Top Quality Custom Metal Component for Your Needs

By:Admin

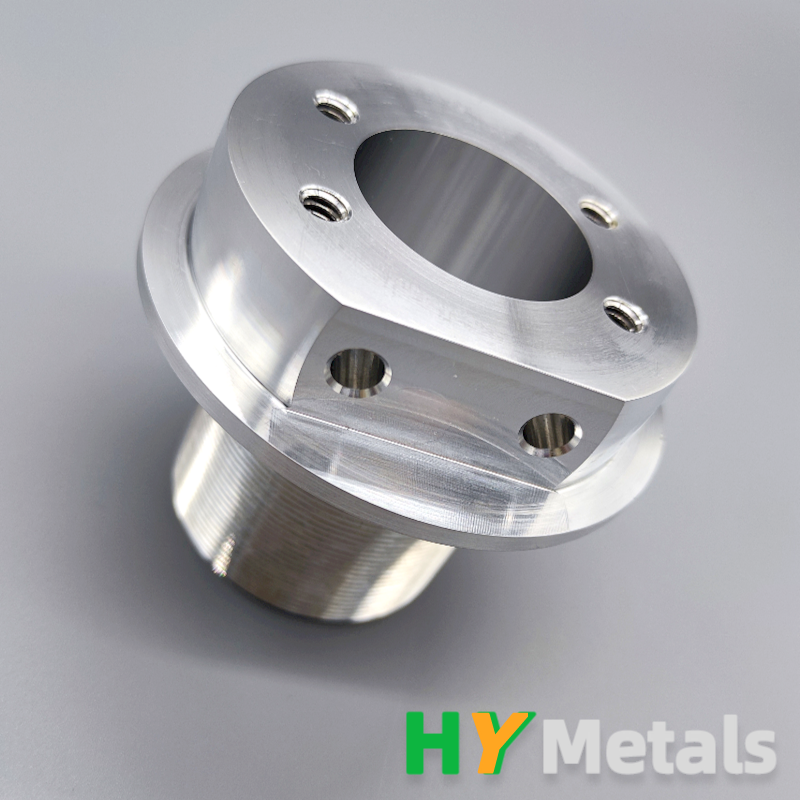

The new product line, which includes a variety of custom metal components, is the result of years of research and development by the team at Custom Metal Component. Using the latest in cutting-edge technology and state-of-the-art equipment, the company has been able to create a range of metal components that offer unparalleled strength, durability, and performance.

One of the key features of the new product line is the company's use of advanced materials, such as high-strength steel and aluminum alloys, which have been specifically chosen for their ability to withstand the most demanding operating conditions. This means that the new metal components are able to perform reliably in the most challenging environments, making them ideal for use in a wide range of applications.

In addition to their exceptional durability, the new metal components from Custom Metal Component also offer a high degree of precision and accuracy. This is thanks to the company's investment in state-of-the-art manufacturing processes, which allow for the production of components with incredibly tight tolerances and exacting specifications. As a result, customers can be assured that the metal components they receive from Custom Metal Component will meet the most exacting standards of quality and performance.

The new product line from Custom Metal Component is already attracting attention from a wide range of industries, with companies in sectors such as automotive, aerospace, and manufacturing expressing strong interest in the company's innovative metal components. This is due in no small part to the company's reputation for delivering superior products and exceptional customer service, as well as its ability to tailor its components to the precise needs of each individual customer.

For example, the automotive industry has long been a key market for Custom Metal Component, with the company supplying a wide range of metal components for use in everything from engine components to chassis and suspension systems. With the introduction of the new product line, Custom Metal Component is aiming to further solidify its position as a key partner for automotive manufacturers, providing them with the high-quality components they need to deliver exceptional performance in their vehicles.

Meanwhile, in the aerospace industry, Custom Metal Component's new product line is also creating waves, with the company's metal components being considered for use in everything from aircraft engines to airframe structures. This is due to the company's proven track record of delivering components that offer exceptional strength and reliability, as well as its ability to work closely with aerospace manufacturers to develop bespoke solutions that meet the exacting requirements of this demanding industry.

