Exploring the Benefits of 3D Printing and Prototyping

By:Admin

The field of manufacturing is witnessing a revolutionary transformation with the introduction of cutting-edge 3D printing and prototyping technologies. Leveraging the latest advancements in additive manufacturing, {} is pioneering the way in creating complex, high-precision parts and prototypes with remarkable efficiency and speed.

Founded in {}, {} has rapidly emerged as a frontrunner in the realm of 3D printing and prototyping. The company's dedication to pushing the boundaries of traditional manufacturing processes has resulted in the development of state-of-the-art technologies that are disrupting industries across the board.

{}'s advanced 3D printing and prototyping capabilities have significantly streamlined the product development cycle for numerous businesses, enabling them to bring their concepts to reality in record time. By utilizing a wide range of materials and techniques, {} is able to cater to diverse industry needs, from aerospace and automotive to healthcare and consumer goods.

One of the key aspects that sets {} apart is its proprietary software, which enables highly precise and customizable designs to be translated into physical objects with unparalleled accuracy. This, in combination with their advanced 3D printers, allows {} to produce intricate parts and prototypes that were previously deemed impossible with conventional manufacturing methods.

Moreover, {}'s commitment to sustainability is evident in its utilization of eco-friendly materials and its dedication to reducing material wastage in the manufacturing process. By embracing additive manufacturing, {} is not only contributing to a greener future but also optimizing production costs for its clients.

The impact of {}'s innovative solutions extends far beyond manufacturing, as they have also been at the forefront of enabling rapid prototyping for various industries. By enabling businesses to quickly iterate and test their designs, {} has played a pivotal role in accelerating innovation and time-to-market for countless products.

Furthermore, {}'s dedication to customer satisfaction is reflected in its end-to-end service, which encompasses everything from initial design consultation to the final production of parts. This comprehensive approach has garnered {} a stellar reputation in the industry, with many businesses turning to them as their go-to partner for all their 3D printing and prototyping needs.

Looking ahead, {} is poised to continue leading the charge in revolutionizing manufacturing through its relentless pursuit of innovation and technological advancement. With a steadfast commitment to pushing the boundaries of what is possible, {} is on a mission to empower businesses to realize their visions and bring groundbreaking products to market with unprecedented speed and precision.

As businesses around the world increasingly turn to additive manufacturing for their production and prototyping needs, {} is well-positioned to remain at the vanguard of this transformative shift in the manufacturing landscape. With their unparalleled expertise, state-of-the-art technology, and unwavering dedication to excellence, {} is set to redefine the future of manufacturing as we know it.

