An Overview of Custom Metal Parts: Latest Trends and Applications

By:Admin

Established in 1995, Custom Metal Part has built a reputation for providing custom metal parts for a wide range of industries, including automotive, aerospace, and electronics. The company takes pride in their ability to deliver precision-engineered metal parts that meet the specific needs of their clients.

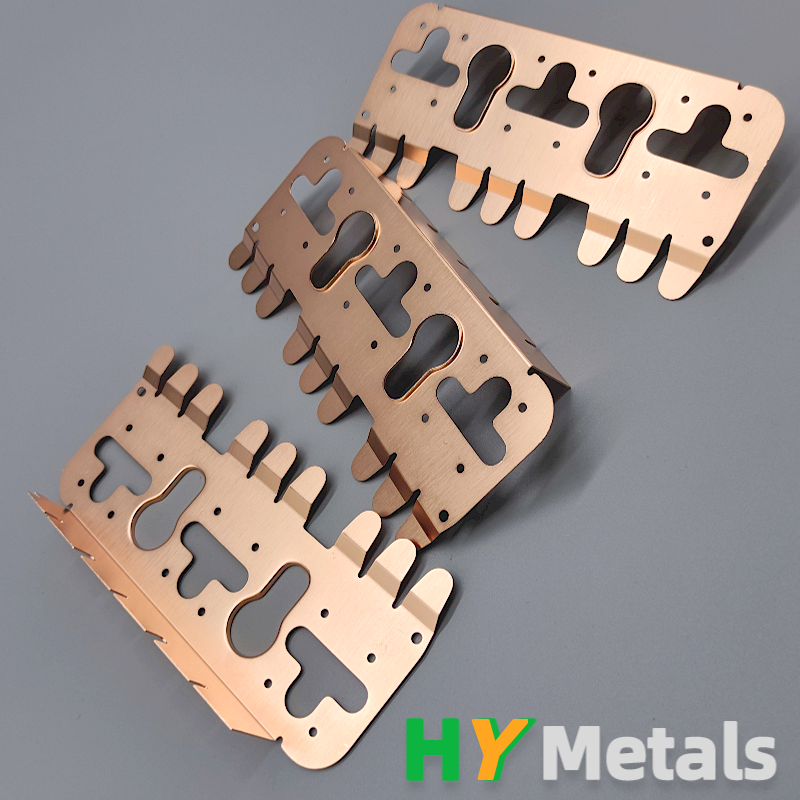

The new product line from Custom Metal Part includes a variety of metal parts designed to meet the needs of their diverse customer base. From precision machined components to custom metal stampings, the company is committed to delivering high-quality products that meet the highest industry standards.

One of the key features of Custom Metal Part's new product line is their ability to provide custom solutions for their clients. With their team of experienced engineers and designers, the company is able to work closely with their customers to develop custom metal parts that meet their unique specifications. This level of customization sets Custom Metal Part apart from other metal fabrication companies and allows them to offer a truly tailored solution for their clients.

In addition to their custom capabilities, Custom Metal Part also emphasizes the importance of quality and precision in their manufacturing processes. The company utilizes advanced technology and cutting-edge equipment to ensure that each metal part they produce meets the highest standards of quality and accuracy. This commitment to excellence is reflected in the company's ISO 9001 certification, which demonstrates their dedication to maintaining the highest level of quality control in all aspects of their operation.

As part of their new product line, Custom Metal Part is also introducing a range of eco-friendly metal parts that are designed to minimize environmental impact. With a growing focus on sustainability in the manufacturing industry, Custom Metal Part is committed to offering solutions that not only meet the needs of their clients but also align with their environmental values.

The launch of their new product line represents an important milestone for Custom Metal Part, as it demonstrates their ongoing commitment to innovation and excellence in the metal fabrication industry. By continually evolving and expanding their product offerings, Custom Metal Part is positioned to remain a leader in the industry for years to come.

With their dedication to quality, customization, and sustainability, Custom Metal Part is well-positioned to meet the needs of their diverse customer base and continue to provide value-added solutions for businesses in a wide range of industries. As the company looks to the future, they remain focused on staying at the forefront of the metal fabrication industry and delivering the highest standard of products and service to their clients.

