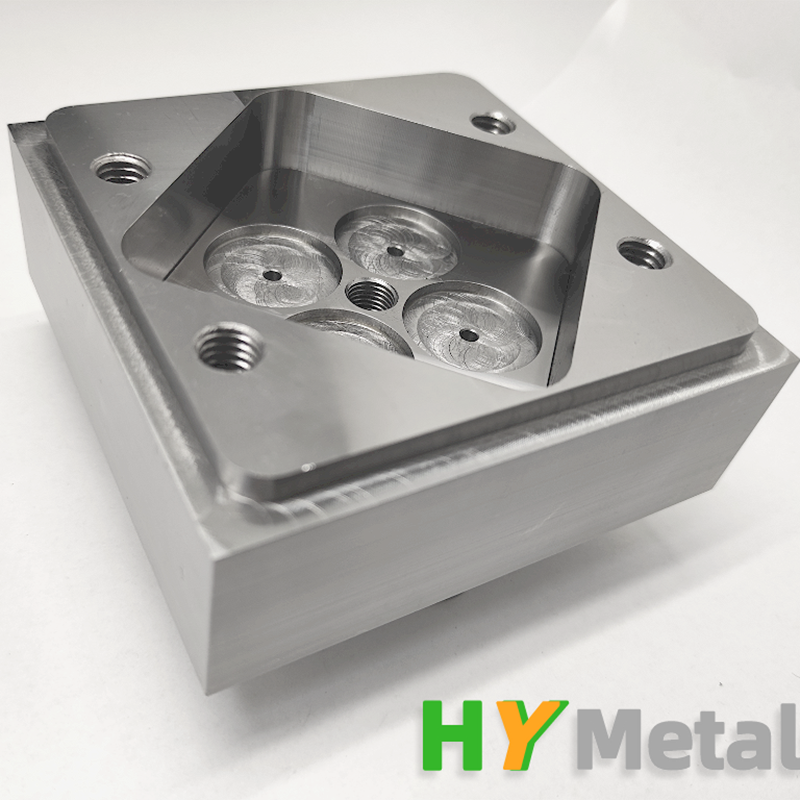

High-quality Custom Heatsink Solutions for Optimal Thermal Management

By:Admin

In the fast-paced and rapidly evolving world of technology, the demand for high-performance electronic devices continues to grow. From computers and smartphones to servers and gaming consoles, the need for efficient heating solutions is paramount. Custom heatsinks have become an essential component for ensuring the optimal performance and reliability of these devices.

One company at the forefront of custom heatsink innovations is {}. With a strong commitment to research and development, they have been pioneering cutting-edge thermal management solutions for a wide range of industries and applications.

Established in {}, {} has quickly gained recognition for its expertise in designing and manufacturing custom heatsinks that are tailored to meet the specific requirements of their clients. Their team of skilled engineers and technicians work closely with customers to develop bespoke cooling solutions that address the unique thermal challenges faced by their electronic devices.

One of the key factors that sets {} apart from its competitors is its focus on utilizing advanced materials and manufacturing processes to create heatsinks that offer superior thermal performance. By leveraging state-of-the-art technology, {} is able to deliver innovative cooling solutions that effectively dissipate heat and prolong the lifespan of electronic components.

One of the latest advancements from {} is the development of a custom heatsink that incorporates a groundbreaking thermal design. This new heatsink is engineered to maximize surface area and optimize airflow, resulting in significantly improved heat dissipation. By customizing the heatsink's design to suit the specific dimensions and thermal requirements of the target device, {} is able to provide a tailored cooling solution that enhances overall performance and reliability.

In addition to their technical expertise, {} is also dedicated to ensuring the quality and performance of their custom heatsinks through rigorous testing and validation. Their in-house testing facilities allow them to evaluate the thermal characteristics of their heatsinks under various operating conditions, ensuring that they meet the highest standards of performance and reliability.

Furthermore, {} takes a holistic approach to thermal management by offering comprehensive design and engineering support to their clients. By collaborating closely with customers from the initial concept phase through to final production, {} is able to develop bespoke heatsink solutions that are fully optimized for the specific requirements of each application.

