Durable Metal Welding Parts for Industrial Applications

By:Admin

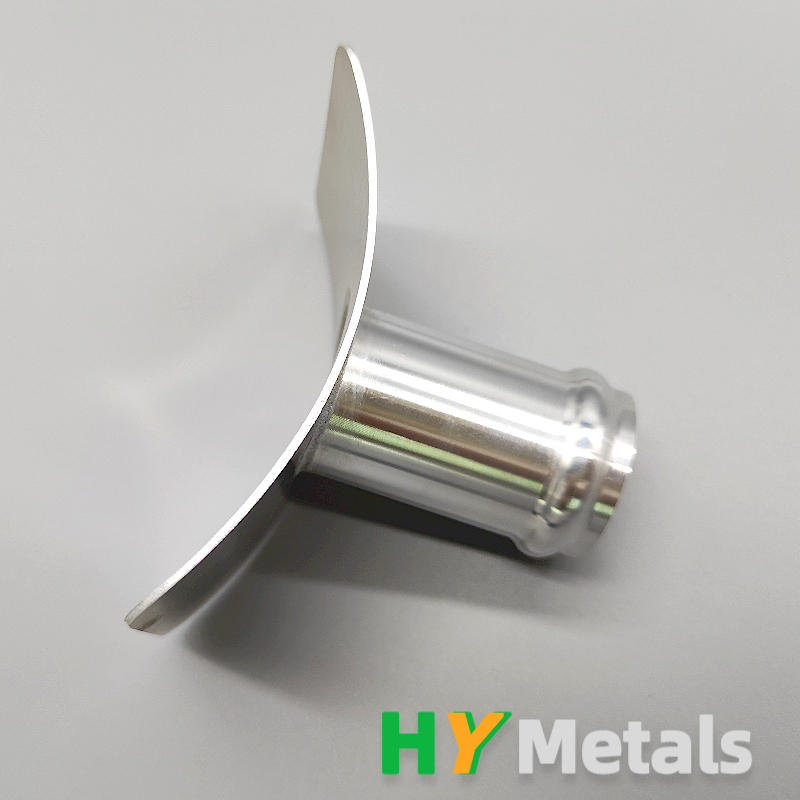

The new product line includes a wide range of welding parts designed to cater to the diverse needs of various industries, such as automotive, aerospace, construction, and manufacturing. The company's state-of-the-art manufacturing facilities and advanced technology ensure that the welding parts meet the highest industry standards and specifications.

One of the key highlights of the new product line is the company's expertise in producing custom welding parts to meet the specific requirements of their clients. With a team of highly skilled engineers and technicians, Metal Welding Parts has the capability to design and manufacture custom welding parts with precision and efficiency. This personalized approach sets the company apart from its competitors and reflects its commitment to providing tailored solutions to its clients.

Metal Welding Parts takes pride in its strict quality control measures throughout the manufacturing process. The company's quality assurance team conducts rigorous inspections and testing to ensure that every welding part meets the highest quality standards before it is delivered to the customer. This emphasis on quality control reflects the company's dedication to delivering reliable and durable welding parts to its clients.

In addition to its focus on product quality, Metal Welding Parts also places a strong emphasis on customer service. The company's team of dedicated professionals is committed to providing exceptional service to its clients, from the initial inquiry stage to the final delivery of the products. Metal Welding Parts strives to build long-term relationships with its clients by understanding their unique needs and delivering solutions that exceed their expectations.

"We are excited to introduce our latest line of welding parts, which showcase our commitment to excellence in metal fabrication," said a spokesperson for Metal Welding Parts. "We take pride in our ability to deliver high-quality, custom welding parts that meet the specific requirements of our clients. Our team's expertise and dedication to customer service sets us apart and positions us as a trusted partner for all metal fabrication needs."

