Discover the process of metal etching and its applications in manufacturing

By:Admin

Metal Etching Company, a leading manufacturer of metal etching equipment, has recently introduced a cutting-edge technology that promises to revolutionize the metal etching process. The company, known for its expertise in providing high-quality, precision etching solutions, has developed a new system that boasts advanced features and improved efficiency, making it the go-to choice for industrial and commercial metal etching applications.

The new technology, which the company has dubbed as the "EtchMaster 5000," is a result of years of research and development aimed at enhancing the metal etching process. With the EtchMaster 5000, Metal Etching Company aims to address the challenges faced by industries and businesses when it comes to etching various types of metal surfaces, including steel, aluminum, and copper.

One of the key features of the EtchMaster 5000 is its advanced etching capabilities that allow for precise and intricate designs to be etched onto metal surfaces with unparalleled accuracy. This is especially beneficial for industries such as aerospace, automotive, and electronics, where the need for intricate and precise markings on metal parts is critical.

In addition to its cutting-edge etching capabilities, the EtchMaster 5000 also boasts a user-friendly interface and intuitive controls, making it easy for even non-technical personnel to operate and manage the etching process. This is a significant advantage for businesses looking to streamline their production processes and reduce downtime caused by complex or difficult-to-operate equipment.

Furthermore, the EtchMaster 5000 is designed to be highly efficient, reducing the time and resources required for the metal etching process. This means that businesses can benefit from increased productivity and lower operating costs, ultimately leading to improved profitability and a competitive edge in the market.

Metal Etching Company has also emphasized the environmental sustainability of the EtchMaster 5000, highlighting its reduced energy consumption and minimal waste generation. As businesses increasingly focus on sustainable practices, the company's commitment to providing eco-friendly metal etching solutions is likely to resonate with environmentally conscious organizations.

"We are thrilled to introduce the EtchMaster 5000 to the market, as we believe it will redefine the metal etching industry," said [Spokesperson], CEO of Metal Etching Company. "Our team has worked tirelessly to develop a system that not only meets the high-quality standards our customers expect from us but also sets a new benchmark for efficiency, precision, and sustainability in metal etching."

The introduction of the EtchMaster 5000 comes at a time when the demand for metal etching solutions is on the rise, driven by the increasing use of metal components in various industrial and consumer products. With its state-of-the-art technology, Metal Etching Company is well-positioned to capitalize on this growing demand and cement its leadership in the metal etching market.

Industry experts have praised the technological advancements brought by Metal Etching Company, noting that the EtchMaster 5000 is set to disrupt the metal etching landscape by offering a comprehensive solution to the challenges faced by businesses in this sector.

As Metal Etching Company continues to roll out the EtchMaster 5000 to its clients, the company looks poised to solidify its reputation as a provider of innovative, high-quality metal etching solutions. With its commitment to excellence and advancement, Metal Etching Company is well-equipped to shape the future of metal etching technology, meeting the evolving needs of industries and businesses across the globe.

