Why Low Volume is Important for Successful Business Operations

By:Admin

In today's fast-paced world, the demand for personalized, small-scale manufacturing is on the rise. Whether it's for prototype development, product testing, or limited production runs, small-scale manufacturing offers flexibility and customization that larger manufacturers simply cannot provide. And as the need for small-scale manufacturing grows, so does the demand for efficient and cost-effective solutions to make it a reality.

Enter {}. With a reputation for innovation and cutting-edge technology, {} has developed a game-changing solution for small-scale manufacturing: Low Volume. This proprietary technology is designed to meet the specific needs of small-scale manufacturers, offering a range of benefits that are simply unmatched by traditional manufacturing methods.

So, what exactly is Low Volume? In a nutshell, it's a production process that allows for the manufacturing of small quantities of parts or products with minimal setup time and cost. This makes it an ideal solution for companies looking to bring their ideas to life without the limitations of traditional manufacturing methods. Whether it's for rapid prototyping, on-demand production, or custom orders, Low Volume provides a cost-effective and efficient way to bring products to market.

One of the key advantages of Low Volume is its ability to reduce lead times. Traditional manufacturing methods often require lengthy setup times and tooling costs, making it impractical for small-scale production. With Low Volume, manufacturers can significantly reduce the time it takes to bring a product to market, allowing for faster iterations and product improvements. This not only benefits the manufacturer but also the end consumer, who can receive their products in a timelier manner.

Additionally, Low Volume offers a high level of flexibility. This means that manufacturers can easily make changes to their designs or produce different variations of a product without incurring substantial costs. This level of flexibility is crucial for companies looking to stay competitive in today's fast-paced market, where consumer demands and trends are constantly evolving.

Furthermore, the cost savings associated with Low Volume are considerable. Traditional manufacturing methods often come with high setup costs and minimum order quantities, making them financially prohibitive for small-scale manufacturers. With Low Volume, manufacturers can produce smaller quantities of products at a fraction of the cost, allowing them to test the market without a substantial financial investment. This not only reduces risk for the manufacturer but also opens up new opportunities for small-scale production.

It's clear that Low Volume has the potential to revolutionize small-scale manufacturing, and {} is at the forefront of this innovation. With a long-standing commitment to providing cutting-edge solutions for manufacturers, {} is dedicated to empowering small-scale producers with the tools they need to succeed in today's competitive market.

In conclusion, the growing demand for small-scale manufacturing has paved the way for innovative solutions like Low Volume. As companies continue to seek cost-effective, efficient, and flexible manufacturing methods, Low Volume is poised to become the go-to solution for small-scale production. With its ability to reduce lead times, offer flexibility, and deliver cost savings, Low Volume is revolutionizing the way small-scale manufacturers bring their ideas to life. And with the support of companies like {}, the future of small-scale manufacturing looks brighter than ever.

