Discover the Latest Sheet Metal Part Innovations and Applications

By:Admin

News Content:

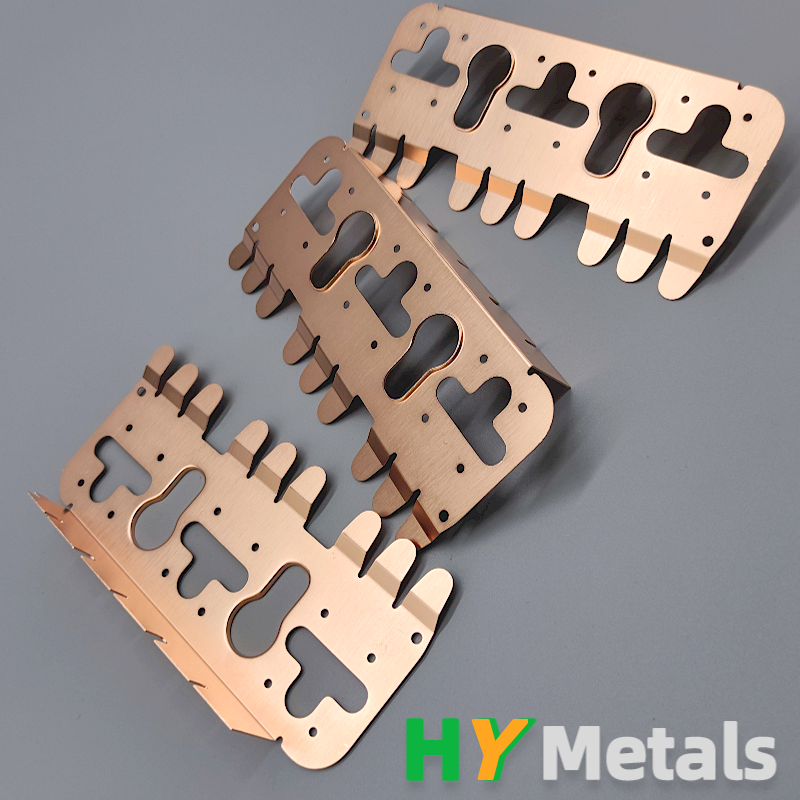

[Company] Delivers Exceptional Sheet Metal Parts for Diverse Applications

As a renowned player in the sheet metal manufacturing industry, [Company] continues to make headlines with its superior quality sheet metal parts and components. Recently, the company unveiled its latest range of sheet metal parts, showcasing its advanced manufacturing capabilities and commitment to meeting the evolving needs of its customers.

One of the standout products from [Company]'s latest range is its precision-engineered sheet metal part, which has been developed using the latest technology and manufacturing processes. The part boasts exceptional dimensional accuracy, surface finish, and durability, making it suitable for a wide range of applications across various industries.

Speaking about the new sheet metal part, a spokesperson for [Company] emphasized the company's dedication to exceeding customer expectations. "We are thrilled to introduce our latest sheet metal part, which represents the pinnacle of our engineering and manufacturing expertise. Our team has worked tirelessly to ensure that this part meets the highest standards of quality and performance, and we are confident that it will deliver exceptional value to our customers."

In addition to its superior quality, the new sheet metal part also highlights [Company]'s commitment to innovation and technology. By leveraging advanced manufacturing processes and cutting-edge equipment, the company has been able to push the boundaries of what is possible in sheet metal fabrication, setting new benchmarks for quality and precision in the industry.

Furthermore, [Company] has also underscored its ability to customize sheet metal parts according to the specific requirements of its customers. With its in-house design and engineering capabilities, the company can collaborate closely with clients to develop tailor-made solutions that meet their exact needs. This flexibility and customer-centric approach have been instrumental in [Company]'s success and continued growth in the highly competitive sheet metal manufacturing sector.

The release of the new sheet metal part is a testament to [Company]'s unwavering commitment to excellence and continuous improvement. By investing in research and development, adopting best practices, and staying abreast of industry trends, [Company] has positioned itself as a trusted partner for businesses seeking top-quality sheet metal parts for their projects.

Looking ahead, [Company] remains focused on expanding its product offerings, enhancing its manufacturing capabilities, and strengthening its position as a leading provider of sheet metal solutions. With a solid track record of delivering superior quality products and a customer-centric approach, the company is well-positioned to capitalize on the growing demand for high-quality sheet metal parts in the global market.