Company News & Blog

High-Quality Precision Machining Parts for Sale: Find the Best Deals Now

Precision Machining Parts, a leading provider of high-quality precision machining services, has recently announced its expanded capabilities to meet the growing demand for custom machining parts. With over 20 years of experience in the industry, Precision Machining Parts has established itself as a trusted partner for businesses across various industries, including aerospace, automotive, medical, and defense.The company's state-of-the-art facility is equipped with advanced CNC machining centers and a team of highly skilled machinists and engineers. This enables Precision Machining Parts to offer a wide range of precision machining services, including CNC milling, turning, grinding, EDM (electrical discharge machining), and more. The company's commitment to quality, precision, and on-time delivery has earned it a reputation for excellence in the industry.In response to the increasing demand for custom machining parts, Precision Machining Parts has invested in new equipment and technology to expand its capabilities. This includes the addition of new CNC machines with multi-axis capabilities, as well as advanced metrology equipment for precision inspection and quality control. These investments have allowed the company to take on more complex and challenging projects while maintaining the highest standards of quality and accuracy."We are excited to announce the expansion of our capabilities to better serve our customers' evolving needs," said [Spokesperson Name], [Title] at Precision Machining Parts. "With our new equipment and expanded capabilities, we are well-positioned to provide our customers with even more comprehensive machining solutions. From prototype development to full-scale production runs, we have the expertise and resources to deliver precision parts that meet the most demanding specifications."Precision Machining Parts' dedication to continuous improvement and innovation has enabled the company to stay ahead of the competition and remain at the forefront of the precision machining industry. By staying abreast of the latest advancements in machining technology and processes, the company is able to offer its customers the most cost-effective and efficient solutions for their machining needs.In addition to its expanded capabilities, Precision Machining Parts has also made significant investments in its workforce. The company provides ongoing training and development opportunities for its employees, ensuring that they have the skills and knowledge needed to handle the most advanced machining projects. This commitment to investing in its people has helped Precision Machining Parts maintain a team of highly skilled and experienced professionals who are dedicated to delivering superior quality and service to every customer.As part of its expansion, Precision Machining Parts has also strengthened its commitment to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its operations, including recycling and waste reduction initiatives, to minimize its environmental impact. By prioritizing sustainability, Precision Machining Parts aims to contribute to a cleaner and healthier planet while meeting the needs of its customers and the industry.With its expanded capabilities, commitment to excellence, and focus on sustainability, Precision Machining Parts is well-positioned to continue serving as a premier provider of precision machining services for businesses across various industries. The company's dedication to quality, precision, and customer satisfaction sets it apart as a trusted partner for companies seeking precision parts that meet the highest standards.For more information about Precision Machining Parts and its expanded capabilities, visit [website] or contact [phone number/email].

3-Axis Milling Machine for Versatile Applications in Die and Mold Construction

Milling Precision Parts: Achieving Unparalleled Accuracy and Versatility with Universal Milling MachinesMilling machines are used extensively in a wide range of industrial applications to create precision parts with high accuracy and efficiency. With the advent of advanced technology and innovative engineering, milling machines have become much more versatile and capable of performing a wide range of functions. Among the most versatile of all milling machines in the market today are the 3-axis universal milling machines.Here, we will highlight the Milling machine | 3 axis | MILL E Series – a universal application offered by GF Machining Solutions. The range of HEM vertical machining center sets standards in the VMC category, and the VCE range is ideally suited for die and mold construction using a round-head cutter.The Mill E series milling machines are highly sophisticated and versatile machines capable of performing a diverse range of functions. They can create precision parts of various sizes to meet the demands of different industries, from aerospace and defense to automotive and medical.What sets the Mill E series apart from other milling machines in the market is its unique design and engineering. It features a 3-axis system that offers unparalleled accuracy and versatility, making it perfect for a range of applications. Additionally, the Mill E series is built to withstand the rigors of industrial use, ensuring reliable and precise performance.One of the main benefits of using the Mill E series milling machines is their ability to reduce production time while increasing output. The fast and precise movement of the spindle head enables them to create complex parts with high accuracy, reducing the need for manual labor and enhancing overall productivity.Moreover, the Mill E series machines are designed with user-friendliness in mind, with intuitive software and user interfaces that enable easy operation of the machines. With these machines, operators can create complex parts with ease, and the machines can be easily customized to suit the demands of different applications.The VCE range of milling machines also makes use of advanced technology and innovative engineering to offer unparalleled performance. These machines are designed to work exclusively with round head cutters, making them ideal for die and mold construction. They are built to provide high precision and repeatability during the machining process, ensuring consistent results every time.One of the main advantages of the VCE range of milling machines is their ability to perform smoothing operations on complex surfaces of molds and dies. Smoothing the surfaces of molds and dies is a critical part of the manufacturing process, as it ensures high-quality parts that are free of blemishes and imperfections.In conclusion, milling precision parts requires high accuracy, precision, and versatility, which is why the Mill E series and VCE range milling machines are ideal for any industrial application. With their ability to create complex parts with precision and accuracy, these machines are the perfect choice for industries that require high-quality parts with tight tolerances. The use of these machines not only enhances productivity but also helps to reduce production costs, making them a valuable addition to any manufacturing facility. If you are searching for a reliable and efficient milling machine to create precision parts, look no further than the Mill E series and VCE range of milling machines.