Company News & Blog

How to Use Silkscreen Printing for Your Business: Tips and Techniques

Silkscreen printing is a popular and versatile technique used to create high-quality prints on a variety of surfaces. This method has been utilized for decades in the production of posters, t-shirts, and other promotional materials. Recently, the demand for silkscreen printing has been on the rise, with many businesses and individuals seeking this timeless and effective method for their printing needs.{Company} is a leading provider of silkscreen printing services, offering a wide range of printing options to meet the needs of their diverse client base. With a dedication to quality and customer satisfaction, {Company} has established itself as a go-to source for silkscreen printing.Silkscreen printing is a process that involves using a stencil to transfer ink onto a substrate, such as fabric, glass, or paper. This method allows for the creation of highly detailed designs and vibrant colors, making it a popular choice for a wide range of applications.{Company} is well-equipped to handle a variety of silkscreen printing projects, from small runs for individuals to large-scale orders for businesses. Their team of experienced professionals works closely with clients to ensure that their vision is brought to life through the printing process. This commitment to customer service has earned {Company} a reputation for excellence in the industry.In addition to traditional silkscreen printing, {Company} also offers specialty services such as foil printing, metallic inks, and custom color matching. This allows clients to create truly unique and eye-catching printed materials that stand out from the competition.The versatility of silkscreen printing makes it an ideal choice for a wide range of products, including apparel, promotional items, signage, and more. Whether it's a custom t-shirt for a special event or a series of posters for a marketing campaign, {Company} has the capabilities to bring any design to life with stunning precision and clarity.One of the key advantages of silkscreen printing is its durability. The ink used in this process is designed to withstand the test of time, making it ideal for products that will be used and worn frequently. This durability ensures that the printed materials will maintain their quality and appearance for years to come.With a focus on innovation and quality, {Company} is constantly exploring new techniques and materials to enhance their silkscreen printing services. This commitment to staying at the forefront of the industry ensures that clients receive the best possible results for their printing needs.In today's competitive marketplace, it's essential for businesses and individuals to make a lasting impression with their printed materials. Silkscreen printing offers a timeless and effective way to achieve this, and {Company} is proud to be a trusted partner for all silkscreen printing needs.As the demand for high-quality printed materials continues to grow, {Company} remains dedicated to providing top-notch silkscreen printing services that exceed client expectations. With a combination of cutting-edge technology, skilled professionals, and a focus on customer satisfaction, {Company} is poised to continue leading the way in the silkscreen printing industry for years to come.

Revolutionizing Manufacturing: Streamline Production with Custom Industrial Design Parts

Build Parts For Industry Design Expands Its Capabilities to Serve Diverse Industrial SectorsBuild Parts For Industry Design, a leading provider of high-quality industrial parts and services, is proud to announce the expansion of its capabilities to better cater to the needs of diverse industrial sectors. With its state-of-the-art facilities and cutting-edge technology, the company aims to deliver innovative solutions and meet the demands of an ever-evolving market.Established in [year], Build Parts For Industry Design has become a trusted name in the industrial design and manufacturing industry. With a team of experienced engineers, designers, and technicians, the company has successfully served various clients across different sectors, including automotive, aerospace, electronics, and consumer goods.Understanding the changing dynamics of the industrial landscape, Build Parts For Industry Design has strategically invested in its facilities to ensure it remains at the forefront of innovation. By leveraging the latest technologies and continuously upgrading its equipment, the company is well-equipped to deliver parts that meet the highest industry standards.One of the key factors that sets Build Parts For Industry Design apart from its competitors is its commitment to precision and quality. The company follows rigorous quality control processes at every step of the manufacturing process to ensure that the parts it produces are of the finest quality. By adhering to industry-leading standards, Build Parts For Industry Design aims to provide its clients with reliable and durable parts that can withstand even the most demanding conditions.Build Parts For Industry Design also places great emphasis on customization and flexibility. The company understands that each industrial sector has its own unique needs and requirements. With its expanded capabilities, Build Parts For Industry Design can now offer tailor-made solutions to meet the specific demands of different industries. Whether it's designing intricate components for the aerospace industry or manufacturing precision parts for the automotive sector, the company has the expertise and resources to deliver exceptional results.In addition to its commitment to quality and customization, Build Parts For Industry Design is also dedicated to sustainable practices. The company recognizes the importance of minimizing its environmental impact and actively seeks out eco-friendly manufacturing processes. By investing in advanced technologies that reduce waste and optimize energy consumption, Build Parts For Industry Design ensures that its operations are as sustainable as possible.Customers of Build Parts For Industry Design can expect not only high-quality parts but also excellent customer service. The company takes pride in its responsive and efficient communication channels, ensuring that clients receive the support they need throughout their project. From initial design consultations to post-production assistance, Build Parts For Industry Design is committed to providing an unparalleled customer experience.As Build Parts For Industry Design expands its capabilities, it looks forward to forging new partnerships and collaborations across a wide range of industries. The company's dedication to innovation, quality, and sustainability positions it as an ideal partner for businesses looking to enhance their industrial design and manufacturing processes.With its state-of-the-art facilities and a team of skilled professionals, Build Parts For Industry Design is ready to take on new challenges and serve the diverse needs of the industrial sector. As the industry continues to evolve, the company remains committed to delivering cutting-edge solutions that drive innovation and economic growth.For more information about Build Parts For Industry Design and its range of services, please visit [website] or contact [email/phone].

