Top 10 Benefits of FDM Technology in 2021

By:Admin

Fused Deposition Modeling (FDM) technology has been making headlines in the manufacturing industry recently, and for good reason. This revolutionary 3D printing technology has transformed the way products are developed and produced, leading to increased efficiency and cost-effectiveness for businesses around the world. With the addition of FDM technology, {Company Name} has solidified its position as a leader in the industry, offering cutting-edge solutions to meet the evolving needs of its customers.

{Company Name} is a global leader in the design and production of advanced manufacturing technologies. With a focus on innovation and excellence, the company has successfully integrated FDM technology into its portfolio of solutions, offering its customers a powerful tool to drive their businesses forward.

Fused Deposition Modeling is a type of additive manufacturing technology that uses a continuous filament of a thermoplastic material to create layers of a part. These layers are laid down one at a time, gradually building up the final product. FDM technology has been particularly popular for its ability to produce high-quality, complex parts with a quick turnaround time. This has made it an attractive option for manufacturers looking to streamline their production processes and reduce costs.

One of the key advantages of FDM technology is its versatility. It can be used to create a wide range of parts, from prototypes and concept models to functional end-use parts. This flexibility has made FDM a popular choice across a variety of industries, including aerospace, automotive, healthcare, and consumer goods.

In addition to its versatility, FDM technology also offers significant cost savings. By using only the material that is needed to build a part, FDM minimizes waste and reduces the overall production costs. This is particularly beneficial for businesses looking to optimize their manufacturing processes and improve their bottom line.

Another important benefit of FDM technology is its speed. The ability to quickly produce high-quality parts has helped businesses to accelerate their product development cycles and respond to market demands more efficiently. This has given companies a competitive edge in today's fast-paced business environment.

{Company Name}'s integration of FDM technology into its portfolio of solutions has been well-received by its customers. The company's commitment to providing cutting-edge manufacturing technologies has allowed its clients to take full advantage of the benefits that FDM offers. By leveraging this advanced technology, businesses have been able to enhance their productivity, reduce costs, and bring their products to market faster.

As the demand for innovative manufacturing solutions continues to grow, {Company Name} is well-positioned to meet the needs of its customers. With its expertise in FDM technology, the company is poised to remain at the forefront of the industry, driving the future of manufacturing forward.

In conclusion, FDM technology has proven to be a game-changer for the manufacturing industry, offering businesses a powerful tool to improve their production processes. With its versatility, cost-effectiveness, and speed, FDM has become a preferred choice for companies looking to stay ahead of the competition. {Company Name}'s integration of FDM technology into its portfolio of solutions has further solidified its position as a leader in the industry. As the demand for advanced manufacturing technologies continues to rise, {Company Name} is well-equipped to meet the needs of its customers and drive the industry forward into the future.