How to Choose the Right 3D Printing Technology for Your Project

Fused Deposition Modeling (FDM) Technology Revolutionizes 3D Printing IndustryThe field of 3D printing has seen remarkable advancements in recent years, with one of the most influential technologies being Fused Deposition Modeling (FDM). This innovative approach to 3D printing has transformed the way that objects are created, and has had a significant impact on a wide range of industries.FDM works by employing a thermoplastic filament, which is melted and extruded through a nozzle in layers to create a 3D object according to a computer-generated design. The layered deposition technique allows for complex and intricate shapes to be produced with high precision and accuracy. In addition, the use of thermoplastic materials provides durability and flexibility to the finished product, making it suitable for a variety of applications.One company that has been at the forefront of FDM technology is {}. Founded in 1989, {} has been a leader in the 3D printing industry, pioneering advancements in FDM technology and pushing the boundaries of what is possible with this innovative approach. With a strong focus on research and development, {} has continually improved its FDM printers and materials, leading to the creation of high-quality products that meet the needs of a diverse range of industries.One of the key advantages of FDM technology is its versatility. The ability to use a wide variety of thermoplastic materials allows for the production of objects with specific characteristics, such as heat resistance, electrical conductivity, or chemical resistance. This versatility has led to the use of FDM in industries such as aerospace, automotive, healthcare, and consumer goods, among others. From prototyping and rapid tooling to end-use parts production, FDM has proven to be a valuable asset for manufacturers seeking to streamline their production processes and reduce time-to-market.Another benefit of FDM technology is its cost-effectiveness. By using thermoplastic materials and a layer-by-layer deposition method, FDM offers a more economical alternative to traditional manufacturing techniques. This has made it an attractive option for small and medium-sized businesses looking to bring their designs to life without breaking the bank. In addition, the high level of precision and repeatability offered by FDM technology ensures that the finished products meet the required specifications every time.As the 3D printing industry continues to grow and evolve, FDM technology is expected to play a significant role in its future development. With ongoing advancements in materials science, printer technology, and software, FDM is poised to become even more versatile and cost-effective, opening up new possibilities for manufacturers and designers around the world.In conclusion, Fused Deposition Modeling (FDM) technology has revolutionized the 3D printing industry, providing a versatile, cost-effective, and high-precision method for creating complex objects. With the ongoing advancements in FDM technology, it is poised to continue making a significant impact on a wide range of industries. As companies like {} continue to push the boundaries of FDM technology, the possibilities for innovation and creativity in 3D printing are limitless.

High-Quality CNC Prototype Parts: Your Ultimate Guide

CNC Prototype Parts: Precision Engineering at Its FinestIn the world of manufacturing, precision is key. Every part and component must be engineered with the utmost accuracy to ensure the smooth operation of the final product. This is where CNC prototype parts come into play. CNC, or computer numerical control, machining is a process that uses computer-aided design (CAD) software to create precise and intricate parts from raw materials. {Company} is a leading provider of CNC prototype parts, specializing in the production of high-quality components for a wide range of industries. With state-of-the-art equipment and a team of experienced engineers, {Company} is dedicated to delivering top-notch prototype parts that meet the exact specifications of their clients.CNC machining allows for the production of complex parts with incredible precision. Using computer-controlled cutting tools, {Company} is able to create intricate designs and shapes that would be impossible to achieve through traditional machining methods. This level of precision is crucial for industries such as aerospace, automotive, medical, and electronics, where even the smallest deviation can have a significant impact on the performance of the final product.One of the key advantages of CNC machining is its ability to produce prototype parts quickly and efficiently. {Company}'s advanced machinery and streamlined production process allow them to rapidly turn around prototype parts, reducing lead times and enabling their clients to bring new products to market faster. This speed and efficiency are crucial for companies looking to stay ahead of the competition and capitalize on new opportunities.In addition to speed and precision, {Company} also places a strong emphasis on quality. Their team of skilled engineers and machinists meticulously inspects every part to ensure it meets the highest standards. This commitment to quality has earned {Company} a reputation for excellence, making them a trusted partner for companies seeking reliable prototype parts.{Company} offers a wide range of materials for CNC prototype parts, including aluminum, steel, titanium, and various plastics. This versatility allows them to accommodate the diverse needs of their clients and produce parts for a wide variety of applications. Whether it's a small, intricate component or a large, complex part, {Company} has the capability to deliver.Furthermore, {Company}'s dedication to customer service sets them apart from the competition. Their team works closely with clients throughout the prototyping process, providing valuable insights and expertise to help optimize designs and improve manufacturability. This collaborative approach ensures that the final parts not only meet the client's specifications but also exceed their expectations.With the demand for precision-engineered parts on the rise, {Company} is well-positioned to meet the needs of a wide range of industries. Their commitment to quality, speed, and customer service has solidified their reputation as a premier provider of CNC prototype parts. As they continue to innovate and expand their capabilities, {Company} is poised to play a crucial role in the advancement of manufacturing and engineering.In conclusion, CNC prototype parts are an essential component of modern manufacturing, and {Company} is at the forefront of delivering high-quality, precision-engineered components. With their advanced machinery, skilled team, and dedication to customer service, {Company} is a trusted partner for companies looking to bring innovative products to market.

