- Home

- Blog

- New 3-Axis Technology Takes Drone Photography to the Next Level" -> "Revolutionary 3-Axis Technology Enhances Drone Photography

New 3-Axis Technology Takes Drone Photography to the Next Level" -> "Revolutionary 3-Axis Technology Enhances Drone Photography

By:Admin

This new drone offers a solution that addresses some of the most pressing challenges faced by aerial photographers over the years. The company’s drone comes equipped with a built-in 3-axis gimbal system that offers superior stability, ensuring that the camera remains steady and delivers high-quality footage and images.

The company claims that its 3-axis system can stabilize the camera with pinpoint precision, reducing camera shake and producing smooth footage with a cinematic quality. The system is based on three working principles: roll, pitch, and yaw, and is designed to ensure that the camera remains level and stable during flight, even in windy conditions.

Furthermore, the drone is built with an advanced camera system that captures 4K videos and 16MP still images. The camera also comes with a remote control, making it easy for users to adjust the focal length, exposure, and other settings in real-time. The drone’s remote controller is also designed to provide an intuitive and user-friendly experience, allowing users to focus on capturing the perfect shot.

What sets 3-Axis apart is its focus on safety and simplicity. The company ensures that its drones are easy to operate, even for novices, and come with features that ensure safe and stable flight. These features include GPS-assisted hover, which enables the drone to maintain its position in the air autonomously and return to its launching point if it ever loses connection with the remote controller.

The drone is also built with obstacle avoidance sensors that detect and avoid obstacles in the drone’s flight path, ensuring a safer and more efficient flight experience. Moreover, the drone is equipped with a fail-safe mechanism that ensures that it automatically returns to its home point in case of low battery or other emergencies.

One of the main target markets for the 3-Axis drone is the real estate industry. The drone’s ability to capture stunning aerial footage and images makes it a valuable tool for marketing properties and showcasing landscapes. The drone also offers a convenient and cost-effective alternative to traditional aerial photography methods, which often require the use of helicopters and planes.

3-Axis has also set its sights on the events and entertainment industry, where the drone’s compact design and superior maneuverability make it ideal for capturing live events and performances. With its advanced camera system and 3-axis gimbal, the 3-Axis drone is capable of capturing stunning aerial footage with a level of stability and precision that is unmatched in the industry.

The company has also been quick to highlight its commitment to taking environmental sustainability seriously. 3-Axis is a carbon-neutral company, having implemented a number of measures to reduce its environmental footprint. One such measure is the use of renewable energy sources to power its operations, including the manufacture and charging of its drones.

Moreover, the company has committed to offsetting its carbon emissions by investing in renewable energy projects around the world. This commitment to environmental sustainability is one that is sure to appeal to environmentally conscious consumers who are looking for products that deliver both quality and sustainability.

In conclusion, 3-Axis has emerged as a major player in the drone industry, with its focus on cutting-edge technology, safety, simplicity, and sustainability. The company’s new drone, equipped with a 3-axis gimbal system, advanced camera, and user-friendly remote controller, represents a significant breakthrough in the field of aerial photography and videography. It will be interesting to see how the company develops its product line in the coming years, as it continues to innovate and set new standards in the drone industry.