Metal Welding Parts' dedication to innovation and excellence has earned the company a reputation as a leader in the metal fabrication industry. The company's extensive knowledge and experience in metal welding and fabrication enable it to provide cutting-edge solutions to its clients, making it a preferred choice for businesses across various industries.

With the launch of its latest product line, Metal Welding Parts aims to further solidify its position as a trusted provider of high-quality welding parts. The company's commitment to quality, precision, and customer satisfaction makes it a reliable partner for businesses seeking reliable and durable welding parts for their operations. As Metal Welding Parts continues to innovate and expand its product offerings, it is well-positioned to meet the evolving needs of the metal fabrication industry and remain at the forefront of the market.

Company News & Blog

Precision Turned Parts: A Guide to Small Turned Components

Small Turned Parts Company: Leading the Industry in Precision ManufacturingSmall Turned Parts Company is a leading manufacturer of high-quality precision turned parts. With a focus on precision engineering, cutting-edge technology, and unmatched expertise, Small Turned Parts Company has earned a reputation for excellence in the industry. The company's commitment to producing top-notch turned parts has made them a trusted partner for a wide range of industries, including aerospace, automotive, medical, and more.Small Turned Parts Company's dedication to quality is evident in every aspect of their operations. From the initial design phase to the final product, the company's team of skilled engineers and technicians ensures that each part meets the highest standards of precision and accuracy. By staying at the forefront of technological advancements, Small Turned Parts Company is able to consistently deliver products that exceed customer expectations.One of the key factors that sets Small Turned Parts Company apart from its competitors is its investment in state-of-the-art manufacturing equipment. The company's modern facilities are equipped with the latest CNC machines, turning centers, and inspection equipment, allowing them to produce turned parts with unrivaled precision and efficiency. This commitment to technological advancement has enabled Small Turned Parts Company to stay ahead of the curve in an ever-evolving industry.In addition to their cutting-edge equipment, Small Turned Parts Company also places a strong emphasis on continuous improvement. The company regularly invests in research and development to explore new techniques and materials, enabling them to offer innovative solutions that meet the changing needs of their customers. By staying proactive and adaptable, Small Turned Parts Company remains a frontrunner in the field of precision manufacturing.Small Turned Parts Company's dedication to quality and innovation has earned them a trusted reputation among their clients. The company has built strong, long-lasting relationships with customers who rely on them for precision turned parts that are crucial to the success of their own businesses. Whether it's a complex aerospace component or a critical medical device, Small Turned Parts Company has proven time and again that they have the expertise and resources to deliver top-quality parts on time, every time.Furthermore, Small Turned Parts Company's commitment to exceptional customer service sets them apart from their competitors. The company's team of knowledgeable professionals is dedicated to providing personalized support and guidance throughout every step of the manufacturing process. By prioritizing open communication and a customer-centric approach, Small Turned Parts Company ensures that each client receives the individual attention they deserve.Small Turned Parts Company's dedication to quality, innovation, and customer satisfaction has positioned them as a leader in the field of precision manufacturing. With a proven track record of delivering top-notch turned parts to diverse industries, the company continues to set the standard for excellence in the industry. As they look to the future, Small Turned Parts Company remains committed to staying at the forefront of technological advancements and meeting the evolving needs of their customers.

