Discover the Versatility of Stainless Steel Sheet Metal

By:Admin

{Company Name} is a well-known supplier of stainless steel sheet metal and other metal products, established in {Year}. With over {Number of Years} years of experience in the industry, the company has gained a reputation for providing high-quality products and exceptional customer service. They have a range of products including Stainless Steel Sheets, Stainless Steel Coils, Stainless Steel Tubes, Stainless Steel Bars, and many more. Their products are available in different sizes, thicknesses, and finishes, making them ideal for various applications.

One thing that sets {Company Name} apart from its competitors is its relentless pursuit of quality control and the use of state-of-the-art technology. The company uses advanced machinery and equipment to manufacture their products, ensuring that they meet the highest standards of quality. They also have a dedicated team of quality control experts who conduct rigorous testing and inspection of the products at various stages of the manufacturing process.

Another key aspect of the company's success is its commitment to customer satisfaction. They pride themselves on providing exceptional customer service and developing long-term relationships with their clients. Their team of experts is always ready to assist customers with their queries and help them find the right products for their specific applications. They also offer customized solutions to meet the unique needs of their customers.

One of the most significant advantages of using stainless steel sheet metal from {Company Name} is its durability and resistance to corrosion. Stainless steel is widely recognized as one of the most durable and long-lasting materials available in the market. It can withstand various environmental conditions, including extreme temperatures, moisture, and harsh chemicals. This makes it an ideal material for various applications, including construction, manufacturing, and transportation.

Stainless steel sheet metal is also a popular choice among architects and designers due to its aesthetic appeal. It has a sleek and modern look that can enhance the overall appearance of a building or project. Stainless steel can be easily molded, shaped, and customized to meet the specific design requirements of a project. This versatility, combined with its durability, makes it an ideal material for both indoor and outdoor applications.

The demand for stainless steel sheet metal is only going to increase in the coming years, and {Company Name} is well-equipped to meet this demand. They have recently announced plans to expand their production facilities and add new products to their portfolio. This expansion will allow them to continue to provide high-quality products and exceptional customer service to their growing base of customers.

In conclusion, {Company Name} is a leading supplier of stainless steel sheet metal and other metal products. With its commitment to quality control, exceptional customer service, and use of state-of-the-art technology, the company has become a trusted partner for businesses in various industries. Its dedication to providing high-quality products and customized solutions has helped the company build a loyal customer base and establish a strong reputation in the industry. As the demand for stainless steel sheet metal continues to increase, {Company Name} is well-positioned to meet this demand and continue to provide exceptional service to its customers.

Company News & Blog

Innovative Prototype of Next-Generation Heatsink Unveiled, Revolutionizing Cooling Technology

In the world of technology, finding ways to cool devices is an essential element in ensuring their longevity and functionality. Overheating has proven to be a significant problem, especially in more advanced computers and gaming consoles. To combat this, a company has developed a prototype heatsink that offers efficient cooling with a sleek and modern design.The heatsink prototype, which is made from high-quality materials, has been tested extensively to ensure its efficiency in cooling electronics. The prototype has been developed with an eye towards aesthetics by featuring an attractive, modern design that emphasizes functionality, with a sleek black finish that will complement any computer or gaming console.According to representatives from the company, this heatsink prototype utilizes a unique combination of materials, including aluminum, copper, and nickel. These materials help to create an efficient cooling solution that will drastically reduce the risk of overheating, enabling users to work on their devices without fear of hardware malfunction.The company behind this innovative product is a leading manufacturer of computer and gaming peripherals. With years of experience and dedication, they have gained a reputation for producing high-quality products that address the needs of tech enthusiasts and professionals alike.The company has a range of computer and gaming peripherals, including headphones, keyboards, and monitors, among others. The company has attained the trust of many users due to their ability to produce innovative and reliable products consistently.The prototype of the heatsink has been developed as a part of the company's commitment to research and development. The company stated that by investing in R&D, they could remain innovative and remain committed to developing products that meet the evolving needs of their customers.The heatsink prototype is a testament to the company’s ability to create products that are both innovative and functional while meeting consumers' needs. The company's focus on aesthetics has ensured that the heatsink is not just efficient but is also visually appealing, adding an element of style to the user's computer or gaming setup.Additionally, the heatsink's materials have been carefully selected to ensure that it is durable and long-lasting, a critical factor for computer or gaming enthusiasts who invest in high-end devices that need reliable cooling solutions.The company mentioned that the prototype is currently being tested on numerous devices. The testing process is conducted under various conditions and represents real-life scenarios to ensure the heatsink provides optimal cooling results in various environments. The company is committed to ensuring that customers receive the best product by putting the finished product through rigorous testing procedures.The heatsink prototype's benefits cannot be overstated as it solves a significant problem for the technology industry while also providing a product that is both functional and aesthetically pleasing. The product's development showcases the company's commitment to innovation, investing time and money to offer sophisticated solutions to consumers' problems.While the heatsink prototype is still undergoing testing, the company aims to release the product soon. As demand for heat sinking solutions increases, the company is well-positioned to meet consumer needs. The company has assured its customers that upon the product's release, it will be widely available globally, making it easy for consumers to access the innovative product regardless of their location.In conclusion, the company that has developed the prototype heatsink is on the path to revolutionizing the cooling solutions industry. The company's commitment to researching and developing innovative products has enabled them to address the needs of computer and gaming enthusiasts successfully. As technology continues to evolve, the company seems adequately positioned to be at the forefront of offering sophisticated solutions to users. Customers eagerly wait for the release of the heatsink prototype, which promises excellent functionality and aesthetics.