Company News & Blog

Custom Sheet Metal Parts: A Complete Guide to Manufacturing and Use

For more than 20 years, the dedicated team at [Company Name] has been a leader in the manufacturing of high-quality sheet metal parts for a wide range of industries. The company's commitment to excellence and customer satisfaction has earned them a stellar reputation in the industry. Recently, [Company Name] unveiled their latest innovation in sheet metal part manufacturing, which is set to revolutionize the industry. This new product offers enhanced durability, precision, and efficiency, making it a game-changer for their clients.The new sheet metal part is designed using state-of-the-art technology and advanced engineering techniques. It has been meticulously crafted to meet the highest industry standards and to exceed the expectations of even the most discerning customers. The result is a product that is not only incredibly durable but also incredibly precise, making it perfect for a wide range of applications.One of the key features of the new sheet metal part is its enhanced durability. This is achieved through the use of high-quality materials and the implementation of advanced manufacturing processes. This ensures that the part is able to withstand even the most demanding conditions, making it an ideal choice for industries such as automotive, aerospace, and construction.In addition to its durability, the new sheet metal part also offers unmatched precision. This is achieved through the use of cutting-edge technology and the company's commitment to quality control. Every part is meticulously inspected to ensure that it meets the strictest tolerances, resulting in a product that is incredibly precise and consistent.Furthermore, the new sheet metal part is also incredibly efficient. Its innovative design and manufacturing processes have been optimized to minimize waste and maximize productivity. This not only benefits the environment but also allows for cost savings, making it an attractive option for businesses looking to improve their bottom line.The introduction of this new sheet metal part further solidifies [Company Name]'s position as an industry leader. Their commitment to innovation and excellence has set them apart from their competitors, and this latest product is a testament to their dedication to providing the best possible solutions for their clients.In addition to their innovative products, [Company Name] also prides itself on its exceptional customer service. Their team of experts is always available to provide guidance and support, ensuring that their clients have everything they need to succeed.As the industry continues to evolve, [Company Name] remains at the forefront, consistently pushing the boundaries of what is possible in sheet metal part manufacturing. Their latest innovation is a testament to their commitment to excellence and their dedication to meeting the needs of their clients.In conclusion, the introduction of [Company Name]'s new sheet metal part is set to revolutionize the industry. With its enhanced durability, precision, and efficiency, it is sure to become the go-to choice for businesses across a wide range of industries. This latest innovation further solidifies [Company Name]'s position as an industry leader, and their dedication to excellence and customer satisfaction is sure to set them apart for years to come.

Maximizing Efficiency and Precision: Unlocking the Potential of Investment Casting

Prototype Investment Casting (PIC) is revolutionizing the manufacturing industry with its cutting-edge technology and innovative approach to investment casting. With a strong focus on quality, efficiency, and customer satisfaction, PIC is quickly becoming a go-to solution for businesses worldwide. By utilizing state-of-the-art equipment and a highly skilled team, PIC is able to deliver superior results and unmatched precision.PIC’s investment casting process begins with the creation of a prototype. Using advanced computer-aided design (CAD) software and 3D printing technology, the engineers at PIC are able to transform a concept into a physical model. This allows for better visualization and understanding of the final product, enabling any necessary adjustments to be made before proceeding to the casting stage.Once the prototype is finalized, PIC employs a unique investment casting method that involves creating a ceramic mold around the prototype. This mold is then filled with molten metal, which takes the shape of the prototype as it cools and solidifies. The ceramic mold is subsequently broken away, revealing the finished product with exceptional precision and surface finish.One of the key advantages of PIC’s investment casting process is its ability to produce complex and intricate parts with ease. Traditional manufacturing methods often struggle with intricate designs, but PIC’s advanced technology allows for the creation of highly detailed parts with minimal limitations. This versatility opens up a world of possibilities for industries such as aerospace, automotive, and medical, where precise components are crucial.In addition to its superior casting capabilities, PIC also places great importance on quality control. Every step of the manufacturing process is closely monitored to ensure that the final product meets the highest standards. From the initial design phase to the mold creation and casting, each component undergoes rigorous inspection and testing. This dedication to quality has earned PIC a reputation for delivering outstanding products that exceed customer expectations.Furthermore, PIC understands the importance of sustainability in the manufacturing industry. By employing an optimized production process and utilizing materials efficiently, PIC strives to minimize waste and reduce its environmental impact. The company also actively seeks out environmentally friendly materials and processes to integrate into its operations. Through its commitment to sustainability, PIC aims to contribute to a greener and more sustainable future for the industry.With its exceptional expertise and commitment to innovation, PIC has successfully served a wide range of industries, including aerospace, automotive, defense, and medical. Its ability to produce high-quality, intricate components has made it a trusted partner for many prominent companies. Whether it’s creating prototypes for new products or producing parts for existing ones, PIC’s investment casting process offers unmatched precision and efficiency.Looking ahead, PIC is continuing to expand its capabilities and refine its processes. The company invests heavily in research and development to stay at the forefront of technological advancements in the industry. By continuously exploring new techniques and materials, PIC aims to further enhance its offerings and remain a leader in investment casting.In conclusion, Prototype Investment Casting (PIC) is spearheading a new era in investment casting, delivering exceptional precision, quality, and efficiency. With its state-of-the-art technology, highly skilled team, and dedication to customer satisfaction, PIC is setting the standard for the manufacturing industry. As it continues to innovate and expand, PIC is poised to revolutionize the way products are made, offering endless possibilities for businesses worldwide.