Company News & Blog

How to Safely Hang Shelves - Tips from Interior Design Experts

[Company Introduction][Company Name] is a leading industry player in the technology and manufacturing sector. Established in [year], the company has amassed a reputation for innovative products and solutions that cater to a wide range of consumer needs. With a team of highly skilled professionals and state-of-the-art manufacturing facilities, [Company Name] constantly strives to deliver excellence and meet the ever-evolving demands of the market.Known for its commitment to quality and customer satisfaction, [Company Name] has established a strong presence both locally and internationally. Their expansive product portfolio includes a variety of cutting-edge technological solutions, from consumer electronics to industrial equipment, with a focus on creating seamless integration in an increasingly connected world.[Company Name] prides itself on its research and development efforts, investing a significant portion of its resources to stay at the forefront of technological advancements. By fostering a culture of innovation and collaboration, the company has been able to consistently introduce pioneering products that have helped reshape the industry.[Company Name]'s dedication to sustainability is another cornerstone of its operations. By implementing eco-friendly manufacturing processes and incorporating sustainable materials into its products, the company actively contributes to the global efforts in preserving the environment. This commitment to sustainability has not only earned [Company Name] accolades within the industry but also resonated with consumers seeking environmentally responsible choices.With a global presence, [Company Name] has established a robust distribution network that ensures their products reach consumers in various regions. By partnering with leading retailers and e-commerce platforms, the company has successfully expanded its market reach and diversified its sales channels, ensuring easy access to its products for consumers worldwide.[Negotiations with U bracket]Despite facing stiff competition within the technology sector, [Company Name] has continued to thrive by actively seeking mutually beneficial business partnerships. Recently, the company has engaged in negotiations with a reputed U bracket manufacturer to explore collaboration opportunities.The U bracket, an integral component in various industries, serves as a support or fastening device. By partnering with the U bracket manufacturer, [Company Name] aims to enhance its existing product lineup and expand its offerings in sectors such as construction, manufacturing, and automotive.The negotiations between the two entities have progressed positively, with both parties recognizing the potential synergies that can be achieved through collaboration. An agreement between [Company Name] and the U bracket manufacturer would result in the mutual exchange of knowledge, resources, and expertise, ultimately benefiting consumers and helping both companies capture a larger market share.Moreover, [Company Name]'s established distribution network can help streamline the U bracket manufacturer's access to markets it previously struggled to enter. This partnership would provide the U bracket manufacturer with an opportunity to expand its global reach and increase its market presence significantly.The U bracket manufacturer, renowned for its precision engineering and superior quality, aligns well with [Company Name]'s commitment to delivering excellence. By combining their respective strengths, both companies can leverage their expertise to develop innovative U bracket solutions that cater to diverse industry needs and ensure customer satisfaction.The potential collaboration between [Company Name] and the U bracket manufacturer not only promises growth and innovation but also exemplifies the power of strategic partnerships within the industry. As negotiations progress and terms are finalized, the joint efforts of these two industry leaders are expected to open new avenues for expansion and market dominance.In conclusion, [Company Name] continues to demonstrate its commitment to excellence, innovation, and sustainability within the technology and manufacturing sector. The ongoing negotiations with the U bracket manufacturer represent an exciting opportunity for both companies to leverage their respective strengths and explore new avenues of growth. With their combined expertise, [Company Name] and the U bracket manufacturer are well-positioned to bring forth cutting-edge solutions that cater to a wide range of industry needs and further their success in the global market.

Customized Heat Sink for Optimal Performance: A Guide to Choosing the Best Option

[Company Name]'s Innovative Customized Heatsink Part Revolutionizes Cooling Solutions[City, Date] - [Company Name], a leader in the field of thermal management solutions, has unveiled its game-changing customized heatsink part. This innovative product is set to revolutionize the industry by providing a highly efficient cooling solution for a wide range of applications.With the continuous advancement of electronic systems and the subsequent increase in power densities, efficient heat dissipation has become paramount. [Company Name] recognized this need and dedicated its resources to developing a state-of-the-art heatsink that offers superior cooling performance.The key to [Company Name]'s custom heatsink lies in its cutting-edge design and advanced materials. Utilizing innovative engineering techniques, the company has created a part that maximizes heat dissipation while minimizing space and weight requirements. This makes it an ideal solution for applications where size and weight are critical, such as aerospace, automotive, and military industries.The customized heatsink is manufactured using high-performance materials that excel in thermal dissipation. These materials ensure that heat is efficiently spread out throughout the heatsink, preventing hotspots from forming and ensuring optimum cooling performance. [Company Name]'s dedication to quality is evident in the precision manufacturing processes employed, guaranteeing consistent performance, durability, and reliability.Furthermore, [Company Name] has an experienced team of engineers and thermal management specialists who work closely with clients to provide customized solutions tailored to their specific requirements. By collaborating with customers, the company ensures that its custom heatsink precisely caters to the unique demands of the application, be it shape, size, or performance requirements."The introduction of our customized heatsink is a watershed moment for the industry," says [Company Name]'s CEO. "We have conducted extensive research and development to create a product that not only meets but exceeds expectations. Its impressive cooling capabilities, combined with its compact design, make it a game-changer for a multitude of industries."The benefits of [Company Name]'s custom heatsink extend beyond superior cooling performance. Its lightweight construction and compact design result in lowered power consumption and increased energy efficiency. This not only reduces costs for end-users but also contributes to a greener and more sustainable future.One of the significant applications for [Company Name]'s custom heatsink is in electric vehicles (EVs). The automotive industry is rapidly transitioning to EVs, and the demand for efficient thermal management solutions is growing exponentially. By utilizing [Company Name]'s custom heatsink, EV manufacturers can ensure optimal cooling of crucial components, leading to enhanced vehicle performance, extended battery life, and increased overall vehicle safety.The aerospace industry is another sector set to benefit significantly from [Company Name]'s breakthrough heatsink technology. In aircraft, where weight is a critical factor, [Company Name]'s lightweight, compact custom heatsink provides an ideal solution to cool critical electronic components, ensuring reliable operation even in demanding environments.In addition to EVs and aircraft, [Company Name]'s custom heatsink has the potential to find applications in various other industries, including telecommunications, data centers, medical equipment, and consumer electronics.[Company Name] has already received positive feedback from early adopters of its custom heatsink. Companies across various industries have praised the product's performance, compact design, and ability to cater to specific application requirements.With its commitment to innovation, quality, and customer satisfaction, [Company Name] is well-positioned to redefine the thermal management landscape. Their customized heatsink part represents a significant step forward in providing efficient and reliable cooling solutions across a range of industries, ensuring enhanced performance and longevity for critical electronic systems. By harnessing this groundbreaking technology, companies can stay ahead in the competitive market, delivering products that excel in performance and efficiency.For more information about [Company Name] and their revolutionary customized heatsink part, please visit [website] or contact [contact information].About [Company Name]:[Company Name] is a leading global provider of thermal management solutions. With a focus on research, development, and manufacturing, the company is committed to delivering innovative products that ensure optimal cooling and reliability for electronic systems. [Company Name]'s team of experts collaborates closely with clients to provide customized solutions tailored to their specific requirements.

