Expert Tips for Efficient Sheet Metal Assembly

By:Admin

One company that has been at the forefront of sheet metal assembly is {}. Established in 1995, {} has quickly risen to become a leading provider of sheet metal assembly and fabrication services. With a focus on quality, precision, and innovation, {} has built a strong reputation for delivering exceptional products to its clients.

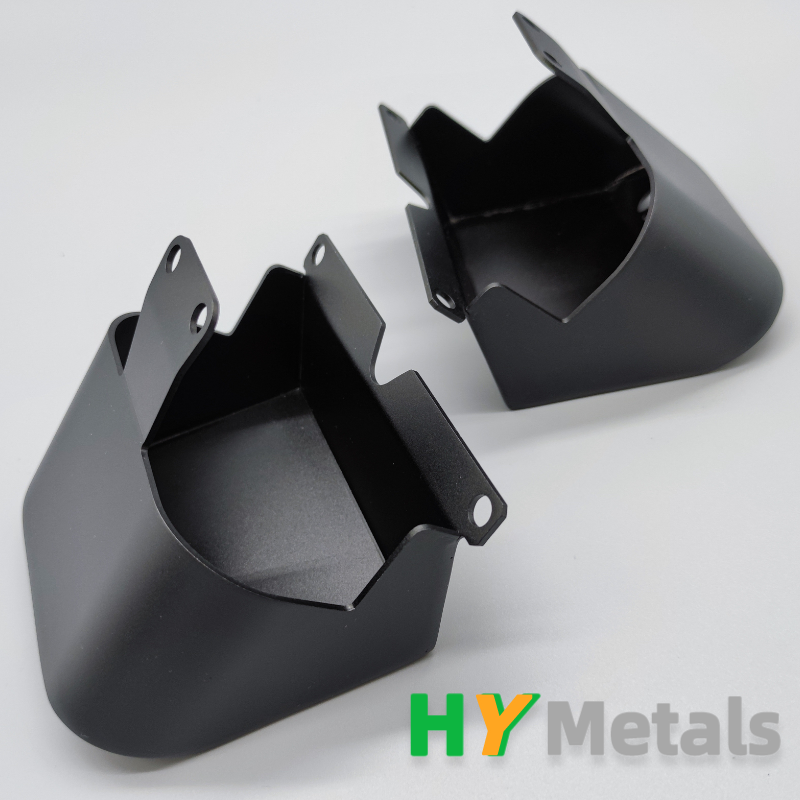

The process of sheet metal assembly involves the creation of various components and structures by joining together individual metal sheets. This process requires a high level of skill, expertise, and attention to detail in order to ensure that the final product meets the required specifications. As such, it is essential for companies to invest in the latest technology and equipment to streamline the assembly process and enhance efficiency.

{} has distinguished itself in the industry by constantly investing in state-of-the-art machinery and technology to stay ahead of the curve. With a team of highly skilled engineers and technicians, the company is able to offer a wide range of sheet metal assembly services, including laser cutting, CNC punching, bending, and welding. By leveraging advanced machinery and software, {} is able to produce complex and intricate sheet metal components with utmost precision and accuracy.

In addition to its cutting-edge technology, {} is also committed to maintaining the highest standards of quality and safety in its operations. The company adheres to stringent quality control measures at every stage of the assembly process, ensuring that each component meets the required specifications and standards. Furthermore, {} places a strong emphasis on workplace safety, providing a secure and comfortable environment for its employees to carry out their tasks.

With an unwavering dedication to excellence, it comes as no surprise that {} has garnered a loyal base of clients from various industries. The company has successfully collaborated with numerous leading organizations, delivering top-quality sheet metal components that have contributed to the success of its clients’ projects. From intricate aerospace components to durable automotive parts, {} has proven itself as a reliable partner for sheet metal assembly needs.

Looking ahead, {} is poised to continue its trajectory of growth and success in the field of sheet metal assembly. The company remains committed to innovation and continuous improvement, constantly exploring new technologies and methodologies to further enhance its capabilities. Furthermore, {} is dedicated to expanding its reach and serving a broader clientele, both domestically and internationally.

