Understanding the Importance of Heat Sink Extrusion in Thermal Management

By:Admin

The global heat sink extrusion market is projected to witness significant growth over the forecast period, according to a new report by {company name}. Heat sink extrusions are widely used in electronic devices to dissipate heat and maintain the temperature of the devices. With the increasing demand for electronic devices such as smartphones, laptops, and LED lighting, the heat sink extrusion market is expected to witness robust expansion in the coming years.

The report provides a comprehensive overview of the global heat sink extrusion market, including market trends, drivers, restraints, opportunities, and challenges. It also includes a detailed analysis of the key players operating in the market, along with their market share, product portfolio, and business strategies. The report also covers the impact of the COVID-19 pandemic on the market and offers strategic recommendations to help companies navigate the challenging business environment.

One of the key factors driving the growth of the heat sink extrusion market is the increasing demand for electronic devices across the globe. With the rapid advancements in technology and the growing popularity of smart devices, the demand for heat sink extrusions is expected to surge in the coming years. Additionally, the increasing focus on energy efficiency and the rising adoption of LED lighting are further fueling the demand for heat sink extrusions. As a result, manufacturers are increasingly investing in advanced technologies to develop innovative and efficient heat sink extrusions to meet the growing demand from various end-use industries.

Moreover, the growing trend of miniaturization of electronic devices is also expected to drive the demand for heat sink extrusions. As electronic devices become smaller and more compact, the need for efficient heat dissipation becomes even more critical. This trend is expected to create new opportunities for market players to develop compact and highly efficient heat sink extrusions to meet the evolving requirements of the electronics industry.

In terms of regional analysis, the Asia Pacific region is expected to dominate the heat sink extrusion market, attributable to the presence of a large number of electronics manufacturing and assembly facilities in countries such as China, Japan, South Korea, and India. The region is also witnessing rapid industrialization and urbanization, leading to an increase in the demand for electronic devices, which, in turn, is driving the demand for heat sink extrusions. North America and Europe are also anticipated to witness considerable growth in the market, owing to the presence of a well-established electronics industry and the increasing adoption of advanced technologies in the region.

As a leading player in the heat sink extrusion market, {company name} is at the forefront of developing cutting-edge heat sink extrusions to cater to the diverse needs of its customers. The company offers a wide range of heat sink extrusions that are designed to deliver high thermal performance and reliability, making them ideal for a wide range of applications. With a strong focus on research and development, {company name} continuously strives to innovate and introduce advanced technologies to enhance the performance and efficiency of its heat sink extrusions, thereby strengthening its position in the market.

Furthermore, {company name} is committed to sustainability and environmental responsibility, and as such, its heat sink extrusions are designed to be energy-efficient and environmentally friendly. The company adheres to stringent quality standards and has a robust quality control process in place to ensure that its products meet the highest industry standards. With a global presence and an extensive distribution network, {company name} is well-equipped to cater to the growing demand for heat sink extrusions across various industries and geographies.

In conclusion, the global heat sink extrusion market is poised for substantial growth in the coming years, driven by the increasing demand for electronic devices, the trend of miniaturization, and the focus on energy efficiency. With its commitment to innovation, quality, and sustainability, {company name} is well-positioned to capitalize on the lucrative opportunities in the market and further consolidate its position as a leading player in the industry.