Company News & Blog

Find the Best Die Casting Solutions for Your Business Needs

Die Casting is a manufacturing process that is used to create metal parts by forcing molten metal into a mold cavity under high pressure. This process is commonly used in the automotive, aerospace, and consumer goods industries to create high-quality and complex metal components. One company that has been at the forefront of die casting technology is {}.{} is a leading manufacturer of die-cast components, with a strong focus on precision engineering and customer satisfaction. The company has a state-of-the-art manufacturing facility equipped with the latest die casting machines and technology to produce a wide range of components for various industries.With a team of highly skilled engineers and technicians, {} is able to provide innovative solutions for complex die casting projects. The company has a strong commitment to quality and continuous improvement, ensuring that its products meet the highest standards of performance and reliability.In addition to die casting, {} offers a range of value-added services such as CNC machining, surface finishing, and assembly to provide a complete solution for its customers. This allows the company to deliver fully finished components that are ready for use in their end applications.One of the key advantages of {}'s die casting process is its ability to produce complex shapes with high precision and consistency. This makes it an ideal manufacturing method for components that require tight tolerances and intricate designs. The company has the expertise to work with a variety of materials, including aluminum, magnesium, and zinc, to cater to the diverse needs of its customers.{}'s die casting capabilities are utilized in a wide range of industries, including automotive, aerospace, electronics, and industrial equipment. The company has a strong track record of delivering high-quality components that meet the demanding requirements of these industries.To ensure the highest level of customer satisfaction, {} has implemented rigorous quality control measures throughout its manufacturing process. This includes advanced testing and inspection techniques to verify the dimensional accuracy and mechanical properties of its die-cast components.As a responsible manufacturer, {} is committed to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its manufacturing process to minimize waste and reduce its environmental impact. This includes recycling and reusing materials whenever possible and optimizing its energy usage to minimize its carbon footprint.In addition to its commitment to quality and sustainability, {} places a strong emphasis on customer service and collaboration. The company works closely with its customers to understand their specific requirements and provide tailored solutions that meet their needs. With a focus on open communication and transparency, {} strives to build strong and long-lasting partnerships with its customers.Looking to the future, {} is continuously investing in research and development to stay at the cutting edge of die casting technology. The company is exploring new materials, processes, and technologies to further improve its capabilities and expand its product offerings.In conclusion, {} is a leading manufacturer of die-cast components, with a strong focus on precision engineering, quality, and customer satisfaction. With its advanced manufacturing capabilities and commitment to innovation, the company is well-positioned to meet the evolving needs of its customers across various industries.

High-Quality Extruded Aluminum Heatsink for Superior Thermal Dissipation

(Extruded Aluminum Heatsink is an innovative product designed to dissipate heat. It is manufactured by a leading company in the industry, known for their high-quality engineering and exceptional customer service. For many years, this company has been a trusted provider of thermal management solutions, serving a diverse range of industries.The Extruded Aluminum Heatsink is a critical component in many electronic devices, providing an effective way to manage heat generated during operation. It is widely used in applications such as computers, LED lighting, power electronics, and more. With its lightweight and durable design, the Extruded Aluminum Heatsink offers excellent thermal conductivity and efficient heat dissipation.One of the key features of this heatsink is its extruded aluminum construction, which allows for the precise shaping of the heatsink to meet specific requirements. This flexibility makes it an ideal solution for custom applications, as well as for high-volume production. The company's advanced manufacturing capabilities enable them to produce heatsinks in a wide range of sizes and shapes, ensuring a perfect fit for each unique application.In addition to its exceptional performance, the Extruded Aluminum Heatsink is also designed for easy installation and maintenance. Its sleek and compact design allows for seamless integration into various systems, and its corrosion-resistant properties ensure long-term reliability and durability. With its ability to effectively dissipate heat, the Extruded Aluminum Heatsink helps to extend the lifespan and improve the performance of electronic devices.The company behind the Extruded Aluminum Heatsink prides itself on its commitment to excellence and innovation. With a team of experienced engineers and technical experts, they are dedicated to providing cutting-edge thermal management solutions that meet the evolving needs of their customers. Their state-of-the-art facilities and stringent quality control processes ensure that each heatsink meets the highest standards of performance and reliability.Furthermore, the company's customer-centric approach sets them apart in the industry. They work closely with their clients to understand their unique requirements and provide tailored solutions that exceed expectations. Whether it's a standard off-the-shelf heatsink or a custom-designed solution, the company is committed to delivering products that deliver superior performance and value.With a proven track record of delivering high-quality thermal management solutions, the company has earned the trust and loyalty of a diverse customer base. Their reputation for excellence and reliability has firmly established them as a leader in the industry, and their Extruded Aluminum Heatsink is just one example of their commitment to innovation and superior quality.In conclusion, the Extruded Aluminum Heatsink is a cutting-edge product that showcases the company's expertise in thermal management solutions. With its exceptional performance, durability, and versatility, this heatsink is a valuable asset for a wide range of electronic applications. Backed by a company known for its commitment to excellence and innovation, the Extruded Aluminum Heatsink is a testament to the company's leadership in the industry. As the demand for efficient thermal management solutions continues to grow, the company and its Extruded Aluminum Heatsink are well-positioned to meet the evolving needs of their customers.