In conclusion, [Company]'s latest sheet metal part exemplifies its unwavering dedication to excellence, innovation, and customer satisfaction. As the company continues to push the boundaries of sheet metal manufacturing, it is poised to set new standards for quality and performance in the industry. With its solid reputation, technical expertise, and commitment to meeting customer needs, [Company] is set to maintain its leadership position in the competitive sheet metal manufacturing landscape.

Company News & Blog

Discover High-Quality Precision Components for CNC Applications

Title: Leading Precision Component Manufacturer Reveals Cutting-Edge Innovations for Industry AdvancementsIntroductionIn the rapidly evolving world of manufacturing and engineering, precision is the key to success. Cnc Precision Components, a renowned industry leader, has consistently prioritized precision engineering and state-of-the-art manufacturing techniques. With a global reputation for excellence, the company continues to push the boundaries of innovation by delivering superior quality products to a wide range of industries. Today, we delve into the innovative solutions offered by Cnc Precision Components and explore how their advanced techniques are transforming the manufacturing landscape.1. Leader in Precision EngineeringCnc Precision Components has established itself as a pioneer in precision engineering, setting new benchmarks for quality and precision in the industry. The company's commitment to accuracy is evident from its technologically advanced infrastructure and cutting-edge machinery. With an unwavering focus on delivering highly precise components, Cnc Precision Components ensures that every product meets the stringent requirements and specifications of its clients. This dedication has allowed the company to become a trusted partner for global businesses in various sectors.2. State-of-the-Art Manufacturing TechniquesIncorporating the latest manufacturing technologies is crucial for staying ahead in today's competitive market. Cnc Precision Components understands this and has invested significantly in state-of-the-art machinery and sophisticated manufacturing techniques. This commitment to innovation has enabled the company to offer an extensive range of precision components tailored to meet the diverse needs of its customers. By seamlessly blending automation and skilled craftsmanship, Cnc Precision Components ensures consistent product quality and reduced lead times, driving operational efficiency for its clients.3. Customized Solutions for Every IndustryRecognizing that each industry has unique requirements, Cnc Precision Components provides customized solutions to cater to the specialized needs of its clients. With a team of highly skilled engineers and technicians, the company collaborates closely with clients to design and manufacture precision components that align perfectly with their specifications. This tailored approach enables Cnc Precision Components to support businesses across sectors, including automotive, aerospace, medical devices, electronics, and more.4. Advancing Industry 4.0 Through Smart ManufacturingAs the world moves towards Industry 4.0, Cnc Precision Components is at the forefront of embracing advanced technologies such as artificial intelligence, internet of things (IoT), and data analytics. These technologies not only optimize manufacturing processes but also enhance product performance and reliability. By implementing smart manufacturing systems, Cnc Precision Components improves quality control, increases production efficiency, and allows for real-time monitoring and analysis. The company's forward-thinking approach ensures customers can count on precision components that satisfy the demands of the digital era.5. Focus on Sustainability and Environmental ResponsibilityIn addition to its commitment to precision and innovation, Cnc Precision Components emphasizes sustainability and environmental responsibility. The company endeavors to reduce its carbon footprint by adopting energy-efficient machinery and optimizing manufacturing processes. Cnc Precision Components also ensures the responsible sourcing of raw materials with a focus on recyclability, contributing to a greener manufacturing ecosystem.6. Collaborative Approach and Customer SatisfactionProviding exceptional customer service and maintaining longstanding relationships is a cornerstone of Cnc Precision Components' success. The company values open communication and collaboration with clients to better understand their specific requirements and challenges. By doing so, Cnc Precision Components ensures that the manufactured components meet or exceed expectations, resulting in high customer satisfaction and loyalty.ConclusionCnc Precision Components continues to be a driving force in the precision manufacturing industry, delivering superior solutions tailored to meet the critical demands of diverse sectors. Through their relentless commitment to precision, state-of-the-art manufacturing techniques, and investment in smart technologies, the company stands at the forefront of innovation. With a sustainable approach and a customer-centric mindset, Cnc Precision Components is poised to shape the future of precision manufacturing, revolutionizing industries and setting new benchmarks for quality and performance.