Rapid prototype: How it works and its benefits for innovation

Rapid Prototype Technology Enhances Factory EfficiencyIn today's fast-paced manufacturing industry, companies are constantly looking for ways to improve their production processes and stay ahead of the competition. The introduction of rapid prototype technology has proven to be a game-changer, allowing manufacturers to quickly and cost-effectively produce high-quality prototypes and streamline their product development cycle.One company at the forefront of this technology is {}. Founded in 2005, {} has established itself as a leading provider of rapid prototype services, offering a comprehensive range of solutions to meet the diverse needs of its clients.With a state-of-the-art facility equipped with the latest 3D printing, CNC machining, and injection molding capabilities, {} is able to deliver rapid prototypes with unmatched speed and precision. The company's team of experienced engineers and technicians work closely with clients to understand their design requirements and provide tailored solutions to bring their ideas to life.The rapid prototype process begins with the creation of a 3D model using advanced CAD software. This digital model is then used to generate the necessary instructions for the production equipment, ensuring the accurate replication of the final product. Once the design is finalized, the rapid prototype machines can quickly produce a physical model using a variety of materials, including plastics, metals, and composites.The speed and flexibility of rapid prototype technology have significantly expedited the product development cycle for manufacturers. By allowing for quick iterations and adjustments, companies can rapidly test and refine their designs, ultimately reducing time to market and saving on overall production costs. This has proven to be especially beneficial for industries such as automotive, aerospace, and consumer electronics, where innovation and time-to-market are critical factors for success.One of the key advantages of rapid prototype technology is its ability to bridge the gap between design and manufacturing. With traditional prototyping methods, the transition from design validation to full-scale production often entails lengthy lead times and substantial investment. Rapid prototype technology, however, enables manufacturers to seamlessly transition from prototype to production, reducing the time and resources required to bring a product to market.In addition to its speed and cost-effectiveness, rapid prototype technology also allows for greater design freedom and complexity. With the ability to produce intricate geometries and complex shapes, manufacturers can push the boundaries of innovation and create products that were once deemed unfeasible. This has opened up new opportunities for the development of lightweight, high-performance components that are revolutionizing various industries.As the demand for rapid prototype services continues to grow, {} remains committed to staying at the forefront of this technology. The company regularly invests in the latest equipment and software, ensuring that it can meet the evolving needs of its clients and deliver the highest quality prototypes in the shortest possible time.With a track record of success and a strong reputation for excellence, {} has established itself as a trusted partner for companies seeking to leverage rapid prototype technology. Whether it's a small-scale startup or a multinational corporation, {} is dedicated to providing innovative solutions that drive efficiency, reduce time to market, and ultimately, help clients achieve their business goals.In conclusion, rapid prototype technology has emerged as a transformative tool for manufacturers looking to enhance their product development process. With its speed, precision, and cost-effectiveness, rapid prototype technology offers a competitive edge in today's fast-paced manufacturing landscape. As companies continue to embrace this technology, the potential for innovation and advancement across various industries is limitless, and {} is poised to lead the way in this exciting new era of manufacturing.