High-Quality Machined Parts for Various Industries - Everything You Need to Know

Machined parts are an essential component in various industries, ranging from automotive to aerospace. These precision components are crucial for the efficient operation of complex machinery and equipment. One company that has been at the forefront of producing high-quality machined parts is (company name).Founded in (year), (company name) has established itself as a leading manufacturer of machined parts. The company's state-of-the-art facility is equipped with the latest technology and machinery to produce precision components to exact specifications. (Company name) prides itself on its commitment to quality and customer satisfaction, and it has earned a stellar reputation in the industry for its reliable products and exceptional service.The machined parts produced by (company name) are used in a wide range of applications, including engine components, hydraulic systems, and structural elements. These parts are crafted with precision and attention to detail, ensuring that they meet the rigorous standards of the industry. (Company name) is known for its ability to work with various materials, including steel, aluminum, and titanium, and its team of highly skilled engineers and technicians is capable of handling complex projects with ease.Recently, (company name) has made significant advancements in its machining capabilities, enabling it to produce even more intricate and high-performing parts. The company has invested in cutting-edge CNC machinery and software, allowing for greater precision and efficiency in the manufacturing process. These advancements have positioned (company name) as a top choice for companies seeking reliable and top-quality machined parts.In addition to its commitment to quality and innovation, (company name) takes great pride in its dedication to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its manufacturing processes, ensuring minimal waste and energy usage. (Company name) is also committed to ethical sourcing and sustainable production methods, further solidifying its reputation as a responsible and conscientious manufacturer.One of the key factors that set (company name) apart from its competitors is its focus on customer collaboration and custom solutions. The company works closely with its clients to understand their unique needs and requirements, and its team of experts is capable of providing tailored solutions to meet specific challenges. Whether it's a one-off prototype or a large-scale production run, (company name) has the expertise and capability to deliver the highest quality machined parts.In a recent interview, the CEO of (company name), (CEO name), expressed the company's dedication to continuous improvement and growth. "We are always looking for ways to enhance our capabilities and expand our offerings," said (CEO name). "Our goal is to be at the forefront of innovation in the industry and to provide our customers with the best possible solutions for their machining needs."Looking ahead, (company name) is poised to continue its upward trajectory in the industry. With its unwavering commitment to quality, innovation, and customer satisfaction, the company is well-positioned to meet the evolving demands of the market and to solidify its reputation as a top-tier manufacturer of machined parts.In conclusion, (company name) is a leading manufacturer of high-quality machined parts, known for its commitment to quality, innovation, and customer satisfaction. With its state-of-the-art facility, cutting-edge technology, and dedicated team, the company is well-equipped to meet the diverse needs of its clients and to maintain its position as a trusted partner in the industry.

Discover the Artistry of Custom Metal Work for Exquisite Designs

Custom Metal Work Expands Portfolio With Innovative SolutionsCustom Metal Work, a leading provider of metal fabrication solutions, is excited to announce the addition of several new products and services to their extensive portfolio. With over two decades of experience, the company has built a reputation for delivering high-quality, customized metalwork to a wide range of industries.As a trusted name in the metal fabrication industry, Custom Metal Work takes pride in their ability to cater to the unique needs of each client. By combining state-of-the-art technology with a team of skilled craftsmen, the company consistently delivers innovative solutions that meet the highest standards of quality and precision.One of the latest additions to Custom Metal Work’s portfolio is their line of cutting-edge laser cutting services. Using cutting-edge machinery, the company can now provide precise and intricate metal cutting, ensuring a superior finish with minimal material waste. This new capability allows them to serve industries such as automotive, aerospace, and construction more efficiently and effectively.In addition to their laser cutting services, Custom Metal Work also offers a diverse range of metal fabrication solutions. From custom sheet metal forming to precision welding, the company can fulfill even the most complex design requirements. Their team of experts work closely with clients to understand their unique needs, providing tailored solutions that exceed expectations.One of the key features that sets Custom Metal Work apart is their commitment to sustainability. The company utilizes advanced recycling techniques and environmentally friendly materials to minimize their impact on the environment. By adopting a greener approach, they not only contribute to a healthier planet but also help clients achieve their sustainability goals.Custom Metal Work’s dedication to innovation and continuous improvement has earned them numerous accolades within the industry. The company’s relentless pursuit of excellence has resulted in long-standing partnerships with leading companies across various sectors, bolstering its reputation as a reliable, customer-centric metal fabrication specialist.“We are thrilled to expand our portfolio with these exciting new products and services,” stated [company spokesperson]. “Our team has worked tirelessly to equip ourselves with the latest technology and expertise to meet the evolving demands of our clients. With these additions, we are confident that we can continue to deliver top-notch metal fabrication solutions that drive success for our clients.”Clients who have worked with Custom Metal Work express their satisfaction with the company’s ability to deliver quality products within budget and on time. Their attention to detail and commitment to customer service sets them apart from competitors in the industry. From large-scale industrial projects to small-scale custom designs, Custom Metal Work has consistently proven their ability to handle projects of any size and complexity.Moving forward, Custom Metal Work aims to remain at the forefront of the metal fabrication industry by continuously exploring new technologies and refining their processes. With their expanded portfolio of services and unwavering dedication to customer satisfaction, the company is poised to bring even greater value to clients across the globe.About Custom Metal Work:Custom Metal Work is a leading provider of innovative metal fabrication solutions. With over twenty years of experience, the company specializes in custom sheet metal forming, precision welding, and laser cutting services. Combining cutting-edge technology with skilled craftsmanship, Custom Metal Work delivers customized metalwork that meets the highest standards of quality and precision. Their commitment to sustainability and attention to detail set them apart from competitors in the industry.

