High-Quality Custom Radiator Parts for Your Vehicle

By:Admin

Custom radiator parts have become an essential component for the heating industry, offering personalized solutions for various heating systems. These parts are specifically designed to fit and function perfectly within a specific radiator system, providing better efficiency and performance. In this regard, {Company Name} has been at the forefront of delivering high-quality custom radiator parts to meet the diverse needs of its customers.

{Company Name} is an industry-leading manufacturer and supplier of custom radiator parts, specializing in designing and producing tailored solutions for both residential and commercial heating applications. With years of experience and expertise in the heating industry, the company has established a solid reputation for delivering top-notch products that meet the highest standards of quality and reliability.

The custom radiator parts offered by {Company Name} are meticulously engineered to align with the specific requirements of different heating systems. Whether it's a unique design, specific dimensions, or special materials, the company can cater to a wide range of customizations to ensure a perfect fit and seamless integration with the existing heating infrastructure. This level of customization not only enhances the performance of the heating system but also ensures a more efficient and cost-effective solution for the end-user.

One of the key advantages of opting for custom radiator parts from {Company Name} is the ability to address complex heating challenges with tailored solutions. The company's team of skilled engineers and technicians work closely with the customers to understand their specific needs and develop customized parts that effectively meet those requirements. This collaborative approach ensures that the custom radiator parts not only enhance the overall performance of the heating system but also contribute to energy savings and reduced maintenance costs in the long run.

Another noteworthy aspect of the custom radiator parts offered by {Company Name} is their exceptional durability and reliability. The company is committed to using high-quality materials and advanced manufacturing processes to ensure that every custom part is built to last. This level of attention to detail and quality control not only instills confidence in the customers but also reflects the company's dedication to delivering long-term value through its products.

Furthermore, {Company Name} prides itself on its ability to provide quick turnaround times for custom radiator parts without compromising on quality. The company understands the importance of timely solutions in the heating industry and has streamlined its manufacturing processes to meet the demands of its customers efficiently. This agility in production, combined with the company's unwavering commitment to excellence, has positioned {Company Name} as a trusted partner for custom radiator solutions.

In conclusion, the demand for custom radiator parts continues to grow as heating systems become more sophisticated and diverse. {Company Name} has emerged as a reliable source for high-quality custom radiator parts, offering tailored solutions to address the unique requirements of its customers. With a focus on precision engineering, durability, and timely delivery, the company has solidified its position as a preferred partner for custom radiator solutions in the heating industry. Whether it's a residential upgrade or a commercial project, {Company Name} is well-equipped to deliver custom radiator parts that exceed expectations and elevate the performance of any heating system.

Company News & Blog

What is Water-jet Technology? A Definition

Water-jet Technology Takes the Industrial World by StormWater-jet technology has been quietly revolutionizing the industrial world over the past decade. Driven by powerful streams of water and sometimes abrasive materials, water-jet cutting technology is quickly becoming the go-to cutting method for a variety of industries. From aerospace to the medical field, water-jet cutting is proving to be more precise and efficient than traditional cutting methods.A water-jet is a cutting tool that creates a high-velocity jet of water, usually mixed with an abrasive material. This creates a powerful cutting force that can cut through virtually any material with precision, including metal, stone, glass, and plastic. Water-jet cutting technology was developed in the 1950s, and since then, it has been continuously refined and improved, becoming one of the most versatile and effective cutting methods available today.One of the many benefits of water-jet cutting is its precision. Unlike traditional cutting methods that rely on brute force and sharp blades, water-jet cutting relies on a powerful stream of water to slice through materials with ease. This allows for incredibly intricate and precise cuts, even on difficult or complicated materials.Another benefit of water-jet cutting is its versatility. Water-jet cutters can handle a wide range of materials, from soft rubber to thick steel. This makes it an ideal choice for industries that require cutting precision on a variety of materials.The aerospace industry, for example, heavily relies on water-jet technology for the precision cutting of parts and components. With water-jet cutting, aerospace manufacturers can create intricate shapes out of tough materials such as titanium and composites, resulting in stronger, lighter-weight aircraft that perform better than ever before. Other industries, such as the medical field, also rely on water-jet cutting for precision cutting of surgical instruments and implantable devices.Water-jet cutting technology has also become more accessible in recent years, with more and more companies offering water-jet cutting services to a variety of industries. Companies like {} offer state-of-the-art water-jet cutting services that can handle large production runs or small, custom projects. By outsourcing their cutting needs, businesses can save time and money on equipment and maintenance costs while still enjoying the precision and versatility of water-jet cutting.Finally, water-jet cutting is also environmentally friendly. Unlike traditional cutting methods that produce harmful dust and debris, water-jet cutting creates minimal waste and leaves the material clean and untouched. This means less waste, fewer environmental hazards, and a safer workplace for employees.In conclusion, water-jet cutting technology is quickly becoming the go-to cutting method for businesses ranging from aerospace to medical manufacturing. With its precision, versatility, accessibility, and environmentally friendly benefits, water-jet cutting is the perfect solution for industries that require precise cutting of a variety of materials. As technology continues to improve, we can only expect to see water-jet cutting become even more essential to the industrial world.