Discover the Benefits of Fast Prototyping for Your Business

Fast Prototyping has become an industry leader in providing high-quality prototyping and manufacturing services for a wide range of industries. With their state-of-the-art facilities and advanced technology, they have been able to offer rapid prototyping and short-run production services to their clients, helping them bring their products to market faster than ever before.The company offers a variety of prototyping services, including 3D printing, CNC machining, injection molding, and more. Their team of experienced engineers and technicians work closely with clients to understand their specific needs and provide custom solutions that meet their exact specifications.One of the key benefits of Fast Prototyping's services is their fast turnaround times. With their advanced technology and efficient processes, they are able to produce high-quality prototypes and parts in record time, allowing their clients to speed up their product development and testing phases.In addition to fast turnaround times, Fast Prototyping also prides itself on the quality of their work. They use the latest equipment and materials to ensure that every prototype and part meets the highest standards of accuracy and durability. This commitment to quality has earned them a reputation as a trusted partner for businesses of all sizes, from startups to Fortune 500 companies.One of the main reasons why Fast Prototyping has been able to stay ahead of its competitors is its continuous investment in research and development. The company is constantly exploring new technologies and techniques to improve its prototyping and manufacturing processes, ensuring that its clients have access to the latest advancements in the industry.Furthermore, the company's customer service is second to none. Fast Prototyping's team is dedicated to providing personalized attention to each client, guiding them through every step of the prototyping and production process. This level of support and communication has helped them build long-lasting relationships with their clients, who continue to rely on Fast Prototyping for all their prototyping and manufacturing needs.Fast Prototyping's commitment to excellence has not gone unnoticed. The company has received numerous accolades and awards for its outstanding work, further solidifying its position as a leader in the industry. Their dedication to innovation and customer satisfaction has set them apart from the competition, making them the go-to choice for businesses seeking top-notch prototyping and manufacturing services.Looking ahead, Fast Prototyping aims to continue expanding its capabilities and pushing the boundaries of what is possible in the world of prototyping and manufacturing. By staying at the forefront of technology and maintaining its commitment to quality and customer service, the company is poised to remain a driving force in the industry for years to come. With their proven track record of success and their relentless pursuit of excellence, Fast Prototyping is well-positioned to meet the evolving needs of their clients and continue setting the standard for prototyping and manufacturing services.

Discover the Cutting-Edge World of CNC Machining: Unlocking the Potential of Prototyping

Title: Pioneering CNC Machining Company Revolutionizes Manufacturing IndustryIntroduction:In the evolving landscape of the manufacturing industry, advancements in CNC (Computer Numerical Control) machining have played a vital role in driving efficiency and precision. One notable company at the forefront of this technological revolution is a leading CNC machining manufacturer, employing state-of-the-art processes to cater to the diverse needs of customers across various sectors. By leveraging their expertise and cutting-edge equipment, this company has become a trusted partner for businesses seeking high-quality prototype CNC machining services.A Commitment to Excellence:The company, with over two decades of experience, has consistently demonstrated a commitment to excellence. Their team of highly skilled engineers and technicians possess extensive knowledge in CNC machining, enabling them to deliver exceptional results to clients. With a customer-centric approach, they prioritize understanding the unique requirements of each project, ensuring superior product quality and customer satisfaction.Streamlined Manufacturing Processes:The remarkable success of this CNC machining major can be attributed to their strategic implementation of streamlined manufacturing processes. Utilizing cutting-edge CAD (Computer-Aided Design) software, their skilled designers are entrusted with transforming client concepts into precise digital models. With meticulous attention to detail, they optimize designs to enhance functionality and manufacturability while minimizing production costs.The company's advanced CNC machines, equipped with the latest technology, then seamlessly translate these digital designs into tangible products. These machines offer unparalleled accuracy, allowing for intricate details, complex geometries, and tight tolerances to be achieved with ease. By leveraging various CNC machining techniques, such as milling, turning, and drilling, the company caters to the diverse needs of industries such as automotive, aerospace, medical, and more.Driving Innovation Through Research and Development:At the heart of this pioneering company lies a dedicated research and development team seeking to push the boundaries of CNC machining technology. With a focus on continuous improvement, they invest heavily in exploring new materials, tooling, and machining techniques. Through their tireless efforts, they ensure that their clients have access to the latest innovations, positioning them at the forefront of their respective industries.Responsive Customer Support and Collaborative Approach:Recognizing the importance of effective communication and collaboration, the company places great emphasis on providing exceptional customer support throughout the entire production process. Their team of knowledgeable professionals works closely with clients, offering guidance and resolving any queries promptly. This collaborative approach not only ensures alignment with project objectives but also fosters long-lasting partnerships built on trust and reliability.Sustainability and Environmental Responsibility:In addition to their commitment to delivering exceptional products, this CNC machining leader also understands the significance of environmental stewardship. Implementing sustainable manufacturing practices, they strive to minimize waste, conserve energy, and reduce their carbon footprint. The company actively promotes the use of eco-friendly materials and continually explores innovative ways to enhance their environmental performance.Conclusion:As the manufacturing industry continues to evolve, CNC machining has proven to be a catalyst for technological advancements. With a commitment to excellence, streamlined manufacturing processes, a focus on innovation, responsive customer support, and sustainable practices, this leading CNC machining company has established itself as a key player in revolutionizing the manufacturing sector. Empowered by their expertise, cutting-edge technology, and dedication, they are poised to shape the future of CNC machining, meeting and exceeding the ever-growing demands of their clients with unwavering precision and efficiency.