Ultimate Guide to 5-Axis Technology: Everything You Need to Know

5-Axis, a cutting-edge technology that revolutionizes manufacturing processes, has been making waves in the industry with its innovative capabilities. This technology, which allows for the simultaneous movement of a workpiece along five different axes, provides a level of precision and flexibility that was previously unattainable. With its ability to produce complex and intricate parts with incredible speed and accuracy, 5-Axis has become an essential tool for companies looking to stay ahead of the competition.One company that has fully embraced the power of 5-Axis technology is []. Founded in [], the company has always been at the forefront of innovation and has continuously invested in the latest manufacturing technologies to ensure the highest quality products for its customers. With the integration of 5-Axis technology into its production processes, [] has been able to greatly enhance its capabilities and efficiency, leading to a significant improvement in its overall productivity.The versatility of 5-Axis technology allows for the machining of intricate geometries and tight tolerances with ease, resulting in parts that are not only of superior quality but also produced in a fraction of the time compared to traditional methods. This has allowed [] to take on a wider range of projects, from simple parts to complex components, all with the same level of precision and consistency. Furthermore, the ability to position the workpiece at virtually any angle without the need for repositioning or reclamping has greatly reduced setup times and increased overall throughput.In addition to its production advantages, the integration of 5-Axis technology has also enabled [] to explore new design possibilities and push the boundaries of what is achievable. The flexibility of the system has allowed the company to manufacture parts with intricate features and intricate contours that were previously impossible to produce, opening up new opportunities in industries such as aerospace, automotive, and medical devices.Despite the initial investment required to adopt 5-Axis technology, the benefits that [] has experienced have far outweighed the costs. The increased efficiency and precision have led to significant cost savings, while the expanded capabilities have allowed the company to take on more lucrative projects, ultimately resulting in a positive impact on its bottom line. In addition, the improved quality of the parts produced has elevated the company's reputation in the industry, leading to new business opportunities and partnerships.Looking ahead, [] is committed to further leveraging the power of 5-Axis technology to drive continuous improvement and innovation in its manufacturing processes. By staying at the forefront of technological advancements, the company aims to solidify its position as a leader in the industry and continue to provide its customers with the highest quality products and services.As 5-Axis technology continues to evolve and advance, more companies are expected to recognize its potential and embrace it as a critical component of their manufacturing operations. With its ability to significantly improve productivity, efficiency, and quality, 5-Axis technology is poised to revolutionize the way parts and components are produced across a wide range of industries. With [] leading the way, it is clear that the future of manufacturing is firmly rooted in the power of 5-Axis technology.