Company News & Blog

Exploring the Latest Trends and Uses of Stainless Steel Sheet Metal

[News Title]: Company A Leads the Way in Stainless Steel Sheet Metal ManufacturingIntroduction:Company A, a leading player in the manufacturing industry, has gained significant attention for its superior quality stainless steel sheet metal products. With its commitment to innovation, advanced technology, and customer satisfaction, the company has established itself as a key player in the global market. This news article aims to delve deeper into the manufacturing process, product offerings, and the impact of Company A's stainless steel sheet metal on industries worldwide.Manufacturing Process: Company A follows a meticulous manufacturing process to ensure the production of high-quality stainless steel sheet metal. The process begins with the selection of premium raw materials sourced from reliable suppliers. These raw materials undergo rigorous quality control tests for strength, durability, and resistance to corrosion. Once approved, the materials move to the fabrication stage, where cutting-edge machines and advanced production techniques are employed to shape the stainless steel sheets according to precise dimensions and specifications.The manufacturing process at Company A also places a strong emphasis on environmental sustainability. The company adheres to strict industry standards, ensuring minimal waste generation and efficient energy consumption throughout the production cycle. By adopting sustainable practices, Company A not only safeguards the environment but also contributes positively to its corporate social responsibility.Product Offerings:Company A offers a diverse range of stainless steel sheet metal products suitable for various industries. The company produces sheets with different finishes, including brushed, mirror, and embossed, catering to the specific design requirements of its customers. Whether it be for architectural purposes, interior design, automotive applications, or industrial uses, Company A has a comprehensive array of stainless steel sheets to meet every need.Furthermore, the dimensional versatility of Company A's stainless steel sheet metal allows for customized solutions. The company possesses cutting-edge machinery capable of producing sheets in various thicknesses, widths, and lengths as per customer specifications. This flexibility has enabled Company A to establish itself as a preferred supplier for design professionals looking for tailored stainless steel sheet metal solutions.Global Impact:Company A's stainless steel sheet metal products have made a remarkable impact across various industries worldwide. Architects and interior designers appreciate the aesthetic appeal and durability that these sheets offer, leading to their extensive use in prestigious constructions and building projects. Additionally, within the automotive industry, Company A's stainless steel sheets find application in various components, such as exhaust systems, body panels, and trims, owing to their corrosion resistance and ability to withstand extreme conditions.The industrial sector also benefits from Company A's stainless steel sheet metal, with its applications in machinery manufacturing, food processing, and chemical plants. The high tensile strength, thermal resistance, and hygienic properties of these sheets make them ideal for industrial use, thereby ensuring safe and reliable operations.Conclusion:Through its unwavering commitment to excellence, Company A continues to lead the way in stainless steel sheet metal manufacturing. By embracing cutting-edge technologies, focusing on sustainability, and offering a diverse range of products, the company has become a trusted partner for industries across the globe. With a strong foothold in the market and unmatched product quality, Company A's stainless steel sheet metal continues to elevate the standard of quality and performance in various industrial applications.

MTConnect-Ready 3D Printer for Aerospace and Production Applications

, MTConnect, FDM, aerospace, production, 3D printing.Additive Manufacturing Magazine recently reported that the Stratasys Fortus 900 3D printer now features an MTConnect-ready interface. This is great news for those working in aerospace and other industries that require high-quality, production-grade 3D printing.The Stratasys Fortus 900 is a Fused Deposition Modeling (FDM) 3D printer designed for large, complex parts. With a build volume of 36 x 24 x 36 inches, it has the capability to produce parts that are larger than those typically produced with plastic extrusion machines. This makes it an ideal choice for aerospace applications, as well as for producing jigs, fixtures, and tooling.Incorporating the MTConnect protocol into the Stratasys Fortus 900 means that users can now monitor and control their 3D printing operations in real time. MTConnect is an open, royalty-free standard for machine tool communication that has become increasingly popular in the manufacturing industry. With MTConnect, users can easily connect machines and devices to a network, allowing them to monitor data and make informed decisions about their operations.For aerospace manufacturers, the Stratasys Fortus 900 with MTConnect-ready interface is ideal, as it provides the capability to produce production-grade parts with repeatable accuracy. Additionally, 3D printing allows for the production of complex geometries that cannot be produced with traditional manufacturing methods.Overall, the integration of MTConnect into the Stratasys Fortus 900 3D printer is a positive development for the additive manufacturing industry. By providing real-time monitoring and control, it enables users to optimize their operations, increase efficiency, and improve the quality of their products. This is especially important in industries such as aerospace, where high-quality, production-grade parts are essential.As the use of 3D printing continues to grow, we can expect to see further developments in this area, and the integration of other technologies into 3D printers. In the meantime, the Stratasys Fortus 900 with MTConnect-ready interface is a great option for those looking to produce high-quality, production-grade parts with 3D printing technology.