What is Water-jet Technology? A Definition

Water-jet Technology Takes the Industrial World by StormWater-jet technology has been quietly revolutionizing the industrial world over the past decade. Driven by powerful streams of water and sometimes abrasive materials, water-jet cutting technology is quickly becoming the go-to cutting method for a variety of industries. From aerospace to the medical field, water-jet cutting is proving to be more precise and efficient than traditional cutting methods.A water-jet is a cutting tool that creates a high-velocity jet of water, usually mixed with an abrasive material. This creates a powerful cutting force that can cut through virtually any material with precision, including metal, stone, glass, and plastic. Water-jet cutting technology was developed in the 1950s, and since then, it has been continuously refined and improved, becoming one of the most versatile and effective cutting methods available today.One of the many benefits of water-jet cutting is its precision. Unlike traditional cutting methods that rely on brute force and sharp blades, water-jet cutting relies on a powerful stream of water to slice through materials with ease. This allows for incredibly intricate and precise cuts, even on difficult or complicated materials.Another benefit of water-jet cutting is its versatility. Water-jet cutters can handle a wide range of materials, from soft rubber to thick steel. This makes it an ideal choice for industries that require cutting precision on a variety of materials.The aerospace industry, for example, heavily relies on water-jet technology for the precision cutting of parts and components. With water-jet cutting, aerospace manufacturers can create intricate shapes out of tough materials such as titanium and composites, resulting in stronger, lighter-weight aircraft that perform better than ever before. Other industries, such as the medical field, also rely on water-jet cutting for precision cutting of surgical instruments and implantable devices.Water-jet cutting technology has also become more accessible in recent years, with more and more companies offering water-jet cutting services to a variety of industries. Companies like {} offer state-of-the-art water-jet cutting services that can handle large production runs or small, custom projects. By outsourcing their cutting needs, businesses can save time and money on equipment and maintenance costs while still enjoying the precision and versatility of water-jet cutting.Finally, water-jet cutting is also environmentally friendly. Unlike traditional cutting methods that produce harmful dust and debris, water-jet cutting creates minimal waste and leaves the material clean and untouched. This means less waste, fewer environmental hazards, and a safer workplace for employees.In conclusion, water-jet cutting technology is quickly becoming the go-to cutting method for businesses ranging from aerospace to medical manufacturing. With its precision, versatility, accessibility, and environmentally friendly benefits, water-jet cutting is the perfect solution for industries that require precise cutting of a variety of materials. As technology continues to improve, we can only expect to see water-jet cutting become even more essential to the industrial world.

Custom Sheet Metal Parts: A Complete Guide to Manufacturing and Use

For more than 20 years, the dedicated team at [Company Name] has been a leader in the manufacturing of high-quality sheet metal parts for a wide range of industries. The company's commitment to excellence and customer satisfaction has earned them a stellar reputation in the industry. Recently, [Company Name] unveiled their latest innovation in sheet metal part manufacturing, which is set to revolutionize the industry. This new product offers enhanced durability, precision, and efficiency, making it a game-changer for their clients.The new sheet metal part is designed using state-of-the-art technology and advanced engineering techniques. It has been meticulously crafted to meet the highest industry standards and to exceed the expectations of even the most discerning customers. The result is a product that is not only incredibly durable but also incredibly precise, making it perfect for a wide range of applications.One of the key features of the new sheet metal part is its enhanced durability. This is achieved through the use of high-quality materials and the implementation of advanced manufacturing processes. This ensures that the part is able to withstand even the most demanding conditions, making it an ideal choice for industries such as automotive, aerospace, and construction.In addition to its durability, the new sheet metal part also offers unmatched precision. This is achieved through the use of cutting-edge technology and the company's commitment to quality control. Every part is meticulously inspected to ensure that it meets the strictest tolerances, resulting in a product that is incredibly precise and consistent.Furthermore, the new sheet metal part is also incredibly efficient. Its innovative design and manufacturing processes have been optimized to minimize waste and maximize productivity. This not only benefits the environment but also allows for cost savings, making it an attractive option for businesses looking to improve their bottom line.The introduction of this new sheet metal part further solidifies [Company Name]'s position as an industry leader. Their commitment to innovation and excellence has set them apart from their competitors, and this latest product is a testament to their dedication to providing the best possible solutions for their clients.In addition to their innovative products, [Company Name] also prides itself on its exceptional customer service. Their team of experts is always available to provide guidance and support, ensuring that their clients have everything they need to succeed.As the industry continues to evolve, [Company Name] remains at the forefront, consistently pushing the boundaries of what is possible in sheet metal part manufacturing. Their latest innovation is a testament to their commitment to excellence and their dedication to meeting the needs of their clients.In conclusion, the introduction of [Company Name]'s new sheet metal part is set to revolutionize the industry. With its enhanced durability, precision, and efficiency, it is sure to become the go-to choice for businesses across a wide range of industries. This latest innovation further solidifies [Company Name]'s position as an industry leader, and their dedication to excellence and customer satisfaction is sure to set them apart for years to come.