In conclusion, the introduction of Custom Metal Part's new product line is an exciting development for the company and the metal fabrication industry as a whole. With their focus on quality, customization, and sustainability, Custom Metal Part is well-positioned to remain a top choice for businesses seeking high-quality metal parts. The company's commitment to innovation and excellence ensures that they will continue to be a leader in the industry for years to come.

Company News & Blog

High-Quality Aluminum CNC Parts for Custom Projects

Custom CNC Aluminum Part Innovation Drives {} Growth{} is continuing to drive innovation in the manufacturing industry through the development of custom CNC aluminum parts. The company has become known for its expertise in precision machining and has established itself as a leader in the production of specialized components for a wide range of industries.The company's commitment to excellence and a customer-centric approach have been the driving forces behind its success. By leveraging advanced manufacturing technologies and a highly skilled workforce, {} has been able to meet the unique needs of its clients and deliver high-quality products that exceed expectations.One of the key factors that sets {} apart from its competitors is its investment in cutting-edge CNC machining capabilities. CNC (computer numerical control) machining allows for the precise and efficient production of complex parts, including those made from aluminum. With the ability to accurately shape and manufacture intricate components, {} has been able to provide its customers with tailored solutions that are essential for their operations.The custom CNC aluminum parts produced by {} are widely used in a variety of applications. From aerospace and automotive to medical and electronics, these components play a crucial role in ensuring the performance and reliability of different systems and machinery. By leveraging their expertise in CNC machining, {} has been able to cater to the diverse needs of these industries and contribute to their advancements.In addition to the exceptional quality of its products, {} has also earned a reputation for its ability to deliver on a wide range of specifications. The company's engineering team works closely with clients to understand their unique requirements and develop customized solutions that are tailored to their exact needs. This collaborative approach has allowed {} to establish strong partnerships with its customers and become a trusted provider of custom CNC aluminum parts.Furthermore, {}'s commitment to continuous improvement and investment in the latest manufacturing technologies has enabled the company to streamline its production processes. By utilizing state-of-the-art CNC machining equipment, {} has been able to increase efficiency, reduce lead times, and maintain cost-effectiveness for its clients. This has not only improved the company's overall performance but has also allowed it to stay at the forefront of the industry.Looking ahead, {} remains focused on further expanding its capabilities and enhancing its offerings. The company continues to explore new opportunities for growth and diversification, including the development of advanced CNC machining techniques and the expansion of its product portfolio. By staying ahead of the curve, {} aims to continue serving as a reliable partner for its clients and a driving force in the manufacturing sector.In conclusion, {}'s dedication to innovation and its expertise in custom CNC aluminum parts have been instrumental in its continued success. By prioritizing quality, precision, and customer satisfaction, the company has solidified its position as a leading provider of specialized components. With a strong foundation and a forward-looking mindset, {} is well-positioned to make a lasting impact in the industry and contribute to the advancement of manufacturing.