Overall, the new product line from Custom Metal Component is set to further enhance the company's reputation as a leading provider of high-quality metal components. With its focus on precision engineering, advanced manufacturing processes, and exceptional customer service, the company is poised to continue its strong growth and cement its position as a key partner for customers in a wide range of industries.

As the company looks to the future, it is clear that Custom Metal Component is committed to pushing the boundaries of what is possible in the world of metal component manufacturing. By investing in the latest technology, exploring new materials and manufacturing processes, and working closely with its customers to understand their exact needs, the company is well-placed to continue delivering innovative solutions that set new standards for quality, performance, and reliability in the industry.

Company News & Blog

How to Cut Sheet Metal Like a Pro: Tips and Techniques for Precision Cuts

{Company Name} has recently announced the launch of a new sheet metal cutting technology that is set to revolutionize the industry. This new technology boasts several advanced features that make it faster, more efficient, and more precise than traditional sheet metal cutting methods. With this innovation, {Company Name} is poised to cement its position as a leader in the sheet metal fabrication industry.The new sheet metal cutting technology utilizes state-of-the-art equipment and software to ensure the highest level of precision and accuracy in cutting various types of sheet metal. This technology is capable of cutting through a wide range of materials, including steel, aluminum, copper, and more, making it an ideal solution for a variety of industries and applications.One of the key advantages of this new technology is its incredible speed. The advanced machinery and software allow for significantly faster cutting times compared to traditional methods, which translates to increased productivity and reduced lead times for clients. This means that {Company Name} will be able to fulfill orders more quickly and efficiently, ultimately leading to improved customer satisfaction and loyalty.In addition to its speed, the new sheet metal cutting technology also offers unparalleled precision. The advanced software enables the machinery to execute intricate and complex cuts with absolute accuracy, ensuring that the final product meets the highest quality standards. This level of precision is essential for industries that require intricate designs and tight tolerances, such as aerospace, automotive, and electronics.Furthermore, the new technology is designed to minimize material waste, thereby reducing costs and environmental impact. The software is programmed to optimize cutting patterns and minimize the amount of scrap material, ensuring that resources are used efficiently and sustainably. This aligns with {Company Name}'s commitment to environmental stewardship and responsible manufacturing practices.{Company Name} has always been at the forefront of innovation in the sheet metal fabrication industry. With a long-standing reputation for delivering high-quality products and exceptional service, {Company Name} has earned the trust and loyalty of a diverse clientele. By introducing this cutting-edge technology, {Company Name} is demonstrating its dedication to continuous improvement and its ability to adapt to the evolving needs of its customers.As a company that prides itself on staying ahead of the curve, {Company Name} is constantly investing in research and development to push the boundaries of what is possible in sheet metal fabrication. This commitment to innovation has not only allowed {Company Name} to stay competitive in a rapidly changing market but also to set new industry standards and raise the bar for excellence.The introduction of the new sheet metal cutting technology is a testament to {Company Name}'s ongoing pursuit of excellence and its determination to provide its customers with the best possible solutions. With this latest innovation, {Company Name} is poised to solidify its position as a leader in the sheet metal fabrication industry and set new benchmarks for quality, efficiency, and customer satisfaction.In conclusion, {Company Name} has unveiled a new sheet metal cutting technology that is set to transform the industry. With its cutting-edge features and advanced capabilities, this technology is poised to deliver faster, more precise, and more efficient results, ultimately raising the bar for excellence in sheet metal fabrication. As a company that is committed to innovation and customer satisfaction, {Company Name} continues to demonstrate its leadership in the industry and its dedication to pushing the boundaries of what is possible.

