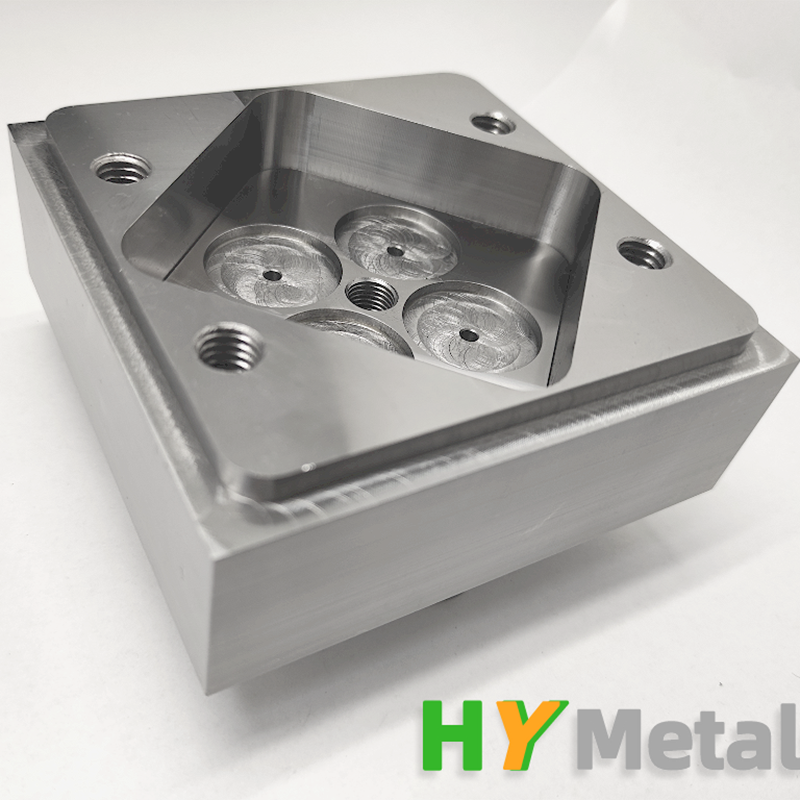

High-Quality CNC Machining Parts for Precision Engineering Needs

By:Admin

In the world of advanced manufacturing, precision is key. From aerospace and automotive industries to medical and electronics, the demand for high-quality, precision CNC machining parts is constantly growing. These parts are essential for the production of complex components and products that require tight tolerances and exact specifications. One company that has been at the forefront of providing top-notch precision CNC machining parts is {company name}.

{Company name} has been a leader in the manufacturing industry for over two decades. They specialize in state-of-the-art CNC machining services, using the latest technology and equipment to produce precision parts for a wide range of industries. Their expertise in CNC machining has made them a trusted partner for companies looking for high-quality, reliable parts that meet their exact specifications.

One of the key factors that sets {company name} apart from their competitors is their commitment to quality. They have invested heavily in advanced CNC machining equipment and are constantly upgrading and improving their processes to ensure that they deliver parts that meet the highest standards. Their team of skilled engineers and technicians are experts in CNC machining, and they work closely with clients to understand their needs and provide customized solutions.

{Company name} offers a wide range of precision CNC machining parts, including complex components, prototypes, and large production runs. They are able to work with a variety of materials, including aluminum, stainless steel, titanium, and plastics, and their state-of-the-art equipment allows them to produce parts with tight tolerances and exact specifications. Whether a client needs a single custom part or a large production run, {company name} has the capabilities to deliver.

In addition to their commitment to quality, {company name} is also focused on providing excellent customer service. They understand the importance of meeting deadlines and delivering parts on time, and they work closely with clients to ensure that their needs are met. Their dedication to customer satisfaction has earned them a reputation as a reliable and trustworthy partner in the manufacturing industry.