Rapid prototype: How it works and its benefits for innovation

Rapid Prototype Technology Enhances Factory EfficiencyIn today's fast-paced manufacturing industry, companies are constantly looking for ways to improve their production processes and stay ahead of the competition. The introduction of rapid prototype technology has proven to be a game-changer, allowing manufacturers to quickly and cost-effectively produce high-quality prototypes and streamline their product development cycle.One company at the forefront of this technology is {}. Founded in 2005, {} has established itself as a leading provider of rapid prototype services, offering a comprehensive range of solutions to meet the diverse needs of its clients.With a state-of-the-art facility equipped with the latest 3D printing, CNC machining, and injection molding capabilities, {} is able to deliver rapid prototypes with unmatched speed and precision. The company's team of experienced engineers and technicians work closely with clients to understand their design requirements and provide tailored solutions to bring their ideas to life.The rapid prototype process begins with the creation of a 3D model using advanced CAD software. This digital model is then used to generate the necessary instructions for the production equipment, ensuring the accurate replication of the final product. Once the design is finalized, the rapid prototype machines can quickly produce a physical model using a variety of materials, including plastics, metals, and composites.The speed and flexibility of rapid prototype technology have significantly expedited the product development cycle for manufacturers. By allowing for quick iterations and adjustments, companies can rapidly test and refine their designs, ultimately reducing time to market and saving on overall production costs. This has proven to be especially beneficial for industries such as automotive, aerospace, and consumer electronics, where innovation and time-to-market are critical factors for success.One of the key advantages of rapid prototype technology is its ability to bridge the gap between design and manufacturing. With traditional prototyping methods, the transition from design validation to full-scale production often entails lengthy lead times and substantial investment. Rapid prototype technology, however, enables manufacturers to seamlessly transition from prototype to production, reducing the time and resources required to bring a product to market.In addition to its speed and cost-effectiveness, rapid prototype technology also allows for greater design freedom and complexity. With the ability to produce intricate geometries and complex shapes, manufacturers can push the boundaries of innovation and create products that were once deemed unfeasible. This has opened up new opportunities for the development of lightweight, high-performance components that are revolutionizing various industries.As the demand for rapid prototype services continues to grow, {} remains committed to staying at the forefront of this technology. The company regularly invests in the latest equipment and software, ensuring that it can meet the evolving needs of its clients and deliver the highest quality prototypes in the shortest possible time.With a track record of success and a strong reputation for excellence, {} has established itself as a trusted partner for companies seeking to leverage rapid prototype technology. Whether it's a small-scale startup or a multinational corporation, {} is dedicated to providing innovative solutions that drive efficiency, reduce time to market, and ultimately, help clients achieve their business goals.In conclusion, rapid prototype technology has emerged as a transformative tool for manufacturers looking to enhance their product development process. With its speed, precision, and cost-effectiveness, rapid prototype technology offers a competitive edge in today's fast-paced manufacturing landscape. As companies continue to embrace this technology, the potential for innovation and advancement across various industries is limitless, and {} is poised to lead the way in this exciting new era of manufacturing.