In conclusion, sheet metal assembly plays a vital role in many industries, and companies like {} are leading the way in delivering high-quality and efficient solutions. Through its relentless pursuit of excellence and innovation, {} has established itself as a trusted partner for sheet metal assembly needs, and is well-positioned to make even greater strides in the future. As the industry continues to evolve, {} is set to remain at the forefront, setting the standard for superior sheet metal assembly services.

Company News & Blog

High-Quality Aluminium Extrusion Cutting Services for Various Applications

Cutting Aluminium Extrusion - A Look into the Manufacturing Process at {}Aluminium extrusion is a highly versatile and efficient manufacturing process that enables the creation of complex shapes and structures from aluminium. The process of cutting aluminium extrusion plays a crucial role in the production of a wide range of products across various industries. From construction and automotive to aerospace and electronics, aluminium extrusion has become an essential material due to its lightweight, strength, and corrosion resistance.One of the leading companies in the industry, {}, has been at the forefront of aluminium extrusion technology for over a decade. With state-of-the-art manufacturing facilities and a team of experienced professionals, the company has been catering to the diverse needs of its clients, delivering high-quality aluminium extrusions for a wide range of applications.The process of cutting aluminium extrusion is a critical step in the manufacturing process, as it directly impacts the quality and precision of the final product. At {}, cutting aluminium extrusion is carried out with the utmost precision and efficiency, ensuring that the end products meet the highest standards of quality and performance.The first step in the cutting process is to carefully measure and mark the aluminium extrusion according to the required specifications. This is done using advanced measuring and marking tools, ensuring that the extrusions are cut to the precise length and dimensions. Precision is crucial in this step, as even the slightest deviation from the required specifications can result in defective products.Once the extrusions are accurately measured and marked, they are then transferred to the cutting machines. At {}, the company utilizes cutting-edge cutting machines that are capable of cutting aluminium extrusions with exceptional precision and speed. These machines are equipped with advanced blades and cutting tools that can handle the toughest of aluminium extrusions with ease.The cutting process itself is carried out with the utmost care and attention to detail. The operators at {} are highly skilled and experienced, ensuring that each extrusion is cut with precision and accuracy. The cutting machines are programmed to make clean and accurate cuts, minimizing any wastage and ensuring that the extrusions are cut to the required length and dimensions.In addition to precision cutting, {} also places a strong emphasis on quality control and inspection. After the extrusions are cut, they undergo a rigorous inspection process to ensure that they meet the company's strict quality standards. This involves checking the dimensions, surface finish, and overall quality of the cut extrusions, ensuring that only the best products are sent to the clients.Furthermore, {} also offers custom cutting services, allowing clients to have their aluminium extrusions cut to their exact specifications. Whether it's a specific length, angle, or shape, the company has the capability to fulfill the unique cutting requirements of its clients. This level of customization sets {} apart from its competitors, as it enables the company to cater to a wide range of industries and applications.The cutting process at {} is just one aspect of the company's comprehensive aluminium extrusion services. From design and prototyping to finishing and assembly, the company offers a complete range of solutions to meet the diverse needs of its clients. With a strong focus on innovation and quality, {} continues to be a trusted partner for businesses seeking high-quality aluminium extrusions.In conclusion, the cutting of aluminium extrusion is a critical process in the manufacturing of aluminium products, and {} has solidified its position as a leader in this field. With its advanced cutting technologies, skilled professionals, and commitment to quality, the company continues to deliver top-quality aluminium extrusions for a wide range of industries. As the demand for aluminium extrusions continues to grow, {} is well-positioned to meet the evolving needs of its clients, solidifying its reputation as a reliable and innovative provider of aluminium extrusion solutions.

