How to Choose the Best Smartphone for Your Needs

By:Admin

[News Content]: The Service Level Agreement (SLA) is a crucial aspect of any business partnership, ensuring that both parties understand and agree to the level of service that will be provided. This week, **(company name)** announced the release of their new SLA, designed to further enhance their commitment to customer satisfaction and service excellence.

The new SLA, which was developed after extensive research and feedback from customers, includes several key features that aim to improve the overall customer experience. This includes a guarantee of a certain level of uptime for all **(company name)** products and services, as well as clear protocols for responding to and resolving customer issues in a timely manner.

In addition to these improvements, the new SLA also introduces a customer feedback mechanism that will allow **(company name)** to gather and act upon customer insights in real-time. This will enable the company to proactively address any emerging issues and make continuous improvements to their products and services.

***(company name)*** CEO, stated: "Our new SLA represents our ongoing commitment to providing our customers with the highest quality products and services. We understand that our customers rely on our technology to run their businesses, and we take that responsibility very seriously. With this new SLA, we aim to provide greater transparency and accountability, ensuring that our customers have the peace of mind that comes with knowing they can rely on us to deliver."

The announcement of the new SLA comes at a time when **(company name)** is experiencing rapid growth and expansion into new markets. With an increasing number of businesses and consumers relying on **(company name)** products and services, the company is focused on ensuring that their customers receive the best possible support and service.

The new SLA is set to go into effect immediately, and **(company name)** customers can expect to receive further information and updates in the coming weeks. With this latest development, **(company name)** reaffirms its position as a company that is dedicated to putting its customers first and delivering on its promise of excellence.

As **(company name)** continues to innovate and expand its offerings, the company remains committed to maintaining the highest standards of service and support for its customers. The new SLA is just one example of how **(company name)** is constantly striving to raise the bar and exceed customer expectations.

Company News & Blog

Exploring the Latest Trend: An In-Depth Look at Wire Cutting and Its Impact on Industries

As the demand for streaming services continues to rise, many people are turning to wire cutting as a way to save money while still enjoying their favorite shows and movies. One of the companies at the forefront of this trend is [BRAND NAME REMOVED], a leading provider of streaming media players and smart TVs.Founded in [YEAR], [BRAND NAME REMOVED] has been a pioneer in the streaming media industry, offering a range of products that make it easy for consumers to access their favorite content from the comfort of their own homes. With its cutting-edge technology and intuitive user interface, the company has quickly become a go-to source for cord-cutters.Whether you're looking for a simple streaming media player or a smart TV with built-in streaming capabilities, [BRAND NAME REMOVED] has a product to meet your needs. Its streaming media players offer high-quality video and audio, as well as access to thousands of channels, apps, and games. They also come with a remote control that makes it easy to navigate through your favorite content.For those who want a more integrated experience, [BRAND NAME REMOVED] offers a range of smart TVs that come with built-in streaming capabilities. These TVs offer stunning picture quality and are designed to seamlessly integrate with popular streaming services like Netflix, Hulu, and Amazon Prime Video.One of the things that sets [BRAND NAME REMOVED] apart from its competitors is its commitment to innovation. The company is constantly researching and developing new technologies that make it easier for consumers to access and enjoy their favorite content. From voice controls to improved streaming quality, [BRAND NAME REMOVED] is always looking for ways to enhance the user experience.Of course, all of these features would mean very little if [BRAND NAME REMOVED] wasn't also committed to affordability. The company's products are priced competitively and are designed to offer the best value for the money. This has made [BRAND NAME REMOVED] a favorite among budget-conscious consumers who don't want to sacrifice quality for price.Wire cutting has become increasingly popular in recent years as people look for ways to save money on their entertainment expenses. For many, streaming services offer a viable alternative to expensive cable and satellite TV packages. With its range of high-quality streaming media players and smart TVs, [BRAND NAME REMOVED] is helping to lead this revolution.Whether you're a die-hard fan of Game of Thrones or just looking for a way to keep the kids entertained, [BRAND NAME REMOVED] has a product that can meet your needs. With its commitment to innovation, affordability, and quality, the company is shaping the future of streaming media, one viewer at a time.