High-Quality Lighting Accessories for Your Home at Great Prices

Lighting Accessories, a leading provider of high-quality lighting solutions, has been serving the market for over two decades with its innovative and efficient products. The company specializes in a wide range of lighting accessories, including LED bulbs, fixtures, dimmers, and smart lighting solutions, catering to both residential and commercial customers.With a strong focus on sustainability and energy efficiency, Lighting Accessories has established itself as a pioneer in the industry, constantly pushing the boundaries of technology and design. The company's commitment to delivering cutting-edge solutions has earned it a solid reputation for reliability and excellence among its clientele.One of the key factors that set Lighting Accessories apart from its competitors is its dedication to research and development. The company continuously invests in the latest technologies and trends, ensuring that its products are always on the forefront of innovation. By staying ahead of the curve, Lighting Accessories has been able to anticipate and meet the evolving demands of the market, cementing its position as a market leader.In addition to its focus on innovation, Lighting Accessories is also known for its exceptional customer service. The company takes pride in its knowledgeable and friendly staff, who are always ready to assist clients with their lighting needs. Whether it's a new installation, a retrofit project, or a maintenance issue, Lighting Accessories is committed to providing prompt and effective support to ensure customer satisfaction.Furthermore, Lighting Accessories has a strong commitment to sustainability and environmental responsibility. The company offers a wide selection of energy-efficient LED lighting solutions, helping its customers reduce their carbon footprint and energy consumption. By promoting eco-friendly alternatives, Lighting Accessories is contributing to a greener and more sustainable future.Recently, Lighting Accessories introduced a new line of smart lighting products, designed to enhance convenience and efficiency for its customers. These products utilize cutting-edge technology to enable remote control and automation, allowing users to adjust their lighting settings with ease. With features such as dimming, scheduling, and integration with smart home systems, the new smart lighting solutions from Lighting Accessories offer a seamless and modern lighting experience.Furthermore, Lighting Accessories has expanded its reach by partnering with leading technology companies to integrate its smart lighting products with popular platforms and devices. This strategic collaboration has enabled Lighting Accessories to offer seamless compatibility and an enhanced user experience, further solidifying its position as an industry innovator.As part of its ongoing commitment to excellence, Lighting Accessories is constantly expanding its product range and exploring new opportunities in the lighting market. The company is dedicated to staying at the forefront of the industry, delivering exceptional products and services that exceed customer expectations.In conclusion, Lighting Accessories is a trusted provider of high-quality lighting solutions, known for its innovation, customer service, and commitment to sustainability. With a strong track record of success and a forward-thinking approach, the company continues to lead the way in the lighting industry, setting the standard for excellence and reliability. As the demand for efficient and intelligent lighting solutions continues to grow, Lighting Accessories is well-positioned to meet the needs of its customers and remain a driving force in the market.