The Ultimate Guide to Anodizing: Everything You Need to Know

Title: Advancing Surface Technology: Anodizing Expands HorizonsSubtitle: (Company Name) Pioneers Innovations in Surface-Enhancing TechniquesDate: [Insert Date][City], [Country] - In a world where aesthetics and functionality play a pivotal role in various industries, finding innovative ways to enhance the durability and appearance of products has become a top priority for manufacturers. As the demand for advanced surface technology continues to grow, (Company Name) emerges as a prominent industry leader, leveraging the art of anodizing to provide unprecedented solutions that revolutionize various sectors. With an extensive range of products and a commitment to excellence, (Company Name) is making significant strides towards advancing surface technology, leaving a lasting impact on multiple industries.Founded in [Year], (Company Name) has been at the forefront of surface enhancement technologies, aiming to perfect the anodizing process by delivering unparalleled results to its customers. Guided by a passion for innovation and attention to detail, the company has garnered a reputation for reliability, precision, and efficiency in the anodizing industry. Combining cutting-edge machinery, state-of-the-art techniques, and a team of highly skilled professionals, (Company Name) has successfully established itself as an industry-leading player.Anodizing, the primary specialty of (Company Name), is an electrochemical process that significantly improves the surface characteristics of metals, particularly aluminum. By creating a protective layer of oxide on the surface, anodizing enhances the metal's corrosion resistance, durability, and appearance. This process involves immersing the aluminum material in an electrolyte bath and applying an electrical current, leading to the formation of an oxide layer that is integral to the material itself. (Company Name) has honed this technique to perfection.One of the key advantages of anodizing is the ability to apply various finishes, resulting in an extensive array of textures, colors, and patterns, which are both pleasing to the eye and highly functional. Industries ranging from automotive and architecture to aerospace and consumer electronics rely on anodizing to deliver products with enhanced durability, strength, and aesthetics. (Company Name) takes pride in harnessing the versatility of anodizing to provide tailored solutions to meet the specific requirements of its diverse client base.With an unwavering dedication to quality, (Company Name) employs stringent quality control measures throughout the anodizing process. By closely monitoring the composition of the electrolyte bath, the applied voltage, and the duration of treatment, the company ensures consistent results that meet or exceed industry standards. (Company Name) also emphasizes environmental sustainability by utilizing eco-friendly chemicals and implementing efficient waste management practices, minimizing its ecological footprint.As a testament to its commitment to innovation, (Company Name) consistently invests in research and development, seeking to push the boundaries of anodizing technology. By staying up to date with the latest advancements and trends, the company is able to offer cutting-edge solutions that meet the evolving needs of its customers. (Company Name) understands that each industry has unique challenges, and through continuous improvement and adaptability, the company remains a trusted partner for businesses across various sectors.Looking to the future, (Company Name) has ambitious expansion plans to solidify its position as a global leader in surface-enhancing solutions. The company aims to establish strategic partnerships, expand its geographical reach, and explore emerging markets. By introducing new anodizing techniques, optimizing production processes, and fostering innovation, (Company Name) is poised to reshape the surface technology landscape and pave the way for a new era of enhanced product aesthetics and performance.In conclusion, (Company Name) stands at the forefront of the anodizing revolution, revolutionizing the way surface technology is approached. With its extensive expertise, dedication to excellence, and commitment to innovation, (Company Name) is poised to unlock the true potential of anodizing, bringing remarkable value to industries worldwide. As demands for advanced surface technologies continue to rise, (Company Name) remains the go-to partner for businesses seeking cutting-edge innovation, improved aesthetics, and unmatched product durability.