{Company name} has also made significant investments in technology and innovation. They are constantly exploring new materials, processes, and techniques to improve their CNC machining capabilities and stay at the forefront of the industry. By staying ahead of the curve, they are able to offer clients the latest advancements in CNC machining technology, providing them with a competitive edge in their respective industries.

The demand for precision CNC machining parts is only expected to grow in the coming years, as industries continue to advance and innovate. As a result, companies like {company name} will play a crucial role in meeting this demand and providing the high-quality parts that are essential for advanced manufacturing.

In conclusion, {company name} has established itself as a leader in the precision CNC machining industry, with a reputation for quality, innovation, and excellent customer service. Their commitment to investing in the latest technology and equipment, as well as their dedication to meeting the needs of their clients, has made them a trusted partner for companies in a wide range of industries. As the demand for precision CNC machining parts continues to grow, {company name} is well-positioned to continue providing the high-quality, reliable parts that are essential for advanced manufacturing.

Company News & Blog

Advancements in Additive Manufacturing: A Look into the Future of 3D Printing

Additive Manufacturing is Revolutionizing the Production ProcessAdditive manufacturing, also known as 3D printing, has been making waves in various industries as a revolutionary technology that is transforming the production process. This innovative method allows for the creation of complex and intricate designs by adding material layer by layer, as opposed to traditional subtractive manufacturing techniques. As a result, additive manufacturing has become increasingly popular in industries such as aerospace, automotive, healthcare, and consumer goods.One company at the forefront of this additive manufacturing revolution is {}. Founded in 2010, {} has quickly become a leading provider of additive manufacturing solutions, offering a wide range of 3D printing technologies and materials to meet the diverse needs of its customers. With a mission to enable the world to innovate and create faster, more affordable, and sustainable solutions, {} has been instrumental in pushing the boundaries of what is possible with additive manufacturing.One of the key advantages of additive manufacturing is its ability to produce intricate and complex designs that would be difficult, if not impossible, to create using traditional manufacturing methods. This has led to significant advancements in product design and development, allowing for faster prototyping and iteration of designs. Additionally, additive manufacturing has the potential to reduce material waste and energy consumption, making it a more sustainable option for production.In the aerospace industry, additive manufacturing has revolutionized the way aircraft components are produced. With the ability to create lightweight and highly durable parts, aircraft manufacturers are able to improve fuel efficiency and reduce overall costs. This has led to an increase in the adoption of additive manufacturing technologies across the aerospace sector, with companies like {} playing a pivotal role in driving these advancements.In healthcare, additive manufacturing has opened up new possibilities for the production of customized medical devices and implants. By using 3D scanning technology to create precise digital models of patients' anatomy, medical professionals are able to design and produce personalized implants that fit the patient perfectly. This has led to improved patient outcomes and reduced recovery times, demonstrating the potential of additive manufacturing to revolutionize the healthcare industry.The automotive industry has also seen significant benefits from additive manufacturing, with the ability to produce lightweight and complex parts that can improve performance and fuel efficiency. Additionally, additive manufacturing has allowed for the production of customized and limited-edition parts for vehicles, giving automotive manufacturers more flexibility in their design and production processes.As additive manufacturing continues to evolve, companies like {} are leading the way in developing new materials and technologies that push the boundaries of what is possible. By investing in research and development, {} has been able to offer cutting-edge solutions that enable its customers to take full advantage of the benefits of additive manufacturing.In addition to its technological advancements, {} has also focused on providing comprehensive support and training to its customers, ensuring that they are able to leverage additive manufacturing to its full potential. With a team of experts and a global network of partners and distributors, {} is committed to helping its customers succeed in the rapidly evolving world of additive manufacturing.With its dedication to innovation and customer success, {} has positioned itself as a key player in the additive manufacturing industry. As the demand for 3D printing technologies continues to grow, {} will undoubtedly play a crucial role in shaping the future of manufacturing across various industries. With a commitment to sustainability, innovation, and customer satisfaction, {} is well-positioned to lead the way in the additive manufacturing revolution.