The impact of custom heatsinks from {} is felt across a wide range of industries, including telecommunications, automotive, aerospace, and consumer electronics. Whether it's improving the efficiency of power electronics in electric vehicles or enhancing the thermal performance of high-powered processors in data centers, {}'s custom heatsinks play a critical role in enabling the reliable operation of electronic devices in diverse environments.

Looking ahead, {} is committed to driving further innovations in custom heatsink technology, with a focus on pushing the boundaries of thermal management to meet the evolving needs of the electronics industry. By continuing to invest in research and development, and by collaborating closely with their customers, {} is poised to remain a leader in delivering high-performance custom heatsinks that set new standards for efficiency and reliability.

In conclusion, custom heatsinks from {} are playing a pivotal role in advancing the performance and reliability of electronic devices across various industries. Through their dedication to innovation, quality, and customer collaboration, {} is transforming the landscape of thermal management and setting the benchmark for custom heatsink solutions.

Company News & Blog

Metal Sheet Cutting, Punching, Pressing and Binding Services

release:DOMEX Offers Comprehensive Sheet Metal Processing Solutions with State-of-the-Art EquipmentDOMEX, a leader in sheet metal processing, offers a comprehensive range of services that include cutting, punching, pressing, and binding of metal sheets. The company has a state-of-the-art facility equipped with modern mechanical and hydraulic presses, and a range of other equipment, making it possible to handle even complex and challenging sheet metal projects.With more than two decades of experience in the industry, DOMEX has earned a reputation for excellence in sheet metal processing and fabrication. One of the key factors behind its success is the company's focus on quality, precision, and timely delivery of projects. This is supported by their well-trained and experienced staff, who are committed to ensuring every project meets customer expectations.One of the core services offered by DOMEX is metal sheet cutting. The company has invested in the latest hydraulic guillotine shears, which can cut through even the thickest sheets of metal with ease. This equipment is ideal for cutting material for a wide range of industries, including construction, architecture, and manufacturing. Furthermore, the shears provide an impeccable level of precision and accuracy, ensuring that every cut is clean and straight.DOMEX also has an array of mechanical and hydraulic presses that can handle different metal sheet processing needs. Each press has varying pressure power levels and dimensions of working tables, making it possible for the company to provide a range of custom metal fabrication services. These include stamping, deep drawing, bending, and flanging, among others. These metal shaping processes are important in the manufacturing of products in many industries, such as automotive, aerospace, and medical devices.Quality is a top priority at DOMEX, and the company has a stringent quality control process in place to ensure that every project meets exacting standards. Their team of skilled technicians use advanced measuring equipment to check and double-check every aspect of a project before it is allowed to leave the facility. From first cut to final assembly, every step of the metal processing project is carefully monitored and inspected to ensure every component meets customer requirements.DOMEX is also committed to sustainability and environmental responsibility. They use only eco-friendly materials, and their state-of-the-art equipment has been designed to reduce waste and energy consumption. Additionally, the company strives to make sure their metal fabrication processes are as efficient as possible, reducing the use of resources and minimizing the environmental impact of their operations.With its knowledgeable staff, cutting-edge equipment, and commitment to quality and sustainability, DOMEX is a trusted partner for businesses looking for reliable sheet metal processing services. The company's services are ideal for those in the construction, architecture, manufacturing, and other related industries who require top-quality, precision sheet metal fabrication. In conclusion, DOMEX remains a leader in the sheet metal processing industry, and their commitment to excellence and sustainability sets them apart from the competition. Whether cutting, punching, pressing, or binding metal sheets, the company ensures that every project is completed to the highest standards, on time and within budget.