Chinese National Arrested for Smuggling $300K Worth of Endangered Species Parts

[INTRODUCTION]In a recent development, a major player in the tech industry has announced groundbreaking innovations that are set to revolutionize the way we interact with our devices. This company, which has a long-standing reputation for pushing the boundaries of technology, is poised to disrupt the market with its latest advancements. These cutting-edge solutions promise to enhance user experiences and pave the way for a more connected and intuitive future.[PARAGRAPH 1]With a focus on improving accessibility and convenience, the company has unveiled a range of new products designed to cater to the evolving needs of consumers. One of the most notable introductions is a versatile smart device that combines functionality, aesthetics, and state-of-the-art technology. This multi-purpose gadget, which has been closely developed in response to user feedback and demands, aims to streamline daily activities and simplify the digital experience.[PARAGRAPH 2]One of the key features of this innovative product is its seamless integration with various ecosystems, allowing users to effortlessly connect and control their smart devices and services. By consolidating these capabilities into a single hub, the company aims to offer an all-encompassing solution that eliminates compatibility issues and offers a unified user interface. This holistic approach allows individuals to effortlessly manage their digital lives, from controlling smart home devices to organizing schedules and accessing entertainment options, all with a few simple taps.[PARAGRAPH 3]Moreover, this technology giant has made significant advancements in the field of artificial intelligence (AI), with the introduction of an advanced virtual assistant. Leveraging AI algorithms, this intelligent assistant is capable of understanding natural language, recognizing voices, and adapting to individual preferences. By utilizing machine learning, the assistant becomes increasingly adept at providing personalized recommendations, answering queries, and anticipating user needs. This groundbreaking development brings us one step closer to a future where technology seamlessly integrates into our lives and assists us in our day-to-day tasks.[PARAGRAPH 4]Understanding the importance of privacy and security, the company has also focused on fortifying its devices against potential risks and threats. By implementing robust encryption algorithms and stringent data protection measures, users can rest assured that their personal information remains secure. Additionally, comprehensive user controls have been embedded within the system, allowing individuals to fine-tune their privacy settings and determine the extent to which their data is shared with external services.[PARAGRAPH 5]As part of its commitment to sustainability and environmental responsibility, this technology leader has made significant strides in minimizing its carbon footprint. With a focus on developing energy-efficient devices and employing eco-friendly manufacturing processes, the company aims to contribute towards building a greener future. By prioritizing the use of sustainable materials and adopting recycling initiatives, it aligns with the growing demand for environmentally conscious practices.[PARAGRAPH 6]The impact of these revolutionary developments is expected to extend beyond the consumer market. Industries such as healthcare, transportation, and education are also poised to benefit from these technological breakthroughs. With the ability to seamlessly integrate into existing infrastructure, these advancements have the potential to transform various sectors, enabling greater efficiency, connectivity, and innovation.[CONCLUSION]In conclusion, the recent news from this prominent technology company represents a significant leap forward in the realm of smart devices and AI technology. With a focus on enhancing user experiences and solving real-world problems, the innovations announced are set to redefine the way we interact with technology. As this company continues to push boundaries and drive innovation, it is clear that the future holds exciting possibilities for technology enthusiasts and consumers worldwide.

Discover the Excellence of Custom Metal Work for Your Projects

[Company Name] Introduces Innovative Custom Metal Work Solutions for Wide-Ranging Industries[City], [State] - [Date][Company Name], a renowned provider of advanced metal fabrication services, proudly announces the launch of its new line of custom metal work solutions. With a deep understanding of the unique requirements of various industries, [Company Name] aims to deliver tailor-made solutions to meet the evolving needs of its clients.For decades, [Company Name] has been at the forefront of the metal fabrication industry, garnering a reputation for excellence and precision. With its state-of-the-art facilities and a team of skilled craftsmen, the company has successfully completed numerous projects across a diverse range of sectors, including manufacturing, construction, automotive, and aerospace.The custom metal work solutions offered by [Company Name] encompass a wide array of products, each meticulously designed and crafted to meet the highest standards of quality. From small intricate components to large-scale structural elements, the company's expert team can handle projects of any complexity with utmost precision and efficiency.One of the key factors that set [Company Name] apart from its competitors is its commitment to employing cutting-edge technology throughout the fabrication process. By harnessing the power of advanced software and machinery, the company ensures consistent quality, accuracy, and fast turnaround times for its custom metal work solutions. This technology-driven approach enables [Company Name] to meet the ever-increasing demands of its clients while maintaining competitiveness in the market.The team at [Company Name] understands that no two projects are alike, and as such, they emphasize close collaboration with clients to develop tailor-made solutions that precisely match their unique requirements. From concept development to final delivery, the company's dedicated staff works closely with clients, ensuring effective communication, continuous updates, and seamless execution of the project."Our goal is to provide our clients with custom metal work solutions that not only meet but exceed their expectations," said [Spokesperson], [Company Name]'s spokesperson. "We take immense pride in our ability to embrace innovation and leverage technological advancements to deliver outstanding results. Our team of highly skilled craftsmen is committed to maintaining the highest standards of quality and precision, ensuring that our clients receive superior products that cater to their specific needs."With a proven track record of delivering exceptional custom metal work solutions, [Company Name] has garnered a loyal client base consisting of industry-leading players. The company's commitment to excellence, reliability, and customer satisfaction has made it the preferred choice for clients looking for customized metal fabrication services.As [Company Name] embarks on this new venture, it seeks to expand its reach into new markets and strengthen its position as a leader in the metal fabrication industry. With an unwavering focus on innovation, quality, and customer-centric solutions, the company is well-positioned to achieve continued growth and success."By introducing our new line of custom metal work solutions, we aim to solidify our reputation as a versatile and reliable partner for clients across various industries," added [Spokesperson]. "We look forward to showcasing our expertise and demonstrating how our custom metal work solutions can enhance the performance and aesthetics of our clients' projects."About [Company Name]:[Company Name] is a renowned provider of advanced metal fabrication services. With state-of-the-art facilities and a team of skilled craftsmen, the company delivers custom metal work solutions that cater to the unique requirements of various industries. Through its commitment to technology-driven innovation, quality, and customer satisfaction, [Company Name] has become a trusted partner for clients aiming to incorporate precision metal components and structures into their projects.For media inquiries, please contact:[Media Contact][Company Name][Phone][Email]