Latest Updates on the World of Electronic Dance Music

[Company Name Removed] Expands Its Footprint in the Dynamic World of Electronic Dance Music (EDM)(Date)The global electronic dance music (EDM) industry has witnessed an unprecedented surge in popularity in recent years. As this vibrant genre continues to captivate millions of music lovers worldwide, [Company Name Removed], a leading player in the music industry, is excited to announce its expanding presence in the EDM scene.With over two decades of experience in curating and promoting extraordinary music events, [Company Name Removed] has cemented its position as a visionary force in the music industry. The company has successfully organized some of the most iconic concerts and festivals, leaving an indelible mark on the hearts of music enthusiasts across the globe.The decision to venture into EDM is a strategic move for [Company Name Removed], considering its immense potential and ever-growing fan base. The genre's fusion of infectious beats, captivating rhythms, and electrifying energy has transcended borders and united people from various cultural backgrounds.As part of its foray into EDM, [Company Name Removed] aims to introduce a fresh wave of artistic talent and provide a platform for emerging DJs and producers. By scouting new talents through collaborations with established EDM artists, the company seeks to foster the growth of the genre and inspire a new generation of music creators.The expansion into EDM will also see [Company Name Removed] launching its own record label specifically dedicated to this genre. With a strong focus on nurturing talents and exploring cutting-edge sounds, the record label aims to become a breeding ground for chart-topping EDM hits and groundbreaking collaborations.In addition to discovering new talents, [Company Name Removed] plans to organize an array of EDM events and festivals to showcase the genre's vast diversity. These events will provide an immersive experience for attendees, combining stunning visual effects, state-of-the-art production, and performances from the biggest names in the EDM scene.[Company Name Removed] also recognizes the importance of technology in shaping the future of music consumption. Thus, the company is actively investing in cutting-edge technologies to enhance the overall experience of EDM enthusiasts. By leveraging virtual reality (VR) and augmented reality (AR), [Company Name Removed] aims to transport its audience into a digital realm where they can feel the pulsating beats and immerse themselves in an otherworldly atmosphere.To further solidify its position in the EDM industry, [Company Name Removed] plans to collaborate with leading EDM festivals and organizations across the globe. By forging strategic partnerships and sharing expertise, the company aims to create a worldwide network that will open doors for collaboration and mutually beneficial ventures.Furthermore, [Company Name Removed]'s expansion into the world of EDM is driven by a strong commitment to sustainability and community welfare. The company aims to organize eco-friendly festivals and events, ensuring responsible waste management and promoting environmental awareness among its audience. Additionally, [Company Name Removed] plans to collaborate with local communities and charitable organizations, using the power of EDM to bring about positive social change.As [Company Name Removed] gears up to enter the electrifying realm of EDM, music enthusiasts can expect groundbreaking collaborations, mesmerizing events, and the discovery of new and innovative sounds. With its unparalleled track record in event organization and artist promotion, [Company Name Removed] is poised to make a lasting impact on the vibrant world of electronic dance music.