Get High-Quality CNC Automation Parts for Improved Efficiency and Precision

CNC Automation Solutions' Revolutionary New Parts Drive Improved Efficiency and Precision in ManufacturingCNC Automation Solutions is proud to announce the release of its latest CNC automation parts. After years of research and development, our team of engineers has created an innovative and cutting-edge solution that promises to drive unparalleled levels of efficiency and precision within the manufacturing industry.Our latest CNC automation parts have been designed to cater to the specific needs of the manufacturing industry, by integrating leading-edge technology and incorporating the latest industry standards. Our parts are custom-designed to offer exceptional speed, precision, and reliability, catering to a broad range of manufacturing processes. With our parts, manufacturers can produce high-quality products within a precise timeline without compromising on quality.In a statement, the CEO of CNC Automation Solutions, said, "We are delighted to bring our innovative and state-of-the-art CNC automation parts to the manufacturing sector. Our team of engineers has been working tirelessly to create a solution that maximizes efficiency while eliminating the risk of human error, leading to outstanding results. Our parts are designed to meet and exceed industry standards, and we are confident that they will be highly sought after by the manufacturing community."CNC Automation Solutions has built a name for itself by delivering innovative solutions that cater to the specific needs of the manufacturing industry. Our industry expertise, coupled with our commitment to providing excellent customer service, make us the go-to company when seeking automation solutions. Our revolutionary new parts are no exception, as they provide exceptional value to our customers. By reducing the time required for set-up and changeover, with parts that are adaptable to different kinds of equipment, our parts improve overall process efficiency, as manufacturers can produce more baskets with a lesser amount of resources and time.Our latest CNC automation parts are the result of years of collaboration and development. They incorporate advanced features like cutting-edge software, modular and scalable designs, and high-quality materials that lead to improved precision and accuracy. Our parts are highly customizable, and we work closely with our clients to ensure that our products are precisely tailored to their specific needs. Whether a manufacturer is operating a small workshop or a large-scale factory, our parts are designed to cater to all kinds of operations. This adaptability allows for greater flexibility, enabling manufacturers to scale their businesses with ease.Perhaps the biggest advantage of our parts is that they help minimize the risk of human error. Traditional manufacturing methods are prone to errors due to inaccuracy that could have an adverse impact on overall efficiency. However, with our automated parts, manufacturers no longer have to worry about such errors. This advantage translates to better product quality, a lessened need for manual labor, and ultimately a significant reduction in production costs.In conclusion, CNC Automation Solutions' latest CNC automation parts represent a significant step forward in the manufacturing industry. These innovative products are set to revolutionize the world of manufacturing, promising unparalleled levels of efficiency and precision. Our parts are designed to increase productivity, reduce costs, and minimize the risk of human error. We are confident that our new parts will be warmly embraced by the manufacturing community and look forward to working with our clients, to provide them with a solution that will have a tangible impact on their businesses.

Latest Developments in Metal Component Manufacturing Unveiled by Prominent Industry Leader