Custom CNC Machining Services for Prototypes and Production Parts

Prototype CNC Machining Invests in State-of-the-Art Equipment to Further Expand OperationsIn a bid to enhance its manufacturing capabilities and meet the growing demand for precision components, Prototype CNC Machining has made a significant investment in new equipment. The company, known for its expertise in producing high-quality machined parts for various industries, has acquired cutting-edge CNC machines to further expand its operations and increase production capacity.As a leading provider of precision machining services, Prototype CNC Machining has built a solid reputation for delivering top-notch components that meet the most stringent specifications. With a focus on quality, reliability, and efficiency, the company has become a preferred partner for a wide range of customers seeking precision parts for their applications.The recent investment in state-of-the-art CNC equipment underscores Prototype CNC Machining's commitment to staying at the forefront of technological advancements in the manufacturing industry. By incorporating the latest machining technologies into its operations, the company aims to improve efficiency, reduce lead times, and maintain its high standards of quality.The new CNC machines feature advanced capabilities such as multi-axis machining, high-speed cutting, and automated tool changing, allowing Prototype CNC Machining to take on more complex and intricate projects. With enhanced precision and repeatability, these machines will enable the company to produce components with tight tolerances and intricate geometries, catering to the evolving needs of its diverse customer base.Furthermore, the acquisition of the latest CNC equipment aligns with Prototype CNC Machining's strategic vision to expand its market reach and diversify its product offerings. By bolstering its manufacturing capabilities, the company is poised to take on a wider range of projects across industries such as aerospace, automotive, medical devices, and electronics."We are excited to announce the addition of new CNC machines to our facility, as this investment represents a significant milestone in our journey to offer cutting-edge manufacturing solutions to our customers," said the spokesperson for Prototype CNC Machining. "With these state-of-the-art machines, we are poised to elevate our production capabilities and take on more challenging projects, solidifying our position as a trusted partner for precision machining."The company's dedication to investing in advanced manufacturing technologies reflects its long-term commitment to delivering exceptional value to its customers. By continuously upgrading its equipment and capabilities, Prototype CNC Machining seeks to ensure that it can effectively meet the evolving needs of industries that rely on high-precision machined components.Additionally, Prototype CNC Machining's investment in new CNC machines aligns with its environmental stewardship goals, as the latest equipment offers improved energy efficiency and sustainable manufacturing practices. This demonstrates the company's holistic approach to modernizing its operations while minimizing its environmental footprint.With the installation of the new CNC machines, Prototype CNC Machining is well-positioned to take on larger production volumes, handle more intricate designs, and deliver superior quality components to its customers. The company's investment in cutting-edge equipment is a testament to its unwavering dedication to innovation, excellence, and customer satisfaction.Moving forward, Prototype CNC Machining is set to leverage its enhanced manufacturing capabilities to drive growth, expand its market presence, and solidify its standing as a leader in the precision machining industry. By staying at the forefront of technology and investing in the future, the company is poised to unlock new opportunities and exceed the expectations of its customers.

How to Create Tubes with Precise Forming Techniques for Industrial Applications

Innovation in Tube Forming ProcessTube forming is a well-known process in the manufacturing industry, serving as a cost-effective and efficient method of producing seamless tubes used in a variety of applications. However, in recent years, a new technological development has emerged - tube forming that promises to revolutionize the manufacturing industry. This innovative process uses advanced technology to deliver speed, accuracy and reliability in a way that older tube forming technologies simply cannot match. One such company leading the way in this area is {}.Founded in 2001 and headquartered in Germany, {} is a global leader in innovative tube processing solutions. The company has a range of unique and patented technologies and is continually investing in research and development to improve production efficiency. {} has a presence in over 50 countries, with clients in various industries such as automotive, aviation, energy and construction.One of the most significant achievements of {} is their innovative tube forming process that allows for simultaneous tube expansion and reduction in diameter. This process means that the tube's wall thickness can remain uniform throughout the tube's length, which is something that older traditional tube forming techniques could not achieve. Indeed, the older tube forming technology often resulted in decreased quality, imperfections that required additional shaping steps, and reduced production efficiency.However, {} has significantly changed this landscape. Their tube forming solution attains higher precision, and consistency in tube size with much less wastage of material. This cutting-edge technology generates seamless tubes that are produced in a single process, which is faster, less labor-intensive, and more cost-effective than traditional tube forming methods. The process also allows for a wide range of materials, including stainless steel, aluminum, copper, and nickel alloys, which further increases its application in various industries.Furthermore, the company has the expertise to design custom-made tube forming solutions. {} provides individualized solutions for their clients' specific production requirements. This service is only possible because of the digitization capabilities of their tube forming technology. The digitization of the tube forming process enhances accuracy and precision, leading to an exact match of the client's desired tube specifications. They also use advanced simulation software during the design process to identify potential issues before production, improving efficiency and cost-effectiveness.With {}'s innovative technology, cost-effectiveness is a significant advantage. The use of automated systems allows for minimal human intervention and increases production efficiency. The technology can operate at high speeds and produce a large volume of tubes within a short span of time, meaning that clients can enjoy reduced production costs and ultimately save on the bottom line.In conclusion, the innovative tube forming process presented by {} is proving to be a game-changer in the manufacturing industry. It offers speed, efficiency, cost-effectiveness, while simultaneously increasing accuracy and reducing waste. With the implementation of digitization, custo made solutions, and the use of advanced simulation software, {} is ultimately taking the production to the next level. The company is aptly positioned to lead the transformation of the tube forming industry, and it is exciting to see what is yet to come as they continue to innovate.