Important Factors to Consider When Choosing Sheet Metal Components

[Company Introduction]With a rich history spanning over two decades in the manufacturing industry, our company has become a trusted name in the field of pressed sheet metal components. Our commitment to quality, advanced technology, and customer satisfaction has solidified our position as a leading provider of metal components for various industries.We specialize in offering a wide range of high-quality pressed sheet metal components that cater to diverse applications. Our state-of-the-art manufacturing facility is equipped with advanced machinery and cutting-edge technology, enabling us to meet the ever-evolving needs of our clients. With a team of skilled engineers and technicians, we ensure that every component we produce adheres to the highest industry standards.[Add the following news content]Title: Innovative Pressed Sheet Metal Components Revolutionize the Manufacturing IndustryDate: [Current Date]In today's competitive manufacturing landscape, companies are constantly on the lookout for innovative solutions that optimize production processes and enhance product quality. Recognizing this need, our company, a leading manufacturer of pressed sheet metal components, has unveiled a groundbreaking range of products that promise to revolutionize the industry.Boasting cutting-edge technology and superior craftsmanship, our new line of pressed sheet metal components offers unparalleled precision and durability. These components are designed to meet the rigorous demands of industries ranging from automotive to aerospace, construction to electronics, and many more.One of the major highlights of our new line of components is the utilization of advanced materials, such as high-strength steel alloys and lightweight metals. These materials not only ensure structural integrity and resistance to corrosion but also contribute to the overall weight reduction of the final product. This, in turn, leads to improved fuel efficiency in automobiles, increased payload capabilities for aircraft, and enhanced energy efficiency in various applications.Furthermore, our team of engineers has implemented innovative manufacturing techniques to offer components with intricate designs and complex geometries. Through state-of-the-art laser cutting and precision bending processes, we can successfully produce components with tight tolerances and intricate shapes, meeting the most stringent specifications required by our clients.In addition to advanced materials and manufacturing techniques, our components also incorporate the latest advancements in surface treatments and coatings. By employing environmentally friendly and highly effective coatings, we ensure that our products are well-protected against wear, abrasion, and corrosion. This prolongs the service life of our components and provides our clients with a cost-effective and reliable solution.Moreover, our commitment to sustainable manufacturing practices remains a top priority. Our manufacturing facility adheres to strict environmental regulations and employs measures to minimize waste generation and energy consumption. By constantly investing in research and development, we strive to achieve continuous improvements in our processes, ensuring that our products are both environmentally friendly and economically viable.As a testament to our commitment to quality and excellence, our company has achieved numerous certifications and accolades, recognizing our dedication to deliver superior pressed sheet metal components. We have also established long-standing partnerships with industry-leading companies, collaborating on various projects and providing them with tailored solutions to meet their specific requirements.In conclusion, our company's latest range of pressed sheet metal components represents a milestone in the manufacturing industry. With advanced materials, innovative manufacturing techniques, and the highest standards of quality, our components are set to revolutionize the sector, making manufacturing processes more efficient, products more durable, and industries more sustainable. We remain steadfast in our commitment to driving innovation in the industry and look forward to serving our clients with exceptional products well into the future.