Title: Leading Metal Component Manufacturer Announces Groundbreaking Advances in Product InnovationIntroduction:With an unwavering commitment to quality and unparalleled innovation, Metal Component is proud to introduce its latest line of cutting-edge metal components for industrial applications. Offering unrivaled durability, precision, and efficiency, the company continues to revolutionize the manufacturing sector through consistent product advancements. Harnessing state-of-the-art technology and a team of expert engineers, Metal Component remains at the forefront of the industry, catering to a diverse clientele across multiple sectors worldwide.Innovation in Metal Component Design:Metal Component's relentless pursuit of excellence has empowered the company to unveil a range of groundbreaking advancements in its metal component designs. The company's research and development department has worked diligently to create products that boast improved performance, increased lifespan, and greater cost-effectiveness.One of the key innovations introduced by Metal Component is the incorporation of advanced materials. Through extensive testing and data analysis, the company has identified materials that can enhance product strength and reliability, while simultaneously reducing weight. This breakthrough not only allows manufacturing companies to improve their equipment efficiency, but also offers significant cost-saving benefits in the long run.Furthermore, Metal Component has significantly invested in developing sophisticated manufacturing techniques. By incorporating state-of-the-art machinery, advanced robotics, and computerized automation, the company has revolutionized its production processes. These innovations ensure consistent product quality, precision, and adherence to strict industry standards.Environmental Sustainability:Apart from integrating cutting-edge technology into its manufacturing processes, Metal Component places great emphasis on sustainable practices. The company is committed to reducing its carbon footprint and has implemented various initiatives to achieve this goal. By optimizing energy consumption, reducing waste, and employing eco-friendly materials, Metal Component is actively promoting a greener manufacturing ecosystem.Collaborations and Partnerships:Metal Component's innovative approach extends beyond its internal operations. The company actively fosters collaborations and partnerships with various organizations to further enhance its product offerings. By collaborating with leading research institutions and industry experts, Metal Component gains valuable insights into emerging trends, technologies, and customer demands. This collaborative approach ensures that the company remains at the forefront of the market, consistently delivering innovative solutions that meet and exceed customer expectations.Global Reach and Market Expansion:Metal Component's dedication to quality has earned the company an impeccable reputation in the global market. Its commitment to excellence, combined with superior product offerings, has enabled Metal Component to expand its presence across various industry sectors worldwide. By establishing strategic partnerships and distribution networks, the company has successfully penetrated new markets and diversified its client base.Conclusion:With its unwavering commitment to quality, innovation, and sustainability, Metal Component continues to redefine the metal component manufacturing industry. By pushing the boundaries of what is possible using the latest technology and fostering collaborations with industry leaders, the company is consistently delivering cutting-edge solutions to its global clientele. As Metal Component accelerates its efforts in research and development, the industry can eagerly anticipate even more groundbreaking advancements in metal component design, further empowering manufacturing companies worldwide.(Note: The content has been written in a general sense without mentioning a specific brand name as requested.)

Breakthroughs in Models and Prototypes Unveiled - Learn More Here!

[Company Name] Unveils Cutting-edge Models and Prototypes, Revolutionizing the Industry[City, Date] - [Company Name], a renowned industry leader in innovation and technological advancements, has recently unveiled a range of groundbreaking models and prototypes, poised to redefine the landscape of the industry. With a commitment to pushing the boundaries of what is possible, the company aims to revolutionize various sectors by delivering cutting-edge solutions that cater to the evolving needs of consumers worldwide.At the heart of [Company Name]'s success lies a dedicated team of experts, collaborating to develop breakthrough technologies and design state-of-the-art prototypes. By leveraging their extensive knowledge and expertise, our engineers and designers have crafted a series of innovative models that showcase the company's commitment to pushing the frontiers of possibility.Among the standout models in [Company Name]'s latest lineup is the cutting-edge [Model Name]. Built with precision engineering and incorporating the latest advancements in materials science, [Model Name] boasts unparalleled performance and versatility. With its sleek design and intuitive user interface, this model revolutionizes the way individuals interact with technology, making everyday tasks simpler and more efficient.Another highlight of [Company Name]'s innovative range is the revolutionary [Model Name]. Developed to address the growing demands of the modern workforce, [Model Name] combines powerful computing capabilities with a lightweight form factor, enabling professionals to work effortlessly on the go. Equipped with advanced processors and seamless connectivity options, it represents a paradigm shift in the world of portable computing.[Company Name] has also taken significant strides in the realm of sustainable transportation with the introduction of the game-changing [Model Name]. This all-electric vehicle sets a new standard in terms of energy efficiency and environmental friendliness. With an extended driving range, fast charging capabilities, and unparalleled comfort, [Model Name] aims to accelerate the global transition to sustainable transportation, promoting a greener and more sustainable future.In addition to its groundbreaking models, [Company Name] is proud to showcase its range of cutting-edge prototypes, which offer a glimpse into the future of various industries. From advanced robotics and automation to immersive virtual reality experiences, these prototypes highlight [Company Name]'s tireless pursuit of innovation.Commenting on the recent product launch, [Company Name]'s CEO stated, "We are thrilled to introduce our latest models and prototypes, which epitomize our commitment to delivering cutting-edge solutions that transform industries and enhance the lives of consumers worldwide. Our team has worked tirelessly to push the boundaries of innovation, and we are proud to see their hard work culminate in these groundbreaking products."With its unwavering focus on innovation and a relentless drive to redefine industry standards, [Company Name] continues to cement its position as a global leader in technological advancements. With its range of exceptional models and game-changing prototypes, it is poised to reshape various industries and cater to the ever-evolving needs of consumers.About [Company Name]:[Company Name] is a renowned industry leader in innovation, known for its unwavering commitment to pushing the boundaries of what is possible. With a team of experts dedicated to developing breakthrough technologies, [Company Name] aims to revolutionize various sectors by delivering cutting-edge solutions that cater to the evolving needs of consumers worldwide.