Durable and Versatile Sheet Metal Flat for Various Applications

Sheet Metal Flat is a leading provider of high-quality sheet metal products to a wide range of industries. With a strong focus on customer satisfaction and cutting-edge technology, the company has established itself as a trusted partner for businesses looking for precision-engineered metal components.The company offers a wide range of sheet metal products, including flat sheets, coils, and custom-cut pieces. With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, Sheet Metal Flat is able to meet the diverse needs of its customers, delivering products that meet the highest standards of quality and precision.One of the key strengths of Sheet Metal Flat is its ability to work with a variety of materials, including stainless steel, aluminum, and carbon steel. This versatility allows the company to cater to the unique requirements of different industries, from automotive and aerospace to construction and electronics.In addition to its manufacturing capabilities, Sheet Metal Flat also offers a range of value-added services, such as metal finishing, coating, and assembly. This comprehensive approach allows the company to offer a one-stop solution for its customers, streamlining the production process and ensuring a seamless experience from start to finish.Furthermore, the company prides itself on its commitment to sustainability and environmentally friendly practices. Sheet Metal Flat has invested in advanced technologies and processes to minimize waste and reduce its carbon footprint, ensuring that its operations are as eco-friendly as possible.In recent news, Sheet Metal Flat has announced the launch of a new line of flat sheets that are designed to meet the growing demand for lightweight yet durable materials in the automotive industry. These sheets are made from high-strength aluminum alloys, offering a combination of excellent formability and corrosion resistance, making them ideal for use in body panels, chassis components, and structural parts."We are excited to introduce our new line of flat sheets that are specifically engineered to meet the stringent requirements of the automotive industry," said [company spokesperson]. "With the increasing focus on fuel efficiency and lightweighting in the automotive sector, our products are well-positioned to address the evolving needs of our customers."The company's investment in research and development has enabled it to stay ahead of industry trends and develop innovative solutions that meet the changing needs of its customers. Sheet Metal Flat continuously collaborates with its clients to identify new opportunities and develop tailored products that address specific challenges in their respective industries.In addition to its focus on product innovation, Sheet Metal Flat also places a strong emphasis on customer service and satisfaction. The company's team of dedicated professionals works closely with clients to understand their requirements and provide personalized solutions that meet their exact specifications.As Sheet Metal Flat continues to grow and expand its capabilities, the company remains committed to upholding its core values of quality, integrity, and innovation. With a track record of excellence and a customer-centric approach, Sheet Metal Flat is well-positioned to be a leading provider of sheet metal products for years to come.