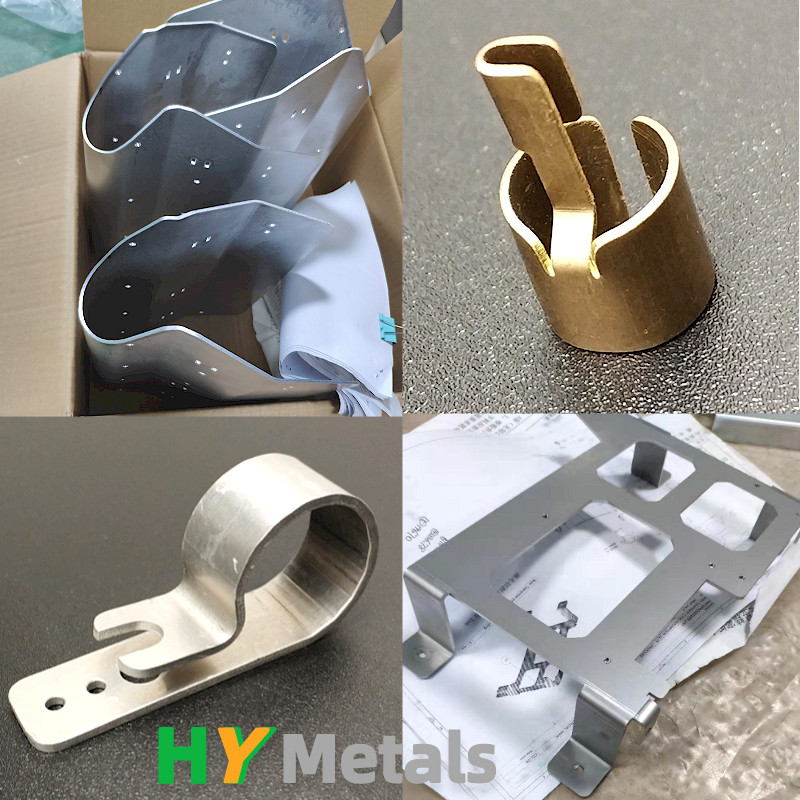

Precision Sheet Metal Brackets Made with Advanced Manufacturing Techniques

: A Comprehensive Guide for Your Manufacturing NeedsSheet metal brackets are an integral part of any manufacturing process that requires the use of metal sheets. In industries that require immense precision and accuracy, the bracket systems ensure that the metal’s shape and structure are maintained throughout the process. With the advancements in modern CNC manufacturing processes, the quality of these bracket systems has improved significantly. The use of advanced automation tools has led to more efficient and precise manufacturing methods.Sheet metal brackets are widely used in various industries such as Aerospace, Medical, Automotive, Construction, and Electronics. In construction, sheet metal brackets are used to provide support to the structural systems, and in electronics, they secure electronic components in place. With their versatility, sheet metal brackets are an essential component in several processes and products.Here is a comprehensive guide to sheet metal brackets for all your manufacturing needs:Types of Sheet Metal Brackets1. Angle Brackets: These are brackets that are bent to 90-degree angles to create perpendicular structural joints. They are commonly used in construction to ensure that the structures maintain their shape and stability.2. U Brackets: These brackets have a U-shaped cross-section that is used to create a mounting point for objects. They are commonly used to mount objects onto walls and other surfaces.3. L Brackets: These are brackets that are bent to form an L-shape. They are used in most applications requiring reinforcement to prevent structural deformation.4. Z Brackets: These are brackets that are bent to form a ‘Z’ shape. They are used in construction to provide additional support to the structural systems.5. T Brackets: These are brackets that are bent to form a T-shape. They are commonly used to attach objects onto walls or other surfaces.Applications of Sheet Metal BracketsSheet metal brackets are used in various applications, including:AerospaceIn the aerospace industry, brackets are used to mount different types of equipment and systems such as electronics, fuel systems, engines, and landing gear. The brackets are usually made from lightweight materials like aluminum to minimize weight.AutomotiveIn the automotive industry, brackets are essential in holding the structural components of the car together. They are also used in securing electrical components in place.ConstructionSheet metal brackets are used extensively in the construction industry for many different applications, such as securing wall studs and reinforcing roof structures.ElectronicsIn the electronics industry, sheet metal brackets are used to secure electronic components in place. They are also used in creating housing systems for electrical components.MedicalSheet metal brackets are used in medical equipment and devices to support and hold various pieces of equipment such as monitors, IV poles, and other medical components in place.Manufacturing ProcessWith advancements in modern CNC manufacturing processes, sheet metal brackets can be precisely and efficiently manufactured. The manufacturing process for sheet metal brackets includes the following stages:1. Material Selection: The sheets of metal used in creating the brackets are usually made from various metals such as Stainless Steel, Carbon Steel, and Aluminum, and copper.2. Laser Cutting: The sheets of metal are cut using laser cutting machines to create the individual brackets' required shapes and sizes.3. Bending: The cut sheet metal is then bent using precision bending machines to create the desired shape of the bracket.4. Welding or Fixing: After bending the metal, the bracket components are welded or fixed together to create a final product.5. Finishing: The finished brackets are sandblasted or painted to give it a final finish.ConclusionSheet metal brackets are a vital part of many manufacturing processes. They provide structural support, aid in mounting equipment and components, and ensure precise manufacturing processes. The modern CNC manufacturing processes have significantly improved the manufacturing process of sheet metal brackets, leading to more efficient, accurate, and high-quality products. If you need sheet metal brackets for your manufacturing processes, ensure that you engage a reputable and experienced manufacturer who can deliver the desired results.