Discover the Advantages of Laser Cutting in Modern Manufacturing

article:Laser Cutting Technology Makes its Way into Industrial ManufacturingIn recent years, industrial manufacturing has undergone a major transformation. The advancement in technology has brought about significant changes in processes, enabling the industry to become more efficient, faster, and more cost-effective. One of the technological advancements that have brought about significant changes in the manufacturing industry is laser cutting technology. Laser cutting technology is a process of cutting materials using laser beams. The technology has been around for some time now and has grown increasingly popular in various industries such as automotive, aerospace, construction, and textiles, among others. It is an incredibly versatile technology that can cut through a wide range of materials such as metal, plastics, wood, and fabrics.Laser cutting technology has been a game-changer for companies that require a high level of precision in their products. The technology's precision enables companies to create intricate designs and shapes that would be impossible to achieve using traditional methods. The technology has also helped to reduce production costs by minimizing material waste and increasing efficiency.One company that has been at the forefront of embracing laser cutting technology is {company name}. The company specializes in industrial manufacturing and has been using laser cutting technology to achieve precision and efficiency in its processes. {Company name} has invested heavily in the latest laser-cutting technologies, ensuring that it remains competitive in the market. The company has a team of skilled professionals who are experts in using laser-cutting technology, ensuring that their products meet the highest standards of quality.One of the advantages of laser cutting technology is its ability to cut through materials quickly and efficiently. This speed makes it possible to produce products in large volumes within a short period. {Company name} has been able to take advantage of this speed to meet the high demand for its products in the market.At {company name}, the use of laser cutting technology has enabled the company to produce high-quality products that meet the specific needs of its clients. The technology is incredibly versatile and can cut through a wide range of materials such as aluminum, stainless steel, and carbon steel, among others. This versatility has enabled the company to cater to clients from different industries with varying needs.The precision of laser cutting technology has also enabled {company name} to create intricate designs and shapes in its products. This precision has helped to set the company apart from its competitors, as it can produce products that are unique to its clients' requirements.Another advantage of laser cutting technology is its ability to minimize material waste during the manufacturing process. The technology works by focusing laser beams on the material, melting it away in a controlled manner. This process results in minimal material wastage, reducing production costs significantly. {Company name} has been able to take advantage of this capability, ensuring that it remains cost-competitive in the market.As technology continues to evolve, laser cutting is expected to become more advanced, increasing its relevance in the manufacturing industry. With laser cutting technology becoming more popular, more companies are expected to adopt it, making it an essential technology in industrial manufacturing.In conclusion, laser cutting technology has revolutionized the industrial manufacturing industry, providing significant benefits such as precision, efficiency, and cost-effectiveness. {Company name} is one of the companies that have embraced this technology, ensuring that it remains competitive in the market and meets the specific needs of its clients. The continued evolution of laser cutting technology is expected to lead to further advancements in the industry, making it an exciting time for the manufacturing industry.

New 3-Axis Technology Takes Drone Photography to the Next Level" -> "Revolutionary 3-Axis Technology Enhances Drone Photography