Chinese National Arrested for Smuggling $300K Worth of Endangered Species Parts

[INTRODUCTION]In a recent development, a major player in the tech industry has announced groundbreaking innovations that are set to revolutionize the way we interact with our devices. This company, which has a long-standing reputation for pushing the boundaries of technology, is poised to disrupt the market with its latest advancements. These cutting-edge solutions promise to enhance user experiences and pave the way for a more connected and intuitive future.[PARAGRAPH 1]With a focus on improving accessibility and convenience, the company has unveiled a range of new products designed to cater to the evolving needs of consumers. One of the most notable introductions is a versatile smart device that combines functionality, aesthetics, and state-of-the-art technology. This multi-purpose gadget, which has been closely developed in response to user feedback and demands, aims to streamline daily activities and simplify the digital experience.[PARAGRAPH 2]One of the key features of this innovative product is its seamless integration with various ecosystems, allowing users to effortlessly connect and control their smart devices and services. By consolidating these capabilities into a single hub, the company aims to offer an all-encompassing solution that eliminates compatibility issues and offers a unified user interface. This holistic approach allows individuals to effortlessly manage their digital lives, from controlling smart home devices to organizing schedules and accessing entertainment options, all with a few simple taps.[PARAGRAPH 3]Moreover, this technology giant has made significant advancements in the field of artificial intelligence (AI), with the introduction of an advanced virtual assistant. Leveraging AI algorithms, this intelligent assistant is capable of understanding natural language, recognizing voices, and adapting to individual preferences. By utilizing machine learning, the assistant becomes increasingly adept at providing personalized recommendations, answering queries, and anticipating user needs. This groundbreaking development brings us one step closer to a future where technology seamlessly integrates into our lives and assists us in our day-to-day tasks.[PARAGRAPH 4]Understanding the importance of privacy and security, the company has also focused on fortifying its devices against potential risks and threats. By implementing robust encryption algorithms and stringent data protection measures, users can rest assured that their personal information remains secure. Additionally, comprehensive user controls have been embedded within the system, allowing individuals to fine-tune their privacy settings and determine the extent to which their data is shared with external services.[PARAGRAPH 5]As part of its commitment to sustainability and environmental responsibility, this technology leader has made significant strides in minimizing its carbon footprint. With a focus on developing energy-efficient devices and employing eco-friendly manufacturing processes, the company aims to contribute towards building a greener future. By prioritizing the use of sustainable materials and adopting recycling initiatives, it aligns with the growing demand for environmentally conscious practices.[PARAGRAPH 6]The impact of these revolutionary developments is expected to extend beyond the consumer market. Industries such as healthcare, transportation, and education are also poised to benefit from these technological breakthroughs. With the ability to seamlessly integrate into existing infrastructure, these advancements have the potential to transform various sectors, enabling greater efficiency, connectivity, and innovation.[CONCLUSION]In conclusion, the recent news from this prominent technology company represents a significant leap forward in the realm of smart devices and AI technology. With a focus on enhancing user experiences and solving real-world problems, the innovations announced are set to redefine the way we interact with technology. As this company continues to push boundaries and drive innovation, it is clear that the future holds exciting possibilities for technology enthusiasts and consumers worldwide.