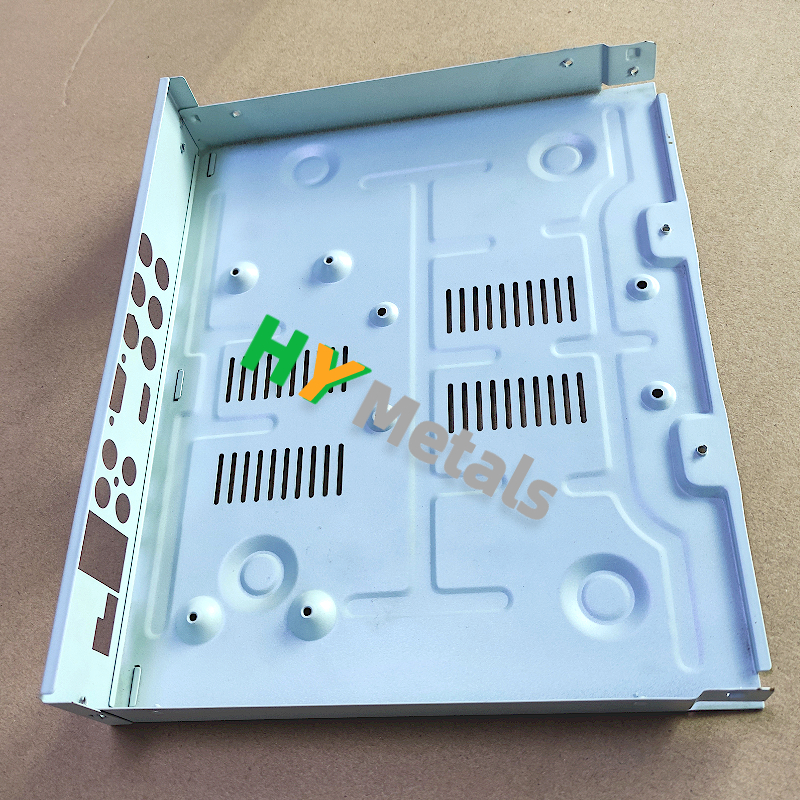

High Quality Sheet Metal Prototype Parts for Your Products

manufactures high-quality sheet metal prototype parts for a wide range of industries. The company's dedication to precision and attention to detail has earned them a reputation as a leader in the field of sheet metal fabrication.With state-of-the-art equipment and a team of skilled technicians, the company is able to produce prototype parts with exceptional accuracy and craftsmanship. Whether it's a custom design or a standard part, they have the expertise to deliver results that meet the highest industry standards.The company's commitment to quality is evident in every aspect of their operation. From the selection of materials to the final finishing touches, their team takes pride in their work and strives to exceed customer expectations. This dedication to excellence has made them a trusted partner for businesses in a variety of sectors, including aerospace, automotive, electronics, and more.In addition to their focus on quality, the company is also dedicated to providing exceptional customer service. Their team works closely with clients to understand their specific needs and ensure that the final product meets or exceeds their requirements. This approach has earned them a loyal customer base and a reputation for reliability and professionalism.One of the company's key strengths is their ability to provide fast turnaround times without compromising on quality. Their streamlined production process and efficient workflow allow them to complete projects quickly and efficiently, helping clients meet tight deadlines and stay on schedule.Furthermore, the company is constantly investing in new technologies and techniques to stay at the forefront of the industry. They understand the importance of staying ahead of the curve and are committed to keeping up with the latest advancements in sheet metal fabrication.The company's dedication to innovation and excellence has earned them numerous accolades and certifications. They are proud to hold various industry certifications, including ISO [insert number] and [other relevant certifications]. These achievements serve as a testament to their ongoing commitment to quality and continuous improvement.The company's impressive track record of success is a testament to their expertise and dedication to excellence. They have earned the trust and loyalty of countless clients by consistently delivering top-quality sheet metal prototype parts that meet their exacting standards.Moving forward, the company is poised for continued growth and success. They are fully committed to maintaining their position as a leader in the industry and will continue to invest in their people, processes, and technologies to ensure that they remain at the forefront of sheet metal fabrication for years to come.In conclusion, the company's dedication to precision, quality, and customer satisfaction sets them apart as a leader in the field of sheet metal prototype parts. With a proven track record of success and a commitment to ongoing innovation, they are well-positioned for continued growth and are a trusted partner for businesses in a variety of industries.