Innovative Riveting Nut Technology: A Game-Changer in Fastening Solutions

Riveting Nut – Your Go-To Solution for Secure and Efficient FasteningIn today's fast-paced manufacturing and construction industry, efficiency and security in fastening solutions are of utmost importance. This is where the riveting nut comes into play, offering a reliable and effective method for fastening in a wide range of applications. With its innovative design and advanced technology, the riveting nut has become a go-to solution for many industries around the world.The riveting nut, also known as a blind rivet nut, is a specialized fastener that is designed to create a strong and secure connection in materials where it may not be possible to use traditional nuts and bolts. It is particularly useful in applications where access to the back of the material is limited or where a one-sided fastening solution is required. This makes it a versatile and practical choice for a variety of industries, including automotive, aerospace, electronics, and construction.One of the key features of the riveting nut is its ability to be installed from one side of the material, making it ideal for applications where access is limited. This saves both time and labor, making it a cost-effective solution for many projects. Additionally, the riveting nut creates a secure and vibration-resistant connection, ensuring that the fastened elements remain in place even under harsh conditions.Furthermore, the riveting nut is available in a variety of materials, including steel, aluminum, and stainless steel, offering the flexibility to choose the right option for specific application requirements. This versatility makes it suitable for use in a wide range of environments, from indoor to outdoor applications.Manufacturers around the world have recognized the benefits of the riveting nut and have integrated it into their production processes to improve efficiency and reliability. One such company leading the way in riveting nut technology is {}. With a strong focus on innovation and product development, {} has become a trusted name in the fastening solutions industry.The riveting nuts offered by {} are designed and manufactured to the highest standards, ensuring quality and performance in every application. The company's commitment to research and development has led to the creation of advanced riveting nut designs that are tailored to meet the specific needs of its customers. With a strong emphasis on customer satisfaction and product excellence, {} has established itself as a leader in the fastening solutions market.In addition to its high-quality products, {} also provides comprehensive support and technical expertise to help customers integrate riveting nuts into their projects seamlessly. This includes assistance with product selection, installation guidance, and ongoing maintenance support, ensuring that customers can rely on {} as a trusted partner for all their fastening needs.Furthermore, {} is dedicated to environmentally-friendly manufacturing practices, ensuring that its products are produced in a sustainable and responsible manner. This commitment to sustainability extends to the entire product lifecycle, from design and production to end-of-life disposal, making {} a preferred choice for environmentally-conscious customers.Overall, the riveting nut has revolutionized the fastening solutions industry, offering a secure, efficient, and versatile option for a wide range of applications. With its advanced technology and practical design, the riveting nut has become an indispensable component in many industries, providing a reliable and cost-effective solution for fastening challenges.As the demand for efficient fastening solutions continues to grow, companies like {} are poised to lead the way with their innovative riveting nut technology, ensuring that customers have access to the best products and support for their projects. Whether it's automotive assembly, structural construction, or electronics manufacturing, the riveting nut is sure to play a crucial role in the advancement of various industries for years to come.With their dedication to excellence and customer satisfaction, companies like {} are driving the continued success and evolution of the riveting nut, making it a fundamental component in the modern era of manufacturing and construction.