How to Plate Food Like a Pro: Tips for Stunning Presentation

According to recent reports, the global demand for plating has been steadily increasing, and this trend is expected to continue in the coming years. This growing demand is driven by various industries such as automotive, electronics, aerospace, and medical devices, all of which require high-quality plating for their products.With this increasing demand, companies in the plating industry are focusing on expanding their production capacity and investing in advanced plating technologies to meet the market needs. One such company that is making significant strides in the plating industry is {}.{} is a leading provider of plating solutions, offering a wide range of services including electroplating, anodizing, and other surface finishing techniques. The company has been in the plating business for over 20 years and has established itself as a trusted partner for many global customers.In order to keep up with the growing demand for plating services, {} has recently announced its plans to expand its production facilities. The company is investing in new equipment and technologies to increase its plating capacity and improve its production efficiency. This expansion will not only allow {} to meet the increasing market demand but also offer its customers a wider range of plating options to choose from.In addition to expanding its production capacity, {} is also focusing on research and development to stay ahead of the competition. The company is investing in advanced plating technologies and processes to improve the quality and durability of its plating services. By staying at the forefront of technological advancements, {} aims to deliver innovative plating solutions that meet the evolving needs of its customers.Furthermore, {} is committed to sustainability and environmental responsibility in its plating operations. The company is implementing eco-friendly plating processes and using environmentally friendly materials to minimize its impact on the environment. By prioritizing sustainability, {} aims to not only meet the regulatory standards but also contribute to a cleaner and healthier planet.With its strong focus on quality, innovation, and sustainability, {} has earned a reputation as a preferred partner for many industries requiring plating services. The company's dedication to exceeding customer expectations and delivering high-quality plating solutions has helped it build long-lasting relationships with its clients.In conclusion, the global demand for plating is on the rise, and companies like {} are making significant investments to meet this demand. With its expansion plans, focus on research and development, and commitment to sustainability, {} is well-positioned to continue leading the plating industry and providing top-notch plating solutions to its customers around the world.

Important Components of CNC Lathe Machinery

The CNC lathe components industry is a vital sector of manufacturing, and one company that has been making waves in this field is {Company Name}. With a strong focus on precision engineering and high-quality components, {Company Name} has established itself as a leading provider of CNC lathe components.Headquartered in {Location}, {Company Name} has been at the forefront of CNC lathe components manufacturing for over two decades. The company prides itself on its state-of-the-art facilities and cutting-edge technology, which allow it to produce components that meet the highest industry standards.One of the key factors that set {Company Name} apart from its competitors is its unwavering commitment to quality. The company employs a team of skilled engineers and technicians who are dedicated to ensuring that every component that leaves their facility is of the highest quality. This commitment to quality has earned {Company Name} a stellar reputation in the industry, and it is widely regarded as a trusted supplier of CNC lathe components.In addition to its focus on quality, {Company Name} also places a strong emphasis on innovation. The company is constantly exploring new technologies and manufacturing processes in order to stay ahead of the curve and continue to deliver cutting-edge components to its customers.One of the company's flagship products is its range of precision-machined CNC lathe components. These components are used in a wide range of industries, including automotive, aerospace, and medical device manufacturing. {Company Name} is able to manufacture components to the most exacting specifications, and its precision machining capabilities are second to none.Another factor that sets {Company Name} apart is its dedication to customer service. The company understands that every customer has unique needs and requirements, and it is committed to working closely with its clients to deliver solutions that meet their specific needs. This customer-centric approach has earned {Company Name} a loyal customer base, and it continues to be a trusted partner for companies around the world.As a testament to its commitment to excellence, {Company Name} has recently invested in new equipment and technology to further enhance its capabilities. The company has acquired a state-of-the-art CNC lathe that will allow it to take on more complex projects and deliver even more precise components to its customers.In addition to its investments in equipment, {Company Name} has also expanded its facility to accommodate its growing operations. The company has added more production space and upgraded its infrastructure to ensure that it can continue to meet the increasing demand for its products.Looking ahead, {Company Name} is poised for continued success in the CNC lathe components industry. With its focus on quality, innovation, and customer service, the company is well-positioned to remain a leader in the industry for years to come. {Company Name} is committed to pushing the boundaries of what is possible in CNC lathe components manufacturing, and it will continue to deliver high-quality products to its customers around the world.