Custom Prototype Tooling: Key Considerations for Efficient Manufacturing

Prototype Tooling, a leading provider of innovative tooling solutions, is proud to announce its latest advancement in the field of prototype tooling technology. With a history of excellence and an unwavering commitment to delivering high-quality products, Prototype Tooling has solidified its position as a trusted partner for companies looking to bring their ideas to life.Headquartered in [location], Prototype Tooling has been at the forefront of the tooling industry for over [number] years. The company’s dedication to innovation and customer satisfaction has made it a preferred partner for a wide range of industries, including automotive, aerospace, medical, and consumer goods.As a pioneer in the field of prototype tooling, Prototype Tooling has always been focused on leveraging the latest technologies to push the boundaries of what is possible. The company’s team of skilled engineers and technicians work tirelessly to develop cutting-edge solutions that meet the unique needs of each customer.The latest advancement from Prototype Tooling is set to revolutionize the way companies approach prototype development. By combining state-of-the-art technology with unparalleled expertise, the new [product name] promises to deliver unmatched precision and efficiency in the prototyping process.“We are very excited to introduce our latest innovation to the market,” said [Spokesperson], CEO of Prototype Tooling. “The [product name] represents a significant leap forward in prototype tooling technology, and we believe it will have a profound impact on the way companies bring their products to market.”The [product name] is designed to streamline the prototyping process, allowing companies to bring their ideas to life faster and more cost-effectively than ever before. With its advanced features and user-friendly interface, the [product name] is poised to become an essential tool for companies looking to stay ahead of the competition.In addition to its groundbreaking capabilities, the [product name] also reflects Prototype Tooling’s commitment to sustainability. By optimizing the prototyping process and reducing waste, the [product name] helps companies minimize their environmental impact while achieving their business goals.“Our team has worked tirelessly to develop a tool that not only delivers exceptional performance but also aligns with our values as a company,” said [Spokesperson]. “We believe that the [product name] will not only benefit our customers but also contribute to a more sustainable future for the industry as a whole.”With its unmatched combination of innovation, performance, and sustainability, the [product name] is set to redefine the prototyping landscape. As companies continue to seek ways to bring their products to market faster and more efficiently, Prototype Tooling’s latest offering is poised to become an essential asset in their arsenal.“For over [number] years, Prototype Tooling has been dedicated to pushing the boundaries of what is possible in the field of prototype tooling,” said [Spokesperson]. “With the introduction of the [product name], we are proud to continue that legacy and support our customers in achieving their goals.”As Prototype Tooling prepares to roll out the [product name] to the market, the company remains committed to its mission of empowering companies with the tools they need to succeed. With a track record of excellence and a relentless pursuit of innovation, Prototype Tooling is well-positioned to lead the way in the rapidly evolving world of prototype tooling technology.For companies looking to gain a competitive edge in their respective industries, the [product name] represents a game-changing solution that has the potential to transform the way they approach prototyping. With its unrivaled performance, sustainability, and user-friendly design, the [product name] is set to become the go-to tool for companies seeking to bring their ideas to life with speed and precision.As Prototype Tooling gears up for the launch of the [product name], industry leaders and customers alike are eagerly anticipating the arrival of this groundbreaking new tool. With its potential to reshape the prototyping landscape, the [product name] is well-positioned to solidify Prototype Tooling’s reputation as an industry leader and trusted partner for companies worldwide.

Durable Metal Frames for Your Home or Office

Metal Frames, a leading manufacturer of high-quality metal frames, has been making waves in the industry with its innovative and stylish designs. The company has been in the business for over 20 years and has gained a strong reputation for its commitment to quality and customer satisfaction.Metal Frames offers a wide range of products, including metal photo frames, metal poster frames, and metal picture frames, all designed to provide a sleek and modern look for any setting. The company prides itself on its ability to create custom frames that meet the specific needs and preferences of its customers, making it a popular choice among interior designers, art collectors, and homeowners alike.One of Metal Frames' standout features is its use of high-quality materials and precision engineering in the manufacturing process. The company uses only the finest metals, such as stainless steel, aluminum, and titanium, to ensure that its frames are durable and long-lasting. Each frame is carefully crafted to provide a seamless finish and to showcase the beauty of the artwork or photograph it holds.In addition to its superior craftsmanship, Metal Frames also offers a variety of finishes and colors to suit any aesthetic. Whether customers are looking for a classic black frame or a bold metallic finish, the company has options to cater to every style and preference. This flexibility has made Metal Frames a go-to choice for both professional and personal framing needs.Furthermore, Metal Frames prioritizes sustainability in its manufacturing processes. The company is committed to reducing its environmental impact by utilizing eco-friendly materials and minimizing waste. By choosing Metal Frames, customers can feel good about supporting a company that values sustainability and strives to make a positive contribution to the planet.Metal Frames has also gained recognition for its exceptional customer service. The company prides itself on its dedication to providing a seamless and enjoyable experience for its clients. Its team of experienced professionals is on hand to assist with design choices, custom orders, and any other inquiries, ensuring that customers receive the personalized attention they deserve.Additionally, Metal Frames offers competitive pricing without compromising on quality. The company understands the importance of affordability, especially in the competitive framing industry, and strives to provide cost-effective solutions without sacrificing the exceptional craftsmanship and design for which it is known.As Metal Frames continues to grow and evolve, it remains committed to staying at the forefront of the industry. The company constantly seeks innovative ways to improve its products and services, ensuring that it remains a top choice for consumers seeking premium metal frames.In conclusion, Metal Frames has established itself as a reputable and reliable manufacturer of high-quality metal frames. With its dedication to quality, sustainability, and exceptional customer service, the company has earned the trust and loyalty of customers worldwide. Whether for personal use or professional projects, Metal Frames is the go-to choice for anyone seeking top-tier metal frames.