Innovative 3D Printing Technology: What You Need to Know

3D Print Technology Revolutionizes Manufacturing ProcessIn today's fast-paced world, technological advancements are constantly changing the way we live and work. One such innovation that has been making waves in the manufacturing industry is 3D printing. This cutting-edge technology, also known as additive manufacturing, has the potential to revolutionize the way products are designed, prototyped, and produced.{Company Name} is a leading provider of 3D printing solutions, offering a wide range of products and services to meet the diverse needs of its customers. The company's advanced printing technology has been used in various industries, including aerospace, automotive, healthcare, and consumer goods. With a team of experienced engineers and experts in the field of additive manufacturing, {Company Name} has been at the forefront of driving innovation and pushing the boundaries of what is possible with 3D printing.The key advantage of 3D printing technology lies in its ability to create complex and intricate designs with utmost precision and efficiency. Traditional manufacturing processes often involve cutting, molding, and shaping materials, which can be time-consuming and wasteful. 3D printing, on the other hand, builds objects layer by layer, using digital models as blueprints. This enables manufacturers to produce custom parts and prototypes with minimal material waste and labor costs.Furthermore, 3D printing opens up new possibilities for product customization and personalization. By leveraging the power of digital design, companies can create unique and tailored products that cater to the specific needs of individual customers. This level of flexibility and agility is unparalleled in traditional manufacturing methods, making 3D printing a game-changer in today's market.One of the most exciting applications of 3D printing is in the field of healthcare. {Company Name}'s technology has been instrumental in producing medical implants, prosthetics, and anatomical models with unprecedented accuracy and detail. These customized solutions have the potential to improve patient care and outcomes, as well as reduce the time and cost associated with traditional production methods.In the aerospace and automotive industries, 3D printing is being used to create lightweight and durable components that enhance performance and fuel efficiency. {Company Name} has worked closely with its clients in these sectors to develop cutting-edge solutions that address their specific challenges and requirements. The ability to rapidly iterate and test new designs has accelerated the pace of innovation and allowed companies to stay ahead of the competition.Moreover, 3D printing has also opened up new opportunities for sustainable manufacturing. By optimizing material usage and minimizing waste, {Company Name}'s technology aligns with the growing demand for eco-friendly alternatives. This not only benefits the environment but also contributes to cost savings and resource efficiency for businesses.As the adoption of 3D printing continues to expand, {Company Name} remains committed to pushing the boundaries of what is possible with additive manufacturing. By investing in research and development, as well as forging strategic partnerships with industry leaders, the company aims to drive further innovation and unlock the full potential of 3D printing technology.In conclusion, 3D printing has emerged as a disruptive force in the manufacturing industry, offering unparalleled flexibility, precision, and customization. With its extensive expertise and state-of-the-art solutions, {Company Name} is at the forefront of this technological revolution, shaping the future of manufacturing and driving positive change across various sectors. As the demand for advanced manufacturing solutions continues to grow, it is clear that 3D printing will play a pivotal role in shaping the industry's future.