Precision Machined Parts for Aerospace Industry

Machined Aerospace Parts plays a critical role in the aviation industry. The leading company has a longstanding reputation for providing high-quality aviation components to airlines and aircraft manufacturers. It boasts a significant market share in the aerospace industry and prides itself on a variety of CNC machining capabilities to deliver exceptional results.The company's proven track record of delivering parts that meet military and commercial aviation standards has made it a trusted supplier in the aviation industry. Customers who partner with Machined Aerospace Parts appreciate the company's focus on innovation, quality, and superior customer service. These are the essential qualities that have propelled the company to the top of the industry.Machined Aerospace Parts' capabilities are vast and diversified to meet the constantly evolving needs of the industry. The company has an array of precision equipment and utilizes the latest tools and technologies to produce a range of components. Whether it's machining parts from solid materials, producing small or large components, or creating complex structures, Machined Aerospace Parts has the expertise to get the job done.The company has a team of highly skilled professionals who are experts in the field of aviation. From engineers to production managers, all staff members are deeply passionate about the industry and take pride in their work. The team is focused on creating efficient, cost-effective solutions that meet customers' unique needs.One of the reasons Machined Aerospace Parts is a preferred supplier in the aviation industry is due to its exceptional quality control process. The company ensures that every component is subject to rigorous testing to meet the strict standards of the industry. The quality control process begins with design reviews and ends with a final inspection of finished products. These stringent checks ensure that all parts meet exacting requirements, and nothing leaves the factory until it meets the company's high standards.Machined Aerospace Parts is committed to continuous improvement, and that includes investing in cutting-edge technology and equipment. The company recently added several new machines to its assembly line, expanding its CNC machining capabilities. The machines allow the company to operate faster, which ensures quicker lead times for customers.Despite the challenges posed by the COVID-19 pandemic, Machined Aerospace Parts has continued to thrive. It has remained committed to serving its customers' needs and has adapted well to the changing landscape. The company maintains safe working conditions and adheres to all regulations and health guidelines to ensure the safety of employees and customers.As a company committed to excellence, Machined Aerospace Parts invests significantly in its people. The company has a rigorous training program that ensures all staff members are up-to-date on the latest industry developments and are equipped with the skills necessary to meet customers' needs. The company also offers training and apprenticeships to young people who want to learn about the aviation industry. By investing in young talent, the company is securing the future of the industry.In conclusion, Machined Aerospace Parts is a well-established, reputable, and innovative aviation company. With its advanced technology, highly skilled workforce, and exceptional quality control, it is no surprise that it continues to succeed in the industry. The company's commitment to providing cost-effective, efficient solutions to customers has propelled it to the top of the industry, and it remains a preferred supplier for many airlines and aircraft manufacturers. In a constantly evolving industry, Machined Aerospace Parts is poised for growth, and its future looks exceedingly bright.