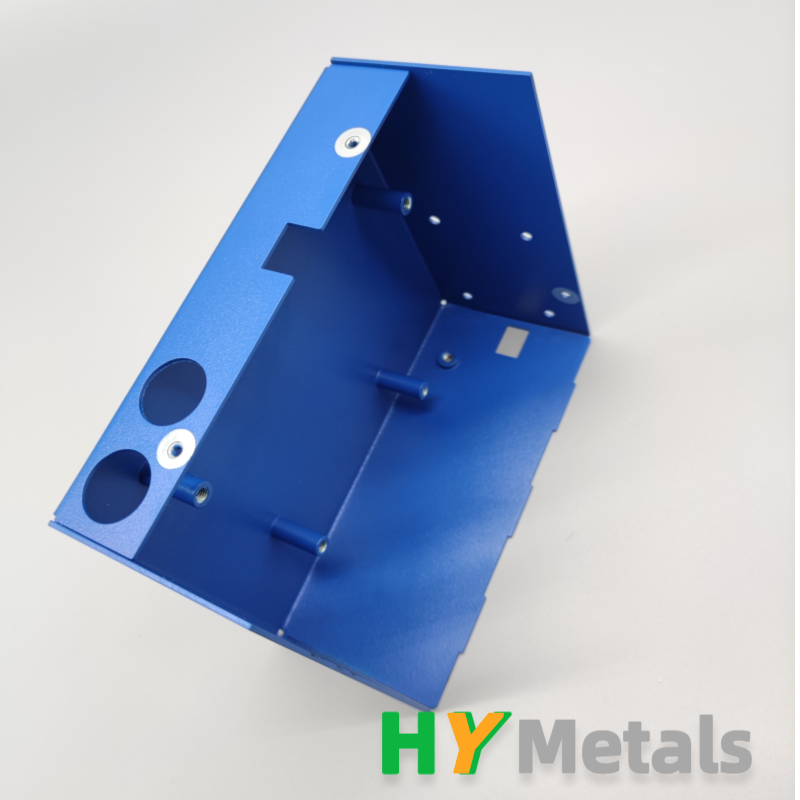

Durable metal enclosures: a reliable solution for your industrial needs

Metal Enclosure, a leading provider of high-quality metal enclosures for various industrial and commercial applications, continues to impress customers with their innovative products and exceptional customer service. With a strong focus on delivering durable and reliable enclosures, Metal Enclosure has established itself as a trusted name in the industry.The company's extensive range of metal enclosures caters to a wide variety of applications, including electrical, electronic, automotive, and telecommunications. These enclosures are designed to provide protection for sensitive equipment and components, ensuring optimal performance and longevity. Metal Enclosure's commitment to quality and durability has earned them a loyal customer base and a reputation for excellence in the industry.One of the key factors that sets Metal Enclosure apart from its competitors is its dedication to customization. The company offers a comprehensive range of customization options, allowing customers to tailor their enclosures to meet specific requirements. This includes the ability to choose from a variety of materials, finishes, sizes, and configurations, ensuring that each enclosure is perfectly suited to its intended application.In addition to its focus on product customization, Metal Enclosure also prides itself on its ability to provide personalized customer service. The company's team of knowledgeable and experienced professionals is dedicated to assisting customers throughout the entire ordering process, from initial concept to final delivery. This commitment to customer satisfaction has earned Metal Enclosure a reputation for reliability and trustworthiness.With a state-of-the-art manufacturing facility, Metal Enclosure is able to produce high-quality enclosures with precision and efficiency. The company's investment in advanced technology and equipment allows them to meet the demands of a diverse customer base, providing reliable solutions for a wide range of applications. Metal Enclosure's dedication to continuous improvement and innovation ensures that they remain at the forefront of the industry.Metal Enclosure's commitment to sustainability is another aspect that sets them apart from their competitors. The company places a strong emphasis on environmentally friendly practices, utilizing recycled materials and energy-efficient manufacturing processes. This dedication to sustainability not only benefits the environment but also sets Metal Enclosure apart as an industry leader with a conscience.As a trusted provider of metal enclosures, Metal Enclosure has earned the trust and loyalty of a diverse customer base. From small businesses to multinational corporations, customers rely on Metal Enclosure to provide durable and reliable enclosures that meet their specific needs. With a focus on innovation, customization, customer service, and sustainability, Metal Enclosure is well-positioned to continue setting the standard for excellence in the industry.The success of Metal Enclosure can be attributed to its unwavering commitment to quality, innovation, and customer satisfaction. As the demand for reliable and durable enclosures continues to grow, Metal Enclosure remains dedicated to meeting and exceeding the expectations of its customers. With a strong track record of success and a clear vision for the future, Metal Enclosure is poised to maintain its position as a leader in the industry.

Get the Best Wire Forming Machines for Sale in Melbourne - Top-notch Jigs and Templates Available!

