the company’s capabilities and offerings. The company has made significant investments in new technologies and equipment to expand its curved sheet metal fabrication capabilities. This includes the addition of advanced machinery for precision cutting and bending, as well as the implementation of innovative techniques for creating complex curved shapes.

As a result of these investments, Curved Sheet Metal is now able to offer an even broader range of curved sheet metal products, including curved panels, tubes, and custom components. The expanded capabilities have opened up new opportunities for the company to serve a wider spectrum of industries and to take on more complex projects.

In addition to its ongoing commitment to innovation and quality, Curved Sheet Metal is also dedicated to sustainability. The company has implemented environmentally friendly practices throughout its operations, including the use of sustainable materials and energy-efficient processes. This focus on sustainability aligns with the company’s values and positions Curved Sheet Metal as a responsible and forward-thinking partner.

Looking ahead, Curved Sheet Metal is focused on continued growth and expansion. The company is actively exploring new markets and opportunities to further establish itself as a leading provider of curved sheet metal products. With its strong foundation of expertise, technology, and commitment to excellence, Curved Sheet Metal is well positioned for success in the evolving landscape of curved sheet metal fabrication.

Company News & Blog

Expert Sheet Metal Box Fabrication Services for Your Business

Sheet metal box fabrication is a crucial process in the manufacturing industry, and it requires precision and skill to create durable and functional boxes for various applications. Sheet metal box fabrication involves cutting, bending, and assembling sheet metal to create a box that meets the specific requirements of the customer. The process is often used in industries such as automotive, aerospace, electronics, and healthcare, where custom-made boxes are needed to house delicate equipment or components.This is where {Company Name} comes in. With years of experience in sheet metal fabrication, {Company Name} has established itself as a leader in the industry, offering high-quality and cost-effective solutions for its customers. The company prides itself on its ability to take on complex fabrication projects and deliver superior results.{Company Name} utilizes advanced machinery and equipment to ensure precision and accuracy in the sheet metal box fabrication process. The company's team of skilled engineers and technicians work closely with customers to understand their specific requirements and design custom solutions that meet their needs. Whether it's a simple junction box or a complex enclosure, {Company Name} has the expertise to deliver.In addition to its technical capabilities, {Company Name} is committed to maintaining the highest standards of quality and efficiency in its operations. The company adheres to stringent quality control measures to ensure that every sheet metal box meets the necessary specifications and standards. With a focus on continuous improvement, {Company Name} constantly seeks ways to enhance its processes and deliver even better results to its customers.{Company Name}'s dedication to customer satisfaction has earned it a reputation for reliability and excellence in the sheet metal fabrication industry. The company has worked with a diverse range of clients, providing custom solutions for their unique requirements. By collaborating with {Company Name}, customers can expect a seamless and efficient process, from initial design to final production.One of the key factors that sets {Company Name} apart from its competitors is its ability to offer cost-effective solutions without compromising on quality. The company understands the importance of delivering value to its customers, and it strives to optimize its processes to ensure competitive pricing for its services. This commitment to affordability has made {Company Name} a preferred partner for many businesses seeking sheet metal box fabrication services.As the demand for custom sheet metal boxes continues to grow across various industries, {Company Name} remains at the forefront of innovation and excellence. The company is constantly investing in technology and skills development to stay ahead of the curve and meet the evolving needs of its customers. Whether it's adopting new fabrication techniques or embracing emerging trends, {Company Name} is dedicated to staying relevant in a rapidly changing industry.In conclusion, sheet metal box fabrication is a critical process that requires expertise and precision to deliver superior results. With its technical capabilities, commitment to quality, and customer-focused approach, {Company Name} has established itself as a leading provider of sheet metal fabrication solutions. For businesses looking for reliable and cost-effective services, {Company Name} is the partner of choice for all their sheet metal box fabrication needs.

