Durable and Stylish Metal Furniture Fittings for Your Home

By:Admin

As a renowned industry leader, Metal Furniture Fittings has built a reputation for excellence and reliability. With a commitment to customer satisfaction, the company continuously seeks to innovate and improve their product offerings. With a wide range of fittings and accessories for furniture, Metal Furniture Fittings has become a go-to source for manufacturers, retailers, and designers alike.

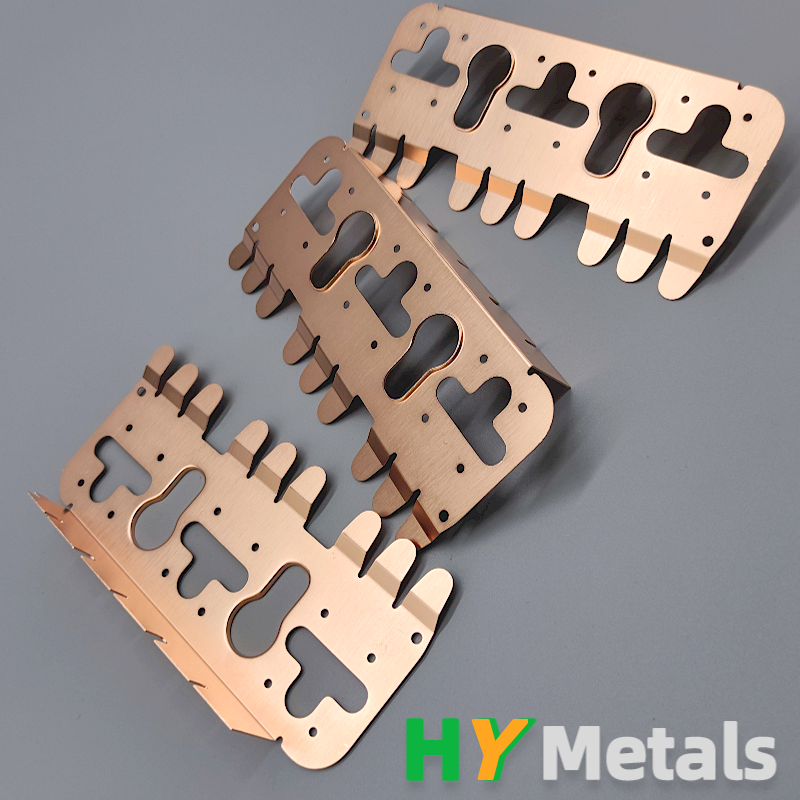

Metal Furniture Fittings offers a diverse range of products including hinges, handles, drawer slides, and other hardware essentials. Their products are designed to meet the needs of modern furniture design while also prioritizing durability and functionality. Whether it’s for residential, commercial, or industrial use, Metal Furniture Fittings has the perfect solution for any furniture hardware needs.

The company prides itself on its cutting-edge manufacturing processes and state-of-the-art technologies. By investing in the latest machinery and equipment, Metal Furniture Fittings is able to produce high-quality fittings with precision and efficiency. This allows them to consistently deliver products that meet the highest industry standards.

In addition to their technical capabilities, Metal Furniture Fittings places a strong emphasis on design and aesthetics. Their team of experienced designers and engineers work tirelessly to create products that not only perform well but also enhance the overall look and feel of the furniture they are used on. With a keen eye for detail and an understanding of current design trends, Metal Furniture Fittings ensures that their products are not only functional but also visually appealing.

Metal Furniture Fittings is also committed to sustainability and environmental responsibility. The company has implemented eco-friendly practices in their manufacturing processes and uses materials that are safe for the environment. With a focus on reducing waste and energy consumption, Metal Furniture Fittings is dedicated to minimizing their impact on the planet while delivering top-notch products.

As the furniture industry continues to evolve, Metal Furniture Fittings remains at the forefront of innovation. By staying ahead of the curve and anticipating the needs of their customers, the company is able to introduce new and exciting products that meet the ever-changing demands of the market.