High-Quality Vaccum Casting Services for Precision Prototyping and Manufacturing

Vaccum Casting Technology Revolutionizing the Manufacturing IndustryIn recent years, the manufacturing industry has witnessed significant advancements in technology, particularly in the field of rapid prototyping and small-scale production. Among these advancements, Vaccum Casting has emerged as a game-changing technology that is revolutionizing the way products are developed and manufactured.Vaccum Casting is a versatile and cost-effective manufacturing process that allows for the production of high-quality, complex parts with fine details and precise dimensions. This process involves creating a silicone mold from a master pattern and then injecting a low-viscosity resin into the mold under vacuum pressure. The result is a replica of the original part that is highly accurate and has excellent surface finish.One of the leading providers of Vaccum Casting technology is {}. They have been at the forefront of this technology, offering innovative solutions to the manufacturing industry. With a state-of-the-art facility and a team of skilled engineers and technicians, they have been able to deliver superior Vaccum Casting services to a wide range of industries, including automotive, aerospace, consumer goods, and medical devices.The company's Vaccum Casting process begins with the creation of a master pattern, typically produced using 3D printing or CNC machining. Once the master pattern is ready, a silicone mold is made around it, and then the mold is placed in a Vaccum Casting machine. The low-viscosity resin is then injected into the mold under vacuum pressure, ensuring that the resin fills every detail of the mold and creating a precise and high-quality replica of the original part.What sets {} apart from other Vaccum Casting service providers is their commitment to delivering not only exceptional quality but also a quick turnaround time. Their advanced Vaccum Casting technology allows for rapid prototyping and small-batch production, enabling their clients to accelerate their product development and get their products to market faster.Furthermore, the company's team of experts works closely with their clients throughout the entire Vaccum Casting process, from design and engineering to prototyping and production. This collaborative approach ensures that the final product meets the client's specifications and requirements, while also providing valuable insights and recommendations to optimize the design for manufacturability.With the growing demand for rapid prototyping and small-batch production, Vaccum Casting has become an indispensable manufacturing technology for companies looking to bring new products to market quickly and efficiently. The ability to produce high-quality, custom parts at a relatively low cost and with short lead times makes Vaccum Casting an attractive option for a wide range of industries.As the manufacturing industry continues to evolve, the demand for innovative and agile manufacturing solutions will only increase. Companies like {} are at the forefront of this evolution, offering cutting-edge Vaccum Casting services that are helping to drive the industry forward.In conclusion, Vaccum Casting technology has become a game-changer in the manufacturing industry, offering a cost-effective and efficient solution for rapid prototyping and small-batch production. With its precision, versatility, and quick turnaround time, Vaccum Casting is reshaping the way products are developed and manufactured. And companies like {} are leading the way with their advanced Vaccum Casting services, providing their clients with the tools and expertise they need to stay ahead in today's fast-paced and competitive market.

Durable and Versatile Sheet Metal Flat for Various Applications

Sheet Metal Flat is a leading provider of high-quality sheet metal products to a wide range of industries. With a strong focus on customer satisfaction and cutting-edge technology, the company has established itself as a trusted partner for businesses looking for precision-engineered metal components.The company offers a wide range of sheet metal products, including flat sheets, coils, and custom-cut pieces. With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, Sheet Metal Flat is able to meet the diverse needs of its customers, delivering products that meet the highest standards of quality and precision.One of the key strengths of Sheet Metal Flat is its ability to work with a variety of materials, including stainless steel, aluminum, and carbon steel. This versatility allows the company to cater to the unique requirements of different industries, from automotive and aerospace to construction and electronics.In addition to its manufacturing capabilities, Sheet Metal Flat also offers a range of value-added services, such as metal finishing, coating, and assembly. This comprehensive approach allows the company to offer a one-stop solution for its customers, streamlining the production process and ensuring a seamless experience from start to finish.Furthermore, the company prides itself on its commitment to sustainability and environmentally friendly practices. Sheet Metal Flat has invested in advanced technologies and processes to minimize waste and reduce its carbon footprint, ensuring that its operations are as eco-friendly as possible.In recent news, Sheet Metal Flat has announced the launch of a new line of flat sheets that are designed to meet the growing demand for lightweight yet durable materials in the automotive industry. These sheets are made from high-strength aluminum alloys, offering a combination of excellent formability and corrosion resistance, making them ideal for use in body panels, chassis components, and structural parts."We are excited to introduce our new line of flat sheets that are specifically engineered to meet the stringent requirements of the automotive industry," said [company spokesperson]. "With the increasing focus on fuel efficiency and lightweighting in the automotive sector, our products are well-positioned to address the evolving needs of our customers."The company's investment in research and development has enabled it to stay ahead of industry trends and develop innovative solutions that meet the changing needs of its customers. Sheet Metal Flat continuously collaborates with its clients to identify new opportunities and develop tailored products that address specific challenges in their respective industries.In addition to its focus on product innovation, Sheet Metal Flat also places a strong emphasis on customer service and satisfaction. The company's team of dedicated professionals works closely with clients to understand their requirements and provide personalized solutions that meet their exact specifications.As Sheet Metal Flat continues to grow and expand its capabilities, the company remains committed to upholding its core values of quality, integrity, and innovation. With a track record of excellence and a customer-centric approach, Sheet Metal Flat is well-positioned to be a leading provider of sheet metal products for years to come.