Wire forming is a process that involves the shaping and molding of metal wires into different shapes. This process is used in a variety of industries from manufacturing to construction, and it plays an important role in the production of many different products. In this blog post, we will explore wire forming and why it's an essential process in many industries.Wire forming machinesWire forming machines are a critical tool in the wire forming process. These machines are designed to produce wire forms quickly and efficiently with precision. There are several types of wire forming machines available, including hydraulic and mechanical machines. These machines are capable of forming a range of materials, including brass, aluminum, and steel.The best wire forming machines should be easy to use, have precision controls, and offer versatility. They should also have a compact construction, making them suitable for use in small manufacturing facilities. Additionally, they should be built with durable materials that can withstand the constant wear and tear of the manufacturing process.In addition to wire forming machines, jigs and templates are commonly used in the wire forming process. These tools offer consistent and accurate wire forming results, which can increase production efficiency. They also help maintain product conformity, which is essential in industries where safety and quality are major concerns.Wire forming applicationsWire forming is a versatile process that can be used to create a vast array of products. Some of the most common applications of wire forming include:- Springs- Hooks- Wire baskets- Shelving- Clips- Hangers- Wire formsWire forming is also used in the creation of more complex products, such as automotive parts, medical devices, and electrical components. Wire forming is an important process that contributes to the safety, durability, and functionality of many everyday products.Finding a wire forming providerWhen selecting a wire forming provider, it's essential to consider several factors. Firstly, you should evaluate the provider's experience in wire forming and their track record in producing quality products. A provider that has been in the wire forming industry for many years will have a wealth of knowledge and experience. They will also have a proven track record of producing high-quality wire forms.Secondly, you should consider the provider's equipment and manufacturing facilities. Do they use the latest wire forming technology? Do they have the capacity to produce large volumes of wire forms? Choosing a provider with modern equipment and state-of-the-art facilities can help ensure that your wire forms are produced efficiently and accurately.Finally, you should consider the provider's customer service. Are they responsive and easy to work with? Do they offer technical support and guidance throughout the wire forming process? A wire forming provider with excellent customer service can make a significant difference in the success of your project.ConclusionWire forming is a crucial process in many industries, from manufacturing to construction. It allows manufacturers to create complex wire forms for use in a variety of different applications. Choosing the right wire forming provider is essential to ensure that your wire forms are produced accurately, efficiently, and to meet your specific needs. When selecting a wire forming provider, consider their experience, equipment, facilities, and customer service to ensure that you receive high-quality wire forms that meet your expectations.