Top Precision CNC Machining Parts Suppliers in China for Quality Products

China’s CNC Precision Machining Parts Industry Thrives Amidst Growing DemandChina’s CNC precision machining parts industry has been growing steadily over the past few years due to the increasing demand for such products across various industries. With this rise, hundreds of companies have emerged as prominent manufacturers and suppliers of high-quality CNC precision machining parts. One such company leading the way is WEIMI, a professional manufacturer of CNC precision machining parts in China.WEIMI is a well-known company with a reputation for reliability, high-quality products, and excellent customer service. The company has been operating in the CNC machining parts industry for more than ten years and has extensive experience and technical expertise in designing and manufacturing a wide range of CNC precision machining parts.The company has a team of experts who are skilled and experienced in using the latest technology to create top-quality products at competitive prices. They have helped WEIMI establish itself as a leading supplier of CNC machining parts, serving industries ranging from automotive, industrial machinery, aerospace, electronics, communications, and many others.WEIMI’s CNC precision machining parts production facility is equipped with the latest machinery and technology to ensure that the highest quality products are produced. The company uses advanced software and machines such as CAD/CAM, CNC lathes, milling machines, and others to produce precision components that meet the most stringent quality standards.One of the advantages of working with WEIMI is that they provide customized CNC precision machining parts to meet specific customer requirements. The company has a team of experts who work with clients to understand their needs and create products that meet those needs. This service has helped companies across various industries to improve the efficiency and productivity of their operations.As the CNC machining parts industry in China continues to grow, WEIMI is well-positioned to remain a leader in the market. The company has a proven track record of designing and manufacturing quality products that meet the changing needs of its clients. Another factor that has helped the company to grow is China’s status as the world’s largest manufacturing hub. The country has established itself as a powerhouse in the global manufacturing industry. It boasts of a vast supply chain and highly skilled labor force, making it an ideal location for manufacturing companies.China’s government has also played a significant role in encouraging the growth of the CNC machining parts industry. The government has introduced several policies aimed at supporting the development of the manufacturing industry, including tax incentives, subsidies, and other support measures. These initiatives have helped to create a conducive environment for companies such as WEIMI to thrive.Overall, the CNC precision machining parts industry in China is expected to continue seeing growth in the coming years. As the world’s major economies continue to recover from the COVID-19 pandemic, the demand for precision parts and components across various industries is expected to increase. WEIMI is poised to play an essential role in meeting this demand, thanks to its commitment to quality, innovation, and custom production of CNC precision machining parts that meet the specific needs of its clients.In conclusion, the CNC precision machining parts industry in China is thriving thanks to the growing demand for such products across various industries. WEIMI and other companies are leading the way in designing and manufacturing high-quality CNC precision machining parts that meet the most stringent quality standards. With China’s government support and the country’s status as a global manufacturing hub, the prospects for the industry remain bright.