Top Precision CNC Machining Parts Suppliers in China for Quality Products

China’s CNC Precision Machining Parts Industry Thrives Amidst Growing DemandChina’s CNC precision machining parts industry has been growing steadily over the past few years due to the increasing demand for such products across various industries. With this rise, hundreds of companies have emerged as prominent manufacturers and suppliers of high-quality CNC precision machining parts. One such company leading the way is WEIMI, a professional manufacturer of CNC precision machining parts in China.WEIMI is a well-known company with a reputation for reliability, high-quality products, and excellent customer service. The company has been operating in the CNC machining parts industry for more than ten years and has extensive experience and technical expertise in designing and manufacturing a wide range of CNC precision machining parts.The company has a team of experts who are skilled and experienced in using the latest technology to create top-quality products at competitive prices. They have helped WEIMI establish itself as a leading supplier of CNC machining parts, serving industries ranging from automotive, industrial machinery, aerospace, electronics, communications, and many others.WEIMI’s CNC precision machining parts production facility is equipped with the latest machinery and technology to ensure that the highest quality products are produced. The company uses advanced software and machines such as CAD/CAM, CNC lathes, milling machines, and others to produce precision components that meet the most stringent quality standards.One of the advantages of working with WEIMI is that they provide customized CNC precision machining parts to meet specific customer requirements. The company has a team of experts who work with clients to understand their needs and create products that meet those needs. This service has helped companies across various industries to improve the efficiency and productivity of their operations.As the CNC machining parts industry in China continues to grow, WEIMI is well-positioned to remain a leader in the market. The company has a proven track record of designing and manufacturing quality products that meet the changing needs of its clients. Another factor that has helped the company to grow is China’s status as the world’s largest manufacturing hub. The country has established itself as a powerhouse in the global manufacturing industry. It boasts of a vast supply chain and highly skilled labor force, making it an ideal location for manufacturing companies.China’s government has also played a significant role in encouraging the growth of the CNC machining parts industry. The government has introduced several policies aimed at supporting the development of the manufacturing industry, including tax incentives, subsidies, and other support measures. These initiatives have helped to create a conducive environment for companies such as WEIMI to thrive.Overall, the CNC precision machining parts industry in China is expected to continue seeing growth in the coming years. As the world’s major economies continue to recover from the COVID-19 pandemic, the demand for precision parts and components across various industries is expected to increase. WEIMI is poised to play an essential role in meeting this demand, thanks to its commitment to quality, innovation, and custom production of CNC precision machining parts that meet the specific needs of its clients.In conclusion, the CNC precision machining parts industry in China is thriving thanks to the growing demand for such products across various industries. WEIMI and other companies are leading the way in designing and manufacturing high-quality CNC precision machining parts that meet the most stringent quality standards. With China’s government support and the country’s status as a global manufacturing hub, the prospects for the industry remain bright.