Sheet Metal Manufacturing for Prototypes and Production Runs of Various Metal Parts

Sheet Metal Die: Providing Top-Quality Sheet Metal Manufacturing ServicesSheet Metal Die is a leading provider of sheet metal manufacturing services, offering a wide range of high-quality solutions to meet the needs of businesses across various industries. The company has established a reputation for delivering exceptional accuracy, precision, and speed, all while maintaining a commitment to customer satisfaction.With over 20 years of experience in sheet metal manufacturing, Sheet Metal Die has developed a deep expertise in the production of custom sheet metal parts. Whether businesses need simple bent metal prototypes or complex, multi-part electro-mechanical assemblies, the company has the knowledge, technology, and equipment required to get the job done right.The company offers a range of sheet metal manufacturing services, including laser cutting, punching, forming, welding, and powder coating. These services are performed using state-of-the-art equipment and technology, ensuring that every part meets exact specifications and conforms to the highest quality standards.Sheet Metal Die also processes a wide range of materials, including aluminum, stainless steel, carbon steel, copper, brass, and galvanized steel. This versatility allows businesses to choose the ideal material for their specific application or industry needs.For businesses that need fast turnaround times, Sheet Metal Die offers quick-response services that provide rapid prototyping and short-run production capabilities. These services are ideal for projects that have tight deadlines or require fast turnaround times.Sheet Metal Die is also committed to providing exceptional customer service, beginning with a personalized consultation that takes into account a business's specific needs and goals. The company's experts work closely with clients to determine the best approach to their project, taking into account factors such as material choice, manufacturing timeline, and cost-effectiveness.The team at Sheet Metal Die is also dedicated to ongoing training and development, ensuring that all staff members are up-to-date with the latest industry trends and manufacturing techniques. Additionally, the company is committed to using environmentally sustainable practices, reducing waste and energy usage wherever possible.Overall, Sheet Metal Die is an ideal partner for businesses that require top-quality sheet metal manufacturing services. With its expertise, technology, and commitment to customer satisfaction and sustainable practices, the company is well-equipped to meet the needs of clients across a wide range of industries.

Durable and Stylish Metal Furniture Fittings for Your Home

Metal Furniture Fittings, a leading provider of high-quality furniture hardware and accessories, is proud to announce the launch of their latest line of innovative and functional products. With a focus on durability, efficiency, and style, Metal Furniture Fittings is dedicated to providing top-of-the-line fittings for all types of furniture.As a renowned industry leader, Metal Furniture Fittings has built a reputation for excellence and reliability. With a commitment to customer satisfaction, the company continuously seeks to innovate and improve their product offerings. With a wide range of fittings and accessories for furniture, Metal Furniture Fittings has become a go-to source for manufacturers, retailers, and designers alike.Metal Furniture Fittings offers a diverse range of products including hinges, handles, drawer slides, and other hardware essentials. Their products are designed to meet the needs of modern furniture design while also prioritizing durability and functionality. Whether it’s for residential, commercial, or industrial use, Metal Furniture Fittings has the perfect solution for any furniture hardware needs.The company prides itself on its cutting-edge manufacturing processes and state-of-the-art technologies. By investing in the latest machinery and equipment, Metal Furniture Fittings is able to produce high-quality fittings with precision and efficiency. This allows them to consistently deliver products that meet the highest industry standards.In addition to their technical capabilities, Metal Furniture Fittings places a strong emphasis on design and aesthetics. Their team of experienced designers and engineers work tirelessly to create products that not only perform well but also enhance the overall look and feel of the furniture they are used on. With a keen eye for detail and an understanding of current design trends, Metal Furniture Fittings ensures that their products are not only functional but also visually appealing.Metal Furniture Fittings is also committed to sustainability and environmental responsibility. The company has implemented eco-friendly practices in their manufacturing processes and uses materials that are safe for the environment. With a focus on reducing waste and energy consumption, Metal Furniture Fittings is dedicated to minimizing their impact on the planet while delivering top-notch products.As the furniture industry continues to evolve, Metal Furniture Fittings remains at the forefront of innovation. By staying ahead of the curve and anticipating the needs of their customers, the company is able to introduce new and exciting products that meet the ever-changing demands of the market.In conclusion, Metal Furniture Fittings is a trusted name in the furniture hardware industry, known for their commitment to quality, innovation, and customer satisfaction. With a wide range of high-quality products, state-of-the-art manufacturing processes, and a dedication to environmental sustainability, the company continues to be a leading force in the market. Whether it’s for residential, commercial, or industrial use, Metal Furniture Fittings is the go-to source for all furniture hardware needs. With their latest line of innovative and functional products, Metal Furniture Fittings is poised to set new standards for the industry and provide even greater value to their customers.