Discover the Excellence of Custom Metal Work for Your Projects

[Company Name] Introduces Innovative Custom Metal Work Solutions for Wide-Ranging Industries[City], [State] - [Date][Company Name], a renowned provider of advanced metal fabrication services, proudly announces the launch of its new line of custom metal work solutions. With a deep understanding of the unique requirements of various industries, [Company Name] aims to deliver tailor-made solutions to meet the evolving needs of its clients.For decades, [Company Name] has been at the forefront of the metal fabrication industry, garnering a reputation for excellence and precision. With its state-of-the-art facilities and a team of skilled craftsmen, the company has successfully completed numerous projects across a diverse range of sectors, including manufacturing, construction, automotive, and aerospace.The custom metal work solutions offered by [Company Name] encompass a wide array of products, each meticulously designed and crafted to meet the highest standards of quality. From small intricate components to large-scale structural elements, the company's expert team can handle projects of any complexity with utmost precision and efficiency.One of the key factors that set [Company Name] apart from its competitors is its commitment to employing cutting-edge technology throughout the fabrication process. By harnessing the power of advanced software and machinery, the company ensures consistent quality, accuracy, and fast turnaround times for its custom metal work solutions. This technology-driven approach enables [Company Name] to meet the ever-increasing demands of its clients while maintaining competitiveness in the market.The team at [Company Name] understands that no two projects are alike, and as such, they emphasize close collaboration with clients to develop tailor-made solutions that precisely match their unique requirements. From concept development to final delivery, the company's dedicated staff works closely with clients, ensuring effective communication, continuous updates, and seamless execution of the project."Our goal is to provide our clients with custom metal work solutions that not only meet but exceed their expectations," said [Spokesperson], [Company Name]'s spokesperson. "We take immense pride in our ability to embrace innovation and leverage technological advancements to deliver outstanding results. Our team of highly skilled craftsmen is committed to maintaining the highest standards of quality and precision, ensuring that our clients receive superior products that cater to their specific needs."With a proven track record of delivering exceptional custom metal work solutions, [Company Name] has garnered a loyal client base consisting of industry-leading players. The company's commitment to excellence, reliability, and customer satisfaction has made it the preferred choice for clients looking for customized metal fabrication services.As [Company Name] embarks on this new venture, it seeks to expand its reach into new markets and strengthen its position as a leader in the metal fabrication industry. With an unwavering focus on innovation, quality, and customer-centric solutions, the company is well-positioned to achieve continued growth and success."By introducing our new line of custom metal work solutions, we aim to solidify our reputation as a versatile and reliable partner for clients across various industries," added [Spokesperson]. "We look forward to showcasing our expertise and demonstrating how our custom metal work solutions can enhance the performance and aesthetics of our clients' projects."About [Company Name]:[Company Name] is a renowned provider of advanced metal fabrication services. With state-of-the-art facilities and a team of skilled craftsmen, the company delivers custom metal work solutions that cater to the unique requirements of various industries. Through its commitment to technology-driven innovation, quality, and customer satisfaction, [Company Name] has become a trusted partner for clients aiming to incorporate precision metal components and structures into their projects.For media inquiries, please contact:[Media Contact][Company Name][Phone][Email]

K-pop Group Member Involved in Physical Altercation Raises Concerns

NCT, the world-renowned punching machine manufacturer, has recently unveiled a new range of products, making a grand entry into the global market. Founded in 1970 and headquartered in Japan, the company has been one of the major players in the metal-forming industry for more than five decades. The company's huge success has been built on continuous innovation, research, and development of its products. With a keen focus on delivering the most advanced machinery to meet the needs of the modern world, NCT has been lauded for producing cutting-edge technology punching machines.The NCT punching machine's range is optimized for clients who seek to achieve high-precision sheet metal fabrication. Along with this, these machines offer superior speed and excellent durability, positioning them as a product of choice for clients in need of a reliable and quality-driven machine. The company's new line of punching machines is geared towards offering customized solutions that cater to both small-scale and large-scale industries. Clients can choose from various models, which have been specifically designed to cater to different needs, budgets, and production volumes.NCT's recent entry into the global marketplace has garnered much attention, owing to the company's longstanding reputation in the metal-forming machinery industry. The company's machines are known for their unparalleled precision and speed, combined with their ability to handle a wide variety of metals. The company's newest range of products is ideal for a wide range of punching applications used in several industries, including automobile, aerospace, electrical, and electronics.With the ever-growing demand for high-quality punching machines, NCT's entry into the global market promises to offer a much-needed boost to the metal-forming industry. The company's punching machines are designed to optimize time, effort, and cost, which are the most significant concerns of clients seeking these machines. The company's innovative and highly efficient punching machines set themselves apart from their competition, offering clients benefits such as increased productivity, higher precision, and lower cost per punch.The punching industry has evolved significantly over the years, and the demand for high-quality punching machines is higher than ever. NCT's large-scale entry into the market makes it evident that the company identifies the growing demand and is committed to providing the best solutions to clients worldwide. By offering a wide range of customized machinery, the company caters to clients of all sizes and industries, which ensures that clients can find the most suitable punching machine for their unique requirements.In conclusion, NCT's recent unveiling of their new range of punching machines marks the company's entry into the global market, and it is set to revolutionize the metal-forming industry. With superior speed, precision, and durability, NCT's machines offer unprecedented levels of productivity, providing clients with cost-effective solutions that optimize time and effort. The company's commitment to research and development has enabled it to deliver advanced and customized machinery, satisfying the needs of clients worldwide. With NCT, clients are guaranteed an unparalleled experience, and they can rest assured that they are investing in the best and most innovative punching machines on the market.