In the latest developments in the field of drone technology, a new player has emerged offering a cutting-edge solution for aerial photography. 3-Axis, a company that specializes in unmanned aerial vehicles (UAVs), has recently launched a drone that has been garnering a lot of attention among photography enthusiasts and professionals alike. This new drone offers a solution that addresses some of the most pressing challenges faced by aerial photographers over the years. The company’s drone comes equipped with a built-in 3-axis gimbal system that offers superior stability, ensuring that the camera remains steady and delivers high-quality footage and images. The company claims that its 3-axis system can stabilize the camera with pinpoint precision, reducing camera shake and producing smooth footage with a cinematic quality. The system is based on three working principles: roll, pitch, and yaw, and is designed to ensure that the camera remains level and stable during flight, even in windy conditions. Furthermore, the drone is built with an advanced camera system that captures 4K videos and 16MP still images. The camera also comes with a remote control, making it easy for users to adjust the focal length, exposure, and other settings in real-time. The drone’s remote controller is also designed to provide an intuitive and user-friendly experience, allowing users to focus on capturing the perfect shot. What sets 3-Axis apart is its focus on safety and simplicity. The company ensures that its drones are easy to operate, even for novices, and come with features that ensure safe and stable flight. These features include GPS-assisted hover, which enables the drone to maintain its position in the air autonomously and return to its launching point if it ever loses connection with the remote controller. The drone is also built with obstacle avoidance sensors that detect and avoid obstacles in the drone’s flight path, ensuring a safer and more efficient flight experience. Moreover, the drone is equipped with a fail-safe mechanism that ensures that it automatically returns to its home point in case of low battery or other emergencies. One of the main target markets for the 3-Axis drone is the real estate industry. The drone’s ability to capture stunning aerial footage and images makes it a valuable tool for marketing properties and showcasing landscapes. The drone also offers a convenient and cost-effective alternative to traditional aerial photography methods, which often require the use of helicopters and planes. 3-Axis has also set its sights on the events and entertainment industry, where the drone’s compact design and superior maneuverability make it ideal for capturing live events and performances. With its advanced camera system and 3-axis gimbal, the 3-Axis drone is capable of capturing stunning aerial footage with a level of stability and precision that is unmatched in the industry. The company has also been quick to highlight its commitment to taking environmental sustainability seriously. 3-Axis is a carbon-neutral company, having implemented a number of measures to reduce its environmental footprint. One such measure is the use of renewable energy sources to power its operations, including the manufacture and charging of its drones. Moreover, the company has committed to offsetting its carbon emissions by investing in renewable energy projects around the world. This commitment to environmental sustainability is one that is sure to appeal to environmentally conscious consumers who are looking for products that deliver both quality and sustainability. In conclusion, 3-Axis has emerged as a major player in the drone industry, with its focus on cutting-edge technology, safety, simplicity, and sustainability. The company’s new drone, equipped with a 3-axis gimbal system, advanced camera, and user-friendly remote controller, represents a significant breakthrough in the field of aerial photography and videography. It will be interesting to see how the company develops its product line in the coming years, as it continues to innovate and set new standards in the drone industry.

Metal Sheet Cutting, Punching, Pressing and Binding Services

release:DOMEX Offers Comprehensive Sheet Metal Processing Solutions with State-of-the-Art EquipmentDOMEX, a leader in sheet metal processing, offers a comprehensive range of services that include cutting, punching, pressing, and binding of metal sheets. The company has a state-of-the-art facility equipped with modern mechanical and hydraulic presses, and a range of other equipment, making it possible to handle even complex and challenging sheet metal projects.With more than two decades of experience in the industry, DOMEX has earned a reputation for excellence in sheet metal processing and fabrication. One of the key factors behind its success is the company's focus on quality, precision, and timely delivery of projects. This is supported by their well-trained and experienced staff, who are committed to ensuring every project meets customer expectations.One of the core services offered by DOMEX is metal sheet cutting. The company has invested in the latest hydraulic guillotine shears, which can cut through even the thickest sheets of metal with ease. This equipment is ideal for cutting material for a wide range of industries, including construction, architecture, and manufacturing. Furthermore, the shears provide an impeccable level of precision and accuracy, ensuring that every cut is clean and straight.DOMEX also has an array of mechanical and hydraulic presses that can handle different metal sheet processing needs. Each press has varying pressure power levels and dimensions of working tables, making it possible for the company to provide a range of custom metal fabrication services. These include stamping, deep drawing, bending, and flanging, among others. These metal shaping processes are important in the manufacturing of products in many industries, such as automotive, aerospace, and medical devices.Quality is a top priority at DOMEX, and the company has a stringent quality control process in place to ensure that every project meets exacting standards. Their team of skilled technicians use advanced measuring equipment to check and double-check every aspect of a project before it is allowed to leave the facility. From first cut to final assembly, every step of the metal processing project is carefully monitored and inspected to ensure every component meets customer requirements.DOMEX is also committed to sustainability and environmental responsibility. They use only eco-friendly materials, and their state-of-the-art equipment has been designed to reduce waste and energy consumption. Additionally, the company strives to make sure their metal fabrication processes are as efficient as possible, reducing the use of resources and minimizing the environmental impact of their operations.With its knowledgeable staff, cutting-edge equipment, and commitment to quality and sustainability, DOMEX is a trusted partner for businesses looking for reliable sheet metal processing services. The company's services are ideal for those in the construction, architecture, manufacturing, and other related industries who require top-quality, precision sheet metal fabrication. In conclusion, DOMEX remains a leader in the sheet metal processing industry, and their commitment to excellence and sustainability sets them apart from the competition. Whether cutting, punching, pressing, or binding metal sheets, the company ensures that every project is completed to the highest standards, on time and within budget.