Ultimate Guide to Sheet Metal Forming Techniques for Manufacturing

article about the advancements in sheet metal forming technology.Sheet metal forming is a process used to transform flat metal sheets into various shapes and products through the application of force. This process is widely used in industries such as automotive, aerospace, construction, and manufacturing to create a wide range of products including car parts, machinery components, and household appliances.In recent years, there have been significant advancements in sheet metal forming technology that have led to improvements in efficiency, precision, and overall product quality. One company at the forefront of these advancements is {}.{} is a leading manufacturer of sheet metal forming equipment and has been instrumental in driving innovation in the industry. With a strong focus on research and development, the company has developed cutting-edge technologies that have revolutionized the sheet metal forming process.One of the key advancements that {} has introduced is the use of advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software to optimize the sheet metal forming process. This software allows manufacturers to create highly detailed and precise designs, which are then used to program the company's state-of-the-art sheet metal forming machines.In addition to software advancements, {} has also developed new techniques for controlling the temperature and pressure during the sheet metal forming process. These techniques have resulted in a more consistent and uniform shaping of the metal, leading to products with higher quality and durability.Furthermore, {} has invested heavily in automation and robotics to streamline the sheet metal forming process. By automating certain tasks, the company has been able to increase production speed and efficiency while reducing the margin of error.The advancements made by {} have not only improved the efficiency and precision of the sheet metal forming process, but they have also had a positive impact on sustainability. By optimizing the process and reducing waste, the company has been able to minimize its environmental footprint.In addition to technological advancements, {} has also focused on the training and development of its workforce. The company has a team of highly skilled engineers and technicians who are constantly pushing the boundaries of what is possible in sheet metal forming.Through their dedication to innovation and excellence, {} has solidified its position as a global leader in the sheet metal forming industry. The company's commitment to pushing the boundaries of what is possible has led to advancements that have transformed the industry and set new standards for quality and efficiency.Looking ahead, {} continues to invest in research and development to further advance sheet metal forming technology. With a focus on sustainability, efficiency, and precision, the company is poised to continue leading the way in the sheet metal forming industry.In conclusion, the advancements made by {} in sheet metal forming technology have had a profound impact on the industry. Through a combination of advanced software, temperature and pressure control techniques, automation, and a focus on sustainability, the company has raised the bar for efficiency, precision, and product quality in sheet metal forming. As {} continues to push the boundaries of what is possible, the future of sheet metal forming looks promising, with even more advancements on the horizon.