Durable and Versatile Aluminum Bending Bracket for Various Applications

Aluminum Bending Bracket Supplier Reaches New MilestoneIn the world of manufacturing, precision is key. Every detail matters, and every part must be crafted with care and expertise. This is especially true in the aerospace and automotive industries, where the demand for high-quality components is at an all-time high.One company that has been meeting and exceeding these demands is [Company Name]. With a proven track record of providing top-notch aluminum bending brackets to some of the biggest names in the industry, [Company Name] has recently reached a new milestone in their journey towards manufacturing excellence.Specializing in the production of aluminum bending brackets, [Company Name] has been a major player in the manufacturing industry for many years. Their parts are known for their precision, durability, and reliability, making them the go-to choice for companies in need of high-quality components.The team at [Company Name] is made up of dedicated professionals who are passionate about their work. With a commitment to delivering the best possible products to their customers, they have built a reputation for excellence and reliability. This has allowed them to forge strong partnerships with some of the most respected companies in the industry, cementing their status as a leading supplier of aluminum bending brackets.Their manufacturing process is second to none, with a focus on quality and precision at every step. From the initial design phase to the final inspection, every part is meticulously crafted to ensure that it meets the highest standards. This dedication to quality has set [Company Name] apart from the competition, making them a trusted name in the industry.Recently, [Company Name] announced that they have reached a new milestone in their production capabilities. Thanks to their continued investment in cutting-edge technology and their unwavering commitment to excellence, they have expanded their manufacturing capacity, allowing them to produce even more high-quality aluminum bending brackets than ever before.This milestone is a testament to [Company Name]'s dedication to innovation and progress. By investing in state-of-the-art equipment and staying ahead of the curve when it comes to manufacturing techniques, they have positioned themselves as a leader in the industry. This expanded capacity will allow them to better serve their customers and meet the growing demand for their products.In addition to their commitment to quality and innovation, [Company Name] also prioritizes sustainability in their manufacturing processes. They understand the importance of minimizing their environmental impact and have taken steps to ensure that their operations are as eco-friendly as possible. This dedication to sustainability has not gone unnoticed, and has further solidified [Company Name]'s reputation as a responsible and forward-thinking supplier.As the demand for high-quality aluminum bending brackets continues to grow, [Company Name] is well-positioned to meet and exceed the needs of their customers. With their expanded production capacity and unwavering commitment to excellence, they are ready to take on new challenges and continue to provide top-notch components to the aerospace and automotive industries.In conclusion, [Company Name] has reached a new milestone in their journey towards manufacturing excellence. With a focus on quality, innovation, and sustainability, they have solidified their position as a leading supplier of aluminum bending brackets. Their dedication to precision and their commitment to meeting the needs of their customers make them a trusted partner for companies in need of high-quality components. As they continue to invest in their capabilities and expand their production capacity, [Company Name] is poised to remain at the forefront of the industry for years to come.

Innovative Solutions for Enhanced Performance: The Benefits of Stamped Sheet Metal

[Company Name]'s Stamped Sheet Metal Revolutionizes Manufacturing Industry[date]Stamping and sheet metal production have long been the backbone of the manufacturing industry, enabling the creation of various products with efficiency and precision. Today, a company called [Company Name] is taking this age-old practice to new heights with their innovative stamped sheet metal technology. With a strong commitment to quality and innovation, [Company Name] is revolutionizing the manufacturing industry and paving the way for a more sustainable future.Founded in [year], [Company Name] has quickly gained recognition for its cutting-edge stamped sheet metal solutions. The company's advanced manufacturing processes and state-of-the-art machinery allow for precise and efficient production, ensuring that each product meets the highest standards of quality. By combining technology and craftsmanship, [Company Name] has positioned itself as a leader in the industry, serving a diverse range of sectors, from automotive to aerospace, electronics to construction.The success of [Company Name] can be attributed to its team of dedicated professionals and their unwavering commitment to excellence. With years of experience and expertise, the company's engineers and designers work closely with clients to understand their specific needs and deliver tailored solutions. This collaborative approach has fostered long-term partnerships with clients, who value the quality, reliability, and efficiency that [Company Name] provides.What sets [Company Name]'s stamped sheet metal apart is its commitment to sustainability. With a growing emphasis on eco-friendly practices, the company has integrated sustainable manufacturing techniques into its processes. By minimizing waste, recycling materials, and optimizing production cycles, [Company Name] reduces its ecological footprint while maintaining the highest standards of quality. Additionally, the use of high-quality materials ensures the longevity of products, reducing the need for replacements and further minimizing waste.One of the key advantages of stamped sheet metal technology is its versatility. [Company Name] understands this well and leverages its expertise to offer customized solutions for each client. Whether it's prototyping, small-scale production, or large-scale manufacturing, the company can accommodate various project sizes and specifications. By staying at the forefront of technological advancements and investing in research and development, [Company Name] consistently introduces new and improved solutions to meet the ever-evolving demands of the market.As the manufacturing industry continues to expand and evolve, [Company Name] remains committed to being at the forefront of innovation. By continuously investing in research and development, the company aims to develop new materials, processes, and applications for stamped sheet metal technology. This drive for innovation not only keeps [Company Name] ahead of its competition but also contributes to pushing the entire manufacturing industry forward.While [Company Name] has achieved significant milestones, the company is not resting on its laurels. With a focus on continuous improvement, the company aims to refine its processes, enhance its production capabilities, and expand its global presence. By investing in its workforce and staying dedicated to delivering exceptional customer service, [Company Name] seeks to become the go-to choice for stamped sheet metal solutions worldwide.In conclusion, [Company Name]'s stamped sheet metal technology is revolutionizing the manufacturing industry. With its commitment to quality, innovation, and sustainability, the company is setting new standards in the industry. By leveraging its expertise and investing in research and development, [Company Name] is poised to shape the future of manufacturing, making it more efficient, precise, and eco-friendly.As the demand for precision-engineered products continues to grow, [Company Name]'s stamped sheet metal technology will play a significant role in meeting these needs. With its dedication to excellence and forward-thinking approach, [Company Name] has undoubtedly carved its place as a leader in the industry.

