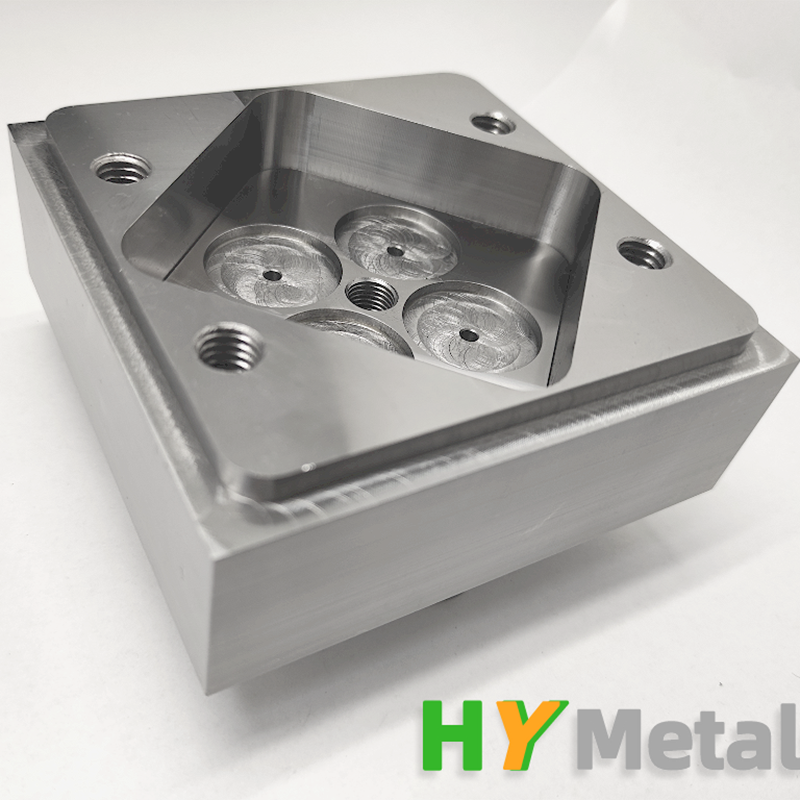

High-Quality CNC Milling Metal Parts for Industrial Applications

By:Admin

In the world of manufacturing, precision and efficiency are key components to success. This is why many companies are turning to CNC milling metal parts to streamline their production processes. With the help of advanced technology and specialized equipment, CNC milling has transformed the way metal parts are created, allowing for increased accuracy and faster turnaround times.

One company that is leading the way in CNC milling metal parts is {}. With a strong focus on innovation and quality, they have become a go-to source for businesses in need of custom metal parts. By utilizing state-of-the-art CNC milling machines and a team of skilled technicians, {} is able to produce high-quality metal parts for a wide range of industries, including automotive, aerospace, and consumer electronics.

The key to the success of CNC milling metal parts lies in the precision and flexibility that this technology offers. Unlike traditional milling methods, CNC milling allows for highly detailed and intricate designs to be achieved with incredible accuracy. This means that companies can produce complex metal parts with tight tolerances, ensuring that each piece meets the exact specifications required for the end product.

Another benefit of CNC milling metal parts is the speed at which they can be produced. With the use of computer-aided design (CAD) software, the entire manufacturing process is automated, reducing the risk of errors and speeding up production. This is particularly important for businesses working on tight deadlines or in need of a quick turnaround on their metal parts.

In addition to precision and efficiency, CNC milling metal parts also offer cost savings for businesses. By eliminating the need for manual labor and reducing the risk of errors, companies can save on labor costs and minimize material waste. This makes CNC milling an attractive option for businesses looking to improve their bottom line without sacrificing quality.

With the demand for custom metal parts on the rise, {} is poised to continue leading the way in the CNC milling industry. By staying ahead of the curve with the latest technology and equipment, they are able to meet the needs of their customers with top-notch precision and efficiency. With a focus on quality and customer satisfaction, {} is dedicated to providing innovative solutions for businesses in need of custom metal parts.