MTConnect-Ready 3D Printer for Aerospace and Production Applications

, MTConnect, FDM, aerospace, production, 3D printing.Additive Manufacturing Magazine recently reported that the Stratasys Fortus 900 3D printer now features an MTConnect-ready interface. This is great news for those working in aerospace and other industries that require high-quality, production-grade 3D printing.The Stratasys Fortus 900 is a Fused Deposition Modeling (FDM) 3D printer designed for large, complex parts. With a build volume of 36 x 24 x 36 inches, it has the capability to produce parts that are larger than those typically produced with plastic extrusion machines. This makes it an ideal choice for aerospace applications, as well as for producing jigs, fixtures, and tooling.Incorporating the MTConnect protocol into the Stratasys Fortus 900 means that users can now monitor and control their 3D printing operations in real time. MTConnect is an open, royalty-free standard for machine tool communication that has become increasingly popular in the manufacturing industry. With MTConnect, users can easily connect machines and devices to a network, allowing them to monitor data and make informed decisions about their operations.For aerospace manufacturers, the Stratasys Fortus 900 with MTConnect-ready interface is ideal, as it provides the capability to produce production-grade parts with repeatable accuracy. Additionally, 3D printing allows for the production of complex geometries that cannot be produced with traditional manufacturing methods.Overall, the integration of MTConnect into the Stratasys Fortus 900 3D printer is a positive development for the additive manufacturing industry. By providing real-time monitoring and control, it enables users to optimize their operations, increase efficiency, and improve the quality of their products. This is especially important in industries such as aerospace, where high-quality, production-grade parts are essential.As the use of 3D printing continues to grow, we can expect to see further developments in this area, and the integration of other technologies into 3D printers. In the meantime, the Stratasys Fortus 900 with MTConnect-ready interface is a great option for those looking to produce high-quality, production-grade parts with 3D printing technology.