China's Reliable Suppliers of High-Quality Machined Parts for Worldwide Buyers

: Why sourcing from China is a popular choice?When it comes to Machining Components, sourcing from China has been an increasingly popular choice, and with good reason. China has quickly become a manufacturing hub, with a large portion of the world's products being produced there. From machined parts to electronics, China has become a global leader in production and manufacturing. In this blog, we will delve into why sourcing from China is a popular choice for Machining Components.Cost-EffectiveOne of the main reasons businesses choose to source from China is the cost-effectiveness. The cost of manufacturing in China is significantly lower than in other countries. This is because the cost of labor is lower in China, making it cheaper to produce machined parts. Additionally, China has well-established manufacturing infrastructure and access to raw materials, which lowers production costs.Quality and ReliabilityChina's manufacturing industry has come a long way in terms of quality and reliability. With many manufacturers adopting ISO certification and implementing quality control measures, you can expect to receive high-quality machined parts from China. When you work with reliable suppliers, you can be certain that the products manufactured are up to international standards.Advanced TechnologyThe manufacturing industry has also been rapidly advancing in China, with many companies investing in advanced technology. This has enabled them to produce high-quality Machining Components and reduce production time while maintaining consistent quality. With advanced technology and equipment, the lead time for products can be significantly reduced, resulting in a faster turnaround time.Large Supplier BaseChina has a vast manufacturing industry, which has resulted in a large supplier base. This is beneficial for businesses as they can easily source the products they require. Moreover, with so many suppliers competing for business, the prices are often competitive, resulting in cost savings for businesses.Customizable ProductsChina is well-equipped to manufacture customized products. Manufacturers can easily tailor their products to meet the specific needs of their customers. Whether it's the dimensions or materials used, manufacturers can create a customized solution that meets your specifications. With customization options available, businesses can have machined parts that are exactly what they need.ConclusionIn conclusion, sourcing from China is a popular choice for Machining Components because of its cost-effectiveness, quality and dependability, advanced technology, large supplier base, and customization options. With these advantages and the continued growth of the manufacturing industry in China, businesses can expect to continue sourcing high-quality machined parts at reasonable prices.