Latest 3D Printing Technology and its Impact on Manufacturing

[Insert Company Logo]Innovative 3D Printing Technology Revolutionizing Manufacturing Industry[City, Date] - As the manufacturing industry continues to evolve, a technological breakthrough has emerged that is changing the way products are designed and produced. 3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by layering materials such as plastics, metals, and ceramics based on a digital model. This revolutionary technology is being embraced by [Company Name], a leading company at the forefront of the 3D printing industry.Since its inception, [Company Name] has been dedicated to advancing 3D printing technology and providing cutting-edge solutions to its customers. The company's state-of-the-art 3D printers and advanced materials have enabled manufacturers to accelerate their product development cycle and create complex, high-quality parts with unparalleled precision.One of the key advantages of 3D printing is its ability to produce customized and intricate designs that traditional manufacturing methods may not be able to achieve. This flexibility and versatility have made 3D printing a game-changer for various industries, including aerospace, automotive, healthcare, and consumer goods.[Company Name] has been instrumental in driving the adoption of 3D printing across different sectors by offering a wide range of services, including prototyping, tooling, and low-volume production. The company's expertise in materials science and additive manufacturing processes has allowed it to develop innovative solutions that meet the specific needs of its customers.Moreover, [Company Name] is committed to sustainability and environmental responsibility. With 3D printing, the company has been able to reduce material waste and energy consumption, leading to a more sustainable and eco-friendly manufacturing process.In addition to its commitment to technological innovation, [Company Name] has also focused on providing comprehensive training and support to its clients. By offering workshops, seminars, and consulting services, the company has empowered its customers to harness the full potential of 3D printing and maximize their operational efficiency.Furthermore, [Company Name] has established strategic partnerships with leading organizations to further advance the adoption of 3D printing in various industries. These collaborations have enabled the company to broaden its market reach and leverage the expertise of industry leaders to drive innovation and growth.The impact of 3D printing on the manufacturing industry is undeniable, as it provides a cost-effective and efficient alternative to traditional manufacturing methods. As [Company Name] continues to push the boundaries of 3D printing technology, it is paving the way for a new era of manufacturing that is characterized by innovation, speed, and sustainability.The future of manufacturing is undoubtedly being shaped by 3D printing, and [Company Name] is at the forefront of this transformative revolution. With its unwavering commitment to excellence and its dedication to providing cutting-edge solutions, [Company Name] is poised to continue leading the way in the 3D printing industry and driving the next wave of innovation in manufacturing.For media inquiries, please contact:[Company Name][Contact Person][Email Address][Phone Number][Website][Company Address]

High Aspect Ratio BGA Heat Sinks: Perfect for Small PCB Spaces

article on the benefits of using BGA High Aspect Ratio Extruded heat sinks in thermal management applications.As electronic devices continue to become more compact, thermal management becomes a crucial aspect to ensure their continuous and reliable operation. To address this challenge, BGA High Aspect Ratio Extruded heat sinks have emerged as a reliable thermal management solution that delivers high performance in compact PCB environments.BGA High Aspect Ratio Extruded heat sinks are designed with a high aspect ratio or length-to-width ratio, which allows for optimal placement of fins, maximizing heat dissipation while maintaining a small footprint. The fins also provide an increased surface area, allowing for more efficient heat transfer, resulting in improved thermal performance.The use of BGA High Aspect Ratio Extruded heat sinks has many benefits. These heat sinks are ideal for compact PCB environments where space is at a premium and traditional heat sinks cannot fit without compromising other critical components. They are suitable for use in a wide range of electronic devices, including routers, switches, amplifiers, power supplies, and more.One of the main advantages of using BGA High Aspect Ratio Extruded heat sinks is their ability to dissipate heat efficiently. These heat sinks have a high aspect ratio, which means that they have a longer distance or length than the width, allowing more fins to be accommodated, providing greater surface area for heat dissipation. The more fins a heat sink has, the more efficient it is in dissipating heat.Moreover, the fins of the BGA High Aspect Ratio Extruded heat sinks are designed in such a way that they promote convective heat transfer, which results in faster and more efficient heat dissipation. With convective heat transfer, hot air moves away from the heat sink and cool air moves in, leading to a continuous cycle of thermal management.Another benefit of BGA High Aspect Ratio Extruded heat sinks is their ability to accommodate a wide range of thermal requirements. These heat sinks are available in different shapes, sizes, and configurations to suit various thermal performance requirements.In addition to their versatile size range, BGA High Aspect Ratio Extruded heat sinks are also available in different materials. Aluminum is a common material used in the fabrication of heat sinks as it is lightweight, durable, and has excellent thermal conductivity. Other materials, such as copper, can also be used for specific applications.BGA High Aspect Ratio Extruded heat sinks also have a longer lifespan when compared to other thermal management solutions. They are designed to withstand high temperatures and thermal cycles, ensuring that they can deliver optimal heat dissipation for extended periods. Overall, the use of BGA High Aspect Ratio Extruded heat sinks provides several advantages over traditional thermal management solutions. They are efficient, versatile, and reliable, making them an ideal choice for various applications where optimizing thermal performance in compact spaces is critical.In summary, BGA High Aspect Ratio Extruded heat sinks offer many benefits in thermal management applications. They maximize heat dissipation through convective heat transfer, accommodate a wide range of thermal requirements, and have a longer lifespan, and provide an optimal solution for compact spaces. As such, they are an excellent choice for electronic devices that require reliable and efficient thermal management.