Discover the Art of Shaping Sheet Metal: A Comprehensive Guide

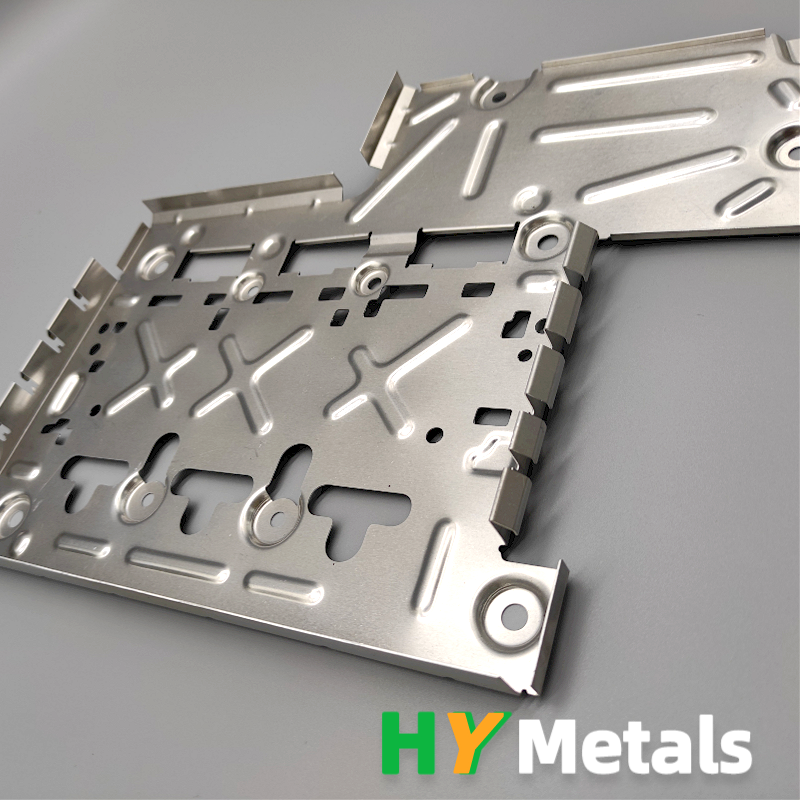

Title: Industry Leader Revolutionizes Sheet Metal ManufacturingIntroduction:In an era of constant innovation and advancement, the sheet metal manufacturing industry continues to evolve. One company, known for its groundbreaking techniques and commitment to excellence, has significantly contributed to the advancements of this sector. With their state-of-the-art production methods and cutting-edge technology, they have revolutionized the sheet metal manufacturing process, ensuring high-quality products and enhanced efficiency. Here, we delve into the key elements that make this company a leader in the industry.Research and Development:At the forefront of the company's success lies its relentless pursuit of research and development. By investing heavily in this area, they have been able to continuously discover and implement novel techniques and technologies into their manufacturing process. With an in-house team of highly skilled engineers and technicians, they consistently break new ground in the sheet metal industry. This dedication to R&D has allowed them to offer innovative solutions to their clients, overcoming challenges and meeting the ever-changing demands of the market.Advanced Machinery and Equipment:The company's commitment to cutting-edge technology is evident in its extensive use of advanced machinery and equipment. The production floor is equipped with high-precision lasers, computer numerical control (CNC) machines, and automated robotics, ensuring accuracy and consistency in every step of the manufacturing process. The integration of such advanced technology not only enhances the quality of the products but also improves overall operational efficiency, reducing production time and costs.Skilled Workforce:A company is only as good as its employees, and this industry leader understands the significance of a skilled workforce. They have assembled a team of highly trained professionals with extensive experience in sheet metal manufacturing. From machine operators and welders to quality control specialists and project managers, their employees possess the necessary expertise to meet the diverse needs of their clients. The company promotes a culture of continuous learning and advancement, providing regular training programs to keep pace with the ever-evolving industry requirements.Quality Assurance and Certifications:The company takes pride in its commitment to delivering the highest quality sheet metal products to its customers. Stringent quality control measures are in place throughout the manufacturing process to ensure that each product meets or exceeds industry standards. By employing cutting-edge inspection techniques and quality assurance protocols, they guarantee the durability, reliability, and precision of their sheet metal products. Additionally, the company holds various certifications, such as ISO 9001:2015 and ISO 14001:2015, further demonstrating their dedication to meeting global quality and environmental standards.Eco-Friendly Practices:In addition to quality manufacturing, the company prioritizes sustainability and environmental responsibility in its operations. By implementing eco-friendly practices, such as the use of energy-efficient machinery and recycling programs, they aim to minimize their carbon footprint. They continuously explore new ways to reduce waste and optimize resource utilization, contributing to a cleaner and greener planet while manufacturing superior sheet metal products.Customer-Centric Approach:Unlike many others in the industry, this company places a strong emphasis on building long-term relationships with its clients. They understand that each customer has unique requirements and tailor their services accordingly. By actively involving clients in the design process and offering personalized solutions, they ensure customer satisfaction throughout every project. The company's dedication to customer service has earned them a loyal clientele, with many returning for repeat business and referrals.Conclusion:In conclusion, this industry-leading company has revolutionized the sheet metal manufacturing industry through its commitment to research and development, advanced machinery, highly skilled workforce, quality assurance, sustainable practices, and customer-centric approach. By continually pushing the boundaries of innovation, they have set themselves apart as pioneers in the field. With their unmatched expertise and unwavering dedication to superior quality, this company will undoubtedly continue to shape the future of sheet metal manufacturing.