As the manufacturing industry continues to evolve, CNC milling metal parts will undoubtedly play a crucial role in shaping the future of production. With its ability to deliver unparalleled precision, speed, and cost savings, CNC milling is revolutionizing the way metal parts are created. Businesses looking to stay competitive in the market can turn to companies like {} for their CNC milling needs, knowing that they will receive top-quality products and exceptional service.

Company News & Blog

How Sheet Metal Bending Dies Can Improve Your Manufacturing Process

[Company Name] Introduces Advanced Sheet Metal Bending Dies for Precision Manufacturing[City, Date] - [Company Name], a leading manufacturer of precision tooling and machinery, has recently introduced a new line of sheet metal bending dies designed to meet the evolving needs of the manufacturing industry. With a focus on precision and efficiency, these advanced bending dies are expected to revolutionize the way sheet metal components are produced.The new sheet metal bending dies from [Company Name] are the result of extensive research and development efforts aimed at addressing the challenges faced by manufacturers in the modern market. With the increasing demand for complex and high-quality sheet metal components, there is a growing need for tooling solutions that can deliver unparalleled precision and efficiency."We are thrilled to introduce our latest line of sheet metal bending dies, which represent a significant advancement in the field of precision manufacturing," said [Spokesperson Name], the CEO of [Company Name]. "Our team has worked tirelessly to develop these dies, and we are confident that they will set a new standard for quality and performance in the industry."The new bending dies are designed to offer a number of key advantages to manufacturers. One of the most notable features is their ability to achieve precise bends with minimal deformation, resulting in higher quality finished parts. This level of precision is made possible by the advanced tooling design and manufacturing techniques employed by [Company Name].In addition to precision, the new bending dies are also highly efficient, allowing manufacturers to increase their productivity and reduce production costs. By streamlining the bending process and minimizing the need for secondary operations, these dies can help companies stay competitive in an increasingly demanding market."We understand the importance of efficiency in manufacturing, which is why our new bending dies are engineered to optimize production processes and reduce waste," [Spokesperson Name] explained. "We believe that these dies will not only improve the quality of finished parts, but also help our customers enhance their overall operational efficiency."The introduction of these advanced sheet metal bending dies further solidifies [Company Name]'s position as a leader in the precision tooling industry. With a long history of innovation and a commitment to excellence, [Company Name] has earned a reputation for delivering cutting-edge solutions that empower manufacturers to achieve their production goals.In addition to the new bending dies, [Company Name] offers a comprehensive range of tooling solutions, including punches, dies, and press brakes, as well as custom tooling services tailored to the specific needs of individual customers. These offerings are backed by the company's expertise and dedication to providing unparalleled support to its clients."At [Company Name], we are dedicated to helping our customers succeed by providing them with the highest quality tooling solutions and support services," [Spokesperson Name] stated. "We are proud to be at the forefront of innovation in the industry, and we will continue to push the boundaries of what is possible in precision manufacturing."As the manufacturing industry continues to evolve, the demand for advanced tooling solutions such as the new sheet metal bending dies from [Company Name] is expected to grow. With their combination of precision, efficiency, and reliability, these dies are poised to become an indispensable asset for manufacturers seeking to stay ahead in a competitive market.For more information about the new sheet metal bending dies and other tooling solutions from [Company Name], visit [company website] or contact [contact information].About [Company Name]:[Company Name] is a leading manufacturer of precision tooling and machinery, serving the needs of manufacturers in various industries. With a focus on innovation and customer satisfaction, the company is dedicated to providing high-quality solutions that enable its clients to achieve their production goals. With a commitment to excellence and a reputation for reliability, [Company Name] continues to be a trusted partner for businesses seeking the best in precision tooling.Contact:[Contact Name][Company Name][Phone Number][Email Address][Company Website]