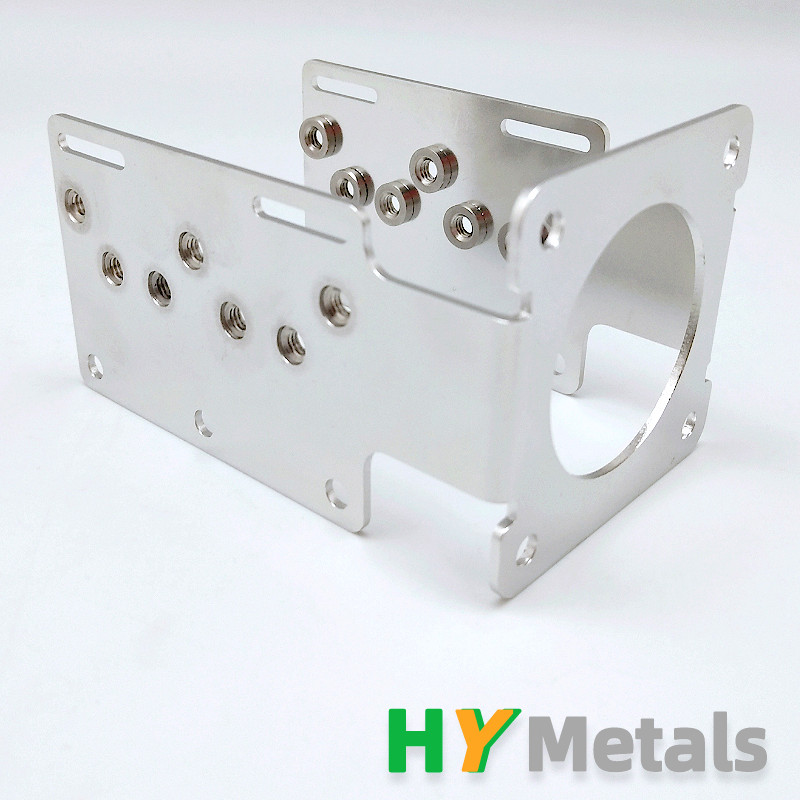

Precision Sheet Metal Brackets Made with Advanced Manufacturing Techniques

: A Comprehensive Guide for Your Manufacturing NeedsSheet metal brackets are an integral part of any manufacturing process that requires the use of metal sheets. In industries that require immense precision and accuracy, the bracket systems ensure that the metal’s shape and structure are maintained throughout the process. With the advancements in modern CNC manufacturing processes, the quality of these bracket systems has improved significantly. The use of advanced automation tools has led to more efficient and precise manufacturing methods.Sheet metal brackets are widely used in various industries such as Aerospace, Medical, Automotive, Construction, and Electronics. In construction, sheet metal brackets are used to provide support to the structural systems, and in electronics, they secure electronic components in place. With their versatility, sheet metal brackets are an essential component in several processes and products.Here is a comprehensive guide to sheet metal brackets for all your manufacturing needs:Types of Sheet Metal Brackets1. Angle Brackets: These are brackets that are bent to 90-degree angles to create perpendicular structural joints. They are commonly used in construction to ensure that the structures maintain their shape and stability.2. U Brackets: These brackets have a U-shaped cross-section that is used to create a mounting point for objects. They are commonly used to mount objects onto walls and other surfaces.3. L Brackets: These are brackets that are bent to form an L-shape. They are used in most applications requiring reinforcement to prevent structural deformation.4. Z Brackets: These are brackets that are bent to form a ‘Z’ shape. They are used in construction to provide additional support to the structural systems.5. T Brackets: These are brackets that are bent to form a T-shape. They are commonly used to attach objects onto walls or other surfaces.Applications of Sheet Metal BracketsSheet metal brackets are used in various applications, including:AerospaceIn the aerospace industry, brackets are used to mount different types of equipment and systems such as electronics, fuel systems, engines, and landing gear. The brackets are usually made from lightweight materials like aluminum to minimize weight.AutomotiveIn the automotive industry, brackets are essential in holding the structural components of the car together. They are also used in securing electrical components in place.ConstructionSheet metal brackets are used extensively in the construction industry for many different applications, such as securing wall studs and reinforcing roof structures.ElectronicsIn the electronics industry, sheet metal brackets are used to secure electronic components in place. They are also used in creating housing systems for electrical components.MedicalSheet metal brackets are used in medical equipment and devices to support and hold various pieces of equipment such as monitors, IV poles, and other medical components in place.Manufacturing ProcessWith advancements in modern CNC manufacturing processes, sheet metal brackets can be precisely and efficiently manufactured. The manufacturing process for sheet metal brackets includes the following stages:1. Material Selection: The sheets of metal used in creating the brackets are usually made from various metals such as Stainless Steel, Carbon Steel, and Aluminum, and copper.2. Laser Cutting: The sheets of metal are cut using laser cutting machines to create the individual brackets' required shapes and sizes.3. Bending: The cut sheet metal is then bent using precision bending machines to create the desired shape of the bracket.4. Welding or Fixing: After bending the metal, the bracket components are welded or fixed together to create a final product.5. Finishing: The finished brackets are sandblasted or painted to give it a final finish.ConclusionSheet metal brackets are a vital part of many manufacturing processes. They provide structural support, aid in mounting equipment and components, and ensure precise manufacturing processes. The modern CNC manufacturing processes have significantly improved the manufacturing process of sheet metal brackets, leading to more efficient, accurate, and high-quality products. If you need sheet metal brackets for your manufacturing processes, ensure that you engage a reputable and experienced manufacturer who can deliver the desired results.