Top Quality Auto Parts for Sale - Find the Best Deals Online

Auto Parts Company is a leading supplier of high-quality auto parts and accessories to the aftermarket industry. With a wide range of products and a commitment to customer satisfaction, Auto Parts Company has earned a reputation for excellence in the automotive industry.The company offers a comprehensive catalog of products, including engine parts, brake systems, suspension components, electrical systems, and much more. Their extensive inventory allows them to meet the needs of customers across the country, from individual car owners to professional mechanics and repair shops.In addition to their extensive product offering, Auto Parts Company is dedicated to providing exceptional customer service. Their knowledgeable staff is available to assist customers with finding the right parts for their specific needs and offer expert advice on installation and maintenance. With a focus on meeting and exceeding customer expectations, Auto Parts Company has built a loyal customer base that relies on them for all of their automotive needs.As a leader in the aftermarket auto parts industry, Auto Parts Company is constantly evolving to meet the changing needs of their customers. They are committed to staying ahead of the curve when it comes to new technology and innovations in the automotive industry, allowing them to offer the latest and most advanced products to their customers.Auto Parts Company also places a strong emphasis on quality and reliability. They work with top manufacturers to ensure that all of their products meet or exceed industry standards for performance and durability. This commitment to quality has earned Auto Parts Company a reputation for excellence in the industry and has helped them to build strong, long-lasting relationships with both customers and suppliers.In addition to their commitment to quality, Auto Parts Company is also dedicated to sustainability and environmental responsibility. They are constantly seeking out new ways to reduce their environmental impact, from reducing waste and emissions in their operations to sourcing eco-friendly products and materials. Their dedication to sustainability sets them apart as a company that not only cares about their customers but also the world around them.Auto Parts Company is also a leader in the community, actively participating in charitable initiatives and supporting local organizations. They believe in giving back to the communities that have supported them and are committed to making a positive impact wherever they can.Overall, Auto Parts Company is a company that is dedicated to excellence in every aspect of their business. From their extensive product offering and commitment to customer service to their focus on quality, innovation, and sustainability, Auto Parts Company sets the standard for excellence in the aftermarket auto parts industry. With a strong reputation and a loyal customer base, they are well-positioned for continued success and growth in the years to come.

What is Water-jet Technology? A Definition

Water-jet Technology Takes the Industrial World by StormWater-jet technology has been quietly revolutionizing the industrial world over the past decade. Driven by powerful streams of water and sometimes abrasive materials, water-jet cutting technology is quickly becoming the go-to cutting method for a variety of industries. From aerospace to the medical field, water-jet cutting is proving to be more precise and efficient than traditional cutting methods.A water-jet is a cutting tool that creates a high-velocity jet of water, usually mixed with an abrasive material. This creates a powerful cutting force that can cut through virtually any material with precision, including metal, stone, glass, and plastic. Water-jet cutting technology was developed in the 1950s, and since then, it has been continuously refined and improved, becoming one of the most versatile and effective cutting methods available today.One of the many benefits of water-jet cutting is its precision. Unlike traditional cutting methods that rely on brute force and sharp blades, water-jet cutting relies on a powerful stream of water to slice through materials with ease. This allows for incredibly intricate and precise cuts, even on difficult or complicated materials.Another benefit of water-jet cutting is its versatility. Water-jet cutters can handle a wide range of materials, from soft rubber to thick steel. This makes it an ideal choice for industries that require cutting precision on a variety of materials.The aerospace industry, for example, heavily relies on water-jet technology for the precision cutting of parts and components. With water-jet cutting, aerospace manufacturers can create intricate shapes out of tough materials such as titanium and composites, resulting in stronger, lighter-weight aircraft that perform better than ever before. Other industries, such as the medical field, also rely on water-jet cutting for precision cutting of surgical instruments and implantable devices.Water-jet cutting technology has also become more accessible in recent years, with more and more companies offering water-jet cutting services to a variety of industries. Companies like {} offer state-of-the-art water-jet cutting services that can handle large production runs or small, custom projects. By outsourcing their cutting needs, businesses can save time and money on equipment and maintenance costs while still enjoying the precision and versatility of water-jet cutting.Finally, water-jet cutting is also environmentally friendly. Unlike traditional cutting methods that produce harmful dust and debris, water-jet cutting creates minimal waste and leaves the material clean and untouched. This means less waste, fewer environmental hazards, and a safer workplace for employees.In conclusion, water-jet cutting technology is quickly becoming the go-to cutting method for businesses ranging from aerospace to medical manufacturing. With its precision, versatility, accessibility, and environmentally friendly benefits, water-jet cutting is the perfect solution for industries that require precise cutting of a variety of materials. As technology continues to improve, we can only expect to see water-jet cutting become even more essential to the industrial world.