In conclusion, Metal Furniture Fittings is a trusted name in the furniture hardware industry, known for their commitment to quality, innovation, and customer satisfaction. With a wide range of high-quality products, state-of-the-art manufacturing processes, and a dedication to environmental sustainability, the company continues to be a leading force in the market. Whether it’s for residential, commercial, or industrial use, Metal Furniture Fittings is the go-to source for all furniture hardware needs. With their latest line of innovative and functional products, Metal Furniture Fittings is poised to set new standards for the industry and provide even greater value to their customers.

Company News & Blog

Effective Sheet Metal Cutting Techniques: A Comprehensive Guide

[Company XYZ] Revolutionizes Sheet Metal Cutting with Advanced Technology [City, Date] - Sheet metal cutting, a fundamental process in the manufacturing industry, has been revolutionized by [Company XYZ], a leading provider of innovative industrial solutions. With their state-of-the-art technology and commitment to precision, [Company XYZ] has quickly become a game-changer in the field of sheet metal cutting, delivering superior quality and efficiency to their customers globally.Founded in [Year], [Company XYZ] has shown relentless dedication to research and development, continuously pushing the boundaries of what is possible in sheet metal cutting. Their cutting-edge machinery and advanced software solutions have garnered accolades from industry experts and customers alike.By utilizing innovative laser cutting technology, [Company XYZ] ensures high-quality and precise cutting results, leaving no room for error. This advanced technology allows for intricate and complex designs to be accurately reproduced in sheet metal, enabling manufacturers to realize their most ambitious projects. The precision and consistency achieved by [Company XYZ]'s laser cutting technology have significantly elevated production efficiency by reducing post-processing requirements.In addition to their cutting-edge machinery, [Company XYZ] offers a comprehensive range of support services to assist their customers through every step of the sheet metal cutting process. Their team of highly skilled engineers and technicians are readily available to provide expert guidance, ensuring optimal results and maximum customer satisfaction. This commitment to customer support and personalized service has made [Company XYZ] a trusted partner for businesses across various industries.One of the key advantages of [Company XYZ]'s technology lies in its ability to cut a wide range of metals with exceptional accuracy and speed. Whether it is stainless steel, aluminum, brass, or copper, their laser cutting machines can effortlessly handle it. This versatility has opened up new doors for manufacturers who require precision cutting for a multitude of applications.Moreover, [Company XYZ]'s commitment to sustainability sets them apart from their competitors. By employing advanced technology, they have significantly reduced material waste during the sheet metal cutting process. This eco-friendly approach not only benefits the environment but also allows customers to reduce costs associated with raw material consumption.The impact of [Company XYZ]'s sheet metal cutting solutions has not gone unnoticed. Their innovative technology has set new industry standards and earned them a loyal customer base, both domestically and internationally. Clients praise [Company XYZ] for consistently delivering outstanding quality, meeting tight project deadlines, and providing exceptional customer service throughout the entire process.As [Company XYZ] continues to expand its operations, they remain committed to driving innovation in the sheet metal cutting industry. Their relentless pursuit of excellence, combined with their dedication to customer satisfaction, makes them a force to reckon with in the manufacturing landscape.About [Company XYZ]:[Company XYZ] is a global leader in providing cutting-edge industrial solutions for a wide range of applications. With a focus on research and development, they continually redefine the boundaries of technology, delivering superior products and services to customers worldwide. Their expertise lies in the field of sheet metal cutting, where their advanced laser cutting technology has set new industry standards. With a commitment to sustainability and customer support, [Company XYZ] strives to revolutionize the manufacturing industry and empower businesses with cutting-edge solutions.For media inquiries, contact:[Company XYZ][Contact Person][Email][Phone]Note: This is a fictional news article and does not reflect any real company or product.