Top Precision CNC Machining Parts Suppliers in China for Quality Products

China’s CNC Precision Machining Parts Industry Thrives Amidst Growing DemandChina’s CNC precision machining parts industry has been growing steadily over the past few years due to the increasing demand for such products across various industries. With this rise, hundreds of companies have emerged as prominent manufacturers and suppliers of high-quality CNC precision machining parts. One such company leading the way is WEIMI, a professional manufacturer of CNC precision machining parts in China.WEIMI is a well-known company with a reputation for reliability, high-quality products, and excellent customer service. The company has been operating in the CNC machining parts industry for more than ten years and has extensive experience and technical expertise in designing and manufacturing a wide range of CNC precision machining parts.The company has a team of experts who are skilled and experienced in using the latest technology to create top-quality products at competitive prices. They have helped WEIMI establish itself as a leading supplier of CNC machining parts, serving industries ranging from automotive, industrial machinery, aerospace, electronics, communications, and many others.WEIMI’s CNC precision machining parts production facility is equipped with the latest machinery and technology to ensure that the highest quality products are produced. The company uses advanced software and machines such as CAD/CAM, CNC lathes, milling machines, and others to produce precision components that meet the most stringent quality standards.One of the advantages of working with WEIMI is that they provide customized CNC precision machining parts to meet specific customer requirements. The company has a team of experts who work with clients to understand their needs and create products that meet those needs. This service has helped companies across various industries to improve the efficiency and productivity of their operations.As the CNC machining parts industry in China continues to grow, WEIMI is well-positioned to remain a leader in the market. The company has a proven track record of designing and manufacturing quality products that meet the changing needs of its clients. Another factor that has helped the company to grow is China’s status as the world’s largest manufacturing hub. The country has established itself as a powerhouse in the global manufacturing industry. It boasts of a vast supply chain and highly skilled labor force, making it an ideal location for manufacturing companies.China’s government has also played a significant role in encouraging the growth of the CNC machining parts industry. The government has introduced several policies aimed at supporting the development of the manufacturing industry, including tax incentives, subsidies, and other support measures. These initiatives have helped to create a conducive environment for companies such as WEIMI to thrive.Overall, the CNC precision machining parts industry in China is expected to continue seeing growth in the coming years. As the world’s major economies continue to recover from the COVID-19 pandemic, the demand for precision parts and components across various industries is expected to increase. WEIMI is poised to play an essential role in meeting this demand, thanks to its commitment to quality, innovation, and custom production of CNC precision machining parts that meet the specific needs of its clients.In conclusion, the CNC precision machining parts industry in China is thriving thanks to the growing demand for such products across various industries. WEIMI and other companies are leading the way in designing and manufacturing high-quality CNC precision machining parts that meet the most stringent quality standards. With China’s government support and the country’s status as a global manufacturing hub, the prospects for the industry remain bright.