Custom Sheet Metal Parts: A Complete Guide to Manufacturing and Use

For more than 20 years, the dedicated team at [Company Name] has been a leader in the manufacturing of high-quality sheet metal parts for a wide range of industries. The company's commitment to excellence and customer satisfaction has earned them a stellar reputation in the industry. Recently, [Company Name] unveiled their latest innovation in sheet metal part manufacturing, which is set to revolutionize the industry. This new product offers enhanced durability, precision, and efficiency, making it a game-changer for their clients.The new sheet metal part is designed using state-of-the-art technology and advanced engineering techniques. It has been meticulously crafted to meet the highest industry standards and to exceed the expectations of even the most discerning customers. The result is a product that is not only incredibly durable but also incredibly precise, making it perfect for a wide range of applications.One of the key features of the new sheet metal part is its enhanced durability. This is achieved through the use of high-quality materials and the implementation of advanced manufacturing processes. This ensures that the part is able to withstand even the most demanding conditions, making it an ideal choice for industries such as automotive, aerospace, and construction.In addition to its durability, the new sheet metal part also offers unmatched precision. This is achieved through the use of cutting-edge technology and the company's commitment to quality control. Every part is meticulously inspected to ensure that it meets the strictest tolerances, resulting in a product that is incredibly precise and consistent.Furthermore, the new sheet metal part is also incredibly efficient. Its innovative design and manufacturing processes have been optimized to minimize waste and maximize productivity. This not only benefits the environment but also allows for cost savings, making it an attractive option for businesses looking to improve their bottom line.The introduction of this new sheet metal part further solidifies [Company Name]'s position as an industry leader. Their commitment to innovation and excellence has set them apart from their competitors, and this latest product is a testament to their dedication to providing the best possible solutions for their clients.In addition to their innovative products, [Company Name] also prides itself on its exceptional customer service. Their team of experts is always available to provide guidance and support, ensuring that their clients have everything they need to succeed.As the industry continues to evolve, [Company Name] remains at the forefront, consistently pushing the boundaries of what is possible in sheet metal part manufacturing. Their latest innovation is a testament to their commitment to excellence and their dedication to meeting the needs of their clients.In conclusion, the introduction of [Company Name]'s new sheet metal part is set to revolutionize the industry. With its enhanced durability, precision, and efficiency, it is sure to become the go-to choice for businesses across a wide range of industries. This latest innovation further solidifies [Company Name]'s position as an industry leader, and their dedication to excellence and customer satisfaction is sure to set them apart for years to come.

Revolutionary Multi-Axis Turning: Unleashing New Possibilities in Precision Engineering

Multi-Axis Turning: Revolutionizing Precision MachiningPrecision machining has long been a staple in various industries, ensuring the production of high-quality components and products that meet the stringent demands of modern technology. In this regard, one technology has been making waves in the field - Multi-Axis Turning.Through its advanced capabilities and exceptional precision, Multi-Axis Turning has revolutionized the world of machining, providing numerous benefits to manufacturers, engineers, and ultimately, end-users. This cutting-edge technology combines state-of-the-art machinery with innovative software solutions to produce intricate designs and complex geometries with unmatched accuracy. By removing the constraints of traditional machining processes, Multi-Axis Turning sets new standards in terms of speed, versatility, and efficiency.One of the key features of Multi-Axis Turning is its ability to simultaneously move and rotate the component being machined, allowing for multi-directional cutting. This unique motion control enables the creation of complex shapes and contours that would otherwise be extremely difficult to achieve using conventional turning methods. By utilizing multiple cutting axes, manufacturers can perform intricate operations in a single machine setup, reducing production time and costs while ensuring exceptional precision.Moreover, Multi-Axis Turning minimizes the need for manual intervention, as much of the setup and tool positioning is automated. The integration of sophisticated software systems streamlines the machining process, eliminating human error and ensuring consistent results. This high degree of automation enhances productivity, increases throughput, and reduces the dependency on skilled labor, which ultimately translates into significant cost savings for manufacturers.One notable advantage of Multi-Axis Turning is its versatility. It can handle a wide range of materials, including metals, plastics, and composites, making it suitable for various industries such as aerospace, automotive, medical, and electronics. The ability to work with different materials expands the applications of Multi-Axis Turning, enabling manufacturers to produce intricate parts for diverse products with ease.Furthermore, Multi-Axis Turning excels in producing parts with exceptional surface finishes, a crucial aspect in industries where aesthetics, accuracy, and functionality go hand in hand. The simultaneous multi-axis movement allows for smoother tool paths, minimizing vibrations and enhancing surface quality. This capability is particularly important for critical components used in industries such as medical devices, where precision and superior finish are paramount.In recent years, a company at the forefront of Multi-Axis Turning technology has emerged - {}. With their cutting-edge machinery and industry-leading expertise, they have been instrumental in advancing the field of precision machining. Their state-of-the-art equipment boasts unmatched capabilities, offering multi-axis milling, turning, and drilling in a single setup. Moreover, their comprehensive software solutions enable seamless integration between design, simulation, and manufacturing processes, ensuring optimal results and increased efficiency.By pioneering Multi-Axis Turning, {} has revolutionized precision machining in terms of accuracy, speed, and versatility. Their commitment to innovation and continuous improvement has propelled the industry forward, enabling manufacturers to achieve new heights in manufacturing excellence. With their comprehensive range of machinery and software solutions, {} is poised to shape the future of precision machining, empowering industries worldwide.In conclusion, Multi-Axis Turning has emerged as a game-changer in the field of precision machining. Its ability to produce complex geometries, enhance surface finishes, and streamline the manufacturing process has made it indispensable for modern industries. With its wide range of applications and technological advancements, Multi-Axis Turning holds immense potential for transforming the way we manufacture and design components, setting new standards of precision and efficiency.