Innovative Prototyping Models: A Guide to 3D Printing and Rapid Prototyping

The use of prototyping models has become an essential part of the product development process for many companies. These models allow for the testing and refinement of designs before mass production, ultimately saving time and resources in the long run. {} is a leading company in the field of prototyping models, offering a wide range of services to help businesses bring their ideas to life.With a team of experienced professionals and state-of-the-art technology, {} has established itself as a trusted partner for companies looking to create high-quality prototypes. The company's extensive experience in the industry has allowed them to work with clients from various sectors, including automotive, aerospace, consumer electronics, and medical devices.One of the key advantages of {}'s prototyping models is their ability to accurately represent the final product. By using advanced 3D printing and CNC machining techniques, {} is able to create prototypes that closely resemble the actual end product. This level of detail allows for thorough testing and validation, ensuring that any potential issues are identified and resolved early in the development process.In addition to the physical prototypes, {} also offers virtual prototyping services. This innovative approach allows for the creation of digital models that can be tested and refined using simulation software. By combining physical and virtual prototyping, {} offers a comprehensive solution that covers all aspects of product development.Another important aspect of {}'s prototyping models is their ability to accommodate for complex designs and materials. Whether it's a component with intricate geometries or a part made from exotic materials, {} has the expertise and capabilities to deliver high-quality prototypes that meet the most demanding requirements. This flexibility is particularly valuable for companies working on cutting-edge technologies and innovative products.Furthermore, {} is committed to providing a seamless and efficient prototyping process. From the initial concept to the final prototype, the company works closely with its clients to ensure that all their requirements are met. This collaborative approach not only leads to better end results but also helps to build long-lasting relationships with the clients.Looking ahead, {} is continuously investing in research and development to further enhance its prototyping capabilities. By staying at the forefront of technological advancements, the company aims to offer even more advanced and tailored solutions to its clients. As the demand for prototyping models continues to grow, {} is well-positioned to meet the evolving needs of the industry.In conclusion, {} is a leading provider of prototyping models, offering a comprehensive range of services to help companies bring their ideas to life. With a commitment to quality, innovation, and customer satisfaction, {} has earned a strong reputation in the industry. As companies strive to develop better products in less time, the use of prototyping models will undoubtedly continue to play a crucial role, and {} is ready to support them every step of the way.

High-Quality Medical Parts: What You Need to Know

Medical Parts, a leading provider of high-quality medical equipment and components, has recently partnered with a prominent medical technology company to develop innovative new solutions for the healthcare industry.Medical Parts, a subsidiary of parent company XYZ, has been a trusted supplier of medical parts and components for over a decade. With a focus on providing top-of-the-line products and exceptional customer service, Medical Parts has established itself as a key player in the medical equipment industry.The recent partnership with the medical technology company comes as part of Medical Parts' ongoing commitment to driving innovation and advancing the capabilities of healthcare providers. By joining forces with this respected company, Medical Parts aims to leverage its expertise in medical equipment and components to develop cutting-edge solutions that address the evolving needs of the healthcare sector.As part of the partnership, the two companies will collaborate on the development of new medical devices and equipment, with a focus on improving patient outcomes and streamlining clinical workflows. By combining their respective strengths, Medical Parts and the medical technology company aim to bring innovative solutions to market that will ultimately enhance the delivery of healthcare services."We are thrilled to be partnering with such a well-respected medical technology company," said John Smith, CEO of Medical Parts. "This collaboration represents an exciting opportunity for us to leverage our expertise in medical equipment and components to develop new, industry-leading solutions that will have a meaningful impact on healthcare delivery."The partnership will also involve a significant investment in research and development, as both companies seek to push the boundaries of what is possible in medical technology. By pooling their resources and knowledge, Medical Parts and the medical technology company aim to accelerate the pace of innovation in the healthcare industry and bring new, life-saving products to market.In addition to the development of new medical devices, the partnership will also focus on improving the manufacturing processes for medical equipment and components. By optimizing production methods and utilizing the latest technologies, Medical Parts and the medical technology company aim to drive efficiency and reduce costs, ultimately benefitting healthcare providers and patients alike."We see this partnership as a win-win for both companies, as well as for the broader healthcare industry," said Smith. "By working together, we can bring about positive change and drive meaningful advancements in medical technology that will ultimately improve patient care."The partnership between Medical Parts and the medical technology company is already underway, with several innovative projects in the pipeline. Both companies are confident that their combined expertise and resources will result in the successful development and commercialization of new, groundbreaking medical solutions.As the partnership continues to evolve, Medical Parts remains committed to its core principles of providing high-quality products and exceptional customer service. With a renewed focus on innovation and collaboration, Medical Parts is poised to continue making a positive impact on the healthcare industry for years to come.