The Ultimate Guide to Sheet Metal Forming Techniques and Processes

Sheetmetal Forming, a leading provider of metal fabrication services, has recently expanded its operations to meet the growing demand for custom metal parts in various industries. With over [number] years of experience in the industry, Sheetmetal Forming has solidified its reputation as a reliable and innovative company that delivers high-quality products.The company offers a wide range of metal fabrication services, including laser cutting, CNC punching, bending, welding, and assembly. Its state-of-the-art facility is equipped with the latest technology and machinery, allowing the company to handle projects of all sizes and complexities. From simple brackets to complex enclosures, Sheetmetal Forming has the capabilities to meet the diverse needs of its customers.One of the key factors that sets Sheetmetal Forming apart from its competitors is its commitment to quality. The company adheres to strict quality control measures at every stage of the fabrication process, ensuring that the final products meet the highest standards. Additionally, Sheetmetal Forming is dedicated to continuous improvement, regularly investing in training and technology to stay ahead of the curve.In response to the increasing demand for custom metal parts, Sheetmetal Forming has recently expanded its facility and added new equipment to its arsenal. This expansion allows the company to take on more projects and deliver results in a timely manner. With a team of highly skilled and experienced professionals, Sheetmetal Forming is well-positioned to handle the growing needs of its customers.“We are excited about the expansion of our operations and the opportunities it brings,” said [Spokesperson], President of Sheetmetal Forming. “Our goal is to provide our customers with the best possible solutions for their metal fabrication needs. With our expanded capabilities, we are confident that we can continue to exceed our customers’ expectations and maintain our position as a leader in the industry.”Sheetmetal Forming serves a wide range of industries, including automotive, aerospace, electronics, and telecommunications. The company has established strong partnerships with leading companies in these sectors, providing them with reliable and cost-effective metal fabrication solutions. Whether it’s prototyping, low-volume production, or high-volume manufacturing, Sheetmetal Forming has the expertise to deliver results that meet the unique requirements of each industry.In addition to its commitment to quality and innovation, Sheetmetal Forming is also dedicated to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its operations, minimizing waste and reducing its carbon footprint. By utilizing efficient manufacturing processes and sustainable materials, Sheetmetal Forming contributes to a greener and more sustainable future.With its expanded operations and a continued focus on excellence, Sheetmetal Forming is well-positioned to meet the evolving needs of its customers and maintain its position as a leader in the metal fabrication industry. The company’s dedication to quality, innovation, and sustainability sets it apart and makes it a preferred partner for companies seeking reliable and high-quality metal fabrication services.About Sheetmetal Forming: Sheetmetal Forming is a leading provider of metal fabrication services, serving a wide range of industries with custom solutions for their metal parts needs. With over [number] years of experience, the company has established a solid reputation for its commitment to quality, innovation, and sustainability. Sheetmetal Forming is dedicated to exceeding its customers’ expectations and delivering results that meet the unique requirements of each industry. For more information, visit [company website].

Top Quality Milling Components for Your Industrial Needs

Milling Components Launches Innovative Product LineMilling Components, a leading manufacturer of precision milling machinery and components, has recently launched an innovative new product line that is expected to revolutionize the industry. This new line of products combines cutting-edge technology with the company's decades of expertise in the field of milling and machining, providing customers with solutions that are more precise, efficient, and cost-effective than ever before.The company, headquartered in [Location], has been at the forefront of the milling industry since its founding in [Year]. With a strong focus on research and development, [Brand name]'s team of engineers and technicians have consistently pushed the boundaries of what is possible in terms of milling technology. The result is a product line that is highly regarded for its precision, reliability, and durability, making [Brand name] a trusted partner for businesses in a wide range of industries.The newest addition to [Brand name]'s product lineup is a series of advanced milling components that have been designed to meet the diverse needs of modern manufacturing operations. These components are built to the highest standards of quality and are capable of delivering exceptional performance in a wide range of applications, from small-scale precision machining to heavy-duty industrial production.One of the key features of this new product line is its focus on versatility and adaptability. The components have been engineered to be highly customizable, allowing customers to tailor their milling setups to their specific requirements. This level of flexibility not only enhances the efficiency of the milling process but also reduces the need for costly and time-consuming retooling.In addition to their customizable nature, the new milling components also incorporate the latest advancements in digital and automation technologies. This allows for seamless integration with other machinery and systems, creating a more streamlined and interconnected manufacturing environment. By leveraging these technologies, customers can improve their overall productivity and reduce the risk of errors and downtime.The launch of this new product line represents a significant milestone for [Brand name]. As a company that has always been committed to innovation, [Brand name] is proud to offer its customers a range of milling components that are truly at the cutting edge of technological advancement. This commitment to excellence has earned [Brand name] a reputation as a forward-thinking and reliable provider of milling solutions.In conjunction with the release of the new product line, [Brand name] is also reinforcing its dedication to customer service and support. The company's team of experts is available to provide guidance and assistance to customers as they integrate the new milling components into their operations. This commitment to customer satisfaction is a cornerstone of [Brand name]'s business philosophy, and it is one of the reasons why the company has maintained long-standing relationships with many of its clients.Looking ahead, the future appears bright for [Brand name] and its innovative new product line. With a strong foundation of expertise and a focus on continuous improvement, [Brand name] is well-positioned to remain a leader in the milling industry for years to come. By staying at the forefront of technological advancements and maintaining its commitment to customer satisfaction, [Brand name] is poised to continue providing its customers with the highest quality milling components and machinery.Overall, the launch of this new product line is a testament to [Brand name]'s dedication to pushing the boundaries of what is possible in the milling and machining industry. With its combination of advanced technology, customizable solutions, and unparalleled customer support, [Brand name] is setting a new standard for excellence in the field of milling components.