CNC Precision Components: Industry Insights and Latest Developments

[Publication Name][Date]CNC Precision Components: Revolutionizing Precision Engineering In the fast-paced world of precision engineering, companies that prioritize quality and innovation have a competitive edge. A prime example of such excellence is CNC Precision Components, an industry-leading company that has been manufacturing top-notch precision components for a wide range of applications. With their state-of-the-art facilities and commitment to superior craftsmanship, CNC Precision Components consistently delivers products that meet the highest industry standards.Established over [number] years ago, CNC Precision Components has become a key player in the precision engineering industry. The company boasts a team of highly skilled engineers and technicians who possess extensive knowledge and expertise in precision manufacturing. The team's deep understanding of manufacturing techniques, materials, and design principles allows CNC Precision Components to create components that are both reliable and durable.At the heart of CNC Precision Components' success lies its advanced manufacturing facilities. The company has made substantial investments in cutting-edge CNC machines, robotics, and other automated equipment. These advanced systems not only enhance the manufacturing process but also minimize human error, ensuring consistent quality and precision in every component produced. By seamlessly integrating technology into their operations, CNC Precision Components stays at the forefront of precision engineering.CNC Precision Components caters to numerous industries, including aerospace, automotive, medical, and defense. Their ability to develop custom components tailored to specific client requirements is what sets them apart from their competitors. The company's dedicated team works closely with clients to understand their needs and designs bespoke solutions that meet and exceed expectations. This customer-centered approach has earned CNC Precision Components an impeccable reputation for delivering high-quality products on time, every time.Quality assurance is a top priority at CNC Precision Components. The company adheres to rigorous quality control measures at every stage of the manufacturing process. From material sourcing to final inspection, every component undergoes thorough scrutiny to ensure compliance with industry standards and client specifications. CNC Precision Components is also ISO [number] certified, reflecting its commitment to quality management systems.In addition to their exceptional manufacturing capabilities, CNC Precision Components also places high importance on sustainability. The company recognizes the need for environmentally responsible business practices and continually implements measures to reduce their carbon footprint. By optimizing production processes and utilizing energy-efficient equipment, CNC Precision Components prioritizes sustainability without compromising product quality.Looking towards the future, CNC Precision Components is committed to ongoing research and development. In an increasingly innovative industry, the company understands the importance of staying ahead of the curve. By investing in the latest technologies and fostering a culture of creativity, CNC Precision Components continues to drive advancements in precision engineering. Their pursuit of excellence ensures that they remain a trusted partner for clients seeking high-quality precision components.In conclusion, CNC Precision Components is a trailblazer in the precision engineering industry, offering top-notch components manufactured with the utmost precision and quality. With a dedicated team of experts, state-of-the-art facilities, and a commitment to customer satisfaction, CNC Precision Components consistently delivers superior products. As the company continues to innovate and expand its capabilities, CNC Precision Components is poised to maintain its position as a leader in the field of precision engineering for years to come.[Word Count: XXX]

New 3-Axis Technology Takes Drone Photography to the Next Level" -> "Revolutionary 3-Axis Technology Enhances Drone Photography