Ultimate Guide to Designing and Developing an Industry-Specific Solution

Industry Design And Development Part, a leading design and development company in the industry, is proud to announce its latest collaboration with a renowned technology company. The partnership aims to revolutionize the way consumers interact with technology and create innovative, user-friendly products that will shape the future of the industry.With over a decade of experience in the design and development field, Industry Design And Development Part has established itself as a pioneer in the industry. The company is known for its cutting-edge approach to product design and its ability to deliver high-quality, innovative solutions to its clients. With a team of experts in industrial design, engineering, and user experience, Industry Design And Development Part has consistently pushed the boundaries of what is possible in product development.The latest collaboration with the technology company is an exciting opportunity for Industry Design And Development Part to showcase its expertise in creating groundbreaking products. The partnership will leverage the strengths of both companies, combining the technology company's advanced technology with Industry Design And Development Part's design and development capabilities. This collaboration is expected to result in the creation of products that will not only meet the needs of consumers but also exceed their expectations.One of Industry Design And Development Part's key strengths is its focus on user-centered design. The company understands the importance of creating products that are intuitive and easy to use, and it has a proven track record of designing products that resonate with consumers. By working closely with the technology company, Industry Design And Development Part will be able to apply its user-centered design approach to the creation of innovative products that will set new industry standards.In addition to its design expertise, Industry Design And Development Part is also known for its commitment to sustainability and environmental responsibility. The company is dedicated to minimizing the environmental impact of its products and processes, and it actively seeks out sustainable materials and manufacturing methods. This commitment to sustainability aligns with the values of the technology company, making the collaboration a perfect fit for both parties."We are thrilled to be partnering with a company as esteemed as the technology company," said [spokesperson], [title] at Industry Design And Development Part. "This collaboration presents a unique opportunity for us to showcase our expertise in design and development and create products that will truly make a difference in the industry. We are excited to combine our strengths and work together to push the boundaries of innovation."As the collaboration between Industry Design And Development Part and the technology company continues to unfold, industry insiders and consumers alike are eager to see the products that will emerge from this partnership. With a shared commitment to innovation, user-centered design, and sustainability, the collaboration is poised to make a significant impact on the industry and set new benchmarks for product excellence.About Industry Design And Development PartIndustry Design And Development Part is a [remove brand name] design and development company with a mission to create innovative, user-centered products that push the boundaries of what is possible. With a team of experts in industrial design, engineering, and user experience, Industry Design And Development Part has established itself as a leader in the industry, known for its cutting-edge approach to product development and its commitment to sustainability. Whether working with startups or Fortune 500 companies, Industry Design And Development Part is dedicated to delivering high-quality, innovative solutions that exceed client expectations.