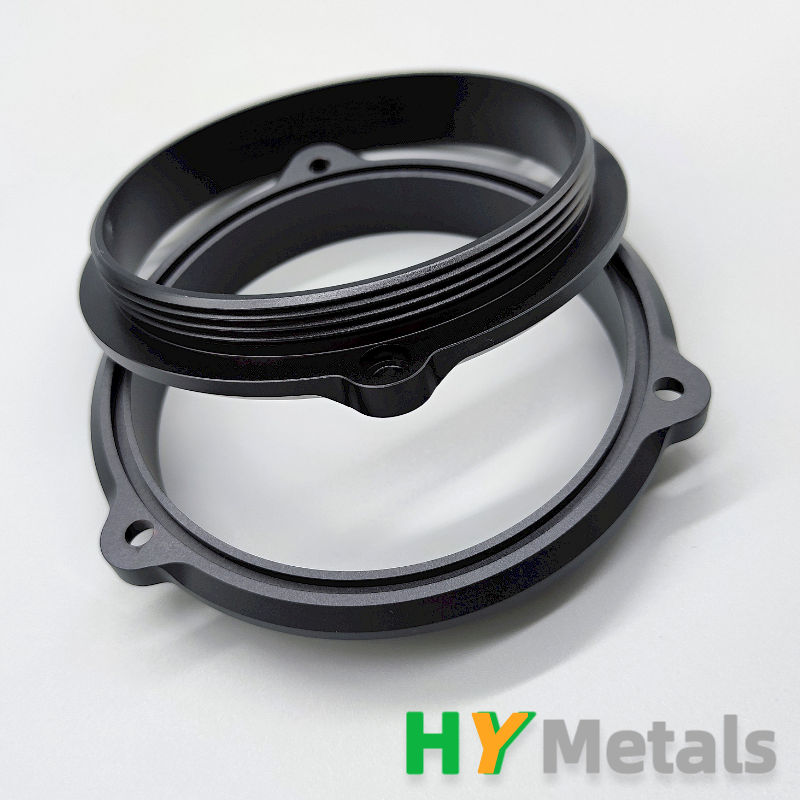

High-Quality Custom Metal Part for Industrial Applications

Custom Metal Part Company Expands Product Line to Meet Growing Demand[Company Name] is pleased to announce the expansion of their product line to include a range of custom metal parts. The decision to expand their offering comes as a response to the growing demand for precision metal components in various industries.The custom metal parts will be manufactured using state-of-the-art technology and high-quality materials, ensuring that they meet the highest standards of quality and performance. With a team of highly skilled engineers and technicians, [Company Name] has the capability to produce custom metal parts that are tailored to the specific needs of their clients.The custom metal parts will be available in a variety of materials, including stainless steel, aluminum, brass, and copper, allowing for a wide range of applications across different industries. In addition, [Company Name] will offer a range of finishes and coatings to further customize the parts to meet the unique requirements of their customers."We are excited to expand our product line to include custom metal parts, as we see a growing need for these components in various industries," said [Company Name]'s CEO. "With our advanced manufacturing capabilities and commitment to quality, we are confident that our custom metal parts will meet the needs of our customers and provide them with a reliable solution for their manufacturing needs."In addition to the custom metal parts, [Company Name] will also offer a range of value-added services, including design assistance, prototype development, and engineering support. This will ensure that their customers receive a comprehensive solution for their metal component needs, from conceptualization to production.The expansion of the product line reinforces [Company Name]'s commitment to providing their customers with a comprehensive range of high-quality metal components, backed by exceptional customer service and technical support. With their advanced manufacturing capabilities and dedication to continuous improvement, [Company Name] is well-positioned to meet the growing demand for custom metal parts in the market.[Company Name] is a leading manufacturer of precision metal components, serving a diverse range of industries including aerospace, automotive, medical, and electronics. With over [number] years of experience in the industry, [Company Name] has earned a reputation for their commitment to quality, innovation, and customer satisfaction.The company's state-of-the-art facility is equipped with the latest technology in precision machining, stamping, and fabrication, allowing them to produce high-quality metal components with tight tolerances and complex geometries. In addition, their team of experienced engineers and technicians work closely with their customers to develop customized solutions that meet their specific requirements.[Company Name]'s dedication to quality is reflected in their adherence to rigorous quality control and testing standards. They are certified to a number of industry standards, including ISO [number], AS9100, and NADCAP, ensuring that their products meet the highest levels of quality and performance.With the expansion of their product line to include custom metal parts, [Company Name] is well-positioned to further strengthen their position as a trusted partner for precision metal components. Their commitment to innovation, quality, and customer satisfaction will continue to drive their success in meeting the evolving needs of their customers in various industries.