Fast and Accurate CNC Turning Services for Precision Parts

Lathe machines are essential tools in the world of manufacturing. They are responsible for the creation of many of the intricate components that make up various products. Among the many types of lathes available, the CNC lathe stands out as one of the most advanced and precise. If you are in need of precision CNC lathe parts, then you need to partner with a reliable and experienced company, and latency is the perfect choice.At Lathe, we specialize in offering fast and accurate CNC turning services. Our lathe department is equipped with state-of-the-art CNC lathes and proven technology, positioning us to serve our customers' needs best. Our experienced and skilled machinists have the knowledge and training required to program even the most complex turning operations. As a result, we can produce highly precise parts while maintaining a fast turnaround time.Our lathes are equipped with cutting-edge technology that enables them to deliver exceptional accuracy, regardless of the complexity of the part. Additionally, our lathes have a range of spindle speeds, allowing us to handle a wide variety of materials, including aluminum, brass, copper, stainless steel, and more.We take quality seriously at Lathe, and we have put measures in place to ensure that our customers receive parts of the highest quality. First, we use state-of-the-art quality control equipment to verify that our parts meet the required specifications. Additionally, we have a team of experienced quality control technicians who conduct regular inspections to ensure that our parts meet our high-quality standards.We understand that time is of the essence in many manufacturing processes, which is why we are committed to offering fast turnaround times. Our efficient machining processes, combined with our team of skilled machinists, enable us to produce parts quickly and efficiently.In conclusion, if you are in need of precision CNC lathe parts, you need to partner with a reliable and experienced company. At Lathe, we have the equipment, technology, and skilled personnel required to deliver high-quality parts that meet your specifications. Contact us today to learn more about our CNC turning services and how we can help you with your manufacturing needs. And if you're searching for terms like "precision CNC lathe part", you can be sure that you've come to the right place.