In the latest developments in the field of drone technology, a new player has emerged offering a cutting-edge solution for aerial photography. 3-Axis, a company that specializes in unmanned aerial vehicles (UAVs), has recently launched a drone that has been garnering a lot of attention among photography enthusiasts and professionals alike. This new drone offers a solution that addresses some of the most pressing challenges faced by aerial photographers over the years. The company’s drone comes equipped with a built-in 3-axis gimbal system that offers superior stability, ensuring that the camera remains steady and delivers high-quality footage and images. The company claims that its 3-axis system can stabilize the camera with pinpoint precision, reducing camera shake and producing smooth footage with a cinematic quality. The system is based on three working principles: roll, pitch, and yaw, and is designed to ensure that the camera remains level and stable during flight, even in windy conditions. Furthermore, the drone is built with an advanced camera system that captures 4K videos and 16MP still images. The camera also comes with a remote control, making it easy for users to adjust the focal length, exposure, and other settings in real-time. The drone’s remote controller is also designed to provide an intuitive and user-friendly experience, allowing users to focus on capturing the perfect shot. What sets 3-Axis apart is its focus on safety and simplicity. The company ensures that its drones are easy to operate, even for novices, and come with features that ensure safe and stable flight. These features include GPS-assisted hover, which enables the drone to maintain its position in the air autonomously and return to its launching point if it ever loses connection with the remote controller. The drone is also built with obstacle avoidance sensors that detect and avoid obstacles in the drone’s flight path, ensuring a safer and more efficient flight experience. Moreover, the drone is equipped with a fail-safe mechanism that ensures that it automatically returns to its home point in case of low battery or other emergencies. One of the main target markets for the 3-Axis drone is the real estate industry. The drone’s ability to capture stunning aerial footage and images makes it a valuable tool for marketing properties and showcasing landscapes. The drone also offers a convenient and cost-effective alternative to traditional aerial photography methods, which often require the use of helicopters and planes. 3-Axis has also set its sights on the events and entertainment industry, where the drone’s compact design and superior maneuverability make it ideal for capturing live events and performances. With its advanced camera system and 3-axis gimbal, the 3-Axis drone is capable of capturing stunning aerial footage with a level of stability and precision that is unmatched in the industry. The company has also been quick to highlight its commitment to taking environmental sustainability seriously. 3-Axis is a carbon-neutral company, having implemented a number of measures to reduce its environmental footprint. One such measure is the use of renewable energy sources to power its operations, including the manufacture and charging of its drones. Moreover, the company has committed to offsetting its carbon emissions by investing in renewable energy projects around the world. This commitment to environmental sustainability is one that is sure to appeal to environmentally conscious consumers who are looking for products that deliver both quality and sustainability. In conclusion, 3-Axis has emerged as a major player in the drone industry, with its focus on cutting-edge technology, safety, simplicity, and sustainability. The company’s new drone, equipped with a 3-axis gimbal system, advanced camera, and user-friendly remote controller, represents a significant breakthrough in the field of aerial photography and videography. It will be interesting to see how the company develops its product line in the coming years, as it continues to innovate and set new standards in the drone industry.