Precision CNC Machining for Small Parts: A Complete Guide

Precision CNC Machining Small Parts: A Specialty of {Company}{Company} is a leading provider of precision CNC machining services, specializing in the production of small parts for a wide range of industries. With state-of-the-art technology and a team of highly skilled engineers and machinists, we have earned a reputation for delivering high-quality, precision-machined small parts that meet the most demanding specifications.Our CNC machining capabilities allow us to produce small parts with tight tolerances and complex geometries, making us the go-to choice for customers who require precision parts for their critical applications. Whether it's components for medical devices, aerospace parts, or intricate electronic components, {Company} has the expertise and resources to deliver top-notch small parts that meet the highest standards.One of the key strengths of {Company} is our ability to work with a wide range of materials, including aluminum, stainless steel, titanium, and various plastics. Our state-of-the-art CNC machines are equipped with the latest cutting tools and software, allowing us to handle even the most challenging materials with precision and efficiency. This enables us to offer a comprehensive solution for our customers, no matter what material their small parts are made from.In addition to our machining capabilities, {Company} also offers a range of secondary processes to ensure that the small parts we produce are fully finished and ready for use. These processes include surface finishing, anodizing, heat treatment, and precision assembly, providing our customers with a one-stop solution for all their small part needs.At {Company}, we understand the importance of quality and reliability when it comes to small parts. That's why we have established rigorous quality control measures at every stage of the machining process. From incoming material inspection to final product validation, we adhere to strict quality standards to ensure that each small part meets the required specifications and exceeds customer expectations.Our commitment to quality and customer satisfaction has made us a trusted partner for businesses across various industries, from aerospace and defense to medical and electronics. We take pride in our ability to deliver small parts that not only meet the technical requirements but also contribute to the success of our customers' products and applications.As part of our continuous improvement efforts, {Company} invests in the latest technologies and training programs to keep our team at the forefront of CNC machining advancements. This allows us to stay ahead of the competition and continue to provide innovative solutions for the production of small parts.In conclusion, {Company} is a leading provider of precision CNC machining services, specializing in the production of small parts for a wide range of industries. With state-of-the-art technology, a team of highly skilled engineers and machinists, and a commitment to quality and customer satisfaction, we have earned a reputation for delivering high-quality, precision-machined small parts that exceed our customers' expectations. Whether it's medical devices, aerospace parts, or electronic components, {Company} has the expertise and resources to deliver top-notch small parts that meet the highest standards.