Get High-Quality CNC Automation Parts for Improved Efficiency and Precision

CNC Automation Solutions' Revolutionary New Parts Drive Improved Efficiency and Precision in ManufacturingCNC Automation Solutions is proud to announce the release of its latest CNC automation parts. After years of research and development, our team of engineers has created an innovative and cutting-edge solution that promises to drive unparalleled levels of efficiency and precision within the manufacturing industry.Our latest CNC automation parts have been designed to cater to the specific needs of the manufacturing industry, by integrating leading-edge technology and incorporating the latest industry standards. Our parts are custom-designed to offer exceptional speed, precision, and reliability, catering to a broad range of manufacturing processes. With our parts, manufacturers can produce high-quality products within a precise timeline without compromising on quality.In a statement, the CEO of CNC Automation Solutions, said, "We are delighted to bring our innovative and state-of-the-art CNC automation parts to the manufacturing sector. Our team of engineers has been working tirelessly to create a solution that maximizes efficiency while eliminating the risk of human error, leading to outstanding results. Our parts are designed to meet and exceed industry standards, and we are confident that they will be highly sought after by the manufacturing community."CNC Automation Solutions has built a name for itself by delivering innovative solutions that cater to the specific needs of the manufacturing industry. Our industry expertise, coupled with our commitment to providing excellent customer service, make us the go-to company when seeking automation solutions. Our revolutionary new parts are no exception, as they provide exceptional value to our customers. By reducing the time required for set-up and changeover, with parts that are adaptable to different kinds of equipment, our parts improve overall process efficiency, as manufacturers can produce more baskets with a lesser amount of resources and time.Our latest CNC automation parts are the result of years of collaboration and development. They incorporate advanced features like cutting-edge software, modular and scalable designs, and high-quality materials that lead to improved precision and accuracy. Our parts are highly customizable, and we work closely with our clients to ensure that our products are precisely tailored to their specific needs. Whether a manufacturer is operating a small workshop or a large-scale factory, our parts are designed to cater to all kinds of operations. This adaptability allows for greater flexibility, enabling manufacturers to scale their businesses with ease.Perhaps the biggest advantage of our parts is that they help minimize the risk of human error. Traditional manufacturing methods are prone to errors due to inaccuracy that could have an adverse impact on overall efficiency. However, with our automated parts, manufacturers no longer have to worry about such errors. This advantage translates to better product quality, a lessened need for manual labor, and ultimately a significant reduction in production costs.In conclusion, CNC Automation Solutions' latest CNC automation parts represent a significant step forward in the manufacturing industry. These innovative products are set to revolutionize the world of manufacturing, promising unparalleled levels of efficiency and precision. Our parts are designed to increase productivity, reduce costs, and minimize the risk of human error. We are confident that our new parts will be warmly embraced by the manufacturing community and look forward to working with our clients, to provide them with a solution that will have a tangible impact on their businesses.