Durable and Trendy Powder Coated Aluminium Extrusions for Your Project

Powder Coated Aluminium Extrusions is a leading company in the manufacturing and supply of high-quality aluminum extrusions. With a commitment to providing superior products and excellent customer service, the company has established itself as a trusted supplier for a wide range of industries.The company's dedication to quality and innovation is evident in its powder coated aluminum extrusions, which are known for their durability, versatility, and aesthetic appeal. These extrusions are used in a variety of applications, including architectural, automotive, aerospace, and industrial uses. The powder coating process not only enhances the appearance of the aluminum extrusions but also provides an additional layer of protection against corrosion, wear, and environmental elements.One of the key advantages of Powder Coated Aluminium Extrusions is its ability to provide custom solutions to meet the specific needs of its customers. The company works closely with clients to understand their requirements and develop tailored extrusion profiles that are engineered to exact specifications. This level of customization ensures that customers receive products that perfectly fit their intended application, resulting in better performance and cost-efficiency.In addition to its product excellence, Powder Coated Aluminium Extrusions is also known for its exceptional customer service. The company's team of experienced professionals is dedicated to providing personalized support and assistance throughout the entire process, from initial consultation to final delivery. This dedication to customer satisfaction has earned the company a strong reputation and a loyal customer base.Furthermore, Powder Coated Aluminium Extrusions is committed to sustainable and environmentally friendly practices. The company places a strong emphasis on reducing its environmental impact by implementing energy-efficient manufacturing processes and utilizing recyclable materials. This commitment aligns with the growing demand for eco-friendly solutions and reflects the company's forward-thinking approach to business.Powder Coated Aluminium Extrusions also stays updated with the latest technological advancements and trends in the industry. The company continuously invests in research and development to enhance its product offerings and stay ahead of the competition. By leveraging the latest technologies, the company is able to improve product performance, efficiency, and quality, ultimately benefiting its customers.With its strong business values, commitment to excellence, and focus on innovation, Powder Coated Aluminium Extrusions is a leader in the aluminum extrusion industry. The company's dedication to providing high-quality, customized solutions, and outstanding customer service sets it apart from its competitors and positions it as a preferred partner for businesses looking for reliable extrusion products.In conclusion, Powder Coated Aluminium Extrusions has firmly established itself as a trusted and respected supplier of powder coated aluminum extrusions. The company's commitment to quality, innovation, customization, and sustainability has set it apart in the industry and earned it a strong reputation. With a focus on customer satisfaction and continuous improvement, Powder Coated Aluminium Extrusions is well-positioned for continued success.

Top Quality Auto Parts for Sale - Find the Best Deals Online

Auto Parts Company is a leading supplier of high-quality auto parts and accessories to the aftermarket industry. With a wide range of products and a commitment to customer satisfaction, Auto Parts Company has earned a reputation for excellence in the automotive industry.The company offers a comprehensive catalog of products, including engine parts, brake systems, suspension components, electrical systems, and much more. Their extensive inventory allows them to meet the needs of customers across the country, from individual car owners to professional mechanics and repair shops.In addition to their extensive product offering, Auto Parts Company is dedicated to providing exceptional customer service. Their knowledgeable staff is available to assist customers with finding the right parts for their specific needs and offer expert advice on installation and maintenance. With a focus on meeting and exceeding customer expectations, Auto Parts Company has built a loyal customer base that relies on them for all of their automotive needs.As a leader in the aftermarket auto parts industry, Auto Parts Company is constantly evolving to meet the changing needs of their customers. They are committed to staying ahead of the curve when it comes to new technology and innovations in the automotive industry, allowing them to offer the latest and most advanced products to their customers.Auto Parts Company also places a strong emphasis on quality and reliability. They work with top manufacturers to ensure that all of their products meet or exceed industry standards for performance and durability. This commitment to quality has earned Auto Parts Company a reputation for excellence in the industry and has helped them to build strong, long-lasting relationships with both customers and suppliers.In addition to their commitment to quality, Auto Parts Company is also dedicated to sustainability and environmental responsibility. They are constantly seeking out new ways to reduce their environmental impact, from reducing waste and emissions in their operations to sourcing eco-friendly products and materials. Their dedication to sustainability sets them apart as a company that not only cares about their customers but also the world around them.Auto Parts Company is also a leader in the community, actively participating in charitable initiatives and supporting local organizations. They believe in giving back to the communities that have supported them and are committed to making a positive impact wherever they can.Overall, Auto Parts Company is a company that is dedicated to excellence in every aspect of their business. From their extensive product offering and commitment to customer service to their focus on quality, innovation, and sustainability, Auto Parts Company sets the standard for excellence in the aftermarket auto parts industry. With a strong reputation and a loyal customer base, they are well-positioned for continued success and growth in the years to come.