Unlocking the Potential of Precision CNC Turning Services for Optimal Results

Precision CNC turning is a highly advanced manufacturing process used to create complex and intricate parts for various industries such as automotive, aerospace, and medical. It is a crucial component of the manufacturing sector, and its demand is only increasing. {Company Name}, a leading provider of precision CNC turning services, has been at the forefront of this technology, providing high-quality solutions to meet the diverse needs of its clients.With state-of-the-art facilities and a team of experienced professionals, {Company Name} has been delivering exceptional results in the precision CNC turning industry. Their commitment to quality and innovation has allowed them to develop cutting-edge solutions that have set new industry standards.Precision CNC turning involves the use of computer-controlled machines to manufacture parts with a high level of accuracy and precision. These machines can perform a wide range of complex machining operations, including turning, boring, facing, threading, and grooving. The process involves the removal of material from a workpiece to create the desired shape and finish.One of the key advantages of using precision CNC turning is the ability to produce parts with consistent quality and dimensional accuracy. The computer-controlled machines ensure that each part is manufactured to the exact specifications, resulting in enhanced efficiency and reduced waste. This level of precision is critical in industries where even small deviations can have a significant impact on performance and safety.{Company Name} has established itself as a trusted partner in the precision CNC turning industry by leveraging its expertise and capabilities. They employ a comprehensive approach that ensures every project is handled with utmost care, from initial design and prototyping to final production. Their team of engineers works closely with clients to understand their specific requirements and develop customized solutions tailored to their needs.In addition to their advanced machining capabilities, {Company Name} also offers a wide range of materials to choose from, including aluminum, stainless steel, titanium, and various alloys. This diversity allows them to cater to a wide range of industries and applications, providing clients with the flexibility to select the most suitable material for their project.Furthermore, {Company Name}'s commitment to continuous improvement and investment in cutting-edge technologies has allowed them to stay ahead of the competition. They regularly upgrade their machinery and software systems, ensuring that they are always equipped with the latest tools and techniques. This dedication to staying at the forefront of technological advancements enables {Company Name} to deliver superior results consistently.In the fast-paced and evolving world of precision manufacturing, {Company Name}'s ability to adapt and innovate has been instrumental in their success. Their commitment to ongoing research and development has enabled them to explore new materials, techniques, and processes, resulting in greater efficiency and cost-effectiveness for their clients.Furthermore, {Company Name} places a strong emphasis on quality control, adhering to rigorous inspection procedures throughout each stage of the manufacturing process. This dedication to quality assurance has earned them various certifications and accreditations, further solidifying their position as a reliable and trusted CNC turning provider.As industries become increasingly reliant on precision engineering, the demand for high-quality CNC turning services continues to grow. {Company Name} continues to spearhead the industry by delivering exceptional results that meet and exceed customer expectations. With their state-of-the-art facilities, highly skilled workforce, and unwavering commitment to excellence, they are well-positioned to remain a leader in the precision CNC turning sector for years to come.In conclusion, precision CNC turning is a critical component of modern manufacturing, and {Company Name} has proven itself to be a leading provider in this field. Their commitment to quality, innovation, and customer satisfaction sets them apart from their competitors. With their advanced capabilities, comprehensive solutions, and dedication to continuous improvement, {Company Name} continues to be the go-to choice for precision CNC turning services.