Durable and Stylish Metal Furniture Fittings for Your Home

Metal Furniture Fittings, a leading provider of high-quality furniture hardware and accessories, is proud to announce the launch of their latest line of innovative and functional products. With a focus on durability, efficiency, and style, Metal Furniture Fittings is dedicated to providing top-of-the-line fittings for all types of furniture.As a renowned industry leader, Metal Furniture Fittings has built a reputation for excellence and reliability. With a commitment to customer satisfaction, the company continuously seeks to innovate and improve their product offerings. With a wide range of fittings and accessories for furniture, Metal Furniture Fittings has become a go-to source for manufacturers, retailers, and designers alike.Metal Furniture Fittings offers a diverse range of products including hinges, handles, drawer slides, and other hardware essentials. Their products are designed to meet the needs of modern furniture design while also prioritizing durability and functionality. Whether it’s for residential, commercial, or industrial use, Metal Furniture Fittings has the perfect solution for any furniture hardware needs.The company prides itself on its cutting-edge manufacturing processes and state-of-the-art technologies. By investing in the latest machinery and equipment, Metal Furniture Fittings is able to produce high-quality fittings with precision and efficiency. This allows them to consistently deliver products that meet the highest industry standards.In addition to their technical capabilities, Metal Furniture Fittings places a strong emphasis on design and aesthetics. Their team of experienced designers and engineers work tirelessly to create products that not only perform well but also enhance the overall look and feel of the furniture they are used on. With a keen eye for detail and an understanding of current design trends, Metal Furniture Fittings ensures that their products are not only functional but also visually appealing.Metal Furniture Fittings is also committed to sustainability and environmental responsibility. The company has implemented eco-friendly practices in their manufacturing processes and uses materials that are safe for the environment. With a focus on reducing waste and energy consumption, Metal Furniture Fittings is dedicated to minimizing their impact on the planet while delivering top-notch products.As the furniture industry continues to evolve, Metal Furniture Fittings remains at the forefront of innovation. By staying ahead of the curve and anticipating the needs of their customers, the company is able to introduce new and exciting products that meet the ever-changing demands of the market.In conclusion, Metal Furniture Fittings is a trusted name in the furniture hardware industry, known for their commitment to quality, innovation, and customer satisfaction. With a wide range of high-quality products, state-of-the-art manufacturing processes, and a dedication to environmental sustainability, the company continues to be a leading force in the market. Whether it’s for residential, commercial, or industrial use, Metal Furniture Fittings is the go-to source for all furniture hardware needs. With their latest line of innovative and functional products, Metal Furniture Fittings is poised to set new standards for the industry and provide even greater value to their customers.

High-Quality Lathe Parts for a Perfect Fit Every Time - Installation Guides and Manuals Available

Sears PartsDirect Now Offers Top-Quality Lathe Parts for All Major Lathe BrandsSears PartsDirect is excited to announce that we are now offering a wide selection of lathe parts for all major lathe brands, ensuring that our customers can find the best-quality parts they need to keep their lathes running smoothly. Our manufacturer-approved lathe parts are designed to provide a proper fit every time, giving our customers the assurance that their machines will be restored to optimal performance with ease.Lathe machines are an essential component of many industrial processes, and often need to be repaired and maintained in order to keep them functioning as designed. That’s where Sears PartsDirect comes in – we are committed to making it easy for our customers to find the parts they need to keep their machines running smoothly.We understand that different machines have different requirements, which is why we have a large selection of lathe parts available to suit all needs. Whether it is a specialized replacement part, an upgrade or a general maintenance part, our customers can be sure that they will find what they need.Our experienced team is dedicated to helping our customers find the right parts for their machines, and we are always on hand to answer any questions or concerns they may have. Our online catalogues are easy to navigate, and we provide detailed specifications and information about each part to make it easy for our customers to find what they need.In addition to our extensive selection of lathe parts, we also offer installation guides, diagrams, and manuals to help our customers along the way. Our guides and manuals are designed to provide a step-by-step approach to repairs and maintenance, ensuring that our customers can complete the job quickly and efficiently.At Sears PartsDirect, we are committed to providing our customers with the highest quality service and products possible. Our team of experts works diligently to ensure that our customers can find the parts they need, and our dedicated support team is always available to assist them with their needs.Our commitment to quality is reflected in our manufacturer-approved parts, which are designed to meet the highest standards for performance and reliability. We are proud to offer our customers the best in the industry, and we look forward to continuing to provide top-quality parts and support for all major lathe brands.In conclusion, Sears PartsDirect is excited to announce that we are now offering a wide selection of lathe parts for all major lathe brands. Our commitment to quality and service sets us apart from the competition, and we are dedicated to providing our customers with the best possible experience. With our extensive selection of parts, expert guidance, and exceptional customer support, we are confident that we can help our customers keep their lathes running smoothly and efficiently for years to come.