Innovative 3D Printing Technology: What You Need to Know

3D Print Technology Revolutionizes Manufacturing ProcessIn today's fast-paced world, technological advancements are constantly changing the way we live and work. One such innovation that has been making waves in the manufacturing industry is 3D printing. This cutting-edge technology, also known as additive manufacturing, has the potential to revolutionize the way products are designed, prototyped, and produced.{Company Name} is a leading provider of 3D printing solutions, offering a wide range of products and services to meet the diverse needs of its customers. The company's advanced printing technology has been used in various industries, including aerospace, automotive, healthcare, and consumer goods. With a team of experienced engineers and experts in the field of additive manufacturing, {Company Name} has been at the forefront of driving innovation and pushing the boundaries of what is possible with 3D printing.The key advantage of 3D printing technology lies in its ability to create complex and intricate designs with utmost precision and efficiency. Traditional manufacturing processes often involve cutting, molding, and shaping materials, which can be time-consuming and wasteful. 3D printing, on the other hand, builds objects layer by layer, using digital models as blueprints. This enables manufacturers to produce custom parts and prototypes with minimal material waste and labor costs.Furthermore, 3D printing opens up new possibilities for product customization and personalization. By leveraging the power of digital design, companies can create unique and tailored products that cater to the specific needs of individual customers. This level of flexibility and agility is unparalleled in traditional manufacturing methods, making 3D printing a game-changer in today's market.One of the most exciting applications of 3D printing is in the field of healthcare. {Company Name}'s technology has been instrumental in producing medical implants, prosthetics, and anatomical models with unprecedented accuracy and detail. These customized solutions have the potential to improve patient care and outcomes, as well as reduce the time and cost associated with traditional production methods.In the aerospace and automotive industries, 3D printing is being used to create lightweight and durable components that enhance performance and fuel efficiency. {Company Name} has worked closely with its clients in these sectors to develop cutting-edge solutions that address their specific challenges and requirements. The ability to rapidly iterate and test new designs has accelerated the pace of innovation and allowed companies to stay ahead of the competition.Moreover, 3D printing has also opened up new opportunities for sustainable manufacturing. By optimizing material usage and minimizing waste, {Company Name}'s technology aligns with the growing demand for eco-friendly alternatives. This not only benefits the environment but also contributes to cost savings and resource efficiency for businesses.As the adoption of 3D printing continues to expand, {Company Name} remains committed to pushing the boundaries of what is possible with additive manufacturing. By investing in research and development, as well as forging strategic partnerships with industry leaders, the company aims to drive further innovation and unlock the full potential of 3D printing technology.In conclusion, 3D printing has emerged as a disruptive force in the manufacturing industry, offering unparalleled flexibility, precision, and customization. With its extensive expertise and state-of-the-art solutions, {Company Name} is at the forefront of this technological revolution, shaping the future of manufacturing and driving positive change across various sectors. As the demand for advanced manufacturing solutions continues to grow, it is clear that 3D printing will play a pivotal role in shaping the industry's future.

High-Quality Pressed Sheet Metal Components for Various Applications

Pressed Sheet Metal Components: A Key Player in the Manufacturing IndustryIn the world of manufacturing, precision and quality are of utmost importance. And when it comes to creating intricate and complex parts, pressed sheet metal components play a vital role. These components are used in a wide range of industries, from automotive to aerospace, and are essential for the production of various products.One company that has been at the forefront of producing high-quality pressed sheet metal components is {}. With a long history of excellence and innovation, {} has established itself as a key player in the manufacturing industry.Established in {year}, {} has been providing top-notch pressed sheet metal components to a diverse range of clients. The company's state-of-the-art manufacturing facilities and expert team of engineers and technicians have enabled them to produce components that meet the highest standards of quality and precision.{}'s press shop is equipped with the latest technology and machinery, allowing them to produce components with a high degree of accuracy and consistency. From simple flat components to intricate three-dimensional parts, {} has the capability to produce a wide variety of pressed sheet metal components to meet the unique needs of their clients.One of the key factors that set {} apart from its competitors is its commitment to quality. The company follows strict quality control measures at every stage of the manufacturing process, ensuring that each component meets the required specifications and standards. This dedication to quality has earned {} a reputation for reliability and excellence in the industry.Furthermore, {}'s team of experienced engineers and technicians work closely with clients to understand their specific requirements and provide customized solutions. Whether it's creating a new component from scratch or modifying an existing design, {} has the expertise and capabilities to deliver tailored solutions to meet the unique demands of their clients.In addition to their commitment to quality and innovation, {} also places a strong emphasis on sustainability and responsible manufacturing practices. The company is dedicated to reducing its environmental impact and operates in compliance with all relevant regulations and standards.In recent years, {} has expanded its operations to cater to a global clientele. With a strong focus on research and development, the company has been able to stay ahead of market trends and offer cutting-edge solutions to its clients worldwide.The future looks bright for the pressed sheet metal components industry, and {} is well-positioned to continue leading the way with its dedication to excellence, innovation, and customer satisfaction. As the demand for precision-engineered components continues to grow, {} remains committed to providing top-quality solutions to meet the evolving needs of the manufacturing industry.With its proven track record of delivering exceptional products and services, {} is poised to remain a key player in the manufacturing industry for years to come. Whether it's automotive, aerospace, or any other industry, {}'s pressed sheet metal components are sure to play a vital role in driving the success of their clients around the world.