Precision Machining for Small Parts: The Ultimate Guide

Milling Small Parts: Precision Engineering at Its FinestIn the world of manufacturing, precision is everything. The ability to produce small, intricate parts with exacting tolerances can mean the difference between success and failure for many companies. That's where the expertise of {} comes into play. Specializing in the production of small, precision parts, {} has established itself as a leader in the field of precision engineering.With a state-of-the-art facility and a team of highly skilled technicians, {} is able to produce small parts with unprecedented accuracy and consistency. One of the key processes that {} utilizes in the production of small parts is milling. Milling is a machining process that involves the use of rotary cutters to remove material from a workpiece. This process is perfect for creating small parts with complex shapes and tight tolerances, making it an ideal choice for the production of precision components.By utilizing the latest milling technology, {} is able to produce small parts that meet the most demanding specifications. Whether it's a complex component for the aerospace industry or a tiny medical device, {} has the expertise and capability to deliver high-quality, precision-machined parts for a wide range of applications.In addition to their cutting-edge milling capabilities, {} also offers a range of other precision engineering services, including turning, grinding, and EDM (electrical discharge machining). This comprehensive suite of services allows {} to be a one-stop shop for companies in need of precision-engineered components.{} takes great pride in their ability to meet the unique needs of each of their clients. They understand that every project is different, and they work closely with their customers to ensure that their precise specifications are met. By providing personalized service and attention to detail, {} has earned a reputation for excellence in the field of precision engineering.One of the key differentiators of {} is their commitment to quality. They adhere to strict quality control processes throughout every step of the manufacturing process, ensuring that the parts they produce are of the highest quality. By maintaining a strong focus on quality, {} has been able to build long-lasting relationships with their clients and establish themselves as a trusted partner in the world of precision engineering.In addition to their dedication to quality, {} is also committed to continuous improvement. They invest in the latest technology and equipment, and they regularly train their team on the most advanced machining techniques. By staying at the forefront of technological advancements, {} is able to consistently deliver innovative solutions to their clients' most challenging engineering problems.With their cutting-edge technology, unwavering commitment to quality, and dedication to continuous improvement, {} has positioned themselves as a leader in the field of precision engineering. Whether it's a simple component or a complex part with intricate details, {} has the expertise and capability to deliver precision-machined parts that meet even the most demanding specifications.As the demand for small, precision parts continues to grow across a wide range of industries, {} is well-positioned to meet the needs of their clients and provide the high-quality parts that are essential for their success. With their focus on precision, quality, and innovation, {} is poised to continue their leadership in the field of precision engineering for years to come.