High-Quality CNC Lathe Turning Parts for Precision Machining Needs

CNC Lathe Turning Parts - An Essential Component of Precision MachiningIn the world of precision machining, CNC lathe turning parts play a crucial role in the production of high-quality components. These parts are used in a wide range of industries, including aerospace, automotive, medical, and more. They are essential for creating precise and intricate components that meet the strict tolerances and specifications required by these industries.CNC lathe turning parts are manufactured using computer numerical control (CNC) technology, which allows for highly accurate and precise machining. This technology enables manufacturers to produce complex parts with tight tolerances and intricate geometries, ensuring that the finished components meet the exact specifications of their intended application.One company that specializes in the production of CNC lathe turning parts is {}. With over 20 years of experience in the precision machining industry, {} has established itself as a leading manufacturer of high-quality CNC lathe turning parts. The company has a proven track record of delivering precision machined components to a wide range of industries, and is known for its commitment to quality, innovation, and customer satisfaction.{} offers a wide range of CNC lathe turning parts, including shafts, bushings, fittings, connectors, and more. The company utilizes state-of-the-art CNC lathes and advanced machining techniques to produce parts that meet the highest standards of quality and precision. With a team of highly skilled engineers and machinists, {} is able to produce even the most complex and challenging parts with utmost precision and accuracy.In addition to its precision machining capabilities, {} is also committed to providing exceptional customer service. The company works closely with its customers to understand their specific needs and requirements, and strives to deliver tailored solutions that meet or exceed their expectations. {} is known for its quick turnaround times, competitive pricing, and dedication to customer satisfaction, making it a trusted partner for businesses in need of high-quality CNC lathe turning parts.With a focus on quality, innovation, and customer satisfaction, {} has positioned itself as a leader in the precision machining industry. The company's CNC lathe turning parts are used in a wide range of critical applications, and are known for their exceptional quality, precision, and reliability.In conclusion, CNC lathe turning parts are an essential component of precision machining, and play a crucial role in the production of high-quality components for a wide range of industries. With its commitment to quality, innovation, and customer satisfaction, {} has established itself as a leading manufacturer of high-quality CNC lathe turning parts, and is a trusted partner for businesses in need of precision machined components.