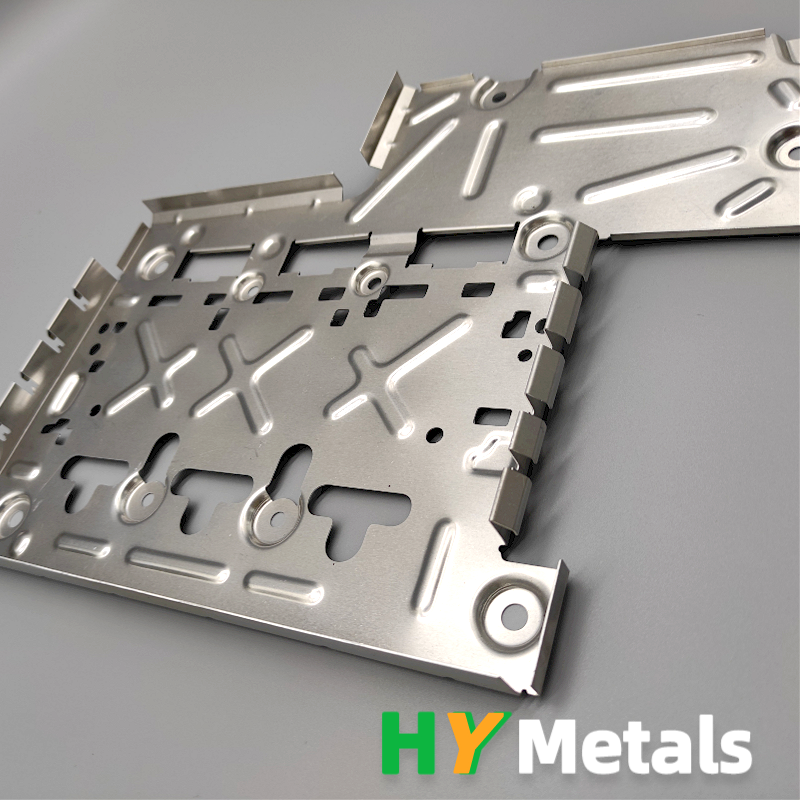

High-Quality Custom Metal Part for Industrial Applications

Custom Metal Part Company Expands Product Line to Meet Growing Demand[Company Name] is pleased to announce the expansion of their product line to include a range of custom metal parts. The decision to expand their offering comes as a response to the growing demand for precision metal components in various industries.The custom metal parts will be manufactured using state-of-the-art technology and high-quality materials, ensuring that they meet the highest standards of quality and performance. With a team of highly skilled engineers and technicians, [Company Name] has the capability to produce custom metal parts that are tailored to the specific needs of their clients.The custom metal parts will be available in a variety of materials, including stainless steel, aluminum, brass, and copper, allowing for a wide range of applications across different industries. In addition, [Company Name] will offer a range of finishes and coatings to further customize the parts to meet the unique requirements of their customers."We are excited to expand our product line to include custom metal parts, as we see a growing need for these components in various industries," said [Company Name]'s CEO. "With our advanced manufacturing capabilities and commitment to quality, we are confident that our custom metal parts will meet the needs of our customers and provide them with a reliable solution for their manufacturing needs."In addition to the custom metal parts, [Company Name] will also offer a range of value-added services, including design assistance, prototype development, and engineering support. This will ensure that their customers receive a comprehensive solution for their metal component needs, from conceptualization to production.The expansion of the product line reinforces [Company Name]'s commitment to providing their customers with a comprehensive range of high-quality metal components, backed by exceptional customer service and technical support. With their advanced manufacturing capabilities and dedication to continuous improvement, [Company Name] is well-positioned to meet the growing demand for custom metal parts in the market.[Company Name] is a leading manufacturer of precision metal components, serving a diverse range of industries including aerospace, automotive, medical, and electronics. With over [number] years of experience in the industry, [Company Name] has earned a reputation for their commitment to quality, innovation, and customer satisfaction.The company's state-of-the-art facility is equipped with the latest technology in precision machining, stamping, and fabrication, allowing them to produce high-quality metal components with tight tolerances and complex geometries. In addition, their team of experienced engineers and technicians work closely with their customers to develop customized solutions that meet their specific requirements.[Company Name]'s dedication to quality is reflected in their adherence to rigorous quality control and testing standards. They are certified to a number of industry standards, including ISO [number], AS9100, and NADCAP, ensuring that their products meet the highest levels of quality and performance.With the expansion of their product line to include custom metal parts, [Company Name] is well-positioned to further strengthen their position as a trusted partner for precision metal components. Their commitment to innovation, quality, and customer satisfaction will continue to drive their success in meeting the evolving needs of their customers in various industries.