How Cnc Turning Lathe Machines are Impacting the Manufacturing Industry

CNC Turning Lathe Revolutionizing Manufacturing IndustryIn recent years, the manufacturing industry has experienced a significant transformation with the introduction of advanced technologies and automated systems. Among these innovations, CNC turning lathes have emerged as a game-changer for companies seeking to enhance their production processes and improve efficiency.One company at the forefront of this technological revolution is {}, a leading manufacturer of CNC turning lathes and other precision machinery. With a strong commitment to innovation and quality, the company has established itself as a trusted partner for businesses across various industries.The CNC turning lathe manufactured by {} incorporates state-of-the-art technology, precision engineering, and advanced automation features, making it an indispensable tool for modern manufacturing operations. This cutting-edge equipment is designed to perform a wide range of turning, drilling, and milling tasks with unparalleled accuracy and speed, thereby enabling companies to meet the increasing demands of the market.One of the key advantages of the CNC turning lathe is its ability to produce complex and intricate components with consistency and precision. With the use of computer-controlled programming, operators can effortlessly create detailed and intricate designs with minimal margin for error, ensuring that each finished product meets the highest quality standards.Furthermore, the CNC turning lathe offers a high level of flexibility, allowing manufacturers to easily switch between different production tasks and adapt to evolving customer requirements. This versatility is particularly valuable in industries such as automotive, aerospace, and medical equipment, where component specifications are constantly changing.With a focus on maximizing productivity and minimizing downtime, the CNC turning lathe is equipped with advanced features such as automatic tool changers, live tooling capabilities, and robotic loading systems, streamlining the production process and reducing manual intervention. As a result, companies can significantly increase their output while optimizing resource utilization.In addition to its superior performance, the CNC turning lathe also prioritizes operator safety and ergonomics. Its user-friendly interface and intuitive controls make it easy for personnel to operate the machine effectively, while built-in safety mechanisms and monitoring systems ensure a secure working environment.The impact of CNC turning lathes on the manufacturing industry cannot be overstated. As businesses continue to pursue higher levels of efficiency and precision, these advanced machines have become indispensable assets in their operations. By integrating this cutting-edge technology into their production processes, companies can gain a competitive edge and stay ahead of market trends.As a prominent player in the field of CNC turning lathes, {} is dedicated to providing comprehensive solutions that empower manufacturers to achieve their production goals and deliver exceptional results. With a focus on continuous innovation and customer satisfaction, the company is poised to lead the industry's transition towards a more advanced and technology-driven future.In conclusion, the advent of CNC turning lathes has ushered in a new era of manufacturing excellence, enabling companies to elevate their capabilities and deliver superior products to their customers. With continued advancements in technology and a strong emphasis on quality and reliability, these innovative machines are set to redefine the standards of precision engineering and drive the industry towards greater efficiency and productivity.