Exploring the Tremendous Benefits of Fast Prototyping in Modern Industries

Title: Revolutionary Prototyping Technology Unveiled by Industry LeaderSubtitle: Pioneering the Future of Product Development and InnovationDate: [Date][City], [State] - [Company Name], a renowned leader in the field of prototyping and product development, has introduced an innovative and ground-breaking technology that is set to revolutionize the industry. The company is changing the game with its cutting-edge Fast Prototyping, a process that enables businesses to bring their ideas to life quicker and more efficiently than ever before.With a knack for pushing boundaries and an unwavering commitment to excellence, [Company Name] has always been at the forefront of technological advancements. The introduction of their Fast Prototyping technology is yet another testament to their status as industry leaders.Fast Prototyping is a game-changer in the product development world, allowing businesses to rapidly iterate and refine their designs in order to accelerate the time-to-market. This technology enables companies to transform their concept into a physical prototype within a matter of days, significantly reducing the time and cost associated with traditional prototyping methods.The key to Fast Prototyping lies in its use of cutting-edge 3D printing technologies. By harnessing the power of additive manufacturing, [Company Name] can create highly intricate and accurate prototypes directly from digital designs. This removes the need for costly and time-consuming manual modeling and machining processes, streamlining the entire development cycle.Furthermore, [Company Name] has developed advanced materials specifically tailored for Fast Prototyping. These materials possess exceptional strength, durability, and surface finish properties, ensuring that the prototypes accurately represent the final product. This allows companies to make critical design decisions early on and avoid costly errors down the line.The benefits of Fast Prototyping are not limited to design iteration speed and cost reduction. By quickly obtaining physical prototypes, businesses can test their products' ergonomics, functionality, and market appeal, gaining valuable insights that can inform further development iterations. This agile approach to product development empowers companies to meet customer demands swiftly and stay ahead of the competition.In addition to their state-of-the-art technology, [Company Name] boasts a highly skilled team of engineers and designers who work closely with clients throughout the prototyping process. Their expertise and collaborative approach ensure that the envisioned product is accurately translated into physical form, guaranteeing customer satisfaction."Our innovation-driven approach has always been centered around helping businesses transform their ideas into tangible realities," said [Company Name]'s CEO. "With Fast Prototyping, we are enabling companies to prototype and iterate at an unprecedented pace, unlocking the potential for faster time-to-market and competitive advantage."The applications of Fast Prototyping are vast and diverse. From aerospace to automotive, consumer electronics to medical devices, [Company Name] is committed to supporting a wide range of industries in their pursuit of innovation and excellence. Their technology will undoubtedly empower businesses to reimagine what is possible and bring their concepts to fruition in record time.For companies looking to harness the power of Fast Prototyping, [Company Name] offers tailored solutions and comprehensive support throughout the entire prototyping process. This includes design optimization, material selection, and seamless integration with existing product development workflows.As an industry leader and innovator, [Company Name] continues to revolutionize the field of product development. With Fast Prototyping, they are pioneering a new era of rapid, efficient, and cost-effective innovation, allowing businesses to turn their ideas into reality with unparalleled speed and precision.About [Company Name]:[Company Name] is a globally recognized leader in advanced product development and prototyping. With a team of highly skilled engineers and designers, they have been at the forefront of technological innovation for over [number of years] years. Their commitment to excellence and passion for driving innovation have cemented their position as a trusted partner for businesses across various industries.