K-pop Group Member Involved in Physical Altercation Raises Concerns

NCT, the world-renowned punching machine manufacturer, has recently unveiled a new range of products, making a grand entry into the global market. Founded in 1970 and headquartered in Japan, the company has been one of the major players in the metal-forming industry for more than five decades. The company's huge success has been built on continuous innovation, research, and development of its products. With a keen focus on delivering the most advanced machinery to meet the needs of the modern world, NCT has been lauded for producing cutting-edge technology punching machines.The NCT punching machine's range is optimized for clients who seek to achieve high-precision sheet metal fabrication. Along with this, these machines offer superior speed and excellent durability, positioning them as a product of choice for clients in need of a reliable and quality-driven machine. The company's new line of punching machines is geared towards offering customized solutions that cater to both small-scale and large-scale industries. Clients can choose from various models, which have been specifically designed to cater to different needs, budgets, and production volumes.NCT's recent entry into the global marketplace has garnered much attention, owing to the company's longstanding reputation in the metal-forming machinery industry. The company's machines are known for their unparalleled precision and speed, combined with their ability to handle a wide variety of metals. The company's newest range of products is ideal for a wide range of punching applications used in several industries, including automobile, aerospace, electrical, and electronics.With the ever-growing demand for high-quality punching machines, NCT's entry into the global market promises to offer a much-needed boost to the metal-forming industry. The company's punching machines are designed to optimize time, effort, and cost, which are the most significant concerns of clients seeking these machines. The company's innovative and highly efficient punching machines set themselves apart from their competition, offering clients benefits such as increased productivity, higher precision, and lower cost per punch.The punching industry has evolved significantly over the years, and the demand for high-quality punching machines is higher than ever. NCT's large-scale entry into the market makes it evident that the company identifies the growing demand and is committed to providing the best solutions to clients worldwide. By offering a wide range of customized machinery, the company caters to clients of all sizes and industries, which ensures that clients can find the most suitable punching machine for their unique requirements.In conclusion, NCT's recent unveiling of their new range of punching machines marks the company's entry into the global market, and it is set to revolutionize the metal-forming industry. With superior speed, precision, and durability, NCT's machines offer unprecedented levels of productivity, providing clients with cost-effective solutions that optimize time and effort. The company's commitment to research and development has enabled it to deliver advanced and customized machinery, satisfying the needs of clients worldwide. With NCT, clients are guaranteed an unparalleled experience, and they can rest assured that they are investing in the best and most innovative punching machines on the market.

Innovative Solutions for Enhanced Performance: The Benefits of Stamped Sheet Metal

[Company Name]'s Stamped Sheet Metal Revolutionizes Manufacturing Industry[date]Stamping and sheet metal production have long been the backbone of the manufacturing industry, enabling the creation of various products with efficiency and precision. Today, a company called [Company Name] is taking this age-old practice to new heights with their innovative stamped sheet metal technology. With a strong commitment to quality and innovation, [Company Name] is revolutionizing the manufacturing industry and paving the way for a more sustainable future.Founded in [year], [Company Name] has quickly gained recognition for its cutting-edge stamped sheet metal solutions. The company's advanced manufacturing processes and state-of-the-art machinery allow for precise and efficient production, ensuring that each product meets the highest standards of quality. By combining technology and craftsmanship, [Company Name] has positioned itself as a leader in the industry, serving a diverse range of sectors, from automotive to aerospace, electronics to construction.The success of [Company Name] can be attributed to its team of dedicated professionals and their unwavering commitment to excellence. With years of experience and expertise, the company's engineers and designers work closely with clients to understand their specific needs and deliver tailored solutions. This collaborative approach has fostered long-term partnerships with clients, who value the quality, reliability, and efficiency that [Company Name] provides.What sets [Company Name]'s stamped sheet metal apart is its commitment to sustainability. With a growing emphasis on eco-friendly practices, the company has integrated sustainable manufacturing techniques into its processes. By minimizing waste, recycling materials, and optimizing production cycles, [Company Name] reduces its ecological footprint while maintaining the highest standards of quality. Additionally, the use of high-quality materials ensures the longevity of products, reducing the need for replacements and further minimizing waste.One of the key advantages of stamped sheet metal technology is its versatility. [Company Name] understands this well and leverages its expertise to offer customized solutions for each client. Whether it's prototyping, small-scale production, or large-scale manufacturing, the company can accommodate various project sizes and specifications. By staying at the forefront of technological advancements and investing in research and development, [Company Name] consistently introduces new and improved solutions to meet the ever-evolving demands of the market.As the manufacturing industry continues to expand and evolve, [Company Name] remains committed to being at the forefront of innovation. By continuously investing in research and development, the company aims to develop new materials, processes, and applications for stamped sheet metal technology. This drive for innovation not only keeps [Company Name] ahead of its competition but also contributes to pushing the entire manufacturing industry forward.While [Company Name] has achieved significant milestones, the company is not resting on its laurels. With a focus on continuous improvement, the company aims to refine its processes, enhance its production capabilities, and expand its global presence. By investing in its workforce and staying dedicated to delivering exceptional customer service, [Company Name] seeks to become the go-to choice for stamped sheet metal solutions worldwide.In conclusion, [Company Name]'s stamped sheet metal technology is revolutionizing the manufacturing industry. With its commitment to quality, innovation, and sustainability, the company is setting new standards in the industry. By leveraging its expertise and investing in research and development, [Company Name] is poised to shape the future of manufacturing, making it more efficient, precise, and eco-friendly.As the demand for precision-engineered products continues to grow, [Company Name]'s stamped sheet metal technology will play a significant role in meeting these needs. With its dedication to excellence and forward-thinking approach, [Company Name] has undoubtedly carved its place as a leader in the industry.