High-Quality Custom Radiator Parts for Your Vehicle

Custom Radiator Part: A Perfect Solution for Your Heating NeedsCustom radiator parts have become an essential component for the heating industry, offering personalized solutions for various heating systems. These parts are specifically designed to fit and function perfectly within a specific radiator system, providing better efficiency and performance. In this regard, {Company Name} has been at the forefront of delivering high-quality custom radiator parts to meet the diverse needs of its customers.{Company Name} is an industry-leading manufacturer and supplier of custom radiator parts, specializing in designing and producing tailored solutions for both residential and commercial heating applications. With years of experience and expertise in the heating industry, the company has established a solid reputation for delivering top-notch products that meet the highest standards of quality and reliability.The custom radiator parts offered by {Company Name} are meticulously engineered to align with the specific requirements of different heating systems. Whether it's a unique design, specific dimensions, or special materials, the company can cater to a wide range of customizations to ensure a perfect fit and seamless integration with the existing heating infrastructure. This level of customization not only enhances the performance of the heating system but also ensures a more efficient and cost-effective solution for the end-user.One of the key advantages of opting for custom radiator parts from {Company Name} is the ability to address complex heating challenges with tailored solutions. The company's team of skilled engineers and technicians work closely with the customers to understand their specific needs and develop customized parts that effectively meet those requirements. This collaborative approach ensures that the custom radiator parts not only enhance the overall performance of the heating system but also contribute to energy savings and reduced maintenance costs in the long run.Another noteworthy aspect of the custom radiator parts offered by {Company Name} is their exceptional durability and reliability. The company is committed to using high-quality materials and advanced manufacturing processes to ensure that every custom part is built to last. This level of attention to detail and quality control not only instills confidence in the customers but also reflects the company's dedication to delivering long-term value through its products.Furthermore, {Company Name} prides itself on its ability to provide quick turnaround times for custom radiator parts without compromising on quality. The company understands the importance of timely solutions in the heating industry and has streamlined its manufacturing processes to meet the demands of its customers efficiently. This agility in production, combined with the company's unwavering commitment to excellence, has positioned {Company Name} as a trusted partner for custom radiator solutions.In conclusion, the demand for custom radiator parts continues to grow as heating systems become more sophisticated and diverse. {Company Name} has emerged as a reliable source for high-quality custom radiator parts, offering tailored solutions to address the unique requirements of its customers. With a focus on precision engineering, durability, and timely delivery, the company has solidified its position as a preferred partner for custom radiator solutions in the heating industry. Whether it's a residential upgrade or a commercial project, {Company Name} is well-equipped to deliver custom radiator parts that exceed expectations and elevate the performance of any heating system.