High-Quality CNC Machined Parts for Precision Engineering

CNC Machined Parts are at the heart of the manufacturing industry, and they play a crucial role in the production of a wide range of products. From automotive components to aerospace parts, CNC machined parts are essential in creating precision-engineered products. One company that is at the forefront of providing top-quality CNC machined parts is {}. With a strong focus on precision and quality, {} has become a trusted partner for many leading companies in various industries.{} specializes in the production of CNC machined parts using the latest technology and advanced machining techniques. The company's state-of-the-art facilities are equipped with high-precision CNC machines that can produce complex and intricate parts with exceptional accuracy. Whether it's a simple prototype or a high-volume production run, {} has the capabilities to meet the most demanding requirements.The company prides itself on its ability to deliver precision-engineered parts with quick turnaround times. By utilizing advanced CAD/CAM software and highly skilled machinists, {} can efficiently program and manufacture CNC machined parts to meet tight deadlines. This rapid production capability has made {} a preferred supplier for companies that require fast and reliable machining services.In addition to its cutting-edge manufacturing capabilities, {} places a strong emphasis on quality control. The company follows strict quality assurance protocols to ensure that each part meets the highest standards of accuracy and consistency. By employing advanced inspection equipment and rigorous quality checks, {} ensures that its CNC machined parts are of the highest quality before they are delivered to customers.As a customer-centric company, {} is committed to providing exceptional customer service and support. The company works closely with its clients to understand their specific needs and requirements, and it offers customized solutions to meet their unique challenges. Whether it's providing design assistance, optimizing manufacturing processes, or offering technical advice, {} goes above and beyond to ensure that its customers receive the best possible service.In addition to its focus on precision and quality, {} is also dedicated to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its manufacturing processes to reduce its environmental impact. By using efficient machining techniques and minimizing waste, {} strives to operate in an environmentally conscious manner.With its unwavering commitment to excellence, {} has established itself as a leading provider of CNC machined parts. The company's dedication to precision, quality, and customer satisfaction has earned it a stellar reputation in the manufacturing industry. Whether it's producing intricate components for the aerospace industry or creating custom parts for the automotive sector, {} continues to set the standard for excellence in CNC machining.In conclusion, CNC machined parts are an integral part of modern manufacturing, and {} is a standout leader in the industry. With its advanced capabilities, stringent quality control, and unwavering commitment to customer satisfaction, {} has become the go-to partner for companies seeking top-quality CNC machined parts. As the manufacturing sector continues to evolve, {} remains at the forefront, delivering precision-engineered parts that meet the highest standards of excellence.

Sheet Metal Component Suppliers Guide: Aluminium Fabricators to Welding & Fabrication Services (Page 1)

Article: Sheet Metal Components: A Leading Manufacturer of Sheet Metal Products Sheet Metal Components is a leading manufacturer of sheet metal products catering to a wide range of industries. With decades of experience in the industry, the company has established itself as a reliable and trusted provider of high-quality sheet metal components. The company offers a wide range of products and services, including sheet metal fabrication, welding, CNC machining, coating, and assembly. They work closely with their clients to understand their unique requirements and provide them with customized solutions that meet their specific needs. Whether it is a small prototype or a large-scale production run, Sheet Metal Components has the expertise and capabilities to deliver high-quality products on time and within budget. One of the key strengths of Sheet Metal Components is its state-of-the-art manufacturing facility. Equipped with the latest technology and equipment, the facility enables the company to produce complex sheet metal components with high accuracy and precision. The company's skilled and experienced team of engineers, designers, and technicians work together to ensure that every product is manufactured to the highest standards of quality and performance. Sheet Metal Components takes great pride in its commitment to sustainability and environmental responsibility. The company has implemented various measures to reduce its environmental footprint and minimize waste generation. This includes optimizing its manufacturing processes, using eco-friendly materials, and implementing efficient energy management practices. The company's extensive portfolio of products includes sheet metal components for various applications, including electronics, telecommunications, automotive, aerospace, and defense. Some of the products they offer include enclosures, cabinets, brackets, chassis, and frames. They also specialize in aluminum fabrication, with expertise in welding and machining aluminum products. Sheet Metal Components has established a strong reputation for delivering high-quality products and services to its clients. The company's dedication to customer satisfaction has earned it a loyal customer base, with many clients continuing to work with them for years. In addition to their manufacturing capabilities, Sheet Metal Components also offers comprehensive design support and engineering services. Their team of experts can assist clients in developing custom solutions that are tailored to their specific needs and requirements. They also offer prototyping services, allowing clients to test and evaluate their designs before moving into production. As a leading manufacturer of sheet metal components, Sheet Metal Components is committed to staying at the forefront of industry trends and technological advancements. They continuously invest in research and development to find new and innovative ways to improve their products and services. This ensures that they are able to deliver cutting-edge solutions that meet the evolving needs of their clients. In conclusion, Sheet Metal Components is a trusted and reliable provider of high-quality sheet metal products and services. With decades of experience in the industry, state-of-the-art manufacturing capabilities, and a commitment to sustainability and customer satisfaction, the company is well-positioned to meet the needs of clients across various industries. To learn more about their products and services, visit their website today.