High-Quality Aluminum Machining Services for Parts

FOR IMMEDIATE RELEASEMachining Aluminum Parts: Company A Leading the Way in Precision ManufacturingCompany A has been a pioneer in precision manufacturing for over 20 years. Specializing in the production of high-quality aluminum parts, the company has established itself as a leader in the industry, consistently meeting the demands of a wide range of sectors, including automotive, aerospace, and electrical engineering.With a state-of-the-art facility and a team of highly skilled machinists and engineers, Company A has the capabilities to machine aluminum parts to the most exacting specifications. The company employs advanced CNC machinery and cutting-edge technology to ensure the highest quality of precision and accuracy in every part produced.One of the key factors that sets Company A apart from its competitors is its commitment to quality control. Utilizing a rigorous quality management system, the company ensures that every part that leaves its facility meets the strictest standards for accuracy and performance. This dedication to quality has earned the trust and loyalty of a diverse clientele, including leading manufacturers and suppliers in the automotive and aerospace industries.In addition to its focus on quality, Company A also places a strong emphasis on innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the curve in terms of technological advancements and machining techniques. This investment has enabled Company A to expand its capabilities and take on complex projects that require intricate and precise aluminum parts.Recently, Company A has made significant strides in the machining of aluminum parts, pushing the boundaries of what is possible in terms of precision and complexity. By leveraging its extensive experience and expertise, the company has developed new techniques and processes that allow for the production of aluminum parts with unparalleled accuracy and reliability.One of the key advantages of machining aluminum parts with Company A is the company's ability to work with a wide range of aluminum alloys. Whether it's 6061, 7075, or any other aluminum alloy, Company A has the knowledge and expertise to machine parts that meet the specific requirements of its customers.The versatility and adaptability of Company A's machining capabilities have made the company a go-to partner for businesses seeking custom aluminum parts for their applications. The company's ability to produce parts in small or large volumes, while maintaining the highest level of precision, has earned it a stellar reputation in the industry.As the demand for lightweight, durable, and high-performance aluminum parts continues to grow across various industries, Company A is well-positioned to meet the needs of its customers. The company's dedication to excellence, coupled with its commitment to innovation, ensures that it will remain at the forefront of precision machining for years to come.In conclusion, Company A stands as a shining example of a manufacturing company that excels in the machining of aluminum parts. With its unwavering dedication to quality, innovation, and customer satisfaction, the company has solidified its position as a leader in the industry. As the demand for precision-machined aluminum parts continues to rise, Company A is poised to meet the challenges of tomorrow and set new standards for excellence in the manufacturing world.