High-Quality Extruded Aluminum Heatsink for Superior Thermal Dissipation

(Extruded Aluminum Heatsink is an innovative product designed to dissipate heat. It is manufactured by a leading company in the industry, known for their high-quality engineering and exceptional customer service. For many years, this company has been a trusted provider of thermal management solutions, serving a diverse range of industries.The Extruded Aluminum Heatsink is a critical component in many electronic devices, providing an effective way to manage heat generated during operation. It is widely used in applications such as computers, LED lighting, power electronics, and more. With its lightweight and durable design, the Extruded Aluminum Heatsink offers excellent thermal conductivity and efficient heat dissipation.One of the key features of this heatsink is its extruded aluminum construction, which allows for the precise shaping of the heatsink to meet specific requirements. This flexibility makes it an ideal solution for custom applications, as well as for high-volume production. The company's advanced manufacturing capabilities enable them to produce heatsinks in a wide range of sizes and shapes, ensuring a perfect fit for each unique application.In addition to its exceptional performance, the Extruded Aluminum Heatsink is also designed for easy installation and maintenance. Its sleek and compact design allows for seamless integration into various systems, and its corrosion-resistant properties ensure long-term reliability and durability. With its ability to effectively dissipate heat, the Extruded Aluminum Heatsink helps to extend the lifespan and improve the performance of electronic devices.The company behind the Extruded Aluminum Heatsink prides itself on its commitment to excellence and innovation. With a team of experienced engineers and technical experts, they are dedicated to providing cutting-edge thermal management solutions that meet the evolving needs of their customers. Their state-of-the-art facilities and stringent quality control processes ensure that each heatsink meets the highest standards of performance and reliability.Furthermore, the company's customer-centric approach sets them apart in the industry. They work closely with their clients to understand their unique requirements and provide tailored solutions that exceed expectations. Whether it's a standard off-the-shelf heatsink or a custom-designed solution, the company is committed to delivering products that deliver superior performance and value.With a proven track record of delivering high-quality thermal management solutions, the company has earned the trust and loyalty of a diverse customer base. Their reputation for excellence and reliability has firmly established them as a leader in the industry, and their Extruded Aluminum Heatsink is just one example of their commitment to innovation and superior quality.In conclusion, the Extruded Aluminum Heatsink is a cutting-edge product that showcases the company's expertise in thermal management solutions. With its exceptional performance, durability, and versatility, this heatsink is a valuable asset for a wide range of electronic applications. Backed by a company known for its commitment to excellence and innovation, the Extruded Aluminum Heatsink is a testament to the company's leadership in the industry. As the demand for efficient thermal management solutions continues to grow, the company and its Extruded Aluminum Heatsink are well-positioned to meet the evolving needs of their customers.