MTConnect-Ready 3D Printer for Aerospace and Production Applications

, MTConnect, FDM, aerospace, production, 3D printing.Additive Manufacturing Magazine recently reported that the Stratasys Fortus 900 3D printer now features an MTConnect-ready interface. This is great news for those working in aerospace and other industries that require high-quality, production-grade 3D printing.The Stratasys Fortus 900 is a Fused Deposition Modeling (FDM) 3D printer designed for large, complex parts. With a build volume of 36 x 24 x 36 inches, it has the capability to produce parts that are larger than those typically produced with plastic extrusion machines. This makes it an ideal choice for aerospace applications, as well as for producing jigs, fixtures, and tooling.Incorporating the MTConnect protocol into the Stratasys Fortus 900 means that users can now monitor and control their 3D printing operations in real time. MTConnect is an open, royalty-free standard for machine tool communication that has become increasingly popular in the manufacturing industry. With MTConnect, users can easily connect machines and devices to a network, allowing them to monitor data and make informed decisions about their operations.For aerospace manufacturers, the Stratasys Fortus 900 with MTConnect-ready interface is ideal, as it provides the capability to produce production-grade parts with repeatable accuracy. Additionally, 3D printing allows for the production of complex geometries that cannot be produced with traditional manufacturing methods.Overall, the integration of MTConnect into the Stratasys Fortus 900 3D printer is a positive development for the additive manufacturing industry. By providing real-time monitoring and control, it enables users to optimize their operations, increase efficiency, and improve the quality of their products. This is especially important in industries such as aerospace, where high-quality, production-grade parts are essential.As the use of 3D printing continues to grow, we can expect to see further developments in this area, and the integration of other technologies into 3D printers. In the meantime, the Stratasys Fortus 900 with MTConnect-ready interface is a great option for those looking to produce high-quality, production-grade parts with 3D printing technology.

CNC Turning Services for High-Quality Lathe Turned Parts

Service, Lathe Turned Production Parts, Prototyping, CNC Machined Parts, Manufacturing Partners, Instant CNC Turning Quote.CNC Turning Service: Your One-Stop Solution for All Your Lathe NeedsIn today's fast-paced manufacturing industry, the demand for precision and accuracy in parts production is more important than ever. Thanks to advances in technology, the CNC turning service has emerged as the go-to solution for manufacturing high-quality lathe-turned production parts. CNC Turning, with its precision, speed, and flexibility, has revolutionized the world of manufacturing and has become an essential part of modern-day production processes.At CNC Turning Service, we understand the importance of getting it right the first time, which is why we offer an exceptional range of services dedicated to providing our clients with the best possible results. Our services provide complete end-to-end solutions, from prototyping to CNC machined parts, and we deliver them with unbeatable speed, quality, and price.Our Global Network of Certified Manufacturing PartnersCNC Turning Service is proud to have a global network of 25 certified manufacturing partners, enabling us to offer our clients the best CNC turning services available. These partners have over 100 CNC turning machines, allowing us to produce everything from simple to complex parts. Our partners undergo a rigorous selection process to ensure they meet our exacting standards of quality, consistency, and efficiency. As a result, our clients benefit significantly from increased savings, faster lead times, and access to a wider range of capabilities.The Most Cost-Effective Solution for PrototypingAt CNC Turning Service, we understand that prototyping is an essential part of the production process. As such, we offer our clients the most cost-effective solution for creating high-quality prototypes. Our CNC turning service gives our clients the ability to produce prototypes that are identical to the final product in terms of specifications, tolerances, and material, which reduces the risk of design errors and allows for necessary modifications before the final production.CNC Machined Parts With Unbeatable Quality and SpeedCNC Turning Service produces CNC machined parts with unbeatable speed and quality. Our partners' CNC turning machines produce precise and accurate parts with precise tolerances, finishes, and features. Whether you need single parts or thousands, our CNC turning service can provide you with the most efficient and cost-effective production.Instant CNC Turning QuoteCNC Turning Service offers an instant CNC turning quote to our clients. Our online quote system is user-friendly, simple, and straightforward to use. Our clients can upload their designs, specify their requirements, and receive a quote instantly. With our instant quote system, our clients can access real-time pricing information and plan their production processes accordingly.ConclusionAt CNC Turning Service, we provide our clients with a complete end-to-end solution for all their lathe-turned production parts needs. Our global network of certified manufacturing partners, our cost-effective prototyping solutions, and our unbeatable quality and speed in producing CNC machined parts, make us the go-to solution for manufacturing high-quality parts. Contact us today and experience the benefits of our CNC turning services.