Unlocking the Potential of Precision CNC Turning Services for Optimal Results

Precision CNC turning is a highly advanced manufacturing process used to create complex and intricate parts for various industries such as automotive, aerospace, and medical. It is a crucial component of the manufacturing sector, and its demand is only increasing. {Company Name}, a leading provider of precision CNC turning services, has been at the forefront of this technology, providing high-quality solutions to meet the diverse needs of its clients.With state-of-the-art facilities and a team of experienced professionals, {Company Name} has been delivering exceptional results in the precision CNC turning industry. Their commitment to quality and innovation has allowed them to develop cutting-edge solutions that have set new industry standards.Precision CNC turning involves the use of computer-controlled machines to manufacture parts with a high level of accuracy and precision. These machines can perform a wide range of complex machining operations, including turning, boring, facing, threading, and grooving. The process involves the removal of material from a workpiece to create the desired shape and finish.One of the key advantages of using precision CNC turning is the ability to produce parts with consistent quality and dimensional accuracy. The computer-controlled machines ensure that each part is manufactured to the exact specifications, resulting in enhanced efficiency and reduced waste. This level of precision is critical in industries where even small deviations can have a significant impact on performance and safety.{Company Name} has established itself as a trusted partner in the precision CNC turning industry by leveraging its expertise and capabilities. They employ a comprehensive approach that ensures every project is handled with utmost care, from initial design and prototyping to final production. Their team of engineers works closely with clients to understand their specific requirements and develop customized solutions tailored to their needs.In addition to their advanced machining capabilities, {Company Name} also offers a wide range of materials to choose from, including aluminum, stainless steel, titanium, and various alloys. This diversity allows them to cater to a wide range of industries and applications, providing clients with the flexibility to select the most suitable material for their project.Furthermore, {Company Name}'s commitment to continuous improvement and investment in cutting-edge technologies has allowed them to stay ahead of the competition. They regularly upgrade their machinery and software systems, ensuring that they are always equipped with the latest tools and techniques. This dedication to staying at the forefront of technological advancements enables {Company Name} to deliver superior results consistently.In the fast-paced and evolving world of precision manufacturing, {Company Name}'s ability to adapt and innovate has been instrumental in their success. Their commitment to ongoing research and development has enabled them to explore new materials, techniques, and processes, resulting in greater efficiency and cost-effectiveness for their clients.Furthermore, {Company Name} places a strong emphasis on quality control, adhering to rigorous inspection procedures throughout each stage of the manufacturing process. This dedication to quality assurance has earned them various certifications and accreditations, further solidifying their position as a reliable and trusted CNC turning provider.As industries become increasingly reliant on precision engineering, the demand for high-quality CNC turning services continues to grow. {Company Name} continues to spearhead the industry by delivering exceptional results that meet and exceed customer expectations. With their state-of-the-art facilities, highly skilled workforce, and unwavering commitment to excellence, they are well-positioned to remain a leader in the precision CNC turning sector for years to come.In conclusion, precision CNC turning is a critical component of modern manufacturing, and {Company Name} has proven itself to be a leading provider in this field. Their commitment to quality, innovation, and customer satisfaction sets them apart from their competitors. With their advanced capabilities, comprehensive solutions, and dedication to continuous improvement, {Company Name} continues to be the go-to choice for precision CNC turning services.

Precision Sheet Metal Brackets Made with Advanced Manufacturing Techniques

: A Comprehensive Guide for Your Manufacturing NeedsSheet metal brackets are an integral part of any manufacturing process that requires the use of metal sheets. In industries that require immense precision and accuracy, the bracket systems ensure that the metal’s shape and structure are maintained throughout the process. With the advancements in modern CNC manufacturing processes, the quality of these bracket systems has improved significantly. The use of advanced automation tools has led to more efficient and precise manufacturing methods.Sheet metal brackets are widely used in various industries such as Aerospace, Medical, Automotive, Construction, and Electronics. In construction, sheet metal brackets are used to provide support to the structural systems, and in electronics, they secure electronic components in place. With their versatility, sheet metal brackets are an essential component in several processes and products.Here is a comprehensive guide to sheet metal brackets for all your manufacturing needs:Types of Sheet Metal Brackets1. Angle Brackets: These are brackets that are bent to 90-degree angles to create perpendicular structural joints. They are commonly used in construction to ensure that the structures maintain their shape and stability.2. U Brackets: These brackets have a U-shaped cross-section that is used to create a mounting point for objects. They are commonly used to mount objects onto walls and other surfaces.3. L Brackets: These are brackets that are bent to form an L-shape. They are used in most applications requiring reinforcement to prevent structural deformation.4. Z Brackets: These are brackets that are bent to form a ‘Z’ shape. They are used in construction to provide additional support to the structural systems.5. T Brackets: These are brackets that are bent to form a T-shape. They are commonly used to attach objects onto walls or other surfaces.Applications of Sheet Metal BracketsSheet metal brackets are used in various applications, including:AerospaceIn the aerospace industry, brackets are used to mount different types of equipment and systems such as electronics, fuel systems, engines, and landing gear. The brackets are usually made from lightweight materials like aluminum to minimize weight.AutomotiveIn the automotive industry, brackets are essential in holding the structural components of the car together. They are also used in securing electrical components in place.ConstructionSheet metal brackets are used extensively in the construction industry for many different applications, such as securing wall studs and reinforcing roof structures.ElectronicsIn the electronics industry, sheet metal brackets are used to secure electronic components in place. They are also used in creating housing systems for electrical components.MedicalSheet metal brackets are used in medical equipment and devices to support and hold various pieces of equipment such as monitors, IV poles, and other medical components in place.Manufacturing ProcessWith advancements in modern CNC manufacturing processes, sheet metal brackets can be precisely and efficiently manufactured. The manufacturing process for sheet metal brackets includes the following stages:1. Material Selection: The sheets of metal used in creating the brackets are usually made from various metals such as Stainless Steel, Carbon Steel, and Aluminum, and copper.2. Laser Cutting: The sheets of metal are cut using laser cutting machines to create the individual brackets' required shapes and sizes.3. Bending: The cut sheet metal is then bent using precision bending machines to create the desired shape of the bracket.4. Welding or Fixing: After bending the metal, the bracket components are welded or fixed together to create a final product.5. Finishing: The finished brackets are sandblasted or painted to give it a final finish.ConclusionSheet metal brackets are a vital part of many manufacturing processes. They provide structural support, aid in mounting equipment and components, and ensure precise manufacturing processes. The modern CNC manufacturing processes have significantly improved the manufacturing process of sheet metal brackets, leading to more efficient, accurate, and high-quality products. If you need sheet metal brackets for your manufacturing processes, ensure that you engage a reputable and experienced manufacturer who can deliver the desired results.