Sheet Metal: A Fundamental Form in Metalworking

Title: Sheet Metal Flat: Revolutionizing Industrial Fabrication ProcessesIntroduction:(sheet metal flat logo)Sheet Metal Flat is a renowned leader in the field of sheet metal fabrication. With a commitment to innovation and quality, the company continues to revolutionize the manufacturing industry. Their expertise lies in the production of thin, flat pieces of metal that can be easily cut and shaped into various forms. This article delves into the significance of sheet metal fabrication, explores the various applications, and highlights Sheet Metal Flat's contributions to this field.Importance of Sheet Metal Fabrication:Sheet metal fabrication plays a pivotal role in numerous industries, making it one of the fundamental forms used in metalworking. By utilizing industrial processes, sheet metal is transformed into thin, flat pieces which can then be molded into a variety of shapes. This versatility enables the creation of countless everyday objects that are an integral part of our lives.Applications of Sheet Metal:The applications of sheet metal fabrication are vast and diverse. From the automotive sector to construction, aerospace, and even household appliances, sheet metal is an essential component in the production of various products. It is widely used in the manufacturing of automobile parts, including body panels, chassis, and engine components due to its durability, strength, and resistance to corrosion.In the construction industry, sheet metal is utilized for roofing, facades, and structural elements due to its lightweight nature and high durability. The aerospace industry leverages sheet metal for aircraft structures, providing strength, stability, and resilience at high altitudes. In household appliances, sheet metal is employed in the manufacturing of refrigerators, stoves, and washing machines due to its ability to withstand high temperatures and repeated use.Sheet Metal Flat: Pioneers in Fabrication:Sheet Metal Flat has emerged as a reliable and innovative player in the sheet metal fabrication industry. The company's commitment to cutting-edge technology and exceptional quality has positioned them as a distinguished leader.Efficient Manufacturing Processes: Sheet Metal Flat employs state-of-the-art machinery and equipment to ensure precision and efficiency in their manufacturing processes. From laser cutting to stamping, bending, and welding, they have perfected every stage of fabrication. This enables them to deliver superior end products while ensuring timely production.Custom Solutions: Recognizing the unique requirements of each client, Sheet Metal Flat offers customized solutions tailored to suit their specific needs. Their team of experienced technicians works closely with customers, providing expert guidance and utilizing cutting-edge software to design and create flawless sheet metal components.Quality Assurance: Sheet Metal Flat is committed to delivering products of the highest quality. Rigorous quality control measures, including inspections at different stages of production, are in place to ensure that every piece meets the highest standards. By adhering to strict quality control protocols, Sheet Metal Flat has fostered long-lasting relationships with their clients.Environmental Responsibility: In an era of increasing environmental awareness, Sheet Metal Flat is committed to minimizing their carbon footprint. They have implemented eco-friendly practices such as recycling scrap metal, reducing waste generation, and incorporating energy-efficient machinery. By choosing Sheet Metal Flat, customers can align with their sustainability goals.Conclusion:Sheet Metal Flat's contribution to the sheet metal fabrication industry cannot be understated. With their innovative manufacturing processes, commitment to quality, and dedication to customer satisfaction, they have set new benchmarks in the field. As the demand for sheet metal continues to grow across various sectors, Sheet Metal Flat is poised to remain at the forefront, constantly pushing the boundaries of possibility and redefining the standards for industrial metalworking.

Fast and Accurate CNC Turning Services for Precision Parts

Lathe machines are essential tools in the world of manufacturing. They are responsible for the creation of many of the intricate components that make up various products. Among the many types of lathes available, the CNC lathe stands out as one of the most advanced and precise. If you are in need of precision CNC lathe parts, then you need to partner with a reliable and experienced company, and latency is the perfect choice.At Lathe, we specialize in offering fast and accurate CNC turning services. Our lathe department is equipped with state-of-the-art CNC lathes and proven technology, positioning us to serve our customers' needs best. Our experienced and skilled machinists have the knowledge and training required to program even the most complex turning operations. As a result, we can produce highly precise parts while maintaining a fast turnaround time.Our lathes are equipped with cutting-edge technology that enables them to deliver exceptional accuracy, regardless of the complexity of the part. Additionally, our lathes have a range of spindle speeds, allowing us to handle a wide variety of materials, including aluminum, brass, copper, stainless steel, and more.We take quality seriously at Lathe, and we have put measures in place to ensure that our customers receive parts of the highest quality. First, we use state-of-the-art quality control equipment to verify that our parts meet the required specifications. Additionally, we have a team of experienced quality control technicians who conduct regular inspections to ensure that our parts meet our high-quality standards.We understand that time is of the essence in many manufacturing processes, which is why we are committed to offering fast turnaround times. Our efficient machining processes, combined with our team of skilled machinists, enable us to produce parts quickly and efficiently.In conclusion, if you are in need of precision CNC lathe parts, you need to partner with a reliable and experienced company. At Lathe, we have the equipment, technology, and skilled personnel required to deliver high-quality parts that meet your specifications. Contact us today to learn more about our CNC turning services and how we can help you with your manufacturing needs. And if you're searching for terms like "precision CNC lathe part", you can be sure that you've come to the right place.