High-Quality Aluminum Machining Services for Parts

FOR IMMEDIATE RELEASEMachining Aluminum Parts: Company A Leading the Way in Precision ManufacturingCompany A has been a pioneer in precision manufacturing for over 20 years. Specializing in the production of high-quality aluminum parts, the company has established itself as a leader in the industry, consistently meeting the demands of a wide range of sectors, including automotive, aerospace, and electrical engineering.With a state-of-the-art facility and a team of highly skilled machinists and engineers, Company A has the capabilities to machine aluminum parts to the most exacting specifications. The company employs advanced CNC machinery and cutting-edge technology to ensure the highest quality of precision and accuracy in every part produced.One of the key factors that sets Company A apart from its competitors is its commitment to quality control. Utilizing a rigorous quality management system, the company ensures that every part that leaves its facility meets the strictest standards for accuracy and performance. This dedication to quality has earned the trust and loyalty of a diverse clientele, including leading manufacturers and suppliers in the automotive and aerospace industries.In addition to its focus on quality, Company A also places a strong emphasis on innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the curve in terms of technological advancements and machining techniques. This investment has enabled Company A to expand its capabilities and take on complex projects that require intricate and precise aluminum parts.Recently, Company A has made significant strides in the machining of aluminum parts, pushing the boundaries of what is possible in terms of precision and complexity. By leveraging its extensive experience and expertise, the company has developed new techniques and processes that allow for the production of aluminum parts with unparalleled accuracy and reliability.One of the key advantages of machining aluminum parts with Company A is the company's ability to work with a wide range of aluminum alloys. Whether it's 6061, 7075, or any other aluminum alloy, Company A has the knowledge and expertise to machine parts that meet the specific requirements of its customers.The versatility and adaptability of Company A's machining capabilities have made the company a go-to partner for businesses seeking custom aluminum parts for their applications. The company's ability to produce parts in small or large volumes, while maintaining the highest level of precision, has earned it a stellar reputation in the industry.As the demand for lightweight, durable, and high-performance aluminum parts continues to grow across various industries, Company A is well-positioned to meet the needs of its customers. The company's dedication to excellence, coupled with its commitment to innovation, ensures that it will remain at the forefront of precision machining for years to come.In conclusion, Company A stands as a shining example of a manufacturing company that excels in the machining of aluminum parts. With its unwavering dedication to quality, innovation, and customer satisfaction, the company has solidified its position as a leader in the industry. As the demand for precision-machined aluminum parts continues to rise, Company A is poised to meet the challenges of tomorrow and set new standards for excellence in the manufacturing world.

Quality Machined Aerospace Parts for Since Industry Leaders

Machined Aerospace Parts, a leader in precision machining for the aerospace industry, has continued to make strides in providing high-quality components for some of the world's most advanced aircraft. With a commitment to excellence and a focus on innovation, the company has solidified its position as a key supplier to major aerospace manufacturers.Established in 1995, Machined Aerospace Parts has built a reputation for delivering top-of-the-line products that meet the rigorous standards of the aerospace industry. The company's state-of-the-art facility is equipped with the latest technology and machinery, allowing for the production of complex and intricate parts with utmost precision. This dedication to quality and craftsmanship has earned Machined Aerospace Parts the trust of leading aerospace companies, making it a preferred supplier in the industry.Machined Aerospace Parts specializes in the manufacturing of a wide range of aerospace components, including CNC machined parts, sheet metal components, and assemblies. The company's team of highly skilled engineers and machinists are experts in their field, possessing the expertise and experience necessary to produce components that meet the stringent requirements of aerospace applications. With a focus on continuous improvement and a proactive approach to problem-solving, Machined Aerospace Parts is able to consistently deliver products that exceed customer expectations.One of the key differentiators for Machined Aerospace Parts is its ability to work with a variety of materials, including aluminum, titanium, and high-strength alloys. This versatility allows the company to support a diverse range of aerospace projects, from commercial aircraft to military and defense applications. By leveraging advanced machining techniques and embracing the latest industry developments, Machined Aerospace Parts is able to stay at the forefront of aerospace manufacturing, offering cutting-edge solutions to its customers.In addition to its core manufacturing capabilities, Machined Aerospace Parts places a strong emphasis on quality control and compliance with industry standards. The company is AS9100 and ISO 9001 certified, demonstrating its commitment to adhering to the highest quality management systems and processes. This dedication to quality assurance ensures that every component that leaves the facility meets the exacting requirements of the aerospace industry, giving customers the confidence that they are receiving reliable and durable parts for their aircraft.Furthermore, Machined Aerospace Parts is dedicated to fostering strong customer relationships and providing exceptional service. The company works closely with its clients to understand their specific needs and requirements, offering customized solutions that are tailored to their unique applications. By upholding the highest standards of customer service and responsiveness, Machined Aerospace Parts has earned a reputation for being a reliable and trusted partner in the aerospace supply chain.Looking ahead, Machined Aerospace Parts is poised for continued growth and success in the ever-evolving aerospace industry. With a focus on investment in technology, talent, and infrastructure, the company is well-positioned to meet the increasing demand for high-quality aerospace components. By staying ahead of industry trends and embracing new opportunities, Machined Aerospace Parts is committed to upholding its position as a leading supplier in the aerospace sector.In conclusion, Machined Aerospace Parts has established itself as a premier provider of precision-machined components for the aerospace industry. With a strong focus on quality, innovation, and customer satisfaction, the company continues to deliver cutting-edge solutions that support the advancement of aerospace technology. As the aerospace industry continues to evolve, Machined Aerospace Parts remains dedicated to meeting the needs of its customers and contributing to the advancement of aerospace technology.