How to Create Tubes with Precise Forming Techniques for Industrial Applications

Innovation in Tube Forming ProcessTube forming is a well-known process in the manufacturing industry, serving as a cost-effective and efficient method of producing seamless tubes used in a variety of applications. However, in recent years, a new technological development has emerged - tube forming that promises to revolutionize the manufacturing industry. This innovative process uses advanced technology to deliver speed, accuracy and reliability in a way that older tube forming technologies simply cannot match. One such company leading the way in this area is {}.Founded in 2001 and headquartered in Germany, {} is a global leader in innovative tube processing solutions. The company has a range of unique and patented technologies and is continually investing in research and development to improve production efficiency. {} has a presence in over 50 countries, with clients in various industries such as automotive, aviation, energy and construction.One of the most significant achievements of {} is their innovative tube forming process that allows for simultaneous tube expansion and reduction in diameter. This process means that the tube's wall thickness can remain uniform throughout the tube's length, which is something that older traditional tube forming techniques could not achieve. Indeed, the older tube forming technology often resulted in decreased quality, imperfections that required additional shaping steps, and reduced production efficiency.However, {} has significantly changed this landscape. Their tube forming solution attains higher precision, and consistency in tube size with much less wastage of material. This cutting-edge technology generates seamless tubes that are produced in a single process, which is faster, less labor-intensive, and more cost-effective than traditional tube forming methods. The process also allows for a wide range of materials, including stainless steel, aluminum, copper, and nickel alloys, which further increases its application in various industries.Furthermore, the company has the expertise to design custom-made tube forming solutions. {} provides individualized solutions for their clients' specific production requirements. This service is only possible because of the digitization capabilities of their tube forming technology. The digitization of the tube forming process enhances accuracy and precision, leading to an exact match of the client's desired tube specifications. They also use advanced simulation software during the design process to identify potential issues before production, improving efficiency and cost-effectiveness.With {}'s innovative technology, cost-effectiveness is a significant advantage. The use of automated systems allows for minimal human intervention and increases production efficiency. The technology can operate at high speeds and produce a large volume of tubes within a short span of time, meaning that clients can enjoy reduced production costs and ultimately save on the bottom line.In conclusion, the innovative tube forming process presented by {} is proving to be a game-changer in the manufacturing industry. It offers speed, efficiency, cost-effectiveness, while simultaneously increasing accuracy and reducing waste. With the implementation of digitization, custo made solutions, and the use of advanced simulation software, {} is ultimately taking the production to the next level. The company is aptly positioned to lead the transformation of the tube forming industry, and it is exciting to see what is yet to come as they continue to innovate.