Milling Small Parts: The Ultimate Guide for Precision Machining

For Immediate ReleaseMilling Small Parts: A New Addition to the Innovative Product Line at [Company Name][City, State], [Date] – [Company Name] is pleased to announce the addition of a new milling small parts to its already extensive product line. The new addition is designed to provide precision and accuracy in the machining of small parts, catering to the needs of various industries and applications.With a commitment to providing high-quality products and exceptional customer service, [Company Name] has been a leading provider of machining solutions for over [X] years. The company specializes in the design and manufacturing of a wide range of precision components and parts for a diverse array of industries, including aerospace, automotive, medical, and electronics.The new milling small parts are the latest addition to the extensive product line offered by [Company Name]. These small parts are designed to meet the growing demand for precise and intricate machining of small components, offering unparalleled accuracy and efficiency. With state-of-the-art technology and advanced manufacturing techniques, the milling small parts are capable of producing complex geometries and tight tolerances, ensuring the highest level of precision in the finished parts.One of the key features of the milling small parts is their versatility in handling a wide range of materials, including metals, plastics, and composites. This broad capability allows [Company Name] to serve the diverse needs of its customers across various industries, providing them with a one-stop solution for their machining requirements.In addition to the milling small parts, [Company Name] also offers a comprehensive range of machining services, including turning, milling, grinding, and EDM, as well as value-added services such as assembly, surface finishing, and quality inspection. By leveraging its extensive expertise and cutting-edge technology, [Company Name] is able to provide its customers with customized solutions that meet their specific needs and requirements.The introduction of the milling small parts is a testament to [Company Name]'s commitment to innovation and continuous improvement. By staying at the forefront of technological advancements and manufacturing capabilities, the company remains dedicated to delivering exceptional products and services that exceed the expectations of its customers."We are thrilled to introduce the new milling small parts to our product line," said [Spokesperson Name], [Title] at [Company Name]. "This addition represents our ongoing dedication to meeting the evolving needs of our customers and providing them with the highest quality machining solutions. With the ability to deliver precision and accuracy in the machining of small parts, we are confident that the milling small parts will further enhance our capabilities and drive value for our customers."As [Company Name] continues to expand its product offerings and capabilities, this latest addition reinforces its position as a trusted and reliable partner for precision machining solutions. With a focus on quality, reliability, and customer satisfaction, the company remains committed to serving the needs of its customers and contributing to their success in an increasingly competitive market.For more information about the milling small parts and other products and services offered by [Company Name], please visit [Company Website] or contact [Contact Person] at [Contact Number].About [Company Name][Company Name] is a leading provider of precision machining solutions for a wide range of industries. With a focus on delivering high-quality products and exceptional customer service, the company offers a comprehensive range of machining services, including turning, milling, grinding, and EDM, as well as value-added services such as assembly, surface finishing, and quality inspection. With state-of-the-art technology and advanced manufacturing techniques, [Company Name] is dedicated to providing its customers with customized solutions that meet their specific needs and requirements.

High-Quality Aluminum Casting Services: What You Need to Know

Aluminum Casting Company Leads the Industry with Innovative SolutionsAluminum has long been recognized as a highly versatile metal, offering a wide range of applications due to its lightweight and durable properties. As the demand for aluminum products continues to grow, companies such as [Company Name] have stepped up to provide innovative casting solutions to meet the needs of various industries.[Company Name] is a leading aluminum casting company that has been at the forefront of the industry for over 20 years. With a strong dedication to quality, innovation, and customer satisfaction, [Company Name] has firmly established itself as a go-to provider for precision aluminum casting solutions.The company's state-of-the-art facilities are equipped with advanced technology and machinery, allowing for the production of high-quality aluminum castings that meet the strictest industry standards. From complex geometries to intricate designs, [Company Name] has the expertise and capabilities to deliver a wide range of custom aluminum casting solutions to its customers.One of the key factors that set [Company Name] apart from its competitors is its commitment to continuous improvement and innovation. The company's team of experienced engineers and technicians are constantly exploring new techniques and processes to enhance the quality and efficiency of its casting operations. This dedication to innovation has led to the development of cutting-edge casting solutions that have earned [Company Name] a reputation for excellence in the industry.In addition to its technical capabilities, [Company Name] prides itself on its customer-centric approach to business. The company works closely with its clients to understand their specific casting requirements, offering personalized solutions that are tailored to meet their exact needs. Whether it's a prototype for a new product or a large-scale production run, [Company Name] is committed to delivering superior aluminum castings that exceed expectations.Furthermore, [Company Name] places a strong emphasis on sustainability and environmental responsibility. The company has implemented various eco-friendly practices in its operations, including the use of recycled aluminum and energy-efficient processes. By reducing its environmental footprint, [Company Name] is helping to promote a more sustainable future for the industry and the planet.Despite the challenges posed by the global pandemic, [Company Name] has continued to demonstrate resilience and adaptability. The company has implemented strict health and safety protocols to protect its employees and maintain uninterrupted operations. This proactive approach has allowed [Company Name] to fulfill its commitments to customers and uphold its reputation as a reliable and trustworthy partner.Looking ahead, [Company Name] is poised to further strengthen its position in the aluminum casting industry. The company is actively investing in new technologies and expanding its production capabilities to meet the evolving demands of its customers. By remaining at the forefront of innovation and customer satisfaction, [Company Name] is well-equipped to lead the industry and continue providing superior aluminum casting solutions for years to come.