High-Precision CNC Machined Component: Expertly Crafted for Superior Performance

CNC Machined Component Provides High-Quality Solutions for Diverse IndustriesIn today's fast-paced and competitive manufacturing industry, the demand for precision-engineered components has never been greater. Companies across various sectors are constantly seeking reliable and efficient machining solutions to meet their specific needs. One company that has been at the forefront of providing high-quality CNC machined components for diverse industries is [Company Name].[Company Name] is a leading provider of CNC machining services, specializing in the production of custom components for a wide range of applications. With state-of-the-art facilities and a team of experienced engineers and technicians, the company is able to deliver precision-engineered parts that meet the exact specifications of its clients.The company's CNC machining capabilities are extensive, allowing it to handle projects of any size and complexity. From prototyping to high-volume production runs, [Company Name] has the expertise and resources to deliver top-quality components with exceptional accuracy and consistency. Whether it's aerospace, automotive, medical, or any other industry, the company's CNC machined components are trusted by leading manufacturers around the world.One of the key factors that sets [Company Name] apart from its competitors is its commitment to utilizing the latest technology and equipment in the industry. The company's investment in advanced CNC machining centers, cutting-edge tooling, and sophisticated software enables it to deliver superior results with quick turnaround times. By leveraging the power of modern machining technology, [Company Name] is able to achieve tight tolerances, intricate geometries, and flawless surface finishes in its components.Moreover, the company's team of skilled engineers and machinists play a pivotal role in ensuring the success of each project. By working closely with clients to understand their specific requirements, [Company Name] is able to provide tailored solutions that address their unique needs. From material selection to design optimization, the company's experts are dedicated to delivering cost-effective and reliable machining solutions that exceed expectations.One of the hallmark offerings of [Company Name] is its range of CNC machined components, which are known for their exceptional quality and performance. The company manufactures a wide variety of parts, including but not limited to, precision gears, shafts, brackets, housings, and much more. Each component is meticulously machined to the highest standards, using a wide range of materials such as aluminum, steel, titanium, and plastics.For customers in industries where quality and reliability are absolutely critical, [Company Name] is the go-to provider for CNC machined components. The company's track record of delivering top-notch parts that meet stringent industry standards has earned it a reputation for excellence and trustworthiness. Whether it's for critical aerospace applications, high-performance automotive systems, or life-saving medical devices, [Company Name] ensures that its CNC machined components deliver the utmost in precision and durability.In conclusion, [Company Name] has established itself as a premier provider of CNC machined components, offering unmatched precision, quality, and expertise to industries worldwide. With its cutting-edge technology, skilled workforce, and commitment to customer satisfaction, the company continues to be a trusted partner for businesses seeking top-quality machining solutions. As the manufacturing landscape evolves, [Company Name] remains at the forefront of delivering innovative and reliable CNC machined components that drive the success of its clients.

How to Build a Heavy CNC Milling Machine: 18 Steps with Pictures

Machine, Instructables, heavy CNC milling, epoxy granite, linear guides, building processCNC Milling Machine: A Comprehensive Guide to Building Your OwnBuilding a heavy-duty CNC milling machine is not a task for the faint-hearted. It requires a lot of different working steps and careful planning to ensure that you end up with a machine that can deliver precise and accurate results. In this blog post, we will take a closer look at the steps involved in building a big CNC machine with good milling performance, as well as the materials and equipment needed for the project.Step 1: Design and PlanningThe first step in building a CNC milling machine is to design and plan the machine. This involves deciding on the size of the machine, the materials to be used, the type of milling machine to be used, and the features and capabilities that the machine should have. It is important to have a clear understanding of the requirements before starting the project to avoid any costly mistakes down the line.Step 2: Building the MoldThe next step is to build a big and accurate mold for casting the epoxy granite. Epoxy granite is a popular material for building milling machines due to its sturdiness and vibration damping properties. The mold should be designed to ensure that it is rigid and can create a smooth surface finish. The casting process should be done carefully to avoid any air bubbles or voids that can cause inaccuracies in the finished cast.Step 3: Aligning the Linear GuidesThe linear guides play a crucial role in the accuracy and precision of the milling machine. They are responsible for guiding the cutting tool along a straight and consistent path. The linear guides should be aligned carefully to ensure that they are in perfect alignment with the cutting tool. This requires careful attention to detail and the use of precision measuring tools.Step 4: Building the Machine FrameThe frame of the milling machine should be built to be strong and rigid. The use of high-quality materials such as aluminum or steel is recommended. The frame should be designed with sufficient clearance to accommodate the linear guides and other machine components.Step 5: Assembling the MachineOnce all the components of the milling machine have been prepared, it is time to start assembling the machine. This requires careful attention to detail and a lot of patience. Each component should be installed carefully and securely to ensure that the machine is stable and can deliver precise and accurate results.ConclusionBuilding a heavy CNC milling machine is a challenging task that requires a lot of time and effort. However, with careful planning and attention to detail, it is possible to build a machine that can deliver precise and accurate results. The use of high-quality materials and precision measuring tools is essential to ensure that the machine is built to the required specifications. With the right approach, anyone can build their own CNC milling machine and take their machining capabilities to the next level.