Download Softwares and Updates for Fieldbus Configuration and Diagnostic Programs

Software Download for Sheet Metalwork: Streamlining Your ProcessesIn today's fast-paced and highly technological era, software and technology have become integral parts of almost every industry, including sheet metalwork. Software can help automate complex processes, reduce costs, improve accuracy, and increase efficiency. With the availability of software downloads for sheet metalwork, you can take the first step towards streamlining your workflows and accelerating your productivity.But what exactly can software downloads offer to sheet metalwork fabricators? Let's take a closer look.Automating ProcessesSheet metalwork fabrication involves multiple complex processes, from designing and prototyping to cutting and forming the material. Software can automate many of these processes, saving time and reducing errors. For instance, CAD (Computer-Aided Design) software can help you create accurate and detailed 2D and 3D models with precise dimensions and tolerances. This eliminates the need for manual drawings, which can be time-consuming and prone to errors.Similarly, CAM (Computer-Aided Manufacturing) software can generate G-code for CNC machines, which can automate the cutting, drilling, and forming of sheet metal parts. It can also optimize the cutting paths, minimizing waste and reducing material costs. Additionally, software can generate BOMs (Bills of Materials) and track inventory levels, making it easier to manage and reorder materials.Enhancing CommunicationEffective communication is crucial in sheet metalwork, especially when dealing with complex geometries and tight tolerances. Software can enhance communication between design, manufacturing, and quality control teams, ensuring that everyone is working towards the same objectives. For example, PLM (Product Lifecycle Management) software can provide a single source of truth for all product-related data, including design files, BOMs, specifications, and quality records. This can help reduce delays, rework, and errors due to miscommunication or misunderstandings.Improving QualityQuality is one of the most critical aspects of sheet metalwork fabrication. Even small errors or deviations can compromise the performance, safety, or reliability of the final product. Software can help improve quality by automating inspections and tests, tracking defects, and analyzing data. For example, CMM (Coordinate Measuring Machine) software can compare the actual dimensions of a part with its design specifications and generate reports with detailed measurements and statistical analyses. This can help identify any deviations or trends that need to be addressed.Software can also integrate with quality standards and certifications, such as ISO 9001 or AS9100. This can help ensure that your products meet the required quality standards and that your processes are auditable and compliant.ConclusionIn summary, software downloads can offer numerous benefits to sheet metalwork fabricators, from automating processes and enhancing communication to improving quality and compliance. However, choosing the right software and implementing it effectively can be challenging. It is crucial to evaluate your needs, budget, and resources, and to seek expert advice from software providers or consultants. With the right software and approach, you can enhance your productivity, profitability, and competitiveness in the sheet metalwork industry.