High-Quality, Durable L-Shaped Bracket for Various Applications

L Shaped Bracket: A Versatile and Reliable Solution for Various ApplicationsL shaped brackets are simple yet versatile components that find application in a wide range of industries, from construction and manufacturing to DIY projects at home. These brackets, as the name suggests, are shaped like the letter "L" and are designed to provide support, reinforcement, and structural stability to various structures and assemblies. They can be found in different materials such as steel, aluminum, and plastic, each offering unique properties that cater to specific needs.One company that has been at the forefront of producing high-quality L shaped brackets is [Company Name]. They have established themselves as a leading manufacturer and supplier of brackets and other industrial components, known for their commitment to quality, precision engineering, and customer satisfaction.[Company Name] has a diverse range of L shaped brackets that cater to different industries and applications. Their brackets are designed and manufactured to meet the highest standards of quality and durability, ensuring that they can withstand the rigors of various environments and use cases. Whether it's for structural support in construction projects, mounting of shelves and furniture, or reinforcement of machinery and equipment, [Company Name] offers a solution for every need.One of the key advantages of [Company Name]'s L shaped brackets is their versatility. They come in a variety of sizes, shapes, and finishes, allowing customers to find the perfect bracket for their specific requirements. Additionally, the company also provides custom manufacturing services, enabling customers to order brackets that are tailored to their exact specifications.Furthermore, [Company Name] prides itself on its commitment to innovation and continuous improvement. They invest in state-of-the-art manufacturing technologies and processes to ensure that their brackets are produced with utmost precision and efficiency. This dedication to excellence has earned them a reputation for reliability and consistency in delivering top-notch products to their customers.In addition to their product offerings, [Company Name] places a strong emphasis on customer service and satisfaction. They have a team of knowledgeable and experienced professionals who are dedicated to providing expert advice and guidance to customers, helping them find the right L shaped bracket for their application. This personalized approach sets them apart from their competitors and has made them a trusted partner for businesses and individuals alike.As a company that is committed to sustainability, [Company Name] also ensures that their manufacturing processes are environmentally friendly and compliant with industry standards. They prioritize the use of sustainable materials and resource-efficient practices, aligning with their goal of minimizing their environmental impact and contributing to a greener future.In conclusion, L shaped brackets are indispensable components that play a crucial role in providing support and stability to a wide variety of structures and assemblies. With [Company Name]'s dedication to excellence, innovation, and customer satisfaction, their range of L shaped brackets stands out as a versatile and reliable solution for various applications. Whether it's for industrial, commercial, or personal use, customers can trust [Company Name] to deliver high-quality brackets that meet their needs and exceed their expectations.

High-quality Sheet Metal Part for Precision Engineering Projects

Sheet Metal Part Company Provides High-Quality Components for Various IndustriesSince its establishment in 1998, Sheet Metal Part Company has been a leading manufacturer and supplier of precision sheet metal components for a wide range of industries. With a dedication to quality, innovation, and customer satisfaction, the company has built a solid reputation for producing high-quality parts that meet the specific requirements of its clients.The company's state-of-the-art manufacturing facility is equipped with advanced machinery and tools that enable the production of complex and precise sheet metal components. From intricate prototypes to large-scale production runs, Sheet Metal Part Company has the capabilities to handle diverse projects with efficiency and precision.One of the key strengths of Sheet Metal Part Company is its team of highly skilled engineers, technicians, and production staff. With years of experience and expertise in the field of sheet metal fabrication, the company's team members are committed to delivering top-notch solutions that exceed customer expectations. Whether it's custom enclosures for the electronics industry, precision components for the automotive sector, or specialized parts for the aerospace industry, the company's team is capable of meeting the unique demands of each customer.In addition to its commitment to quality and precision, Sheet Metal Part Company places a strong emphasis on innovation and continuous improvement. The company invests in research and development to stay at the forefront of technological advancements in the sheet metal fabrication industry. By embracing new techniques, processes, and materials, the company is able to offer innovative solutions that address the evolving needs of its customers.Furthermore, Sheet Metal Part Company takes pride in its strict adherence to industry standards and regulations. The company is certified to ISO 9001 standards, ensuring that its manufacturing processes and quality management systems are of the highest caliber. This dedication to quality and compliance has earned the company the trust and confidence of its customers, who rely on Sheet Metal Part Company for their most critical sheet metal component needs.With a strong focus on customer satisfaction, Sheet Metal Part Company works closely with its clients to understand their requirements and provide tailored solutions that meet their specific needs. The company's customer-centric approach, combined with its technical expertise and manufacturing capabilities, has resulted in long-term partnerships with a diverse range of customers across various industries.In recent news, Sheet Metal Part Company has introduced a new line of environmentally friendly sheet metal components that are designed to reduce waste and energy consumption in manufacturing processes. By utilizing sustainable materials and implementing eco-friendly production methods, the company aims to contribute to environmental conservation while meeting the needs of its customers.As Sheet Metal Part Company continues to expand its product offerings and reach new markets, the company remains committed to its founding principles of quality, innovation, and customer satisfaction. With a solid track record of delivering high-quality sheet metal components for diverse applications, the company is poised to remain a trusted partner for industries that require precision and reliability in their sheet metal parts.In conclusion, Sheet Metal Part Company stands as a leading provider of high-quality sheet metal components for a wide range of industries. With a focus on quality, innovation, and customer satisfaction, the company has established itself as a reliable partner for businesses seeking precision and reliability in their sheet metal parts. With a dedication to continuous improvement and environmental stewardship, Sheet Metal Part Company is well-positioned to meet the evolving needs of its customers and the market.