CNC Turning Services for High-Quality Lathe Turned Parts

Service, Lathe Turned Production Parts, Prototyping, CNC Machined Parts, Manufacturing Partners, Instant CNC Turning Quote.CNC Turning Service: Your One-Stop Solution for All Your Lathe NeedsIn today's fast-paced manufacturing industry, the demand for precision and accuracy in parts production is more important than ever. Thanks to advances in technology, the CNC turning service has emerged as the go-to solution for manufacturing high-quality lathe-turned production parts. CNC Turning, with its precision, speed, and flexibility, has revolutionized the world of manufacturing and has become an essential part of modern-day production processes.At CNC Turning Service, we understand the importance of getting it right the first time, which is why we offer an exceptional range of services dedicated to providing our clients with the best possible results. Our services provide complete end-to-end solutions, from prototyping to CNC machined parts, and we deliver them with unbeatable speed, quality, and price.Our Global Network of Certified Manufacturing PartnersCNC Turning Service is proud to have a global network of 25 certified manufacturing partners, enabling us to offer our clients the best CNC turning services available. These partners have over 100 CNC turning machines, allowing us to produce everything from simple to complex parts. Our partners undergo a rigorous selection process to ensure they meet our exacting standards of quality, consistency, and efficiency. As a result, our clients benefit significantly from increased savings, faster lead times, and access to a wider range of capabilities.The Most Cost-Effective Solution for PrototypingAt CNC Turning Service, we understand that prototyping is an essential part of the production process. As such, we offer our clients the most cost-effective solution for creating high-quality prototypes. Our CNC turning service gives our clients the ability to produce prototypes that are identical to the final product in terms of specifications, tolerances, and material, which reduces the risk of design errors and allows for necessary modifications before the final production.CNC Machined Parts With Unbeatable Quality and SpeedCNC Turning Service produces CNC machined parts with unbeatable speed and quality. Our partners' CNC turning machines produce precise and accurate parts with precise tolerances, finishes, and features. Whether you need single parts or thousands, our CNC turning service can provide you with the most efficient and cost-effective production.Instant CNC Turning QuoteCNC Turning Service offers an instant CNC turning quote to our clients. Our online quote system is user-friendly, simple, and straightforward to use. Our clients can upload their designs, specify their requirements, and receive a quote instantly. With our instant quote system, our clients can access real-time pricing information and plan their production processes accordingly.ConclusionAt CNC Turning Service, we provide our clients with a complete end-to-end solution for all their lathe-turned production parts needs. Our global network of certified manufacturing partners, our cost-effective prototyping solutions, and our unbeatable quality and speed in producing CNC machined parts, make us the go-to solution for manufacturing high-quality parts. Contact us today and experience the benefits of our CNC turning services.