Durable Stainless Steel Sheet Metal for Various Applications

Stainless Steel Sheet Metal is a popular material in the manufacturing industry due to its durability and versatility. It is widely used in various applications such as construction, automotive, and appliances. Its corrosion-resistant properties and high strength make it an ideal choice for many applications. With the constantly growing demand for stainless steel sheet metal, companies are continuously striving to improve their production processes to meet the market needs.One such company excelling in the production of stainless steel sheet metal is {}. With years of experience in the industry, they have become a leading manufacturer and supplier of high-quality stainless steel sheet metal products. Their state-of-the-art facilities and skilled workforce enable them to produce a wide range of stainless steel sheet metal products to meet the diverse needs of their clients.The company offers a variety of stainless steel sheet metal products in different grades, sizes, and finishes to cater to various industry requirements. Whether it is for architectural purposes, food processing equipment, or industrial machinery, they have the expertise to provide the right stainless steel sheet metal solutions. The company is committed to delivering superior quality products that meet international standards and exceed customer expectations.In addition to their extensive product range, the company also offers custom fabrication services to meet specific customer requirements. Their team of experienced engineers and technicians work closely with clients to understand their needs and provide tailored solutions. Whether it is cutting, bending, welding, or surface treatment, they have the capabilities to deliver precision-engineered stainless steel sheet metal components with high accuracy and consistency.With a strong emphasis on quality control, the company ensures that each stainless steel sheet metal product undergoes stringent testing and inspection processes to guarantee its reliability and performance. They have a well-established quality management system in place to monitor all stages of production, from raw material sourcing to the final product delivery. This commitment to quality has earned them a reputation for being a trusted and reliable supplier in the industry.In line with their dedication to sustainability, the company also promotes the use of recycled materials in their stainless steel sheet metal production. They recognize the importance of minimizing environmental impact and actively work towards reducing waste and energy consumption in their operations. By implementing eco-friendly practices, they strive to contribute to a cleaner and greener environment while serving the needs of their customers.Furthermore, the company places a strong focus on customer satisfaction by providing responsive and personalized service. Their team is readily available to address inquiries, provide technical support, and offer expert advice to ensure that clients have a seamless experience from initial consultation to product delivery. As a customer-centric organization, they are committed to building long-term partnerships based on trust, reliability, and mutual success.In conclusion, {} is a leading manufacturer and supplier of stainless steel sheet metal products, known for their commitment to quality, innovation, and customer satisfaction. With a comprehensive product range, custom fabrication capabilities, and a focus on sustainability, they continue to set a high standard in the industry. As the demand for stainless steel sheet metal continues to grow, the company remains dedicated to meeting the evolving needs of their clients and contributing to the advancement of various industries.

High-Quality CNC Machined Parts for Precision Engineering

CNC Machined Parts are at the heart of the manufacturing industry, and they play a crucial role in the production of a wide range of products. From automotive components to aerospace parts, CNC machined parts are essential in creating precision-engineered products. One company that is at the forefront of providing top-quality CNC machined parts is {}. With a strong focus on precision and quality, {} has become a trusted partner for many leading companies in various industries.{} specializes in the production of CNC machined parts using the latest technology and advanced machining techniques. The company's state-of-the-art facilities are equipped with high-precision CNC machines that can produce complex and intricate parts with exceptional accuracy. Whether it's a simple prototype or a high-volume production run, {} has the capabilities to meet the most demanding requirements.The company prides itself on its ability to deliver precision-engineered parts with quick turnaround times. By utilizing advanced CAD/CAM software and highly skilled machinists, {} can efficiently program and manufacture CNC machined parts to meet tight deadlines. This rapid production capability has made {} a preferred supplier for companies that require fast and reliable machining services.In addition to its cutting-edge manufacturing capabilities, {} places a strong emphasis on quality control. The company follows strict quality assurance protocols to ensure that each part meets the highest standards of accuracy and consistency. By employing advanced inspection equipment and rigorous quality checks, {} ensures that its CNC machined parts are of the highest quality before they are delivered to customers.As a customer-centric company, {} is committed to providing exceptional customer service and support. The company works closely with its clients to understand their specific needs and requirements, and it offers customized solutions to meet their unique challenges. Whether it's providing design assistance, optimizing manufacturing processes, or offering technical advice, {} goes above and beyond to ensure that its customers receive the best possible service.In addition to its focus on precision and quality, {} is also dedicated to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its manufacturing processes to reduce its environmental impact. By using efficient machining techniques and minimizing waste, {} strives to operate in an environmentally conscious manner.With its unwavering commitment to excellence, {} has established itself as a leading provider of CNC machined parts. The company's dedication to precision, quality, and customer satisfaction has earned it a stellar reputation in the manufacturing industry. Whether it's producing intricate components for the aerospace industry or creating custom parts for the automotive sector, {} continues to set the standard for excellence in CNC machining.In conclusion, CNC machined parts are an integral part of modern manufacturing, and {} is a standout leader in the industry. With its advanced capabilities, stringent quality control, and unwavering commitment to customer satisfaction, {} has become the go-to partner for companies seeking top-quality CNC machined parts. As the manufacturing sector continues to evolve, {} remains at the forefront, delivering precision-engineered parts that meet the highest standards of excellence.