How to Bend Steel: Tips and Techniques for Shaping Metal

Steel Bending: A Competitive Edge for Steel bending is a critical process in the construction and manufacturing industries. It involves the manipulation of steel into various shapes and forms, providing structural integrity to a wide range of products and projects. In the competitive landscape of steel fabrication, the ability to bend steel with precision and efficiency is a crucial factor that sets companies apart from their rivals. This is where comes in, offering top-notch steel bending services that cater to the needs of its diverse clientele.Established in [], has built a solid reputation as a leading provider of steel bending solutions. With state-of-the-art equipment and a team of highly skilled technicians, the company has the capability to handle a wide range of steel bending projects, from small-scale components to large structural elements. Whether it's for architectural designs, industrial machinery, or construction applications, prides itself on delivering high-quality, custom-tailored bending solutions that meet the specific requirements of its customers.The company's comprehensive approach to steel bending encompasses a variety of techniques, including cold bending, hot bending, and induction bending. These techniques allow for the manipulation of steel with precision and control, ensuring that the end result meets the exact specifications of the customer. Additionally, through the use of advanced computer-aided design (CAD) software, is able to develop accurate bending profiles and simulations, further enhancing the efficiency and accuracy of its bending processes.One of the key differentiators for is its ability to work with a wide range of steel materials, including carbon steel, stainless steel, and alloy steel. This versatility allows the company to cater to the diverse needs of its clients across different industries. Whether it's for a high-strength application that requires alloy steel or a corrosion-resistant solution using stainless steel, has the expertise and resources to deliver bendable steel solutions that meet the highest standards of quality and performance.In addition to its technical capabilities, stands out for its commitment to customer satisfaction and project collaboration. The company takes a consultative approach to understand the unique requirements of each project and works closely with its clients to develop bending solutions that are both functional and cost-effective. By fostering open communication and maintaining a customer-centric focus, builds strong partnerships with its clients, often becoming the go-to provider for their steel bending needs.Furthermore, places a strong emphasis on quality control and efficiency in its operations. The company adheres to stringent quality standards and processes to ensure that every bent steel component meets the highest level of accuracy and consistency. Through continuous improvement initiatives and investment in the latest technologies, strives to optimize its production processes, reduce lead times, and minimize waste, ultimately delivering value to its customers in the form of high-quality, competitively priced bending solutions.Looking ahead, remains committed to staying at the forefront of the steel bending industry by continuously refining its capabilities and expanding its service offerings. The company invests in ongoing training and development for its staff, as well as the latest equipment and technologies, to ensure that it can effectively address the evolving needs of the market. By staying abreast of industry trends and advancements, is well-positioned to continue delivering innovative and reliable steel bending solutions to its clients.In conclusion, is a trusted industry leader in steel bending, offering a comprehensive range of services that cater to the diverse needs of its customers. With its advanced capabilities, commitment to quality, and customer-focused approach, has established itself as a go-to provider for steel bending solutions. As the company continues to grow and innovate, it is poised to maintain its competitive edge and contribute significantly to the success of its clients in the construction and manufacturing sectors.