High-Quality Custom Metal Part for Industrial Applications

Custom Metal Part Company Expands Product Line to Meet Growing Demand[Company Name] is pleased to announce the expansion of their product line to include a range of custom metal parts. The decision to expand their offering comes as a response to the growing demand for precision metal components in various industries.The custom metal parts will be manufactured using state-of-the-art technology and high-quality materials, ensuring that they meet the highest standards of quality and performance. With a team of highly skilled engineers and technicians, [Company Name] has the capability to produce custom metal parts that are tailored to the specific needs of their clients.The custom metal parts will be available in a variety of materials, including stainless steel, aluminum, brass, and copper, allowing for a wide range of applications across different industries. In addition, [Company Name] will offer a range of finishes and coatings to further customize the parts to meet the unique requirements of their customers."We are excited to expand our product line to include custom metal parts, as we see a growing need for these components in various industries," said [Company Name]'s CEO. "With our advanced manufacturing capabilities and commitment to quality, we are confident that our custom metal parts will meet the needs of our customers and provide them with a reliable solution for their manufacturing needs."In addition to the custom metal parts, [Company Name] will also offer a range of value-added services, including design assistance, prototype development, and engineering support. This will ensure that their customers receive a comprehensive solution for their metal component needs, from conceptualization to production.The expansion of the product line reinforces [Company Name]'s commitment to providing their customers with a comprehensive range of high-quality metal components, backed by exceptional customer service and technical support. With their advanced manufacturing capabilities and dedication to continuous improvement, [Company Name] is well-positioned to meet the growing demand for custom metal parts in the market.[Company Name] is a leading manufacturer of precision metal components, serving a diverse range of industries including aerospace, automotive, medical, and electronics. With over [number] years of experience in the industry, [Company Name] has earned a reputation for their commitment to quality, innovation, and customer satisfaction.The company's state-of-the-art facility is equipped with the latest technology in precision machining, stamping, and fabrication, allowing them to produce high-quality metal components with tight tolerances and complex geometries. In addition, their team of experienced engineers and technicians work closely with their customers to develop customized solutions that meet their specific requirements.[Company Name]'s dedication to quality is reflected in their adherence to rigorous quality control and testing standards. They are certified to a number of industry standards, including ISO [number], AS9100, and NADCAP, ensuring that their products meet the highest levels of quality and performance.With the expansion of their product line to include custom metal parts, [Company Name] is well-positioned to further strengthen their position as a trusted partner for precision metal components. Their commitment to innovation, quality, and customer satisfaction will continue to drive their success in meeting the evolving needs of their customers in various industries.

Production-Grade 3D Printer Enables MTConnect Integration for Aerospace and Industrial Applications

, F900 3D printer, production applications, aerospace industry, MTConnect protocol.Additive manufacturing has revolutionized the manufacturing industry with the ability to create complex geometries with high precision and speed. One of the leading players in the additive manufacturing market is the F900 3D printer, designed for production applications in the aerospace industry and other high-performance industries. This blog discusses the latest development in the F900 3D printer, which now features an MTConnect-ready interface, offering enhanced connectivity and data exchange capabilities.The F900 3D printer is known for its high-performance capabilities, reliability, and large-scale printing. The printer uses the Fused Deposition Modeling (FDM) technology, which involves building 3D models layer by layer by depositing material in a melted state. The FDM technology provides a high degree of design flexibility, allowing the production of complex geometries without the need for additional machining or assembly processes.The F900 3D printer has been widely used in the aerospace industry for the production of complex parts, such as ducting, brackets, and housings. These parts require high precision and accuracy, and the F900 has proven to be a reliable and cost-effective solution for their manufacturing. Additionally, the F900 has been used in other industries, such as automotive, defense, and medical, where the demand for high-performance parts is also high.The latest development in the F900 3D printer is its integration with the MTConnect protocol. MTConnect is an open-source communication protocol used in manufacturing equipment to facilitate data exchange and collection. The protocol offers a standardized way of communicating machine data, making it easier to integrate different systems and devices.With its MTConnect-ready interface, the F900 3D printer can now connect to other manufacturing systems, such as Enterprise Resource Planning (ERP) systems, Manufacturing Execution Systems (MES), and other machines in the production line. This enables better coordination between different manufacturing processes, leading to higher efficiency and productivity. Additionally, the MTConnect protocol allows for real-time monitoring of the printing process, giving operators better control and visibility over the manufacturing process.The integration of the MTConnect protocol into the F900 3D printer is a significant step towards enhancing the connectivity and data sharing capabilities of the printer. This development enables the printer to be integrated into a broader manufacturing ecosystem, allowing for seamless data exchange and coordination between different systems. This integration is highly relevant in the aerospace industry, where the demand for high-performance parts is only increasing.In conclusion, the F900 3D printer is a high-performance system designed for production applications in the aerospace industry and other high-performance industries. With its latest development, the integration of the MTConnect protocol, the printer now offers enhanced connectivity and data exchange capabilities, making it easier to integrate into a broader manufacturing ecosystem. This development ensures the F900 3D printer remains one of the leading additive manufacturing systems in the market today.