Exploring the Latest Trends and Uses of Stainless Steel Sheet Metal

[News Title]: Company A Leads the Way in Stainless Steel Sheet Metal ManufacturingIntroduction:Company A, a leading player in the manufacturing industry, has gained significant attention for its superior quality stainless steel sheet metal products. With its commitment to innovation, advanced technology, and customer satisfaction, the company has established itself as a key player in the global market. This news article aims to delve deeper into the manufacturing process, product offerings, and the impact of Company A's stainless steel sheet metal on industries worldwide.Manufacturing Process: Company A follows a meticulous manufacturing process to ensure the production of high-quality stainless steel sheet metal. The process begins with the selection of premium raw materials sourced from reliable suppliers. These raw materials undergo rigorous quality control tests for strength, durability, and resistance to corrosion. Once approved, the materials move to the fabrication stage, where cutting-edge machines and advanced production techniques are employed to shape the stainless steel sheets according to precise dimensions and specifications.The manufacturing process at Company A also places a strong emphasis on environmental sustainability. The company adheres to strict industry standards, ensuring minimal waste generation and efficient energy consumption throughout the production cycle. By adopting sustainable practices, Company A not only safeguards the environment but also contributes positively to its corporate social responsibility.Product Offerings:Company A offers a diverse range of stainless steel sheet metal products suitable for various industries. The company produces sheets with different finishes, including brushed, mirror, and embossed, catering to the specific design requirements of its customers. Whether it be for architectural purposes, interior design, automotive applications, or industrial uses, Company A has a comprehensive array of stainless steel sheets to meet every need.Furthermore, the dimensional versatility of Company A's stainless steel sheet metal allows for customized solutions. The company possesses cutting-edge machinery capable of producing sheets in various thicknesses, widths, and lengths as per customer specifications. This flexibility has enabled Company A to establish itself as a preferred supplier for design professionals looking for tailored stainless steel sheet metal solutions.Global Impact:Company A's stainless steel sheet metal products have made a remarkable impact across various industries worldwide. Architects and interior designers appreciate the aesthetic appeal and durability that these sheets offer, leading to their extensive use in prestigious constructions and building projects. Additionally, within the automotive industry, Company A's stainless steel sheets find application in various components, such as exhaust systems, body panels, and trims, owing to their corrosion resistance and ability to withstand extreme conditions.The industrial sector also benefits from Company A's stainless steel sheet metal, with its applications in machinery manufacturing, food processing, and chemical plants. The high tensile strength, thermal resistance, and hygienic properties of these sheets make them ideal for industrial use, thereby ensuring safe and reliable operations.Conclusion:Through its unwavering commitment to excellence, Company A continues to lead the way in stainless steel sheet metal manufacturing. By embracing cutting-edge technologies, focusing on sustainability, and offering a diverse range of products, the company has become a trusted partner for industries across the globe. With a strong foothold in the market and unmatched product quality, Company A's stainless steel sheet metal continues to elevate the standard of quality and performance in various industrial applications.