How to Plate Food Like a Pro: Tips for Stunning Presentation

According to recent reports, the global demand for plating has been steadily increasing, and this trend is expected to continue in the coming years. This growing demand is driven by various industries such as automotive, electronics, aerospace, and medical devices, all of which require high-quality plating for their products.With this increasing demand, companies in the plating industry are focusing on expanding their production capacity and investing in advanced plating technologies to meet the market needs. One such company that is making significant strides in the plating industry is {}.{} is a leading provider of plating solutions, offering a wide range of services including electroplating, anodizing, and other surface finishing techniques. The company has been in the plating business for over 20 years and has established itself as a trusted partner for many global customers.In order to keep up with the growing demand for plating services, {} has recently announced its plans to expand its production facilities. The company is investing in new equipment and technologies to increase its plating capacity and improve its production efficiency. This expansion will not only allow {} to meet the increasing market demand but also offer its customers a wider range of plating options to choose from.In addition to expanding its production capacity, {} is also focusing on research and development to stay ahead of the competition. The company is investing in advanced plating technologies and processes to improve the quality and durability of its plating services. By staying at the forefront of technological advancements, {} aims to deliver innovative plating solutions that meet the evolving needs of its customers.Furthermore, {} is committed to sustainability and environmental responsibility in its plating operations. The company is implementing eco-friendly plating processes and using environmentally friendly materials to minimize its impact on the environment. By prioritizing sustainability, {} aims to not only meet the regulatory standards but also contribute to a cleaner and healthier planet.With its strong focus on quality, innovation, and sustainability, {} has earned a reputation as a preferred partner for many industries requiring plating services. The company's dedication to exceeding customer expectations and delivering high-quality plating solutions has helped it build long-lasting relationships with its clients.In conclusion, the global demand for plating is on the rise, and companies like {} are making significant investments to meet this demand. With its expansion plans, focus on research and development, and commitment to sustainability, {} is well-positioned to continue leading the plating industry and providing top-notch plating solutions to its customers around the world.

How to Bend Steel: Tips and Techniques for Shaping Metal

Steel Bending: A Competitive Edge for Steel bending is a critical process in the construction and manufacturing industries. It involves the manipulation of steel into various shapes and forms, providing structural integrity to a wide range of products and projects. In the competitive landscape of steel fabrication, the ability to bend steel with precision and efficiency is a crucial factor that sets companies apart from their rivals. This is where comes in, offering top-notch steel bending services that cater to the needs of its diverse clientele.Established in [], has built a solid reputation as a leading provider of steel bending solutions. With state-of-the-art equipment and a team of highly skilled technicians, the company has the capability to handle a wide range of steel bending projects, from small-scale components to large structural elements. Whether it's for architectural designs, industrial machinery, or construction applications, prides itself on delivering high-quality, custom-tailored bending solutions that meet the specific requirements of its customers.The company's comprehensive approach to steel bending encompasses a variety of techniques, including cold bending, hot bending, and induction bending. These techniques allow for the manipulation of steel with precision and control, ensuring that the end result meets the exact specifications of the customer. Additionally, through the use of advanced computer-aided design (CAD) software, is able to develop accurate bending profiles and simulations, further enhancing the efficiency and accuracy of its bending processes.One of the key differentiators for is its ability to work with a wide range of steel materials, including carbon steel, stainless steel, and alloy steel. This versatility allows the company to cater to the diverse needs of its clients across different industries. Whether it's for a high-strength application that requires alloy steel or a corrosion-resistant solution using stainless steel, has the expertise and resources to deliver bendable steel solutions that meet the highest standards of quality and performance.In addition to its technical capabilities, stands out for its commitment to customer satisfaction and project collaboration. The company takes a consultative approach to understand the unique requirements of each project and works closely with its clients to develop bending solutions that are both functional and cost-effective. By fostering open communication and maintaining a customer-centric focus, builds strong partnerships with its clients, often becoming the go-to provider for their steel bending needs.Furthermore, places a strong emphasis on quality control and efficiency in its operations. The company adheres to stringent quality standards and processes to ensure that every bent steel component meets the highest level of accuracy and consistency. Through continuous improvement initiatives and investment in the latest technologies, strives to optimize its production processes, reduce lead times, and minimize waste, ultimately delivering value to its customers in the form of high-quality, competitively priced bending solutions.Looking ahead, remains committed to staying at the forefront of the steel bending industry by continuously refining its capabilities and expanding its service offerings. The company invests in ongoing training and development for its staff, as well as the latest equipment and technologies, to ensure that it can effectively address the evolving needs of the market. By staying abreast of industry trends and advancements, is well-positioned to continue delivering innovative and reliable steel bending solutions to its clients.In conclusion, is a trusted industry leader in steel bending, offering a comprehensive range of services that cater to the diverse needs of its customers. With its advanced capabilities, commitment to quality, and customer-focused approach, has established itself as a go-to provider for steel bending solutions. As the company continues to grow and innovate, it is poised to maintain its competitive edge and contribute significantly to the success of its clients in the construction and manufacturing sectors.