High-Quality CNC Milling Metal Parts for Industrial Applications

CNC Milling Metal Parts Revolutionizes Manufacturing ProcessIn the world of manufacturing, precision and efficiency are key components to success. This is why many companies are turning to CNC milling metal parts to streamline their production processes. With the help of advanced technology and specialized equipment, CNC milling has transformed the way metal parts are created, allowing for increased accuracy and faster turnaround times.One company that is leading the way in CNC milling metal parts is {}. With a strong focus on innovation and quality, they have become a go-to source for businesses in need of custom metal parts. By utilizing state-of-the-art CNC milling machines and a team of skilled technicians, {} is able to produce high-quality metal parts for a wide range of industries, including automotive, aerospace, and consumer electronics.The key to the success of CNC milling metal parts lies in the precision and flexibility that this technology offers. Unlike traditional milling methods, CNC milling allows for highly detailed and intricate designs to be achieved with incredible accuracy. This means that companies can produce complex metal parts with tight tolerances, ensuring that each piece meets the exact specifications required for the end product.Another benefit of CNC milling metal parts is the speed at which they can be produced. With the use of computer-aided design (CAD) software, the entire manufacturing process is automated, reducing the risk of errors and speeding up production. This is particularly important for businesses working on tight deadlines or in need of a quick turnaround on their metal parts.In addition to precision and efficiency, CNC milling metal parts also offer cost savings for businesses. By eliminating the need for manual labor and reducing the risk of errors, companies can save on labor costs and minimize material waste. This makes CNC milling an attractive option for businesses looking to improve their bottom line without sacrificing quality.With the demand for custom metal parts on the rise, {} is poised to continue leading the way in the CNC milling industry. By staying ahead of the curve with the latest technology and equipment, they are able to meet the needs of their customers with top-notch precision and efficiency. With a focus on quality and customer satisfaction, {} is dedicated to providing innovative solutions for businesses in need of custom metal parts.As the manufacturing industry continues to evolve, CNC milling metal parts will undoubtedly play a crucial role in shaping the future of production. With its ability to deliver unparalleled precision, speed, and cost savings, CNC milling is revolutionizing the way metal parts are created. Businesses looking to stay competitive in the market can turn to companies like {} for their CNC milling needs, knowing that they will receive top-quality products and exceptional service.