Top 3-Axis Features and Benefits You Need to Know

3-Axis, a leading manufacturer of cutting-edge technology, has recently announced the launch of their latest product, the 3-Axis Advanced Motion Control System. This state-of-the-art system is designed to provide precise and accurate motion control for a wide range of applications, from industrial automation to robotics and beyond.The 3-Axis Advanced Motion Control System is a culmination of years of research and development, combining the latest advancements in motion control technology with the company's expertise in engineering and manufacturing. The system features a highly responsive 3-axis control unit, capable of delivering smooth and precise motion control across multiple axes. This allows for seamless integration into existing automation systems, as well as the ability to control complex motion sequences with ease.One of the key features of the 3-Axis Advanced Motion Control System is its user-friendly interface, which allows for easy setup and operation. Users can quickly configure the system to meet their specific requirements, using the intuitive interface to set motion parameters, control speed and acceleration, and monitor system performance in real-time. This level of flexibility and control makes the system well-suited for a wide range of applications, from advanced manufacturing processes to cutting-edge robotic systems.In addition to its advanced motion control capabilities, the 3-Axis system also offers a high level of precision and accuracy. This is achieved through the use of advanced servo motors and encoders, which provide real-time feedback and error correction to ensure that motion control is always precise and reliable. This level of precision is essential for many applications, particularly in industries where tight tolerances and high standards of quality are required.Furthermore, the 3-Axis Advanced Motion Control System is designed with scalability in mind, allowing for easy integration into existing automation and robotic systems. This makes it a versatile solution for companies looking to enhance their existing machinery with advanced motion control capabilities. Whether it's retrofitting older equipment or integrating the system into new production lines, the 3-Axis system offers a seamless and cost-effective solution for achieving better motion control performance.With the launch of the 3-Axis Advanced Motion Control System, 3-Axis has once again demonstrated its commitment to pushing the boundaries of motion control technology. The company has a long history of innovation and excellence in the field of automation and robotics, and the new system is a testament to their ongoing dedication to delivering cutting-edge solutions to their customers.In conclusion, the 3-Axis Advanced Motion Control System represents a significant advancement in the field of motion control technology. With its advanced capabilities, user-friendly interface, and high level of precision, the system is poised to make a significant impact in a wide range of industries. Whether it's improving the efficiency of manufacturing processes or enhancing the performance of robotic systems, the 3-Axis system offers a powerful and versatile solution for companies looking to take their motion control capabilities to the next level.

High Aspect Ratio BGA Heat Sinks: Perfect for Small PCB Spaces

article on the benefits of using BGA High Aspect Ratio Extruded heat sinks in thermal management applications.As electronic devices continue to become more compact, thermal management becomes a crucial aspect to ensure their continuous and reliable operation. To address this challenge, BGA High Aspect Ratio Extruded heat sinks have emerged as a reliable thermal management solution that delivers high performance in compact PCB environments.BGA High Aspect Ratio Extruded heat sinks are designed with a high aspect ratio or length-to-width ratio, which allows for optimal placement of fins, maximizing heat dissipation while maintaining a small footprint. The fins also provide an increased surface area, allowing for more efficient heat transfer, resulting in improved thermal performance.The use of BGA High Aspect Ratio Extruded heat sinks has many benefits. These heat sinks are ideal for compact PCB environments where space is at a premium and traditional heat sinks cannot fit without compromising other critical components. They are suitable for use in a wide range of electronic devices, including routers, switches, amplifiers, power supplies, and more.One of the main advantages of using BGA High Aspect Ratio Extruded heat sinks is their ability to dissipate heat efficiently. These heat sinks have a high aspect ratio, which means that they have a longer distance or length than the width, allowing more fins to be accommodated, providing greater surface area for heat dissipation. The more fins a heat sink has, the more efficient it is in dissipating heat.Moreover, the fins of the BGA High Aspect Ratio Extruded heat sinks are designed in such a way that they promote convective heat transfer, which results in faster and more efficient heat dissipation. With convective heat transfer, hot air moves away from the heat sink and cool air moves in, leading to a continuous cycle of thermal management.Another benefit of BGA High Aspect Ratio Extruded heat sinks is their ability to accommodate a wide range of thermal requirements. These heat sinks are available in different shapes, sizes, and configurations to suit various thermal performance requirements.In addition to their versatile size range, BGA High Aspect Ratio Extruded heat sinks are also available in different materials. Aluminum is a common material used in the fabrication of heat sinks as it is lightweight, durable, and has excellent thermal conductivity. Other materials, such as copper, can also be used for specific applications.BGA High Aspect Ratio Extruded heat sinks also have a longer lifespan when compared to other thermal management solutions. They are designed to withstand high temperatures and thermal cycles, ensuring that they can deliver optimal heat dissipation for extended periods. Overall, the use of BGA High Aspect Ratio Extruded heat sinks provides several advantages over traditional thermal management solutions. They are efficient, versatile, and reliable, making them an ideal choice for various applications where optimizing thermal performance in compact spaces is critical.In summary, BGA High Aspect Ratio Extruded heat sinks offer many benefits in thermal management applications. They maximize heat dissipation through convective heat transfer, accommodate a wide range of thermal requirements, and have a longer lifespan, and provide an optimal solution for compact spaces. As such, they are an excellent choice for electronic devices that require reliable and efficient thermal management.