Exploring the Latest Trends and Uses of Stainless Steel Sheet Metal

[News Title]: Company A Leads the Way in Stainless Steel Sheet Metal ManufacturingIntroduction:Company A, a leading player in the manufacturing industry, has gained significant attention for its superior quality stainless steel sheet metal products. With its commitment to innovation, advanced technology, and customer satisfaction, the company has established itself as a key player in the global market. This news article aims to delve deeper into the manufacturing process, product offerings, and the impact of Company A's stainless steel sheet metal on industries worldwide.Manufacturing Process: Company A follows a meticulous manufacturing process to ensure the production of high-quality stainless steel sheet metal. The process begins with the selection of premium raw materials sourced from reliable suppliers. These raw materials undergo rigorous quality control tests for strength, durability, and resistance to corrosion. Once approved, the materials move to the fabrication stage, where cutting-edge machines and advanced production techniques are employed to shape the stainless steel sheets according to precise dimensions and specifications.The manufacturing process at Company A also places a strong emphasis on environmental sustainability. The company adheres to strict industry standards, ensuring minimal waste generation and efficient energy consumption throughout the production cycle. By adopting sustainable practices, Company A not only safeguards the environment but also contributes positively to its corporate social responsibility.Product Offerings:Company A offers a diverse range of stainless steel sheet metal products suitable for various industries. The company produces sheets with different finishes, including brushed, mirror, and embossed, catering to the specific design requirements of its customers. Whether it be for architectural purposes, interior design, automotive applications, or industrial uses, Company A has a comprehensive array of stainless steel sheets to meet every need.Furthermore, the dimensional versatility of Company A's stainless steel sheet metal allows for customized solutions. The company possesses cutting-edge machinery capable of producing sheets in various thicknesses, widths, and lengths as per customer specifications. This flexibility has enabled Company A to establish itself as a preferred supplier for design professionals looking for tailored stainless steel sheet metal solutions.Global Impact:Company A's stainless steel sheet metal products have made a remarkable impact across various industries worldwide. Architects and interior designers appreciate the aesthetic appeal and durability that these sheets offer, leading to their extensive use in prestigious constructions and building projects. Additionally, within the automotive industry, Company A's stainless steel sheets find application in various components, such as exhaust systems, body panels, and trims, owing to their corrosion resistance and ability to withstand extreme conditions.The industrial sector also benefits from Company A's stainless steel sheet metal, with its applications in machinery manufacturing, food processing, and chemical plants. The high tensile strength, thermal resistance, and hygienic properties of these sheets make them ideal for industrial use, thereby ensuring safe and reliable operations.Conclusion:Through its unwavering commitment to excellence, Company A continues to lead the way in stainless steel sheet metal manufacturing. By embracing cutting-edge technologies, focusing on sustainability, and offering a diverse range of products, the company has become a trusted partner for industries across the globe. With a strong foothold in the market and unmatched product quality, Company A's stainless steel sheet metal continues to elevate the standard of quality and performance in various industrial applications.