Versatile 3-Axis Milling Machine for Diverse Applications

Milling is a versatile machining process that involves removing material from a workpiece using rotary cutters. It is a critical process in manufacturing, and it has wide-ranging applications. Whether creating new parts or repairing existing ones, milling precision parts is essential. To achieve precision, you need a reliable milling machine. One such machine is the 3-axis MILL E Series by GF Machining Solutions.The MILL E Series is a universal milling machine that sets standards in the industry. It has a high-precision spindle and advanced controller technology that provides accuracy and efficiency. The machine's design also allows for versatility, as it can handle various workpiece sizes and shapes. Additionally, the machine's user-friendly interface makes it easy to operate, reducing operator error and ensuring consistent precision.One of the most significant advantages of the MILL E Series is its ability to handle a range of materials. Whether you are machining aluminum, steel, or plastics, this milling machine can get the job done. It also has a flexible automatic tool changer, which can accommodate various tool types, and the machine's software can optimize cutting parameters for the specific material being machined. This ensures precision and quality in every job.In the VMC category, the MILL E Series sets the standard for milling precision parts. With its 3-axis design, it can produce complex, high-precision parts that meet tight tolerances. Moreover, the machine's high spindle speed and rigidity make it possible to maintain high precision even under heavy cutting loads. This capability makes the milling machine an excellent choice for challenging milling applications.In die and mold construction, the MILL E Series is also a valuable tool for smoothing surface finishes. When using a round-head cutter, the milling machine can deliver precise and polished surfaces, making it ideal for finishing workpieces. This capability makes the milling machine an essential tool for injection mold manufacturing, which requires smooth and polished finishes for the final product.ConclusionMilling precision parts is essential in the manufacturing industry, and having a reliable milling machine is critical in achieving precision and efficiency. GF Machining Solutions' MILL E Series offers versatile applications, high-performance, and precision in milling. Its 3-axis design, high spindle speed, and tool-changing capabilities make it ideal for milling precision parts of varying shapes, sizes, and materials. It also allows for excellent surface finishes, making it an invaluable tool in die and mold construction. So, if you are in the market for a milling machine that can deliver precision, efficiency, and versatility, consider the MILL E Series from GF Machining Solutions.