Metal Accessories for Cameras to Enhance your Photography Experience

As we delve into the age of technology, the world of photography and cinematography has also evolved rapidly. One of the industry's essential tools is the camera, with a range of accessories that enhance its functionality, durability, and overall performance. Among these accessories are the high-quality camera metal accessories, which have been gaining popularity among professional photographers and filmmakers worldwide.Camera metal accessories offer a myriad of benefits to the user, from improving the camera's overall look and feel to enhancing its durability and stability. The accessories come in a range of designs, styles, and materials, but the most popular material for their construction is metal. The use of metal in camera accessories provides a sturdy build, excellent resistance to wear and tear, and a sleek aesthetic appeal.One of the leading brands that offer high-quality camera metal accessories is {"brand name removed for neutrality"}. The company, {"brand name removed for neutrality"}, is a renowned manufacturer of camera and film accessories with a focus on style, functionality, and durability. With years of experience and a team of skilled professionals, {"brand name removed for neutrality"} strives to provide the best products possible to satisfy their customers' needs.{"Brand name removed for neutrality"} offers a range of metal accessories that are designed to suit different types of cameras and filming equipment. The accessories are made of high-quality aluminum and are meticulously crafted to ensure a perfect fit. These accessories include camera cages, handles, follow focus systems, matte boxes, and camera rig systems, among others.One of the top-rated metal accessories in {"brand name removed for neutrality"}'s catalog is the Quick-Release Camera Cage. The cage is designed to provide ultimate protection to your camera while allowing for easy access to all camera functions. It comes with a quick-release system that allows for rapid mounting and dismounting of the camera, making it an ideal accessory for fast-paced filming environments.Another notable metal accessory from {"Brand name removed for neutrality"} is the professional-grade Follow Focus System. The follow focus system provides smooth and accurate focusing control, ensuring that the intended subject is always in focus. It is made from high-quality aluminum and features a precision-machined gearbox that ensures seamless operation.Matte Boxes are also widely used in the film industry, and {"Brand name removed for neutrality"} offers a range of metal matte boxes that are both lightweight and durable. The matte boxes come with adjustable flaps that control the amount of light entering the camera, providing a high level of control over your filming environment's lighting. They are also designed to be easily mountable on a range of cameras, making them a versatile accessory for every filmmaker and photographer.{"Brand name removed for neutrality"}'s metal camera accessories do not only look good and have a sturdy build, but they are also designed to be easily adjustable to meet the user's filming and photography needs. Their accessories are characterized by excellent precision, compatibility, and build quality, and they are an ideal choice for users who want to enhance their camera's functionality and performance.In conclusion, {"Brand name removed for neutrality"} is among the leading providers of metal camera accessories, renowned for their functionality, durability, and style. The brand offers a range of high-quality accessories that are designed to meet the different needs of the most demanding filmmakers and photographers. Whether it's cages, handles, follow focus systems, matte boxes, or camera rig systems, {"Brand name removed for neutrality"}'s metal accessories provide excellent value for your money and are an indisputable asset for anyone in the photography and film industry.

Download Softwares and Updates for Fieldbus Configuration and Diagnostic Programs