How steel bending is revolutionizing the manufacturing industry

Steel Bending Innovation: A New Milestone for {}{} is proud to announce a groundbreaking innovation in the steel industry with the introduction of a revolutionary steel bending technology. This new development promises to revolutionize the way steel is handled and shaped, setting a new standard for efficiency and precision in the manufacturing process.The new steel bending technology, developed by a team of experts at {}, represents a major advancement in the industry. With this innovation, {}, a leading name in the steel manufacturing sector, is well-positioned to further solidify its position as a leader in the industry.This cutting-edge technology allows for the bending of steel with unprecedented accuracy and efficiency, ensuring that each piece of steel is precisely shaped according to specifications. This level of precision is crucial in industries such as construction and manufacturing, where the structural integrity of steel components is paramount.The new steel bending technology also offers significant advantages in terms of speed and cost-efficiency. By streamlining the bending process, {} can significantly reduce production times, leading to faster turnaround times for customer orders. This increased efficiency also translates to cost savings, allowing {} to offer competitive pricing without compromising on quality.The introduction of this innovation underscores {}'s commitment to pushing the boundaries of what is possible in the steel industry. With a track record of delivering high-quality steel products to a wide range of industries, {} continues to invest in cutting-edge technologies that set new benchmarks for excellence.In addition to the technological advancements, {}'s steel bending process is also environmentally friendly. By reducing waste and optimizing production processes, {} is minimizing its environmental footprint and contributing to sustainability efforts in the industry."We are thrilled to introduce this game-changing steel bending technology to the market," said {}'s CEO. "This innovation is a testament to our commitment to driving progress and delivering the best possible products to our customers. With this new technology, we are confident that we can meet the evolving needs of the industry and continue to raise the bar for excellence in steel manufacturing."The introduction of this innovative steel bending technology comes at a time of rapid growth for {}. The company has been gaining momentum in the market, expanding its client base and strengthening its reputation as a trusted provider of high-quality steel products.Looking ahead, {} plans to continue investing in research and development to further enhance its technological capabilities and maintain its competitive edge in the industry. By staying at the forefront of innovation, {} is well-positioned to lead the way in shaping the future of steel manufacturing.With the introduction of this groundbreaking steel bending technology, {} is setting a new standard for precision, efficiency, and sustainability in the industry. As the company continues to push the boundaries of what is possible, it is poised to make a lasting impact on the steel manufacturing sector, delivering unparalleled value to its customers and driving progress across the industry.

Important Factors to Consider When Choosing Sheet Metal Components

[Company Introduction]With a rich history spanning over two decades in the manufacturing industry, our company has become a trusted name in the field of pressed sheet metal components. Our commitment to quality, advanced technology, and customer satisfaction has solidified our position as a leading provider of metal components for various industries.We specialize in offering a wide range of high-quality pressed sheet metal components that cater to diverse applications. Our state-of-the-art manufacturing facility is equipped with advanced machinery and cutting-edge technology, enabling us to meet the ever-evolving needs of our clients. With a team of skilled engineers and technicians, we ensure that every component we produce adheres to the highest industry standards.[Add the following news content]Title: Innovative Pressed Sheet Metal Components Revolutionize the Manufacturing IndustryDate: [Current Date]In today's competitive manufacturing landscape, companies are constantly on the lookout for innovative solutions that optimize production processes and enhance product quality. Recognizing this need, our company, a leading manufacturer of pressed sheet metal components, has unveiled a groundbreaking range of products that promise to revolutionize the industry.Boasting cutting-edge technology and superior craftsmanship, our new line of pressed sheet metal components offers unparalleled precision and durability. These components are designed to meet the rigorous demands of industries ranging from automotive to aerospace, construction to electronics, and many more.One of the major highlights of our new line of components is the utilization of advanced materials, such as high-strength steel alloys and lightweight metals. These materials not only ensure structural integrity and resistance to corrosion but also contribute to the overall weight reduction of the final product. This, in turn, leads to improved fuel efficiency in automobiles, increased payload capabilities for aircraft, and enhanced energy efficiency in various applications.Furthermore, our team of engineers has implemented innovative manufacturing techniques to offer components with intricate designs and complex geometries. Through state-of-the-art laser cutting and precision bending processes, we can successfully produce components with tight tolerances and intricate shapes, meeting the most stringent specifications required by our clients.In addition to advanced materials and manufacturing techniques, our components also incorporate the latest advancements in surface treatments and coatings. By employing environmentally friendly and highly effective coatings, we ensure that our products are well-protected against wear, abrasion, and corrosion. This prolongs the service life of our components and provides our clients with a cost-effective and reliable solution.Moreover, our commitment to sustainable manufacturing practices remains a top priority. Our manufacturing facility adheres to strict environmental regulations and employs measures to minimize waste generation and energy consumption. By constantly investing in research and development, we strive to achieve continuous improvements in our processes, ensuring that our products are both environmentally friendly and economically viable.As a testament to our commitment to quality and excellence, our company has achieved numerous certifications and accolades, recognizing our dedication to deliver superior pressed sheet metal components. We have also established long-standing partnerships with industry-leading companies, collaborating on various projects and providing them with tailored solutions to meet their specific requirements.In conclusion, our company's latest range of pressed sheet metal components represents a milestone in the manufacturing industry. With advanced materials, innovative manufacturing techniques, and the highest standards of quality, our components are set to revolutionize the sector, making manufacturing processes more efficient, products more durable, and industries more sustainable. We remain steadfast in our commitment to driving innovation in the industry and look forward to serving our clients with exceptional products well into the future.