How to Bend Steel: Tips and Techniques for Shaping Metal

Steel Bending: A Competitive Edge for Steel bending is a critical process in the construction and manufacturing industries. It involves the manipulation of steel into various shapes and forms, providing structural integrity to a wide range of products and projects. In the competitive landscape of steel fabrication, the ability to bend steel with precision and efficiency is a crucial factor that sets companies apart from their rivals. This is where comes in, offering top-notch steel bending services that cater to the needs of its diverse clientele.Established in [], has built a solid reputation as a leading provider of steel bending solutions. With state-of-the-art equipment and a team of highly skilled technicians, the company has the capability to handle a wide range of steel bending projects, from small-scale components to large structural elements. Whether it's for architectural designs, industrial machinery, or construction applications, prides itself on delivering high-quality, custom-tailored bending solutions that meet the specific requirements of its customers.The company's comprehensive approach to steel bending encompasses a variety of techniques, including cold bending, hot bending, and induction bending. These techniques allow for the manipulation of steel with precision and control, ensuring that the end result meets the exact specifications of the customer. Additionally, through the use of advanced computer-aided design (CAD) software, is able to develop accurate bending profiles and simulations, further enhancing the efficiency and accuracy of its bending processes.One of the key differentiators for is its ability to work with a wide range of steel materials, including carbon steel, stainless steel, and alloy steel. This versatility allows the company to cater to the diverse needs of its clients across different industries. Whether it's for a high-strength application that requires alloy steel or a corrosion-resistant solution using stainless steel, has the expertise and resources to deliver bendable steel solutions that meet the highest standards of quality and performance.In addition to its technical capabilities, stands out for its commitment to customer satisfaction and project collaboration. The company takes a consultative approach to understand the unique requirements of each project and works closely with its clients to develop bending solutions that are both functional and cost-effective. By fostering open communication and maintaining a customer-centric focus, builds strong partnerships with its clients, often becoming the go-to provider for their steel bending needs.Furthermore, places a strong emphasis on quality control and efficiency in its operations. The company adheres to stringent quality standards and processes to ensure that every bent steel component meets the highest level of accuracy and consistency. Through continuous improvement initiatives and investment in the latest technologies, strives to optimize its production processes, reduce lead times, and minimize waste, ultimately delivering value to its customers in the form of high-quality, competitively priced bending solutions.Looking ahead, remains committed to staying at the forefront of the steel bending industry by continuously refining its capabilities and expanding its service offerings. The company invests in ongoing training and development for its staff, as well as the latest equipment and technologies, to ensure that it can effectively address the evolving needs of the market. By staying abreast of industry trends and advancements, is well-positioned to continue delivering innovative and reliable steel bending solutions to its clients.In conclusion, is a trusted industry leader in steel bending, offering a comprehensive range of services that cater to the diverse needs of its customers. With its advanced capabilities, commitment to quality, and customer-focused approach, has established itself as a go-to provider for steel bending solutions. As the company continues to grow and innovate, it is poised to maintain its competitive edge and contribute significantly to the success of its clients in the construction and manufacturing sectors.

Find Top Quality Aluminum Extrusion Suppliers and Manufacturers

for Improved Durability and Aesthetic Appeal.Aluminum extrusions are widely used in various industries due to their versatility, strength, and lightweight properties. These extrusions are produced by pushing an aluminum billet through a die to create a specific cross-sectional shape. The end product is then used for various applications such as construction, automotive, aerospace, and consumer goods industries.Aluminum extrusions can be further enhanced by anodizing. Anodized aluminum extrusions have a protective layer of oxide coating on the surface, which results in improved durability and aesthetic appeal. This process involves immersing the aluminum extrusion into an acidic electrolyte bath and applying an electrical current to create an oxide layer on the surface. The thickness of the oxide layer can be controlled to achieve the desired level of protection and color.The benefits of anodized aluminum extrusions are numerous. Firstly, this process provides corrosion resistance, making it ideal for outdoor applications that are exposed to harsh weather conditions. Secondly, the oxide layer is hard and abrasion-resistant, improving the durability of the aluminum extrusion. Thirdly, anodized aluminum extrusions have a uniform color that is long-lasting and does not fade over time. This is particularly beneficial for products that require attractive finishes such as furniture, lighting fixtures, and consumer electronics.In addition to the practical benefits, anodized aluminum extrusions offer a range of aesthetic benefits. Anodizing can produce a variety of colors, from natural silver to shades of black, blue, and red. This makes it possible to create customized finishes for different applications. Anodized aluminum extrusions also have a matte or satin finish, which adds a touch of elegance to the end product.Anodized aluminum extrusions are produced by many manufacturers and suppliers listed on IQS Directory. These companies have the expertise and equipment to create high-quality anodized aluminum extrusions that meet customer specifications. The process of anodizing can be customized to achieve specific colors, thicknesses, and finishes. IQS Directory has a wide range of anodized aluminum extrusion suppliers that offer competitive prices and quick response times. This means that customers can get the products they need, when they need them.In conclusion, anodized aluminum extrusions offer a range of benefits that make them superior to other types of material. The process of anodizing improves durability, corrosion resistance, and aesthetic appeal. It also allows for customization of colors and finishes, making it ideal for various applications. IQS Directory has a vast network of anodized aluminum extrusion suppliers that offer top-quality products at affordable prices. For those looking for durable and attractive aluminum extrusions, anodizing is the answer.