Sheet Metal Bending Tools: Dies, Press Brakes, Tube & Wire Bending

Sheet metal bending is a process that involves creating a bend in a metal sheet to give it a certain shape or form. This process is done using specialized tools and equipment such as bending dies, press brakes, and tube & wire bending machines.Bending dies are the main tool used for sheet metal bending. They are used to apply force to the metal to create a bend. These dies come in different shapes and sizes depending on the shape and size of the bend required. The dies can be used with a stamping press or press brakes.Stamping presses are machines that are used to apply pressure to the metal sheet to create the desired shape. The press brake is another machine that is used for sheet metal bending. It is a large machine that uses a hydraulic system to apply force to the metal sheet. The press brake can create several bends in the metal sheet at once.There are several types of bending dies that can be used for sheet metal bending. The most common type of bending die is the progressive bending die. This die allows multiple bends to be created simultaneously, which makes the process faster and more efficient. Other types of bending dies include the wiping die, rotary die, and the air-bending die.Wire bending machines are used to create bends in wire or rod-shaped materials. These machines use specialized dies to create precise bends in the wire. The bending process is done using a combination of force and heat to create the desired shape.Tube bending machines are used for creating bends in tubes and pipes. These machines use mandrels and dies to create precise bends in the tube. The mandrel is a rod that is placed inside the tube to prevent it from collapsing during the bending process.When it comes to sheet metal bending, it is important to use the right tools and equipment to ensure that the sheet metal is bent correctly. Bending dies and tools are crucial in this process. With the right tools and equipment, it is possible to create precise bends that will meet the desired requirements.In conclusion, sheet metal bending is a complex process that requires specialized tools and equipment like bending dies, press brakes, tube & wire bending machines. Each of these pieces of equipment plays a crucial role in the bending process and is designed to create precise bends. When used correctly, these tools can help you achieve the desired shape and form for your sheet metal project.

Discover the Artistry of Custom Metal Work for Exquisite Designs

Custom Metal Work Expands Portfolio With Innovative SolutionsCustom Metal Work, a leading provider of metal fabrication solutions, is excited to announce the addition of several new products and services to their extensive portfolio. With over two decades of experience, the company has built a reputation for delivering high-quality, customized metalwork to a wide range of industries.As a trusted name in the metal fabrication industry, Custom Metal Work takes pride in their ability to cater to the unique needs of each client. By combining state-of-the-art technology with a team of skilled craftsmen, the company consistently delivers innovative solutions that meet the highest standards of quality and precision.One of the latest additions to Custom Metal Work’s portfolio is their line of cutting-edge laser cutting services. Using cutting-edge machinery, the company can now provide precise and intricate metal cutting, ensuring a superior finish with minimal material waste. This new capability allows them to serve industries such as automotive, aerospace, and construction more efficiently and effectively.In addition to their laser cutting services, Custom Metal Work also offers a diverse range of metal fabrication solutions. From custom sheet metal forming to precision welding, the company can fulfill even the most complex design requirements. Their team of experts work closely with clients to understand their unique needs, providing tailored solutions that exceed expectations.One of the key features that sets Custom Metal Work apart is their commitment to sustainability. The company utilizes advanced recycling techniques and environmentally friendly materials to minimize their impact on the environment. By adopting a greener approach, they not only contribute to a healthier planet but also help clients achieve their sustainability goals.Custom Metal Work’s dedication to innovation and continuous improvement has earned them numerous accolades within the industry. The company’s relentless pursuit of excellence has resulted in long-standing partnerships with leading companies across various sectors, bolstering its reputation as a reliable, customer-centric metal fabrication specialist.“We are thrilled to expand our portfolio with these exciting new products and services,” stated [company spokesperson]. “Our team has worked tirelessly to equip ourselves with the latest technology and expertise to meet the evolving demands of our clients. With these additions, we are confident that we can continue to deliver top-notch metal fabrication solutions that drive success for our clients.”Clients who have worked with Custom Metal Work express their satisfaction with the company’s ability to deliver quality products within budget and on time. Their attention to detail and commitment to customer service sets them apart from competitors in the industry. From large-scale industrial projects to small-scale custom designs, Custom Metal Work has consistently proven their ability to handle projects of any size and complexity.Moving forward, Custom Metal Work aims to remain at the forefront of the metal fabrication industry by continuously exploring new technologies and refining their processes. With their expanded portfolio of services and unwavering dedication to customer satisfaction, the company is poised to bring even greater value to clients across the globe.About Custom Metal Work:Custom Metal Work is a leading provider of innovative metal fabrication solutions. With over twenty years of experience, the company specializes in custom sheet metal forming, precision welding, and laser cutting services. Combining cutting-edge technology with skilled craftsmanship, Custom Metal Work delivers customized metalwork that meets the highest standards of quality and precision. Their commitment to sustainability and attention to detail set them apart from competitors in the industry.