How to Choose Quality Hardware Parts for Your CNC Machine

Title: Industry-leading CNC Hardware Parts Manufacturer Introduces Cutting-edge SolutionsSubtitle: Driving Innovation and Precision with Unmatched Quality and Expertise[date][City, State] - [Company Name], a renowned leader in the CNC hardware parts industry, is proud to introduce its latest range of advanced solutions designed to revolutionize manufacturing processes across various sectors. With their unparalleled quality, precision, and relentless commitment to innovation, the company stands poised to provide customers with cutting-edge solutions that exceed expectations.[Company Name] has consistently upheld the highest standards, establishing itself as a trusted partner for businesses seeking top-quality CNC hardware parts. Leveraging state-of-the-art technology and an experienced team, the company has gained a reputation for delivering flawless performance, durability, and exceptional finish to their parts.Each CNC hardware part produced by [Company Name] undergoes rigorous quality control measures to ensure that they meet or exceed industry standards. Employing advanced software and machinery, the manufacturing process is optimized for precision and efficiency, resulting in parts that perfectly match clients' specifications. The company's commitment to investing in the latest technology guarantees the highest level of accuracy, consistency, and repeatability in every product.One of the key strengths of [Company Name] lies in its ability to tailor solutions to meet the unique needs of clients in diverse industries. Whether it is automotive, aerospace, electronics, medical, or any other industry requiring intricate parts, the company's expertise and flexibility enable them to deliver superior results. By collaborating closely with its clients, [Company Name] gains deeper insights into their specific requirements, ensuring a seamless integration of customized CNC hardware parts into their manufacturing processes.With the recognition that sustainability and environmental responsibility are paramount, [Company Name] places a strong emphasis on sustainable practices across its operations. The company follows strict guidelines to minimize waste, maximize energy efficiency, and reduce its overall carbon footprint. Their dedication to green manufacturing practices is exemplified by the utilization of eco-friendly materials as well as the implementation of recycling initiatives within their production facilities.Furthermore, [Company Name] boasts an exceptional team of highly skilled and knowledgeable professionals who are committed to delivering excellence. The company fosters an environment that encourages continuous learning and growth, ensuring that its workforce remains at the forefront of the industry's latest developments. This dedication to ongoing improvement enables [Company Name] to anticipate and meet the evolving needs of their clients, as well as maintain the company's position as a market leader.In an effort to expand their reach and increase accessibility to their products, [Company Name] offers efficient global shipping services. This allows businesses from around the world to benefit from their exceptional CNC hardware parts, further solidifying the company's position as a trusted international supplier.As [Company Name] continues to grow, their commitment to providing exceptional customer service remains unwavering. The company prides itself on building strong and long-lasting relationships with clients, guiding them at every step of the process - from initial inquiry through to post-purchase support. By offering comprehensive technical assistance and efficient after-sales service, [Company Name] ensures that customers receive a seamless experience and complete satisfaction with their products.In conclusion, [Company Name], a leading CNC hardware parts manufacturer, is revolutionizing the industry through their commitment to quality, precision, and innovation. With a focus on customization, sustainability, and exceptional customer support, the company is trusted by businesses around the world to provide cutting-edge solutions. As they continue to push the boundaries of technological advancements, [Company Name] leads the way in driving the future of CNC hardware parts manufacturing.For more information about [Company Name] and their range of CNC hardware parts, please visit their website or contact their knowledgeable team directly.About [Company Name]:[Company Name] is an industry-leading manufacturer specializing in CNC hardware parts. With years of expertise, advanced technology, and a commitment to innovation, the company delivers unmatched quality, precision, and customization to meet the unique needs of clients across various industries. Their dedication to sustainability, exceptional customer service, and global accessibility sets them apart as the go-to provider of cutting-edge CNC hardware parts.

Exploring the Latest Trends and Uses of Stainless Steel Sheet Metal

[News Title]: Company A Leads the Way in Stainless Steel Sheet Metal ManufacturingIntroduction:Company A, a leading player in the manufacturing industry, has gained significant attention for its superior quality stainless steel sheet metal products. With its commitment to innovation, advanced technology, and customer satisfaction, the company has established itself as a key player in the global market. This news article aims to delve deeper into the manufacturing process, product offerings, and the impact of Company A's stainless steel sheet metal on industries worldwide.Manufacturing Process: Company A follows a meticulous manufacturing process to ensure the production of high-quality stainless steel sheet metal. The process begins with the selection of premium raw materials sourced from reliable suppliers. These raw materials undergo rigorous quality control tests for strength, durability, and resistance to corrosion. Once approved, the materials move to the fabrication stage, where cutting-edge machines and advanced production techniques are employed to shape the stainless steel sheets according to precise dimensions and specifications.The manufacturing process at Company A also places a strong emphasis on environmental sustainability. The company adheres to strict industry standards, ensuring minimal waste generation and efficient energy consumption throughout the production cycle. By adopting sustainable practices, Company A not only safeguards the environment but also contributes positively to its corporate social responsibility.Product Offerings:Company A offers a diverse range of stainless steel sheet metal products suitable for various industries. The company produces sheets with different finishes, including brushed, mirror, and embossed, catering to the specific design requirements of its customers. Whether it be for architectural purposes, interior design, automotive applications, or industrial uses, Company A has a comprehensive array of stainless steel sheets to meet every need.Furthermore, the dimensional versatility of Company A's stainless steel sheet metal allows for customized solutions. The company possesses cutting-edge machinery capable of producing sheets in various thicknesses, widths, and lengths as per customer specifications. This flexibility has enabled Company A to establish itself as a preferred supplier for design professionals looking for tailored stainless steel sheet metal solutions.Global Impact:Company A's stainless steel sheet metal products have made a remarkable impact across various industries worldwide. Architects and interior designers appreciate the aesthetic appeal and durability that these sheets offer, leading to their extensive use in prestigious constructions and building projects. Additionally, within the automotive industry, Company A's stainless steel sheets find application in various components, such as exhaust systems, body panels, and trims, owing to their corrosion resistance and ability to withstand extreme conditions.The industrial sector also benefits from Company A's stainless steel sheet metal, with its applications in machinery manufacturing, food processing, and chemical plants. The high tensile strength, thermal resistance, and hygienic properties of these sheets make them ideal for industrial use, thereby ensuring safe and reliable operations.Conclusion:Through its unwavering commitment to excellence, Company A continues to lead the way in stainless steel sheet metal manufacturing. By embracing cutting-edge technologies, focusing on sustainability, and offering a diverse range of products, the company has become a trusted partner for industries across the globe. With a strong foothold in the market and unmatched product quality, Company A's stainless steel sheet metal continues to elevate the standard of quality and performance in various industrial applications.