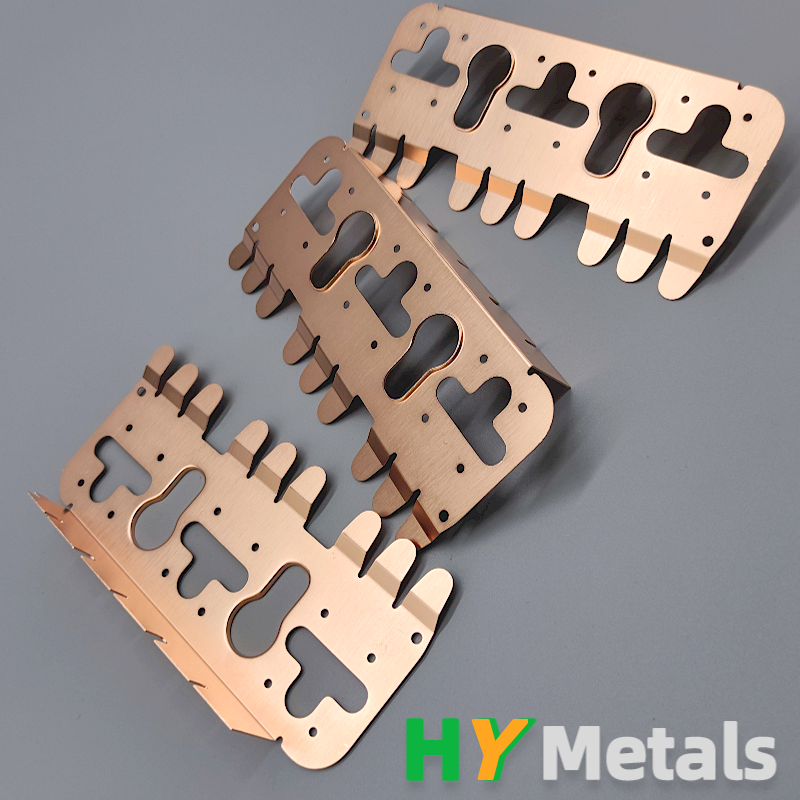

High-Quality Sheet Metal Copper Contacts: Your Ultimate Guide

Metal copper contact is an important component in the manufacturing industry, used in a wide range of applications such as electrical equipment, machinery, and automotive parts. Known for its excellent electrical and thermal conductivity, as well as its ability to resist corrosion, copper has long been a popular material for making electrical contacts. With the growing demand for high-quality metal copper contacts, companies like {} have been at the forefront of producing top-notch products to meet the needs of various industries.{} is a leading manufacturer of metal copper contacts, specializing in the production of precision components for a wide range of applications. With a strong focus on quality, innovation, and customer satisfaction, {} has built a reputation for delivering superior products that meet the highest industry standards.The company's state-of-the-art manufacturing facilities are equipped with advanced machinery and technology, allowing them to produce metal copper contacts with exceptional precision and consistency. Their team of skilled engineers and technicians are dedicated to ensuring that each product meets the exact specifications and requirements of their clients. With a commitment to continuous improvement and investment in research and development, {} remains at the forefront of technological advancements in the industry.One of the key factors that sets {} apart from its competitors is its dedication to sustainability and environmental responsibility. The company places a high priority on minimizing its carbon footprint and reducing waste in its manufacturing processes. By utilizing efficient production methods and implementing eco-friendly initiatives, {} is able to produce high-quality metal copper contacts while minimizing its impact on the environment.In addition to its commitment to quality and sustainability, {} places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific needs and requirements, offering custom solutions and personalized service to ensure that every customer receives the right product for their application. With a focus on building long-term partnerships, {} strives to exceed customer expectations and provide ongoing support and technical expertise.The demand for metal copper contacts is expected to continue growing in the coming years, driven by advancements in technology and the increasing need for reliable electrical components. As a leader in the industry, {} is well-positioned to meet this demand and continue providing high-quality products to its clients. With a strong commitment to excellence, innovation, and customer satisfaction, {} is poised to remain a trusted partner for companies seeking top-notch metal copper contacts.In conclusion, metal copper contacts play a crucial role in various industries, and companies like {} are instrumental in meeting the growing demand for these essential components. With a focus on quality, sustainability, and customer satisfaction, {} continues to lead the way in producing high-quality metal copper contacts for a wide range of applications. As the industry evolves, {} remains dedicated to staying at the forefront of technological advancements and providing innovative solutions to meet the needs of its clients.