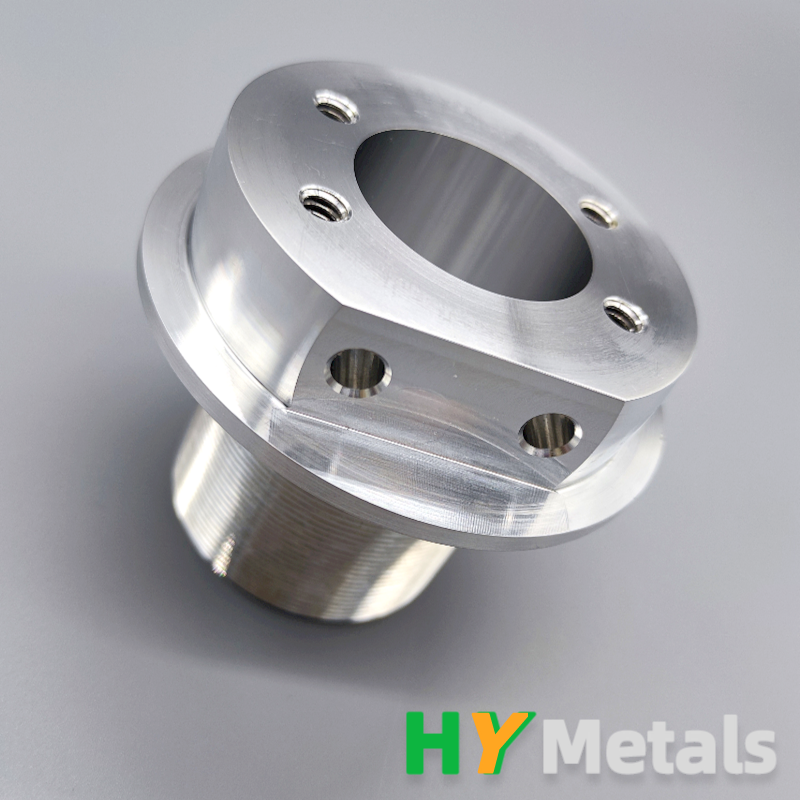

High-Quality CNC Parts for Precision Machining

[Your Company Name] Expands Operations with Precision CNC Parts[Your Company Name], a leading provider of precision engineering solutions, has announced the expansion of its operations with the addition of precision CNC parts to its product offerings. With this new capability, [Your Company Name] is poised to further strengthen its position in the market and meet the growing demand for high-quality, precision-engineered parts.The addition of precision CNC parts to [Your Company Name]'s portfolio is a strategic move that will enable the company to better serve its customers and provide a wider range of solutions for their manufacturing needs. The new CNC parts will include a variety of components such as shafts, gears, and housings, all of which will be manufactured to the highest standards of precision and quality."We are thrilled to announce the expansion of our operations with the addition of precision CNC parts," said [Your Company Name]'s CEO. "This development is a testament to our commitment to providing our customers with the best possible engineering solutions. With the addition of CNC parts, we are well-positioned to meet the evolving needs of our customers and further solidify our standing as a trusted provider of precision-engineered components."In addition to the expansion of its product offerings, [Your Company Name] has also made significant investments in state-of-the-art CNC machining equipment and technology. This investment will enable the company to produce CNC parts with exceptional accuracy and efficiency, ensuring that customers receive top-quality parts that meet their exact specifications."With our new CNC machining capabilities, we have the ability to produce parts with unmatched precision and consistency," said [Your Company Name]'s Chief Engineer. "Our state-of-the-art equipment allows us to achieve tight tolerances and complex geometries, giving our customers the assurance that their parts will perform at the highest level."The expansion into CNC parts comes at a time of steady growth for [Your Company Name], which has been steadily building its reputation as a provider of high-quality engineering solutions. With a focus on innovation and continuous improvement, the company has earned the trust of customers in a wide range of industries, including aerospace, automotive, and medical devices.In addition to serving existing customers, the addition of precision CNC parts will also open up new opportunities for [Your Company Name] to expand its customer base and enter new markets. By offering a broader range of products, the company can appeal to a wider audience and strengthen its position as a leading provider of precision-engineered components."We see the addition of CNC parts as a significant milestone in our growth journey," said [Your Company Name]'s Vice President of Sales. "This expansion demonstrates our commitment to meeting the diverse needs of our customers and providing them with comprehensive solutions for their manufacturing requirements. We are excited about the potential this new capability brings and the opportunities it presents for us to serve a broader range of industries."As [Your Company Name] continues to expand its operations and capabilities, the company remains dedicated to upholding its core values of quality, innovation, and customer satisfaction. With the addition of precision CNC parts, [Your Company Name] is well-positioned to meet the evolving needs of its customers and establish itself as a trusted partner for precision engineering solutions.About [Your Company Name]:[Your Company Name] is a leading provider of precision engineering solutions, offering a comprehensive range of services including design, prototyping, and manufacturing. With a commitment to quality and innovation, the company serves customers in a wide range of industries and has established a strong reputation for excellence in precision engineering. For more information, visit [Your Company Name]'s website at www.yourcompanywebsite.com.