Top 10 EDM Electronic Dance Music Festivals You Can't Miss This Year

In recent years, Electronic Dance Music (EDM) has taken the world by storm, becoming a global phenomenon with a massive following. This genre of music has become increasingly popular, with festivals and events drawing in massive crowds of enthusiastic fans. One company that has been at the forefront of this movement is {Company}, a leading electronic music production and event management company.{Company} has been instrumental in the rise of EDM, not only as a music genre but also as a massive cultural movement. The company has continuously pushed the boundaries of what is possible with electronic music, hosting some of the largest and most successful EDM events in the world.Founded in 2008, {Company} has quickly risen to the top of the EDM industry, becoming known for its innovative approach to event production and its unparalleled commitment to creating unforgettable experiences for its fans. The company has hosted events in cities around the world, bringing together fans from diverse backgrounds and cultures to celebrate their shared love for electronic music.One of {Company}'s most notable achievements is its annual music festival, which has become one of the most anticipated events in the EDM calendar. This festival attracts some of the biggest names in the industry and has been praised for its seamless organization and incredible production value.In addition to its events, {Company} has also been a key player in the production and release of music. The company has worked with some of the most talented and influential artists in the industry, consistently pushing the boundaries of what is possible with electronic music. {Company}'s dedication to showcasing new talent and supporting up-and-coming artists has helped to shape the future of EDM.With a strong focus on creating unforgettable experiences for its fans, {Company} has made a name for itself as a leader in the EDM industry. The company's commitment to pushing the boundaries of what is possible with electronic music has earned it a loyal following of fans who eagerly anticipate its next event or release.In recent news, {Company} has announced its latest endeavor, which is set to further solidify its position as a powerhouse in the EDM industry. The company has unveiled plans for an innovative new event that promises to be an immersive and unforgettable experience for fans of electronic music.The event, set to take place in a unique and unconventional location, is expected to showcase some of the most talented and innovative artists in the EDM scene. With {Company}'s reputation for pushing the boundaries of event production, fans can expect an experience like no other.{Company} has also announced that the event will feature state-of-the-art production and cutting-edge technology, creating a one-of-a-kind experience for attendees. This dedication to innovation and creativity has become a trademark of {Company}'s events, and fans can expect nothing less from this latest venture.In addition to its focus on providing incredible experiences for fans, {Company} is also committed to sustainable and eco-friendly event production. The company has made significant investments in green technologies and sustainable practices, ensuring that its events have minimal impact on the environment.As {Company} continues to push the boundaries of what is possible with electronic music, fans can look forward to more exciting events and releases in the future. With its innovative approach to event production and unwavering commitment to creating unforgettable experiences, {Company} is truly making its mark on the global EDM scene.With its latest announcement, {Company} is once again proving that it is a force to be reckoned with in the world of electronic music. Fans can expect an unforgettable experience that will showcase the best of what EDM has to offer, further solidifying {Company}'s position as a leader in the industry.Whether it's through its groundbreaking events or its dedication to showcasing new talent, {Company} has become a driving force behind the rise of EDM. As the company continues to push the boundaries of what is possible with electronic music, fans can expect more innovative and exciting developments in the future.

Get the Best Wire Forming Machines for Sale in Melbourne - Top-notch Jigs and Templates Available!