Ultimate Guide to Sheet Metal Chassis: Everything You Need to Know

Sheet Metal Chassis: A Look at the Innovative Products from [][Company name]'s passion for innovation and commitment to excellence have fueled the development of cutting-edge products in the industry. With a focus on precision engineering and superior quality, the company has consistently raised the bar for sheet metal chassis technology. As a leader in the field, [company name] continues to push the boundaries of what is possible, offering customers innovative solutions that meet and exceed their expectations.One of the most significant contributions of [company name] to the industry is its world-class sheet metal chassis. These innovative products have set new standards for quality, durability, and performance. Designed to meet the demands of the modern world, [company name]'s sheet metal chassis are the go-to choice for a wide range of applications, from automotive and aerospace to electronics and telecommunications.The company's sheet metal chassis are engineered with precision and manufactured with the highest quality materials. This ensures that they are able to withstand the rigors of the most demanding environments, providing a level of durability that is unmatched by any other competitor in the market. In addition, the company's commitment to excellence means that its sheet metal chassis are consistently tested and improved to ensure that they meet the highest industry standards.What sets [company name]'s sheet metal chassis apart from the competition is their unparalleled performance. Whether it is in terms of strength, weight, or versatility, these products have been designed to deliver exceptional results. This has made them the top choice for customers who are looking for a durable and reliable solution that can withstand the most challenging conditions.Moreover, [company name]'s sheet metal chassis are known for their versatility. They are available in a wide range of sizes and configurations, making them suitable for a diverse set of applications. Whether it is a small electronic device or a large industrial equipment, the company has a sheet metal chassis that can meet the specific needs of each customer.Another key advantage of [company name]'s sheet metal chassis is their cost-effectiveness. The company has leveraged its expertise and experience to develop manufacturing processes that ensure high-quality products at competitive prices. This has made its sheet metal chassis a cost-effective solution for businesses looking to maximize their return on investment without compromising on quality.In addition to its focus on product excellence, [company name] is also known for its outstanding customer service. The company values its relationship with customers and is committed to providing them with the support and guidance they need to make informed decisions. Its team of experienced professionals is always on hand to answer questions, provide technical assistance, and offer customized solutions to meet specific needs.Looking towards the future, [company name] remains dedicated to innovation and continuous improvement. The company is constantly investing in research and development to stay ahead of the curve and anticipate the evolving needs of its customers. This commitment to innovation ensures that [company name]'s sheet metal chassis will continue to be at the forefront of the industry for years to come.In conclusion, [company name]'s sheet metal chassis are a testament to the company's commitment to excellence and innovation. With their superior quality, unmatched performance, and cost-effectiveness, these products have set new standards for the industry. As [company name] continues to push the boundaries of what is possible, customers can expect to see even more groundbreaking products that will redefine the way we think about sheet metal chassis technology.