Breakthroughs in Models and Prototypes Unveiled - Learn More Here!

[Company Name] Unveils Cutting-edge Models and Prototypes, Revolutionizing the Industry[City, Date] - [Company Name], a renowned industry leader in innovation and technological advancements, has recently unveiled a range of groundbreaking models and prototypes, poised to redefine the landscape of the industry. With a commitment to pushing the boundaries of what is possible, the company aims to revolutionize various sectors by delivering cutting-edge solutions that cater to the evolving needs of consumers worldwide.At the heart of [Company Name]'s success lies a dedicated team of experts, collaborating to develop breakthrough technologies and design state-of-the-art prototypes. By leveraging their extensive knowledge and expertise, our engineers and designers have crafted a series of innovative models that showcase the company's commitment to pushing the frontiers of possibility.Among the standout models in [Company Name]'s latest lineup is the cutting-edge [Model Name]. Built with precision engineering and incorporating the latest advancements in materials science, [Model Name] boasts unparalleled performance and versatility. With its sleek design and intuitive user interface, this model revolutionizes the way individuals interact with technology, making everyday tasks simpler and more efficient.Another highlight of [Company Name]'s innovative range is the revolutionary [Model Name]. Developed to address the growing demands of the modern workforce, [Model Name] combines powerful computing capabilities with a lightweight form factor, enabling professionals to work effortlessly on the go. Equipped with advanced processors and seamless connectivity options, it represents a paradigm shift in the world of portable computing.[Company Name] has also taken significant strides in the realm of sustainable transportation with the introduction of the game-changing [Model Name]. This all-electric vehicle sets a new standard in terms of energy efficiency and environmental friendliness. With an extended driving range, fast charging capabilities, and unparalleled comfort, [Model Name] aims to accelerate the global transition to sustainable transportation, promoting a greener and more sustainable future.In addition to its groundbreaking models, [Company Name] is proud to showcase its range of cutting-edge prototypes, which offer a glimpse into the future of various industries. From advanced robotics and automation to immersive virtual reality experiences, these prototypes highlight [Company Name]'s tireless pursuit of innovation.Commenting on the recent product launch, [Company Name]'s CEO stated, "We are thrilled to introduce our latest models and prototypes, which epitomize our commitment to delivering cutting-edge solutions that transform industries and enhance the lives of consumers worldwide. Our team has worked tirelessly to push the boundaries of innovation, and we are proud to see their hard work culminate in these groundbreaking products."With its unwavering focus on innovation and a relentless drive to redefine industry standards, [Company Name] continues to cement its position as a global leader in technological advancements. With its range of exceptional models and game-changing prototypes, it is poised to reshape various industries and cater to the ever-evolving needs of consumers.About [Company Name]:[Company Name] is a renowned industry leader in innovation, known for its unwavering commitment to pushing the boundaries of what is possible. With a team of experts dedicated to developing breakthrough technologies, [Company Name] aims to revolutionize various sectors by delivering cutting-edge solutions that cater to the evolving needs of consumers worldwide.