Ultimate Guide to Sheet Metal Forming Techniques for Manufacturing

article about the advancements in sheet metal forming technology.Sheet metal forming is a process used to transform flat metal sheets into various shapes and products through the application of force. This process is widely used in industries such as automotive, aerospace, construction, and manufacturing to create a wide range of products including car parts, machinery components, and household appliances.In recent years, there have been significant advancements in sheet metal forming technology that have led to improvements in efficiency, precision, and overall product quality. One company at the forefront of these advancements is {}.{} is a leading manufacturer of sheet metal forming equipment and has been instrumental in driving innovation in the industry. With a strong focus on research and development, the company has developed cutting-edge technologies that have revolutionized the sheet metal forming process.One of the key advancements that {} has introduced is the use of advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software to optimize the sheet metal forming process. This software allows manufacturers to create highly detailed and precise designs, which are then used to program the company's state-of-the-art sheet metal forming machines.In addition to software advancements, {} has also developed new techniques for controlling the temperature and pressure during the sheet metal forming process. These techniques have resulted in a more consistent and uniform shaping of the metal, leading to products with higher quality and durability.Furthermore, {} has invested heavily in automation and robotics to streamline the sheet metal forming process. By automating certain tasks, the company has been able to increase production speed and efficiency while reducing the margin of error.The advancements made by {} have not only improved the efficiency and precision of the sheet metal forming process, but they have also had a positive impact on sustainability. By optimizing the process and reducing waste, the company has been able to minimize its environmental footprint.In addition to technological advancements, {} has also focused on the training and development of its workforce. The company has a team of highly skilled engineers and technicians who are constantly pushing the boundaries of what is possible in sheet metal forming.Through their dedication to innovation and excellence, {} has solidified its position as a global leader in the sheet metal forming industry. The company's commitment to pushing the boundaries of what is possible has led to advancements that have transformed the industry and set new standards for quality and efficiency.Looking ahead, {} continues to invest in research and development to further advance sheet metal forming technology. With a focus on sustainability, efficiency, and precision, the company is poised to continue leading the way in the sheet metal forming industry.In conclusion, the advancements made by {} in sheet metal forming technology have had a profound impact on the industry. Through a combination of advanced software, temperature and pressure control techniques, automation, and a focus on sustainability, the company has raised the bar for efficiency, precision, and product quality in sheet metal forming. As {} continues to push the boundaries of what is possible, the future of sheet metal forming looks promising, with even more advancements on the horizon.