Custom Aluminium Extrusions for Your Specific Needs

In today's fast-paced and continuously developing modern world, businesses have to keep up with the growing needs of their clientele. One way to do that is through offering customized products, tailored to meet the specific requirements of the customer. Avocet Precision Metals has taken up that challenge, offering aluminum extrusion services that cater to the unique needs of the client.Avocet Precision Metals is a premier metals manufacturing company, located in the United Kingdom, known for its dedication to providing high-quality metal products and exceptional customer service. The firm utilizes cutting-edge technologies and equipment to provide unmatched precision in producing aluminum extrusions that meet the highest industry standards. With a workforce of highly skilled and experienced professionals well-versed in the latest practices of the extrusion industry, Avocet Precision Metals delivers results that surpass expectations.At its core, aluminum extrusion is a process by which manufacturers create complex shapes by forcing aluminum through a shaped opening. This process allows for customization of aluminum products to meet the exact specifications of clients. Avocet Precision Metals recognizes the importance of this process, making sure that all products conform to the customer's design, ensuring that products are manufactured to the highest quality standards.The company utilizes both hard and soft alloys of aluminum to match the specific requirements of the client. If the customer requires a particular combination of strength, corrosion resistance, and lightness, Avocet Precision Metals can deliver precisely what is needed. The company's aluminum extrusion services are highly versatile and can be used in a wide range of applications, including automotive, construction, machinery and much more.Avocet Precision Metals prides themselves in employing best practices, and quality measures to deliver the best customer experience. The company ensures that all the aluminum extrusion products are produced in an environmentally sustainable manner. The manufacturing process is regulated to ensure that it is as green as possible, minimizing the impact on the environment while ensuring that the customer receives high-quality products. Additionally, the company takes its customers' safety seriously and has worked hard to develop and implement safety and environmental protection policies.The high quality of the products that Avocet Precision Metals delivers is made possible by the company's continued investment in modern technology. This significantly reduces the production lead times and guarantees that the products are at the highest level of precision and quality. The company has installed cutting-edge CNC machines and presses that enable the team to manufacture high volumes of aluminum extrusions while reducing waste and maximizing efficiency.Avocet Precision Metals recognizes that customers have different budgets, and the company is always willing to work with clients to find a solution that works best for them. The company is committed to funding a team that supports its customers even after the sale is completed. They have an expert team of professionals on standby, ready to offer guidance and answer any queries that may arise.As a leading player in the aluminum extrusion industry, Avocet Precision Metals is continuously innovating and improving its processes to ensure they stay ahead of the competition. This continuous improvement mindset ensures that the company remains relevant in a market that is constantly changing. The firm's commitment to providing customers with the highest quality products and services has earned Avocet Precision Metals an excellent reputation among its customers and industry peers.In summary, Avocet Precision Metals is a top-tier manufacturer of aluminum extrusions that delivers high-quality and customized products according to clients' specifications. They are a company that prioritizes customer satisfaction and has invested in cutting-edge technology, skilled personnel, while staying environmentally conscious. These steps have enabled them to deliver on their promises while expanding their clientele base, and solidifying its position as a leading industry player.

CNC Turning Services for High-Quality Lathe Turned Parts

Service, Lathe Turned Production Parts, Prototyping, CNC Machined Parts, Manufacturing Partners, Instant CNC Turning Quote.CNC Turning Service: Your One-Stop Solution for All Your Lathe NeedsIn today's fast-paced manufacturing industry, the demand for precision and accuracy in parts production is more important than ever. Thanks to advances in technology, the CNC turning service has emerged as the go-to solution for manufacturing high-quality lathe-turned production parts. CNC Turning, with its precision, speed, and flexibility, has revolutionized the world of manufacturing and has become an essential part of modern-day production processes.At CNC Turning Service, we understand the importance of getting it right the first time, which is why we offer an exceptional range of services dedicated to providing our clients with the best possible results. Our services provide complete end-to-end solutions, from prototyping to CNC machined parts, and we deliver them with unbeatable speed, quality, and price.Our Global Network of Certified Manufacturing PartnersCNC Turning Service is proud to have a global network of 25 certified manufacturing partners, enabling us to offer our clients the best CNC turning services available. These partners have over 100 CNC turning machines, allowing us to produce everything from simple to complex parts. Our partners undergo a rigorous selection process to ensure they meet our exacting standards of quality, consistency, and efficiency. As a result, our clients benefit significantly from increased savings, faster lead times, and access to a wider range of capabilities.The Most Cost-Effective Solution for PrototypingAt CNC Turning Service, we understand that prototyping is an essential part of the production process. As such, we offer our clients the most cost-effective solution for creating high-quality prototypes. Our CNC turning service gives our clients the ability to produce prototypes that are identical to the final product in terms of specifications, tolerances, and material, which reduces the risk of design errors and allows for necessary modifications before the final production.CNC Machined Parts With Unbeatable Quality and SpeedCNC Turning Service produces CNC machined parts with unbeatable speed and quality. Our partners' CNC turning machines produce precise and accurate parts with precise tolerances, finishes, and features. Whether you need single parts or thousands, our CNC turning service can provide you with the most efficient and cost-effective production.Instant CNC Turning QuoteCNC Turning Service offers an instant CNC turning quote to our clients. Our online quote system is user-friendly, simple, and straightforward to use. Our clients can upload their designs, specify their requirements, and receive a quote instantly. With our instant quote system, our clients can access real-time pricing information and plan their production processes accordingly.ConclusionAt CNC Turning Service, we provide our clients with a complete end-to-end solution for all their lathe-turned production parts needs. Our global network of certified manufacturing partners, our cost-effective prototyping solutions, and our unbeatable quality and speed in producing CNC machined parts, make us the go-to solution for manufacturing high-quality parts. Contact us today and experience the benefits of our CNC turning services.