Master the Art of Sheet Metal Bending with These Expert Tips

[Company Name], a leader in the sheet metal bending industry, is revolutionizing the manufacturing sector with its cutting-edge technology and exceptional quality. With their commitment to excellence and innovative solutions, the company has made its mark as a trusted partner for customers across various industries.Sheet metal bending plays a crucial role in the manufacturing process, allowing for the creation of complex and intricate metal components. With their state-of-the-art equipment and skilled team, [Company Name] takes this process to new heights, delivering precise and efficient results to meet the diverse needs of their clients. Whether it's a small-scale project or a large industrial application, their expertise ensures a seamless and reliable outcome.One of the key factors that sets [Company Name] apart from its competitors is its focus on technological advancements. They continuously invest in the latest equipment and software to enhance their capabilities and provide their customers with the highest level of precision and accuracy. By utilizing advanced computer numerical control (CNC) machines, they are able to achieve complex bending angles and radii with ease, resulting in superior quality products.Furthermore, [Company Name] prioritizes sustainability in its operations. The company uses environmentally-friendly materials and practices, demonstrating its commitment to reducing its carbon footprint. By adopting energy-efficient systems and implementing waste management strategies, they contribute to a greener future while maintaining the highest standards of manufacturing excellence.In addition to their technical prowess, [Company Name] prides itself on its team of highly skilled professionals. Each member undergoes rigorous training and possesses extensive knowledge of sheet metal bending techniques. Their expertise enables them to tackle even the most challenging projects and find innovative solutions tailored to their clients' unique needs. Moreover, the company emphasizes employee development and fosters a culture of collaboration and continuous learning.[Company Name]'s dedication to customer satisfaction is second to none. They understand the importance of clear communication and effective project management. From project inception to completion, their team works closely with clients, providing regular updates and ensuring that all specifications and timelines are met. This customer-centric approach has earned them a stellar reputation in the industry, with numerous clients relying on their expertise for their sheet metal bending requirements.The versatility of [Company Name]'s sheet metal bending services makes them invaluable to a wide range of industries. From automotive manufacturing to aerospace engineering, their products are utilized in diverse applications. With their ability to handle various materials, thicknesses, and specifications, they have become a preferred choice for customers seeking exceptional quality and durability.As a frontrunner in the industry, [Company Name] consistently delivers exceptional results that surpass industry standards. By investing in cutting-edge technology, fostering a skilled workforce, and prioritizing customer satisfaction, the company continues to set new benchmarks in the sheet metal bending sector.In conclusion, [Company Name] is a renowned leader in the sheet metal bending industry, known for its exceptional quality, advanced technology, and commitment to customer satisfaction. With their state-of-the-art equipment, skilled team, and dedication to sustainability, they have established themselves as a trusted partner for clients across various industries. As they continue to push the boundaries of what is possible in sheet metal bending, [Company Name] is set to shape the future of manufacturing with their innovative solutions.