Custom Aluminium Extrusions for Your Specific Needs

In today's fast-paced and continuously developing modern world, businesses have to keep up with the growing needs of their clientele. One way to do that is through offering customized products, tailored to meet the specific requirements of the customer. Avocet Precision Metals has taken up that challenge, offering aluminum extrusion services that cater to the unique needs of the client.Avocet Precision Metals is a premier metals manufacturing company, located in the United Kingdom, known for its dedication to providing high-quality metal products and exceptional customer service. The firm utilizes cutting-edge technologies and equipment to provide unmatched precision in producing aluminum extrusions that meet the highest industry standards. With a workforce of highly skilled and experienced professionals well-versed in the latest practices of the extrusion industry, Avocet Precision Metals delivers results that surpass expectations.At its core, aluminum extrusion is a process by which manufacturers create complex shapes by forcing aluminum through a shaped opening. This process allows for customization of aluminum products to meet the exact specifications of clients. Avocet Precision Metals recognizes the importance of this process, making sure that all products conform to the customer's design, ensuring that products are manufactured to the highest quality standards.The company utilizes both hard and soft alloys of aluminum to match the specific requirements of the client. If the customer requires a particular combination of strength, corrosion resistance, and lightness, Avocet Precision Metals can deliver precisely what is needed. The company's aluminum extrusion services are highly versatile and can be used in a wide range of applications, including automotive, construction, machinery and much more.Avocet Precision Metals prides themselves in employing best practices, and quality measures to deliver the best customer experience. The company ensures that all the aluminum extrusion products are produced in an environmentally sustainable manner. The manufacturing process is regulated to ensure that it is as green as possible, minimizing the impact on the environment while ensuring that the customer receives high-quality products. Additionally, the company takes its customers' safety seriously and has worked hard to develop and implement safety and environmental protection policies.The high quality of the products that Avocet Precision Metals delivers is made possible by the company's continued investment in modern technology. This significantly reduces the production lead times and guarantees that the products are at the highest level of precision and quality. The company has installed cutting-edge CNC machines and presses that enable the team to manufacture high volumes of aluminum extrusions while reducing waste and maximizing efficiency.Avocet Precision Metals recognizes that customers have different budgets, and the company is always willing to work with clients to find a solution that works best for them. The company is committed to funding a team that supports its customers even after the sale is completed. They have an expert team of professionals on standby, ready to offer guidance and answer any queries that may arise.As a leading player in the aluminum extrusion industry, Avocet Precision Metals is continuously innovating and improving its processes to ensure they stay ahead of the competition. This continuous improvement mindset ensures that the company remains relevant in a market that is constantly changing. The firm's commitment to providing customers with the highest quality products and services has earned Avocet Precision Metals an excellent reputation among its customers and industry peers.In summary, Avocet Precision Metals is a top-tier manufacturer of aluminum extrusions that delivers high-quality and customized products according to clients' specifications. They are a company that prioritizes customer satisfaction and has invested in cutting-edge technology, skilled personnel, while staying environmentally conscious. These steps have enabled them to deliver on their promises while expanding their clientele base, and solidifying its position as a leading industry player.

Fast and Reliable MP3 Downloads for the Best Wet Paint Songs Without Registration