Expert Aircraft Sheet Metal Fabrication Services for Precision and Durability

Aircraft Sheet Metal Fabrication is a critical aspect of the aerospace industry, as it involves the manufacturing and assembly of metal components for aircraft structures. These components must be fabricated with precision and accuracy to ensure the safety and performance of the aircraft. One company that specializes in this field is {}, which has been a leading provider of aircraft sheet metal fabrication for over two decades.{} is equipped with state-of-the-art technology and a team of highly skilled engineers and fabricators who are dedicated to delivering top-quality products. The company's commitment to excellence has earned them a reputation as a trusted supplier in the aerospace industry.The process of aircraft sheet metal fabrication involves cutting, bending, and assembling various types of metal, such as aluminum, steel, and titanium. These metal components are used in the construction of aircraft fuselages, wings, and other structural elements. Precision is key in this process, as even the smallest error can have serious consequences for the aircraft's performance and safety.One of the key factors that sets {} apart from other manufacturers is their stringent quality control measures. Every phase of the fabrication process is carefully monitored to ensure that each component meets the highest standards. This dedication to quality has made {} a preferred supplier for many major aerospace companies.In addition to their commitment to quality, {} also strives to be a leader in innovation and efficiency. The company continues to invest in the latest technology and equipment to streamline their manufacturing processes and reduce lead times. This not only benefits their customers by providing quicker turnaround times, but also contributes to the overall advancement of the aerospace industry.Furthermore, {} is dedicated to sustainability and environmental responsibility. They have implemented eco-friendly practices in their manufacturing processes, such as waste reduction and energy-efficient operations. By prioritizing sustainability, {} is not only contributing to a greener planet, but also fulfilling the increasing demand for environmentally conscious manufacturing practices in the aerospace industry.As a testament to their expertise and dedication, {} has been recognized with several industry certifications and awards. These accolades further demonstrate their commitment to excellence and their position as a leader in the field of aircraft sheet metal fabrication.With the aerospace industry constantly evolving and demanding higher standards, {} remains at the forefront of innovation and advancement. The company's ongoing investment in technology, commitment to quality, and dedication to sustainability make them an invaluable partner for aerospace companies around the world.In summary, {} is a leading provider of aircraft sheet metal fabrication, with a reputation for excellence, innovation, and sustainability. With their state-of-the-art facilities and highly skilled team, {} continues to set the standard for quality and reliability in the aerospace industry. Their commitment to excellence and dedication to advancing the field of aircraft sheet metal fabrication make them a trusted partner for aerospace companies seeking top-quality components for their aircraft structures.