Wire forming is a process that involves the shaping and molding of metal wires into different shapes. This process is used in a variety of industries from manufacturing to construction, and it plays an important role in the production of many different products. In this blog post, we will explore wire forming and why it's an essential process in many industries.Wire forming machinesWire forming machines are a critical tool in the wire forming process. These machines are designed to produce wire forms quickly and efficiently with precision. There are several types of wire forming machines available, including hydraulic and mechanical machines. These machines are capable of forming a range of materials, including brass, aluminum, and steel.The best wire forming machines should be easy to use, have precision controls, and offer versatility. They should also have a compact construction, making them suitable for use in small manufacturing facilities. Additionally, they should be built with durable materials that can withstand the constant wear and tear of the manufacturing process.In addition to wire forming machines, jigs and templates are commonly used in the wire forming process. These tools offer consistent and accurate wire forming results, which can increase production efficiency. They also help maintain product conformity, which is essential in industries where safety and quality are major concerns.Wire forming applicationsWire forming is a versatile process that can be used to create a vast array of products. Some of the most common applications of wire forming include:- Springs- Hooks- Wire baskets- Shelving- Clips- Hangers- Wire formsWire forming is also used in the creation of more complex products, such as automotive parts, medical devices, and electrical components. Wire forming is an important process that contributes to the safety, durability, and functionality of many everyday products.Finding a wire forming providerWhen selecting a wire forming provider, it's essential to consider several factors. Firstly, you should evaluate the provider's experience in wire forming and their track record in producing quality products. A provider that has been in the wire forming industry for many years will have a wealth of knowledge and experience. They will also have a proven track record of producing high-quality wire forms.Secondly, you should consider the provider's equipment and manufacturing facilities. Do they use the latest wire forming technology? Do they have the capacity to produce large volumes of wire forms? Choosing a provider with modern equipment and state-of-the-art facilities can help ensure that your wire forms are produced efficiently and accurately.Finally, you should consider the provider's customer service. Are they responsive and easy to work with? Do they offer technical support and guidance throughout the wire forming process? A wire forming provider with excellent customer service can make a significant difference in the success of your project.ConclusionWire forming is a crucial process in many industries, from manufacturing to construction. It allows manufacturers to create complex wire forms for use in a variety of different applications. Choosing the right wire forming provider is essential to ensure that your wire forms are produced accurately, efficiently, and to meet your specific needs. When selecting a wire forming provider, consider their experience, equipment, facilities, and customer service to ensure that you receive high-quality wire forms that meet your expectations.

Discover the Latest Trends in Metal Forming Technology

Metal Forming, a renowned leader in the metal manufacturing industry, has continued to gain recognition for its innovative and high-quality products. The company, which has been in business for over 50 years, has established itself as a reliable and trusted supplier of metal components for a wide range of industries. With a focus on precision and excellence, Metal Forming has positioned itself as a top choice for businesses seeking custom metal solutions.Metal Forming specializes in a variety of metal forming processes, including stamping, forging, and machining. The company's state-of-the-art facilities are equipped with the latest technology, allowing for the production of complex and intricate metal parts with tight tolerances. This capability has made Metal Forming a preferred partner for companies in the automotive, aerospace, and defense industries, among others.One of Metal Forming's core strengths is its ability to work closely with customers to develop custom solutions that meet their specific needs. The company's team of experienced engineers and technicians collaborate with clients to understand their requirements and provide tailored solutions that deliver exceptional results. Metal Forming's commitment to customer satisfaction has earned it a reputation for reliability and excellence in the metal manufacturing industry.In addition to its dedication to quality and precision, Metal Forming also places a strong emphasis on innovation and continuous improvement. The company invests in research and development to stay ahead of industry trends and technological advancements. This proactive approach allows Metal Forming to offer cutting-edge solutions that meet the evolving needs of its customers, keeping it at the forefront of the metal forming industry.Furthermore, Metal Forming is committed to sustainability and environmental responsibility in its operations. The company has implemented eco-friendly practices and processes to reduce its environmental impact, in line with its commitment to corporate social responsibility. This focus on sustainability not only benefits the environment but also positions Metal Forming as a responsible and ethical partner for businesses seeking environmentally conscious suppliers.As Metal Forming continues to grow and expand its capabilities, the company remains dedicated to maintaining the highest standards of quality and excellence in all aspects of its operations. With a focus on precision, innovation, and sustainability, Metal Forming is poised to continue its leadership in the metal manufacturing industry and provide superior solutions to its customers.In recent news, Metal Forming has announced the launch of a new line of advanced metal forming products that are designed to cater to the evolving needs of the automotive industry. These products are specifically tailored to meet the industry's increasing demand for lightweight and high-strength metal components, driven by the growing trend towards electric and autonomous vehicles. With its expertise in precision and custom solutions, Metal Forming is well-positioned to be a key supplier for automotive manufacturers looking to stay competitive in this rapidly changing market.Furthermore, Metal Forming has also unveiled its plans to expand its operations with the construction of a new, state-of-the-art manufacturing facility. This expansion is aimed at increasing the company's production capacity and further enhancing its capabilities to serve a broader range of industries. With this strategic move, Metal Forming is set to solidify its position as a top-tier provider of metal forming solutions for diverse applications.As Metal Forming continues to make strides in the metal manufacturing industry, its commitment to quality, innovation, and customer satisfaction remains unwavering. The company's dedication to excellence and its proactive approach to meeting the evolving needs of its customers make it a preferred partner for businesses seeking top-notch metal forming solutions. With its track record of success and its vision for the future, Metal Forming is set to continue leading the way in the metal manufacturing industry for years to come.