Precision CNC Machining Services in Texas with Low Costs and Fast Lead Times

In the world of manufacturing, precision is paramount. The emergence of Computer Numerical Control (CNC) machines revolutionized the way manufacturers produced parts. CNC milling and turning are some of the most common machining processes, and with technological advancements, the processes have become more efficient, accurate, and cost-effective. 3D Hubs provides a CNC machining service in Texas that delivers low-cost, precision machined parts with an 8-day lead time from America, China, Europe, and India. CNC milling is a process that involves removing material from a workpiece using rotary cutters. The milling machine uses computer-aided design (CAD) to guide the cutting tool along different axes to achieve the desired shape. The machine can produce complex parts with a high level of precision and accuracy. The process is ideal for producing parts with intricate shapes, contours, and features that would be challenging to make using manual machining methods.CNC turning involves spinning a workpiece on a lathe machine while a cutting tool removes material to achieve the desired shape. The lathe machine uses CAD to guide the cutting tool along different axes. The process is ideal for producing round or cylindrical parts, including threads and grooves. Like CNC milling, the process is efficient and accurate, enabling the production of high-quality parts with tight tolerances.3D Hubs' CNC machining service in Texas utilizes both milling and turning processes to deliver high-precision, low-cost machined parts. The company uses computer-controlled machines that operate 24/7 to minimize lead times and reduce the cost of production. The machines are capable of machining a wide range of materials, including metals, plastics, and composites. The company's CNC milling machines use up to 5 axes, enabling the production of complex geometries with highly accurate finishes. The machines can produce parts with tolerances as tight as ± 0.005mm, ensuring that the parts meet the required specifications. The CNC turning machines, on the other hand, can produce parts with a diameter as small as 1mm and a length of up to 300mm. In addition to CNC milling and turning, 3D Hubs' CNC machining service in Texas includes finishing processes such as sandblasting, polishing, and anodizing. The finishing processes are essential to improve the appearance and functionality of the parts. Sandblasting, for instance, can give the parts a textured surface that improves their grip, while anodizing can enhance their corrosion resistance.3D Hubs' CNC machining service in Texas is ideal for businesses that require low-cost, high-precision machined parts. The company's ability to produce parts with tight tolerances, short lead times, and a wide range of materials makes it a valuable partner for manufacturers across different industries. The company's commitment to quality and customer satisfaction ensures that businesses get the best value for their money.In conclusion, CNC milling and turning are essential machining processes that have transformed the manufacturing industry. The processes are efficient, accurate, and cost-effective, making them ideal for producing high-quality parts with tight tolerances. 3D Hubs' CNC machining service in Texas utilizes these processes to deliver low-cost, high-precision machined parts with short lead times. With their commitment to quality and customer satisfaction, businesses can rely on 3D Hubs to provide the best value for their money.