Durable and Versatile Sheet Metal Flat for Various Applications

Sheet Metal Flat is a leading provider of high-quality sheet metal products to a wide range of industries. With a strong focus on customer satisfaction and cutting-edge technology, the company has established itself as a trusted partner for businesses looking for precision-engineered metal components.The company offers a wide range of sheet metal products, including flat sheets, coils, and custom-cut pieces. With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, Sheet Metal Flat is able to meet the diverse needs of its customers, delivering products that meet the highest standards of quality and precision.One of the key strengths of Sheet Metal Flat is its ability to work with a variety of materials, including stainless steel, aluminum, and carbon steel. This versatility allows the company to cater to the unique requirements of different industries, from automotive and aerospace to construction and electronics.In addition to its manufacturing capabilities, Sheet Metal Flat also offers a range of value-added services, such as metal finishing, coating, and assembly. This comprehensive approach allows the company to offer a one-stop solution for its customers, streamlining the production process and ensuring a seamless experience from start to finish.Furthermore, the company prides itself on its commitment to sustainability and environmentally friendly practices. Sheet Metal Flat has invested in advanced technologies and processes to minimize waste and reduce its carbon footprint, ensuring that its operations are as eco-friendly as possible.In recent news, Sheet Metal Flat has announced the launch of a new line of flat sheets that are designed to meet the growing demand for lightweight yet durable materials in the automotive industry. These sheets are made from high-strength aluminum alloys, offering a combination of excellent formability and corrosion resistance, making them ideal for use in body panels, chassis components, and structural parts."We are excited to introduce our new line of flat sheets that are specifically engineered to meet the stringent requirements of the automotive industry," said [company spokesperson]. "With the increasing focus on fuel efficiency and lightweighting in the automotive sector, our products are well-positioned to address the evolving needs of our customers."The company's investment in research and development has enabled it to stay ahead of industry trends and develop innovative solutions that meet the changing needs of its customers. Sheet Metal Flat continuously collaborates with its clients to identify new opportunities and develop tailored products that address specific challenges in their respective industries.In addition to its focus on product innovation, Sheet Metal Flat also places a strong emphasis on customer service and satisfaction. The company's team of dedicated professionals works closely with clients to understand their requirements and provide personalized solutions that meet their exact specifications.As Sheet Metal Flat continues to grow and expand its capabilities, the company remains committed to upholding its core values of quality, integrity, and innovation. With a track record of excellence and a customer-centric approach, Sheet Metal Flat is well-positioned to be a leading provider of sheet metal products for years to come.

Precision Milling of Parts for High-Quality Results

Milling Precision Parts, based in Texas, is a leading manufacturer of high-quality precision parts for a wide range of industries. The company specializes in producing custom components for applications in the aerospace, automotive, medical, and defense sectors, among others. With state-of-the-art equipment and a team of highly skilled technicians, Milling Precision Parts has earned a reputation for delivering superior products that meet and exceed the exacting standards of its diverse customer base.Founded in 2005, Milling Precision Parts has grown steadily over the years, expanding its capabilities and investing in the latest manufacturing technologies to ensure that it remains at the forefront of the industry. The company's commitment to quality, innovation, and customer satisfaction has been the driving force behind its success, enabling it to build lasting partnerships with clients and establish itself as a trusted source for precision-engineered components.Milling Precision Parts offers a comprehensive range of machining services, including milling, turning, grinding, and EDM (electrical discharge machining). The company works with a variety of materials, such as aluminum, stainless steel, titanium, and plastics, and is capable of producing parts in a wide range of sizes and complexities. Whether it's a small-batch prototype or a large-scale production run, Milling Precision Parts has the expertise and capacity to handle projects of any scope and scale.One of the key differentiators for Milling Precision Parts is its dedication to precision and quality control. The company maintains rigorous quality assurance protocols to ensure that every component it produces meets the strictest tolerances and specifications. By leveraging advanced inspection equipment and a meticulous attention to detail, Milling Precision Parts is able to deliver parts that consistently uphold the highest standards of accuracy and performance.In addition to its commitment to precision manufacturing, Milling Precision Parts places a strong emphasis on customer collaboration and support. The company works closely with clients at every stage of the production process, from initial design and prototyping to final manufacturing and delivery. By fostering open communication and transparency, Milling Precision Parts strives to provide a seamless and efficient experience for its customers, helping them bring their concepts to fruition with speed and precision.Milling Precision Parts is also deeply committed to environmental sustainability and corporate responsibility. The company adheres to strict environmental standards in its operations and is continuously exploring new ways to minimize its ecological footprint. By implementing eco-friendly practices and investing in energy-efficient technologies, Milling Precision Parts aims to contribute to a cleaner, greener future while maintaining the highest standards of manufacturing excellence.Looking ahead, Milling Precision Parts is poised for continued growth and success as it seeks to further expand its capabilities and reach new markets. The company remains dedicated to ongoing innovation and improvement, continually investing in the latest technologies and talent to ensure that it remains a leader in the field of precision parts manufacturing.With its unwavering commitment to quality, precision, and customer satisfaction, Milling Precision Parts stands as a trusted partner for companies seeking top-notch precision components. As the company continues to raise the bar for excellence in the industry, it is well-positioned to meet the evolving needs of its clients and drive the future of precision manufacturing.