Discover the Cutting-Edge World of CNC Machining: Unlocking the Potential of Prototyping

Title: Pioneering CNC Machining Company Revolutionizes Manufacturing IndustryIntroduction:In the evolving landscape of the manufacturing industry, advancements in CNC (Computer Numerical Control) machining have played a vital role in driving efficiency and precision. One notable company at the forefront of this technological revolution is a leading CNC machining manufacturer, employing state-of-the-art processes to cater to the diverse needs of customers across various sectors. By leveraging their expertise and cutting-edge equipment, this company has become a trusted partner for businesses seeking high-quality prototype CNC machining services.A Commitment to Excellence:The company, with over two decades of experience, has consistently demonstrated a commitment to excellence. Their team of highly skilled engineers and technicians possess extensive knowledge in CNC machining, enabling them to deliver exceptional results to clients. With a customer-centric approach, they prioritize understanding the unique requirements of each project, ensuring superior product quality and customer satisfaction.Streamlined Manufacturing Processes:The remarkable success of this CNC machining major can be attributed to their strategic implementation of streamlined manufacturing processes. Utilizing cutting-edge CAD (Computer-Aided Design) software, their skilled designers are entrusted with transforming client concepts into precise digital models. With meticulous attention to detail, they optimize designs to enhance functionality and manufacturability while minimizing production costs.The company's advanced CNC machines, equipped with the latest technology, then seamlessly translate these digital designs into tangible products. These machines offer unparalleled accuracy, allowing for intricate details, complex geometries, and tight tolerances to be achieved with ease. By leveraging various CNC machining techniques, such as milling, turning, and drilling, the company caters to the diverse needs of industries such as automotive, aerospace, medical, and more.Driving Innovation Through Research and Development:At the heart of this pioneering company lies a dedicated research and development team seeking to push the boundaries of CNC machining technology. With a focus on continuous improvement, they invest heavily in exploring new materials, tooling, and machining techniques. Through their tireless efforts, they ensure that their clients have access to the latest innovations, positioning them at the forefront of their respective industries.Responsive Customer Support and Collaborative Approach:Recognizing the importance of effective communication and collaboration, the company places great emphasis on providing exceptional customer support throughout the entire production process. Their team of knowledgeable professionals works closely with clients, offering guidance and resolving any queries promptly. This collaborative approach not only ensures alignment with project objectives but also fosters long-lasting partnerships built on trust and reliability.Sustainability and Environmental Responsibility:In addition to their commitment to delivering exceptional products, this CNC machining leader also understands the significance of environmental stewardship. Implementing sustainable manufacturing practices, they strive to minimize waste, conserve energy, and reduce their carbon footprint. The company actively promotes the use of eco-friendly materials and continually explores innovative ways to enhance their environmental performance.Conclusion:As the manufacturing industry continues to evolve, CNC machining has proven to be a catalyst for technological advancements. With a commitment to excellence, streamlined manufacturing processes, a focus on innovation, responsive customer support, and sustainable practices, this leading CNC machining company has established itself as a key player in revolutionizing the manufacturing sector. Empowered by their expertise, cutting-edge technology, and dedication, they are poised to shape the future of CNC machining, meeting and exceeding the ever-growing demands of their clients with unwavering precision and efficiency.