Discover the Advantages of Working with Curved Sheet Metal

Curved Sheet Metal is a leading provider of high-quality, custom curved sheet metal products. With a strong emphasis on precision and innovation, Curved Sheet Metal has become a trusted partner for industries ranging from architecture and construction to aerospace and automotive. The company’s state-of-the-art facilities and advanced equipment allow for the production of complex, curved sheet metal components that meet the unique needs of each customer.Curved Sheet Metal offers a wide range of capabilities in curved sheet metal fabrication, including cutting, bending, welding, and finishing. By utilizing advanced technologies and a team of experienced professionals, the company is able to deliver superior curved sheet metal products that exceed industry standards.One of the key differentiators for Curved Sheet Metal is its commitment to quality. The company follows strict quality control processes throughout every stage of production to ensure that each curved sheet metal component meets the highest standards. This dedication to quality has earned Curved Sheet Metal a solid reputation for reliability and excellence within the industry.In addition to its focus on quality, Curved Sheet Metal also places a strong emphasis on customer satisfaction. The company works closely with each client to understand their specific requirements and to provide tailored solutions that meet their individual needs. This collaborative approach has led to long-standing partnerships with a diverse array of customers, from small businesses to large corporations.Recent developments at Curved Sheet Metal have further enhanced the company’s capabilities and offerings. The company has made significant investments in new technologies and equipment to expand its curved sheet metal fabrication capabilities. This includes the addition of advanced machinery for precision cutting and bending, as well as the implementation of innovative techniques for creating complex curved shapes.As a result of these investments, Curved Sheet Metal is now able to offer an even broader range of curved sheet metal products, including curved panels, tubes, and custom components. The expanded capabilities have opened up new opportunities for the company to serve a wider spectrum of industries and to take on more complex projects.In addition to its ongoing commitment to innovation and quality, Curved Sheet Metal is also dedicated to sustainability. The company has implemented environmentally friendly practices throughout its operations, including the use of sustainable materials and energy-efficient processes. This focus on sustainability aligns with the company’s values and positions Curved Sheet Metal as a responsible and forward-thinking partner.Looking ahead, Curved Sheet Metal is focused on continued growth and expansion. The company is actively exploring new markets and opportunities to further establish itself as a leading provider of curved sheet metal products. With its strong foundation of expertise, technology, and commitment to excellence, Curved Sheet Metal is well positioned for success in the evolving landscape of curved sheet metal fabrication.

Top Tips for Machining High-Quality Aluminum Parts

With over 20 years of experience in the manufacturing industry, {} has become a leading provider of high-quality aluminum parts for a wide range of applications. Specializing in precision machining, the company has developed a reputation for delivering top-notch products that meet the needs of their diverse customer base.Utilizing state-of-the-art machining equipment and advanced technology, {} is able to produce aluminum parts with exceptional precision and accuracy. Their team of skilled engineers and technicians are highly trained and experienced in working with aluminum, ensuring that each part meets the strictest quality standards.One of the key advantages of aluminum parts is their lightweight yet durable nature, making them ideal for a variety of industries including aerospace, automotive, electronics, and more. With {}’s expertise in machining aluminum, they are able to offer custom solutions for their customers, meeting their specific requirements and delivering parts that perform to their exact specifications.From simple components to complex parts, {} has the capabilities to produce a wide range of aluminum products. Whether it’s milling, turning, drilling, or any other machining process, their team is equipped to handle the most challenging projects. Their attention to detail and commitment to excellence ensures that every part that comes out of their facility is of the highest quality.In addition to their machining capabilities, {} also offers a range of finishing services to further enhance the appearance and performance of their aluminum parts. This includes anodizing, powder coating, and other specialized treatments that provide added protection and aesthetic appeal.As a customer-focused company, {} places a strong emphasis on communication and collaboration throughout the production process. From the initial design phase to the final delivery, their team works closely with customers to understand their needs and deliver solutions that exceed their expectations.With a commitment to continuous improvement and investing in the latest technology, {} is well-positioned to meet the evolving demands of the manufacturing industry. Their dedication to quality, innovation, and customer satisfaction has earned them a reputation as a trusted partner for companies seeking high-quality aluminum parts.In the ever-changing world of manufacturing, {} remains at the forefront of the industry, providing reliable and cost-effective solutions for businesses of all sizes. Their extensive experience, technical expertise, and dedication to excellence make them the go-to source for machining aluminum parts.As the demand for precision-machined aluminum parts continues to grow, {} is well-prepared to meet the needs of their customers and deliver exceptional products that meet the highest standards. With a focus on quality, reliability, and customer satisfaction, they are poised to remain a leader in the industry for years to come.