Durable and Stylish Metal Furniture Fittings for Your Home

Metal Furniture Fittings, a leading provider of high-quality furniture hardware and accessories, is proud to announce the launch of their latest line of innovative and functional products. With a focus on durability, efficiency, and style, Metal Furniture Fittings is dedicated to providing top-of-the-line fittings for all types of furniture.As a renowned industry leader, Metal Furniture Fittings has built a reputation for excellence and reliability. With a commitment to customer satisfaction, the company continuously seeks to innovate and improve their product offerings. With a wide range of fittings and accessories for furniture, Metal Furniture Fittings has become a go-to source for manufacturers, retailers, and designers alike.Metal Furniture Fittings offers a diverse range of products including hinges, handles, drawer slides, and other hardware essentials. Their products are designed to meet the needs of modern furniture design while also prioritizing durability and functionality. Whether it’s for residential, commercial, or industrial use, Metal Furniture Fittings has the perfect solution for any furniture hardware needs.The company prides itself on its cutting-edge manufacturing processes and state-of-the-art technologies. By investing in the latest machinery and equipment, Metal Furniture Fittings is able to produce high-quality fittings with precision and efficiency. This allows them to consistently deliver products that meet the highest industry standards.In addition to their technical capabilities, Metal Furniture Fittings places a strong emphasis on design and aesthetics. Their team of experienced designers and engineers work tirelessly to create products that not only perform well but also enhance the overall look and feel of the furniture they are used on. With a keen eye for detail and an understanding of current design trends, Metal Furniture Fittings ensures that their products are not only functional but also visually appealing.Metal Furniture Fittings is also committed to sustainability and environmental responsibility. The company has implemented eco-friendly practices in their manufacturing processes and uses materials that are safe for the environment. With a focus on reducing waste and energy consumption, Metal Furniture Fittings is dedicated to minimizing their impact on the planet while delivering top-notch products.As the furniture industry continues to evolve, Metal Furniture Fittings remains at the forefront of innovation. By staying ahead of the curve and anticipating the needs of their customers, the company is able to introduce new and exciting products that meet the ever-changing demands of the market.In conclusion, Metal Furniture Fittings is a trusted name in the furniture hardware industry, known for their commitment to quality, innovation, and customer satisfaction. With a wide range of high-quality products, state-of-the-art manufacturing processes, and a dedication to environmental sustainability, the company continues to be a leading force in the market. Whether it’s for residential, commercial, or industrial use, Metal Furniture Fittings is the go-to source for all furniture hardware needs. With their latest line of innovative and functional products, Metal Furniture Fittings is poised to set new standards for the industry and provide even greater value to their customers.

High-quality precision components for CNC machining.