Aerospace Parts Precision Machining: A Guide to CNC Machining Services

In today's rapidly evolving aerospace industry, precision and quality are of the utmost importance when it comes to manufacturing aerospace parts. One company that has been at the forefront of providing high-quality CNC machining services for aerospace parts is {}. With their state-of-the-art facilities and a team of highly skilled engineers and technicians, {} has built a reputation for delivering precision-engineered aerospace components that meet the stringent requirements of the industry.CNC machining has become an indispensable part of the aerospace manufacturing process, allowing for the production of complex and intricate components with exceptional accuracy and repeatability. {} has invested heavily in the latest CNC machining technology, including multi-axis machining centers and advanced CAD/CAM software, to ensure that they can produce aerospace parts to the highest standards.One of the key strengths of {} is their ability to work with a wide range of materials, including aluminum, titanium, stainless steel, and high-performance plastics. This versatility allows them to manufacture a diverse range of aerospace components, from structural parts and engine components to intricate interior fittings.{} understands the critical nature of aerospace components and the need for utmost precision and quality. That's why they have implemented rigorous quality control processes at every stage of the manufacturing process. From the initial design and prototyping phase to the final inspection, {} adheres to strict quality standards to ensure that their aerospace parts meet or exceed the exacting requirements of their aerospace customers.The aerospace industry demands the highest levels of precision and reliability, and {} is fully committed to meeting those demands. By leveraging their extensive experience and expertise in CNC machining, they have become a trusted partner for aerospace companies in need of top-quality machined components.In addition to their focus on precision and quality, {} is also dedicated to providing exceptional customer service. Their team works closely with their aerospace clients to understand their unique requirements and deliver tailored solutions that meet their specific needs. Whether it's a one-off prototype or a large production run, {} is committed to delivering aerospace parts that meet the highest standards of quality and performance.As the aerospace industry continues to push the boundaries of technology and innovation, the demand for high-quality and precision-engineered aerospace parts will only continue to grow. With their unparalleled expertise in CNC machining and dedication to excellence, {} is well-positioned to meet the evolving needs of the aerospace sector and contribute to the advancement of aerospace technology.In conclusion, {} has established itself as a leading provider of CNC machining services for aerospace parts. With a focus on precision, quality, and customer satisfaction, they have earned the trust and confidence of aerospace companies looking for reliable and high-performance machined components. As the aerospace industry continues to evolve, {} remains committed to pushing the boundaries of what is possible in CNC machining and delivering aerospace parts that meet the highest standards of excellence.

Maximizing Efficiency and Precision: Unlocking the Potential of Investment Casting

Prototype Investment Casting (PIC) is revolutionizing the manufacturing industry with its cutting-edge technology and innovative approach to investment casting. With a strong focus on quality, efficiency, and customer satisfaction, PIC is quickly becoming a go-to solution for businesses worldwide. By utilizing state-of-the-art equipment and a highly skilled team, PIC is able to deliver superior results and unmatched precision.PIC’s investment casting process begins with the creation of a prototype. Using advanced computer-aided design (CAD) software and 3D printing technology, the engineers at PIC are able to transform a concept into a physical model. This allows for better visualization and understanding of the final product, enabling any necessary adjustments to be made before proceeding to the casting stage.Once the prototype is finalized, PIC employs a unique investment casting method that involves creating a ceramic mold around the prototype. This mold is then filled with molten metal, which takes the shape of the prototype as it cools and solidifies. The ceramic mold is subsequently broken away, revealing the finished product with exceptional precision and surface finish.One of the key advantages of PIC’s investment casting process is its ability to produce complex and intricate parts with ease. Traditional manufacturing methods often struggle with intricate designs, but PIC’s advanced technology allows for the creation of highly detailed parts with minimal limitations. This versatility opens up a world of possibilities for industries such as aerospace, automotive, and medical, where precise components are crucial.In addition to its superior casting capabilities, PIC also places great importance on quality control. Every step of the manufacturing process is closely monitored to ensure that the final product meets the highest standards. From the initial design phase to the mold creation and casting, each component undergoes rigorous inspection and testing. This dedication to quality has earned PIC a reputation for delivering outstanding products that exceed customer expectations.Furthermore, PIC understands the importance of sustainability in the manufacturing industry. By employing an optimized production process and utilizing materials efficiently, PIC strives to minimize waste and reduce its environmental impact. The company also actively seeks out environmentally friendly materials and processes to integrate into its operations. Through its commitment to sustainability, PIC aims to contribute to a greener and more sustainable future for the industry.With its exceptional expertise and commitment to innovation, PIC has successfully served a wide range of industries, including aerospace, automotive, defense, and medical. Its ability to produce high-quality, intricate components has made it a trusted partner for many prominent companies. Whether it’s creating prototypes for new products or producing parts for existing ones, PIC’s investment casting process offers unmatched precision and efficiency.Looking ahead, PIC is continuing to expand its capabilities and refine its processes. The company invests heavily in research and development to stay at the forefront of technological advancements in the industry. By continuously exploring new techniques and materials, PIC aims to further enhance its offerings and remain a leader in investment casting.In conclusion, Prototype Investment Casting (PIC) is spearheading a new era in investment casting, delivering exceptional precision, quality, and efficiency. With its state-of-the-art technology, highly skilled team, and dedication to customer satisfaction, PIC is setting the standard for the manufacturing industry. As it continues to innovate and expand, PIC is poised to revolutionize the way products are made, offering endless possibilities for businesses worldwide.