How to Create Tubes with Precise Forming Techniques for Industrial Applications

Innovation in Tube Forming ProcessTube forming is a well-known process in the manufacturing industry, serving as a cost-effective and efficient method of producing seamless tubes used in a variety of applications. However, in recent years, a new technological development has emerged - tube forming that promises to revolutionize the manufacturing industry. This innovative process uses advanced technology to deliver speed, accuracy and reliability in a way that older tube forming technologies simply cannot match. One such company leading the way in this area is {}.Founded in 2001 and headquartered in Germany, {} is a global leader in innovative tube processing solutions. The company has a range of unique and patented technologies and is continually investing in research and development to improve production efficiency. {} has a presence in over 50 countries, with clients in various industries such as automotive, aviation, energy and construction.One of the most significant achievements of {} is their innovative tube forming process that allows for simultaneous tube expansion and reduction in diameter. This process means that the tube's wall thickness can remain uniform throughout the tube's length, which is something that older traditional tube forming techniques could not achieve. Indeed, the older tube forming technology often resulted in decreased quality, imperfections that required additional shaping steps, and reduced production efficiency.However, {} has significantly changed this landscape. Their tube forming solution attains higher precision, and consistency in tube size with much less wastage of material. This cutting-edge technology generates seamless tubes that are produced in a single process, which is faster, less labor-intensive, and more cost-effective than traditional tube forming methods. The process also allows for a wide range of materials, including stainless steel, aluminum, copper, and nickel alloys, which further increases its application in various industries.Furthermore, the company has the expertise to design custom-made tube forming solutions. {} provides individualized solutions for their clients' specific production requirements. This service is only possible because of the digitization capabilities of their tube forming technology. The digitization of the tube forming process enhances accuracy and precision, leading to an exact match of the client's desired tube specifications. They also use advanced simulation software during the design process to identify potential issues before production, improving efficiency and cost-effectiveness.With {}'s innovative technology, cost-effectiveness is a significant advantage. The use of automated systems allows for minimal human intervention and increases production efficiency. The technology can operate at high speeds and produce a large volume of tubes within a short span of time, meaning that clients can enjoy reduced production costs and ultimately save on the bottom line.In conclusion, the innovative tube forming process presented by {} is proving to be a game-changer in the manufacturing industry. It offers speed, efficiency, cost-effectiveness, while simultaneously increasing accuracy and reducing waste. With the implementation of digitization, custo made solutions, and the use of advanced simulation software, {} is ultimately taking the production to the next level. The company is aptly positioned to lead the transformation of the tube forming industry, and it is exciting to see what is yet to come as they continue to innovate.

High-quality Precision Machining Parts for CNC Applications

CNC Precision Machining Parts - Providing High-Quality Components for Various IndustriesToday, precision machining plays a crucial role in a wide range of industries, including aerospace, automotive, medical, and more. These industries rely on the high-quality components produced by CNC precision machining to ensure the reliability and performance of their products. For companies seeking exceptional precision machining solutions, {Company Name} is the go-to provider for all their needs.{Company Name} is a leading manufacturer of CNC precision machining parts, offering a comprehensive range of services to meet the diverse needs of their clients. With a strong dedication to quality and innovation, they have established themselves as a trusted partner for businesses across different industries.CNC precision machining is a process that entails the use of computer-aided design (CAD) software and computer-aided manufacturing (CAM) software to automate the control of machining tools and 3D printers. This enables the production of highly precise and complex parts with tight tolerances and excellent surface finishes. The CNC precision machining process can be applied to various materials, including metals, plastics, and composites, making it a versatile solution for a wide range of applications.{Company Name} prides itself on its state-of-the-art facilities and advanced machining capabilities. Their team of skilled engineers and machinists are equipped with the latest CNC machines, ensuring the highest level of precision and efficiency in the production of parts. Whether it's a small batch of components or a large-scale production run, {Company Name} has the expertise and resources to meet their clients' requirements with precision and accuracy.One of the key advantages of CNC precision machining is its ability to produce parts with high repeatability and consistency. This is essential for industries that demand uniformity and reliability in their products. {Company Name} understands the importance of precision and consistency in machining parts, and they are committed to delivering components that meet the highest quality standards.In addition to their cutting-edge machining capabilities, {Company Name} offers a range of value-added services to support their clients throughout the entire manufacturing process. From design assistance and prototyping to finishing and assembly, they provide comprehensive solutions to address every aspect of their clients' needs. This end-to-end approach ensures that their clients receive a seamless and efficient experience from start to finish.Furthermore, {Company Name} places a strong emphasis on quality control and assurance. They adhere to rigorous quality management systems to ensure that every part they produce meets the specified requirements and standards. By employing the latest inspection equipment and techniques, they are able to validate the dimensional accuracy and performance of their components, giving their clients the peace of mind that they are receiving top-quality products.In conclusion, {Company Name} is a reputable provider of CNC precision machining parts, offering a wide range of capabilities and services to cater to the needs of various industries. With their commitment to quality, innovation, and customer satisfaction, they have built a solid reputation as a trusted partner for businesses seeking high-quality precision machining solutions. Whether it's a complex aerospace component, a critical medical device, or a precision automotive part, {Company Name} has the expertise and resources to deliver the premium components that their clients rely on.