CNC Precision Components: Industry Insights and Latest Developments

[Publication Name][Date]CNC Precision Components: Revolutionizing Precision Engineering In the fast-paced world of precision engineering, companies that prioritize quality and innovation have a competitive edge. A prime example of such excellence is CNC Precision Components, an industry-leading company that has been manufacturing top-notch precision components for a wide range of applications. With their state-of-the-art facilities and commitment to superior craftsmanship, CNC Precision Components consistently delivers products that meet the highest industry standards.Established over [number] years ago, CNC Precision Components has become a key player in the precision engineering industry. The company boasts a team of highly skilled engineers and technicians who possess extensive knowledge and expertise in precision manufacturing. The team's deep understanding of manufacturing techniques, materials, and design principles allows CNC Precision Components to create components that are both reliable and durable.At the heart of CNC Precision Components' success lies its advanced manufacturing facilities. The company has made substantial investments in cutting-edge CNC machines, robotics, and other automated equipment. These advanced systems not only enhance the manufacturing process but also minimize human error, ensuring consistent quality and precision in every component produced. By seamlessly integrating technology into their operations, CNC Precision Components stays at the forefront of precision engineering.CNC Precision Components caters to numerous industries, including aerospace, automotive, medical, and defense. Their ability to develop custom components tailored to specific client requirements is what sets them apart from their competitors. The company's dedicated team works closely with clients to understand their needs and designs bespoke solutions that meet and exceed expectations. This customer-centered approach has earned CNC Precision Components an impeccable reputation for delivering high-quality products on time, every time.Quality assurance is a top priority at CNC Precision Components. The company adheres to rigorous quality control measures at every stage of the manufacturing process. From material sourcing to final inspection, every component undergoes thorough scrutiny to ensure compliance with industry standards and client specifications. CNC Precision Components is also ISO [number] certified, reflecting its commitment to quality management systems.In addition to their exceptional manufacturing capabilities, CNC Precision Components also places high importance on sustainability. The company recognizes the need for environmentally responsible business practices and continually implements measures to reduce their carbon footprint. By optimizing production processes and utilizing energy-efficient equipment, CNC Precision Components prioritizes sustainability without compromising product quality.Looking towards the future, CNC Precision Components is committed to ongoing research and development. In an increasingly innovative industry, the company understands the importance of staying ahead of the curve. By investing in the latest technologies and fostering a culture of creativity, CNC Precision Components continues to drive advancements in precision engineering. Their pursuit of excellence ensures that they remain a trusted partner for clients seeking high-quality precision components.In conclusion, CNC Precision Components is a trailblazer in the precision engineering industry, offering top-notch components manufactured with the utmost precision and quality. With a dedicated team of experts, state-of-the-art facilities, and a commitment to customer satisfaction, CNC Precision Components consistently delivers superior products. As the company continues to innovate and expand its capabilities, CNC Precision Components is poised to maintain its position as a leader in the field of precision engineering for years to come.[Word Count: XXX]