CNC Precision Components, a leading manufacturer in the field of precision machining, has recently announced its expansion plans to meet the growing demand for its products. The company, known for its high-quality components and superior customer service, is set to increase its production capacity and expand its global reach to better serve its customers.With over [number of years] of experience in the industry, CNC Precision Components has built a solid reputation for its ability to deliver precision-engineered parts to a wide range of industries including aerospace, automotive, medical, and defense. The company’s state-of-the-art facility is equipped with the latest CNC machines and advanced manufacturing technologies, allowing it to produce complex components with tight tolerances and exacting specifications.As part of its expansion plans, CNC Precision Components will be adding new machining centers, hiring additional skilled personnel, and implementing advanced quality control measures to ensure that its products meet the highest standards. This investment in new technology and talent will enable the company to increase its production capacity and reduce lead times, allowing it to better support its customers’ growing needs.In addition to expanding its production capabilities, CNC Precision Components is also focusing on strengthening its global presence. The company plans to establish strategic partnerships and distribution channels in key international markets to better serve its growing customer base. By building relationships with local partners, CNC Precision Components aims to provide localized support and faster turnaround times for its customers around the world.“We are excited about the opportunities that lie ahead for CNC Precision Components,” said [Spokesperson Name], [Job Title] of the company. “Our expansion plans will enable us to better meet the needs of our customers while solidifying our position as a leader in the precision machining industry. We are committed to maintaining the high quality and reliability that our customers have come to expect from us.”In addition to its expansion plans, CNC Precision Components is also dedicated to maintaining its commitment to sustainability and environmental responsibility. The company is continuously looking for ways to reduce its environmental footprint, minimize waste, and optimize its manufacturing processes to operate in an environmentally friendly manner.CNC Precision Components takes great pride in its ability to deliver high-quality precision components while maintaining a focus on sustainable and responsible business practices. By investing in the latest technology, expanding its production capacity, and enhancing its global reach, the company is well-positioned to continue meeting the evolving needs of its customers while maintaining its dedication to excellence.About CNC Precision Components:CNC Precision Components is a leading manufacturer specializing in the production of high-quality precision components for a wide range of industries. With a focus on quality, reliability, and customer satisfaction, the company has established itself as a trusted partner for businesses in need of precision-engineered parts. With its commitment to excellence and continuous improvement, CNC Precision Components is dedicated to meeting the evolving needs of its customers while upholding the highest standards of quality and service. For more information, please visit [company website].

Top 3-Axis Features and Benefits You Need to Know

3-Axis, a leading manufacturer of cutting-edge technology, has recently announced the launch of their latest product, the 3-Axis Advanced Motion Control System. This state-of-the-art system is designed to provide precise and accurate motion control for a wide range of applications, from industrial automation to robotics and beyond.The 3-Axis Advanced Motion Control System is a culmination of years of research and development, combining the latest advancements in motion control technology with the company's expertise in engineering and manufacturing. The system features a highly responsive 3-axis control unit, capable of delivering smooth and precise motion control across multiple axes. This allows for seamless integration into existing automation systems, as well as the ability to control complex motion sequences with ease.One of the key features of the 3-Axis Advanced Motion Control System is its user-friendly interface, which allows for easy setup and operation. Users can quickly configure the system to meet their specific requirements, using the intuitive interface to set motion parameters, control speed and acceleration, and monitor system performance in real-time. This level of flexibility and control makes the system well-suited for a wide range of applications, from advanced manufacturing processes to cutting-edge robotic systems.In addition to its advanced motion control capabilities, the 3-Axis system also offers a high level of precision and accuracy. This is achieved through the use of advanced servo motors and encoders, which provide real-time feedback and error correction to ensure that motion control is always precise and reliable. This level of precision is essential for many applications, particularly in industries where tight tolerances and high standards of quality are required.Furthermore, the 3-Axis Advanced Motion Control System is designed with scalability in mind, allowing for easy integration into existing automation and robotic systems. This makes it a versatile solution for companies looking to enhance their existing machinery with advanced motion control capabilities. Whether it's retrofitting older equipment or integrating the system into new production lines, the 3-Axis system offers a seamless and cost-effective solution for achieving better motion control performance.With the launch of the 3-Axis Advanced Motion Control System, 3-Axis has once again demonstrated its commitment to pushing the boundaries of motion control technology. The company has a long history of innovation and excellence in the field of automation and robotics, and the new system is a testament to their ongoing dedication to delivering cutting-edge solutions to their customers.In conclusion, the 3-Axis Advanced Motion Control System represents a significant advancement in the field of motion control technology. With its advanced capabilities, user-friendly interface, and high level of precision, the system is poised to make a significant impact in a wide range of industries. Whether it's improving the efficiency of manufacturing processes or enhancing the performance of robotic systems, the 3-Axis system offers a powerful and versatile solution for companies looking to take their motion control capabilities to the next level.