Custom Aluminium Extrusions for Your Specific Needs

In today's fast-paced and continuously developing modern world, businesses have to keep up with the growing needs of their clientele. One way to do that is through offering customized products, tailored to meet the specific requirements of the customer. Avocet Precision Metals has taken up that challenge, offering aluminum extrusion services that cater to the unique needs of the client.Avocet Precision Metals is a premier metals manufacturing company, located in the United Kingdom, known for its dedication to providing high-quality metal products and exceptional customer service. The firm utilizes cutting-edge technologies and equipment to provide unmatched precision in producing aluminum extrusions that meet the highest industry standards. With a workforce of highly skilled and experienced professionals well-versed in the latest practices of the extrusion industry, Avocet Precision Metals delivers results that surpass expectations.At its core, aluminum extrusion is a process by which manufacturers create complex shapes by forcing aluminum through a shaped opening. This process allows for customization of aluminum products to meet the exact specifications of clients. Avocet Precision Metals recognizes the importance of this process, making sure that all products conform to the customer's design, ensuring that products are manufactured to the highest quality standards.The company utilizes both hard and soft alloys of aluminum to match the specific requirements of the client. If the customer requires a particular combination of strength, corrosion resistance, and lightness, Avocet Precision Metals can deliver precisely what is needed. The company's aluminum extrusion services are highly versatile and can be used in a wide range of applications, including automotive, construction, machinery and much more.Avocet Precision Metals prides themselves in employing best practices, and quality measures to deliver the best customer experience. The company ensures that all the aluminum extrusion products are produced in an environmentally sustainable manner. The manufacturing process is regulated to ensure that it is as green as possible, minimizing the impact on the environment while ensuring that the customer receives high-quality products. Additionally, the company takes its customers' safety seriously and has worked hard to develop and implement safety and environmental protection policies.The high quality of the products that Avocet Precision Metals delivers is made possible by the company's continued investment in modern technology. This significantly reduces the production lead times and guarantees that the products are at the highest level of precision and quality. The company has installed cutting-edge CNC machines and presses that enable the team to manufacture high volumes of aluminum extrusions while reducing waste and maximizing efficiency.Avocet Precision Metals recognizes that customers have different budgets, and the company is always willing to work with clients to find a solution that works best for them. The company is committed to funding a team that supports its customers even after the sale is completed. They have an expert team of professionals on standby, ready to offer guidance and answer any queries that may arise.As a leading player in the aluminum extrusion industry, Avocet Precision Metals is continuously innovating and improving its processes to ensure they stay ahead of the competition. This continuous improvement mindset ensures that the company remains relevant in a market that is constantly changing. The firm's commitment to providing customers with the highest quality products and services has earned Avocet Precision Metals an excellent reputation among its customers and industry peers.In summary, Avocet Precision Metals is a top-tier manufacturer of aluminum extrusions that delivers high-quality and customized products according to clients' specifications. They are a company that prioritizes customer satisfaction and has invested in cutting-edge technology, skilled personnel, while staying environmentally conscious. These steps have enabled them to deliver on their promises while expanding their clientele base, and solidifying its position as a leading industry player.