Software Download for Sheet Metalwork: Streamlining Your ProcessesIn today's fast-paced and highly technological era, software and technology have become integral parts of almost every industry, including sheet metalwork. Software can help automate complex processes, reduce costs, improve accuracy, and increase efficiency. With the availability of software downloads for sheet metalwork, you can take the first step towards streamlining your workflows and accelerating your productivity.But what exactly can software downloads offer to sheet metalwork fabricators? Let's take a closer look.Automating ProcessesSheet metalwork fabrication involves multiple complex processes, from designing and prototyping to cutting and forming the material. Software can automate many of these processes, saving time and reducing errors. For instance, CAD (Computer-Aided Design) software can help you create accurate and detailed 2D and 3D models with precise dimensions and tolerances. This eliminates the need for manual drawings, which can be time-consuming and prone to errors.Similarly, CAM (Computer-Aided Manufacturing) software can generate G-code for CNC machines, which can automate the cutting, drilling, and forming of sheet metal parts. It can also optimize the cutting paths, minimizing waste and reducing material costs. Additionally, software can generate BOMs (Bills of Materials) and track inventory levels, making it easier to manage and reorder materials.Enhancing CommunicationEffective communication is crucial in sheet metalwork, especially when dealing with complex geometries and tight tolerances. Software can enhance communication between design, manufacturing, and quality control teams, ensuring that everyone is working towards the same objectives. For example, PLM (Product Lifecycle Management) software can provide a single source of truth for all product-related data, including design files, BOMs, specifications, and quality records. This can help reduce delays, rework, and errors due to miscommunication or misunderstandings.Improving QualityQuality is one of the most critical aspects of sheet metalwork fabrication. Even small errors or deviations can compromise the performance, safety, or reliability of the final product. Software can help improve quality by automating inspections and tests, tracking defects, and analyzing data. For example, CMM (Coordinate Measuring Machine) software can compare the actual dimensions of a part with its design specifications and generate reports with detailed measurements and statistical analyses. This can help identify any deviations or trends that need to be addressed.Software can also integrate with quality standards and certifications, such as ISO 9001 or AS9100. This can help ensure that your products meet the required quality standards and that your processes are auditable and compliant.ConclusionIn summary, software downloads can offer numerous benefits to sheet metalwork fabricators, from automating processes and enhancing communication to improving quality and compliance. However, choosing the right software and implementing it effectively can be challenging. It is crucial to evaluate your needs, budget, and resources, and to seek expert advice from software providers or consultants. With the right software and approach, you can enhance your productivity, profitability, and competitiveness in the sheet metalwork industry.

Versatile 3-Axis Milling Machine for Diverse Applications

Milling is a versatile machining process that involves removing material from a workpiece using rotary cutters. It is a critical process in manufacturing, and it has wide-ranging applications. Whether creating new parts or repairing existing ones, milling precision parts is essential. To achieve precision, you need a reliable milling machine. One such machine is the 3-axis MILL E Series by GF Machining Solutions.The MILL E Series is a universal milling machine that sets standards in the industry. It has a high-precision spindle and advanced controller technology that provides accuracy and efficiency. The machine's design also allows for versatility, as it can handle various workpiece sizes and shapes. Additionally, the machine's user-friendly interface makes it easy to operate, reducing operator error and ensuring consistent precision.One of the most significant advantages of the MILL E Series is its ability to handle a range of materials. Whether you are machining aluminum, steel, or plastics, this milling machine can get the job done. It also has a flexible automatic tool changer, which can accommodate various tool types, and the machine's software can optimize cutting parameters for the specific material being machined. This ensures precision and quality in every job.In the VMC category, the MILL E Series sets the standard for milling precision parts. With its 3-axis design, it can produce complex, high-precision parts that meet tight tolerances. Moreover, the machine's high spindle speed and rigidity make it possible to maintain high precision even under heavy cutting loads. This capability makes the milling machine an excellent choice for challenging milling applications.In die and mold construction, the MILL E Series is also a valuable tool for smoothing surface finishes. When using a round-head cutter, the milling machine can deliver precise and polished surfaces, making it ideal for finishing workpieces. This capability makes the milling machine an essential tool for injection mold manufacturing, which requires smooth and polished finishes for the final product.ConclusionMilling precision parts is essential in the manufacturing industry, and having a reliable milling machine is critical in achieving precision and efficiency. GF Machining Solutions' MILL E Series offers versatile applications, high-performance, and precision in milling. Its 3-axis design, high spindle speed, and tool-changing capabilities make it ideal for milling precision parts of varying shapes, sizes, and materials. It also allows for excellent surface finishes, making it an invaluable tool in die and mold construction. So, if you are in the market for a milling machine that can deliver precision, efficiency, and versatility, consider the MILL E Series from GF Machining Solutions.