Wet Paint Launches Exciting New Music DownloadsMusic lovers, rejoice! Wet Paint, a leading independent music platform, has just launched a new range of MP3 song downloads that are sure to get you grooving. The new collection features some of the biggest hits by the hottest artists of the moment, giving you access to the top tunes and latest tracks that are taking the music world by storm.Wet Paint has always been a reliable destination for music fans looking to stay on top of the latest trends in pop, rock, hip-hop, electronic, and indie music. The platform offers an extensive library of tracks from local and international artists, spanning a range of styles and genres. Whether you're a fan of classic rock bands, mainstream pop icons, or emerging indie acts, you're sure to find something to suit your musical tastes on Wet Paint.Now, with the launch of the new MP3 song downloads, music lovers will have even more options to explore. The downloads are fast, reliable, and secure, ensuring that you can quickly and conveniently get your hands on the latest tracks without any hassles.To celebrate the launch of the new MP3 downloads, Wet Paint is offering fans a special deal. For a limited time, users can get a discount on downloads by using a promo code provided by the platform. This is a great opportunity for music fans to access some of the hottest new tracks without breaking the bank.Wet Paint is committed to providing fans with a superior music experience, and the new MP3 downloads are just the latest offering in this regard. The platform is continually seeking to improve its service and expand its library, with a focus on offering the best content and features to users.In addition to its extensive collection of music tracks, Wet Paint also offers users a range of other features and resources. These include insightful music news, in-depth interviews with artists, and a lively social community where fans can connect with one another and share their love for music.Overall, the new MP3 downloads from Wet Paint are a welcome addition to the platform's impressive arsenal of music resources. With its focus on quality, variety, and user satisfaction, Wet Paint is quickly becoming one of the most trusted and popular destinations for music fans around the world. Whether you're a long-time fan of the platform or a new user, the new MP3 downloads are sure to offer hours of musical enjoyment and discovery. So what are you waiting for? Head to Wet Paint and start downloading the best tunes of the moment today!

Top 10 Benefits of FDM Technology in 2021

FDM Technology Revolutionizes Manufacturing ProcessesFused Deposition Modeling (FDM) technology has been making headlines in the manufacturing industry recently, and for good reason. This revolutionary 3D printing technology has transformed the way products are developed and produced, leading to increased efficiency and cost-effectiveness for businesses around the world. With the addition of FDM technology, {Company Name} has solidified its position as a leader in the industry, offering cutting-edge solutions to meet the evolving needs of its customers.{Company Name} is a global leader in the design and production of advanced manufacturing technologies. With a focus on innovation and excellence, the company has successfully integrated FDM technology into its portfolio of solutions, offering its customers a powerful tool to drive their businesses forward.Fused Deposition Modeling is a type of additive manufacturing technology that uses a continuous filament of a thermoplastic material to create layers of a part. These layers are laid down one at a time, gradually building up the final product. FDM technology has been particularly popular for its ability to produce high-quality, complex parts with a quick turnaround time. This has made it an attractive option for manufacturers looking to streamline their production processes and reduce costs.One of the key advantages of FDM technology is its versatility. It can be used to create a wide range of parts, from prototypes and concept models to functional end-use parts. This flexibility has made FDM a popular choice across a variety of industries, including aerospace, automotive, healthcare, and consumer goods.In addition to its versatility, FDM technology also offers significant cost savings. By using only the material that is needed to build a part, FDM minimizes waste and reduces the overall production costs. This is particularly beneficial for businesses looking to optimize their manufacturing processes and improve their bottom line.Another important benefit of FDM technology is its speed. The ability to quickly produce high-quality parts has helped businesses to accelerate their product development cycles and respond to market demands more efficiently. This has given companies a competitive edge in today's fast-paced business environment.{Company Name}'s integration of FDM technology into its portfolio of solutions has been well-received by its customers. The company's commitment to providing cutting-edge manufacturing technologies has allowed its clients to take full advantage of the benefits that FDM offers. By leveraging this advanced technology, businesses have been able to enhance their productivity, reduce costs, and bring their products to market faster.As the demand for innovative manufacturing solutions continues to grow, {Company Name} is well-positioned to meet the needs of its customers. With its expertise in FDM technology, the company is poised to remain at the forefront of the industry, driving the future of manufacturing forward.In conclusion, FDM technology has proven to be a game-changer for the manufacturing industry, offering businesses a powerful tool to improve their production processes. With its versatility, cost-effectiveness, and speed, FDM has become a preferred choice for companies looking to stay ahead of the competition. {Company Name}'s integration of FDM technology into its portfolio of solutions has further solidified its position as a leader in the industry. As the demand for advanced manufacturing technologies continues to rise, {Company Name} is well-equipped to meet the needs of its customers and drive the industry forward into the future.