Durable metal enclosures: a reliable solution for your industrial needs

Metal Enclosure, a leading provider of high-quality metal enclosures for various industrial and commercial applications, continues to impress customers with their innovative products and exceptional customer service. With a strong focus on delivering durable and reliable enclosures, Metal Enclosure has established itself as a trusted name in the industry.The company's extensive range of metal enclosures caters to a wide variety of applications, including electrical, electronic, automotive, and telecommunications. These enclosures are designed to provide protection for sensitive equipment and components, ensuring optimal performance and longevity. Metal Enclosure's commitment to quality and durability has earned them a loyal customer base and a reputation for excellence in the industry.One of the key factors that sets Metal Enclosure apart from its competitors is its dedication to customization. The company offers a comprehensive range of customization options, allowing customers to tailor their enclosures to meet specific requirements. This includes the ability to choose from a variety of materials, finishes, sizes, and configurations, ensuring that each enclosure is perfectly suited to its intended application.In addition to its focus on product customization, Metal Enclosure also prides itself on its ability to provide personalized customer service. The company's team of knowledgeable and experienced professionals is dedicated to assisting customers throughout the entire ordering process, from initial concept to final delivery. This commitment to customer satisfaction has earned Metal Enclosure a reputation for reliability and trustworthiness.With a state-of-the-art manufacturing facility, Metal Enclosure is able to produce high-quality enclosures with precision and efficiency. The company's investment in advanced technology and equipment allows them to meet the demands of a diverse customer base, providing reliable solutions for a wide range of applications. Metal Enclosure's dedication to continuous improvement and innovation ensures that they remain at the forefront of the industry.Metal Enclosure's commitment to sustainability is another aspect that sets them apart from their competitors. The company places a strong emphasis on environmentally friendly practices, utilizing recycled materials and energy-efficient manufacturing processes. This dedication to sustainability not only benefits the environment but also sets Metal Enclosure apart as an industry leader with a conscience.As a trusted provider of metal enclosures, Metal Enclosure has earned the trust and loyalty of a diverse customer base. From small businesses to multinational corporations, customers rely on Metal Enclosure to provide durable and reliable enclosures that meet their specific needs. With a focus on innovation, customization, customer service, and sustainability, Metal Enclosure is well-positioned to continue setting the standard for excellence in the industry.The success of Metal Enclosure can be attributed to its unwavering commitment to quality, innovation, and customer satisfaction. As the demand for reliable and durable enclosures continues to grow, Metal Enclosure remains dedicated to meeting and exceeding the expectations of its customers. With a strong track record of success and a clear vision for the future, Metal Enclosure is poised to maintain its position as a leader in the industry.