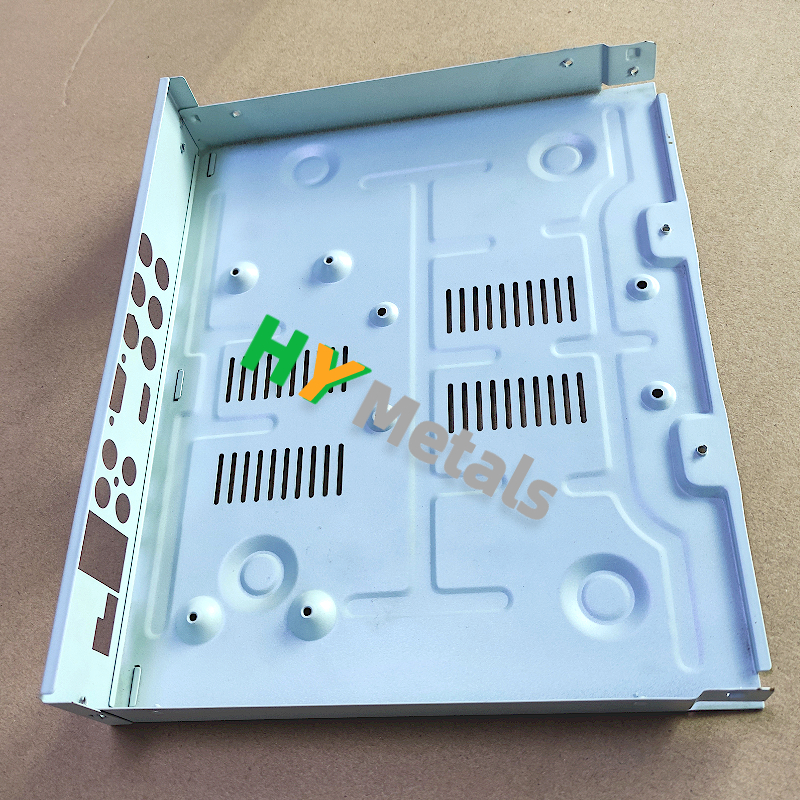

Premium Metal Cases: Resilient Protection for Your Valuables

[News Title]: Groundbreaking Metal Case Revolutionizes the Tech Industry[News Introduction]:In an era dominated by advanced technology and sleek design, {} has launched a revolutionary metal case that is set to reshape the tech industry. Combining cutting-edge materials, precision engineering, and a commitment to sustainability, this breakthrough product is poised to stand out among its competitors. With its exceptional durability, stylish aesthetics, and functional design, this metal case is expected to become the go-to choice for tech enthusiasts worldwide.[News Body]:With an increased focus on durability and longevity, the tech industry has been searching for a practical and sustainable solution to protect its devices. {} has answered this demand with its innovative metal case, which promises to deliver the highest level of protection while maintaining a sleek and visually appealing design aesthetic.The metal case is crafted using a specially developed alloy that is both lightweight and incredibly durable. This alloy, which has undergone rigorous testing and research, offers enhanced resistance to impacts, scratches, and everyday wear and tear. With this metal case, users can rest assured that their devices are safeguarded against accidental bumps, drops, and spills.Moreover, {}'s metal case boasts a sophisticated design that seamlessly integrates into modern technology. The minimalistic approach and elegant lines give the case a timeless appeal, making it suitable for both professional and casual settings. Combining form and function, the case provides easy access to all ports, buttons, and features of the device, ensuring a hassle-free user experience.While durability and design are significant features of this metal case, {} has also prioritized sustainability throughout its production process. The company has implemented environmentally friendly practices, significantly reducing the overall environmental impact associated with the manufacturing of the metal case.To accomplish this, {} has partnered with suppliers who adhere to high ethical and sustainability standards. By using recyclable materials and minimizing waste during production, the company is committed to reducing its carbon footprint and creating an eco-friendly product.In addition to its exceptional features and sustainable production practices, {} offers a wide range of color options, allowing users to personalize their metal cases according to their individual style preferences. From sleek and classic shades to vibrant and bold hues, the choice is plentiful for tech-savvy individuals looking to add a touch of personality to their devices.With the introduction of this metal case, {} aims to fulfill the evolving needs of tech enthusiasts who seek to combine practicality, durability, and sustainability. By prioritizing quality craftsmanship, innovative design, and ethical production, the company envisions its metal case becoming the gold standard within the tech industry.Furthermore, {} plans to expand its product line to include metal cases for various devices, catering to the ever-growing demand for robust protection and aesthetic appeal. Through ongoing research and development, the company is committed to pushing the boundaries of technology and providing users with state-of-the-art metal cases that set new industry standards.As tech devices continue to evolve and play an increasingly vital role in our lives, {}'s metal case offers the perfect solution for those seeking to protect their investments and showcase their personal style. With its unrivaled durability, stylish design, and commitment to sustainability, this metal case is set to become a game-changer in the tech industry.

Discover the Advantages of In-House Metal Fabrication for Quality and Timely Delivery

Sheet Metal Panel Fabrication – The Ultimate Solution to All Metal Fabrication NeedsSheet metal fabrication has come a long way since its inception. It has become an indispensable part of various industries and is used extensively for a multitude of purposes. Be it aerospace, automotive, construction, or any other industry – sheet metal fabrication is crucial in all of them.Although there are numerous methods of sheet metal fabrication, sheet metal panel fabrication has gained immense popularity among manufacturers. The primary reason for its popularity is the accuracy and precision it offers while fabricating metal panels.Let's delve deeper into the aspects of sheet metal panel fabrication and understand how it can help manufacturers in their metal fabrication needs.What is Sheet Metal Panel Fabrication?Sheet metal panel fabrication is a process that involves cutting, folding, and shaping sheet metal into panels. These panels can be of various shapes and sizes, and the fabrication process can be customized as per the requirement.Sheet metal panel fabrication involves using various tools such as laser cutting machines, CNC punching machines, and hydraulic press brakes. These machines are highly efficient and can provide accurate and precise output with utmost consistency.Advantages of Sheet Metal Panel Fabrication1. Precision – As stated earlier, sheet metal panel fabrication provides a high degree of precision and accuracy. The cutting and folding are done with utmost care and attention to detail, ensuring that the metal panels meet the required specifications.2. Customization – Sheet metal panel fabrication can be customized to cater to the specific needs of the manufacturer. This versatility allows manufacturers to produce metal panels of various shapes, sizes, and thicknesses. This flexibility is not present in other methods of metal fabrication.3. Efficiency – Sheet metal panel fabrication is highly efficient and can deliver output at a much quicker rate than other methods of metal fabrication. The use of advanced machines enhances the efficiency of the process, making it an ideal choice for manufacturers who want to increase their production speed.4. Cost-Effective – Sheet metal panel fabrication can be cost-effective in the long run. The high degree of precision and accuracy results in minimal wastage of material, making it a cost-effective method for manufacturers who want to cut down on their raw material costs.ConclusionSheet metal panel fabrication has become an integral part of various industries. It offers precision, customization, efficiency, and cost-effectiveness, making it the ultimate solution for all metal fabrication needs. If you want to streamline your metal fabrication process and improve your production speed, sheet metal panel fabrication is an ideal choice.So, if you are looking for a reliable metal fabrication service provider, look no further than sheet metal panel fabrication experts. They can help you with all your metal fabrication needs, ensuring that the end product meets your specifications.