Precision CNC Machining for Aerospace Parts

CNC Machining Aerospace Parts: A Crucial Step in Advancing Aerospace TechnologyWith the rapid advancement of technology in the aerospace industry, the demand for high-precision, top-quality aerospace parts has never been higher. This has led to the increasing use of CNC machining in the production of aerospace components. CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computerized controls and machine tools to produce complex and intricate parts with a high level of precision and accuracy. This technology has proven to be integral in the production of aerospace parts, as it allows for the fabrication of sophisticated and durable components that meet the stringent requirements of the aerospace industry.One company at the forefront of CNC machining aerospace parts is {}. With over 20 years of experience in the aerospace and defense industries, {} has been a leading provider of high-quality precision parts and assemblies. Using state-of-the-art CNC machining technology, {} has been able to produce a wide range of aerospace components that meet the exacting standards of its aerospace customers.In the aerospace industry, the production of components with precise and intricate geometries is crucial to the performance and safety of aircraft. The use of CNC machining allows for the production of complex aerospace components, such as aircraft engine parts, landing gear components, and structural assemblies, with tight tolerances and high accuracy. This is essential for ensuring the reliability and safety of aerospace systems, as any discrepancies in the dimensions of these components can lead to catastrophic failures.Moreover, CNC machining enables the production of aerospace parts from a wide range of materials, including aluminum, titanium, and various high-performance alloys. These materials are known for their superior strength-to-weight ratio and resistance to corrosion, making them ideal for aerospace applications. By utilizing CNC machining, aerospace manufacturers can fabricate components from these materials with a high degree of precision, ensuring the structural integrity and performance of the final parts.Additionally, CNC machining offers the flexibility to produce both prototype and production quantities of aerospace parts. This is particularly beneficial for aerospace companies that require rapid prototyping and iterative design processes to optimize the performance of their components. With CNC machining, aerospace manufacturers can quickly produce prototype parts for testing and evaluation, allowing for the efficient development of new aerospace technologies and systems.Furthermore, the use of CNC machining in the production of aerospace parts results in improved efficiency and cost-effectiveness. The precision and repeatability of CNC machining processes minimize material wastage and reduce the need for secondary operations, such as finishing and assembly. This not only streamlines the manufacturing process but also lowers the overall production costs, making CNC machining an attractive option for aerospace manufacturers looking to enhance their competitiveness in the industry.As the demand for advanced aerospace technologies continues to grow, the role of CNC machining in the production of aerospace parts will only become more critical. With its ability to produce high-precision, top-quality aerospace components, CNC machining is poised to drive the advancement of aerospace technology and propel the industry into the future.In conclusion, {}'s expertise in CNC machining aerospace parts has positioned the company as a key player in the aerospace industry. With its commitment to delivering top-quality precision parts and assemblies, {} has solidified its reputation as a trusted partner for aerospace manufacturers seeking cutting-edge solutions. As the aerospace industry continues to evolve, the use of CNC machining will undoubtedly play a pivotal role in shaping the future of aerospace technology, and {} is well-equipped to lead the way.