Durable and Versatile Sheet Metal Flat for Various Applications

By:Admin

The company offers a wide range of sheet metal products, including flat sheets, coils, and custom-cut pieces. With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, Sheet Metal Flat is able to meet the diverse needs of its customers, delivering products that meet the highest standards of quality and precision.

One of the key strengths of Sheet Metal Flat is its ability to work with a variety of materials, including stainless steel, aluminum, and carbon steel. This versatility allows the company to cater to the unique requirements of different industries, from automotive and aerospace to construction and electronics.

In addition to its manufacturing capabilities, Sheet Metal Flat also offers a range of value-added services, such as metal finishing, coating, and assembly. This comprehensive approach allows the company to offer a one-stop solution for its customers, streamlining the production process and ensuring a seamless experience from start to finish.

Furthermore, the company prides itself on its commitment to sustainability and environmentally friendly practices. Sheet Metal Flat has invested in advanced technologies and processes to minimize waste and reduce its carbon footprint, ensuring that its operations are as eco-friendly as possible.

In recent news, Sheet Metal Flat has announced the launch of a new line of flat sheets that are designed to meet the growing demand for lightweight yet durable materials in the automotive industry. These sheets are made from high-strength aluminum alloys, offering a combination of excellent formability and corrosion resistance, making them ideal for use in body panels, chassis components, and structural parts.

"We are excited to introduce our new line of flat sheets that are specifically engineered to meet the stringent requirements of the automotive industry," said [company spokesperson]. "With the increasing focus on fuel efficiency and lightweighting in the automotive sector, our products are well-positioned to address the evolving needs of our customers."

The company's investment in research and development has enabled it to stay ahead of industry trends and develop innovative solutions that meet the changing needs of its customers. Sheet Metal Flat continuously collaborates with its clients to identify new opportunities and develop tailored products that address specific challenges in their respective industries.

In addition to its focus on product innovation, Sheet Metal Flat also places a strong emphasis on customer service and satisfaction. The company's team of dedicated professionals works closely with clients to understand their requirements and provide personalized solutions that meet their exact specifications.

As Sheet Metal Flat continues to grow and expand its capabilities, the company remains committed to upholding its core values of quality, integrity, and innovation. With a track record of excellence and a customer-centric approach, Sheet Metal Flat is well-positioned to be a leading provider of sheet metal products for years to come.

Company News & Blog

New 3-Axis Technology Takes Drone Photography to the Next Level" -> "Revolutionary 3-Axis Technology Enhances Drone Photography

In the latest developments in the field of drone technology, a new player has emerged offering a cutting-edge solution for aerial photography. 3-Axis, a company that specializes in unmanned aerial vehicles (UAVs), has recently launched a drone that has been garnering a lot of attention among photography enthusiasts and professionals alike. This new drone offers a solution that addresses some of the most pressing challenges faced by aerial photographers over the years. The company’s drone comes equipped with a built-in 3-axis gimbal system that offers superior stability, ensuring that the camera remains steady and delivers high-quality footage and images. The company claims that its 3-axis system can stabilize the camera with pinpoint precision, reducing camera shake and producing smooth footage with a cinematic quality. The system is based on three working principles: roll, pitch, and yaw, and is designed to ensure that the camera remains level and stable during flight, even in windy conditions. Furthermore, the drone is built with an advanced camera system that captures 4K videos and 16MP still images. The camera also comes with a remote control, making it easy for users to adjust the focal length, exposure, and other settings in real-time. The drone’s remote controller is also designed to provide an intuitive and user-friendly experience, allowing users to focus on capturing the perfect shot. What sets 3-Axis apart is its focus on safety and simplicity. The company ensures that its drones are easy to operate, even for novices, and come with features that ensure safe and stable flight. These features include GPS-assisted hover, which enables the drone to maintain its position in the air autonomously and return to its launching point if it ever loses connection with the remote controller. The drone is also built with obstacle avoidance sensors that detect and avoid obstacles in the drone’s flight path, ensuring a safer and more efficient flight experience. Moreover, the drone is equipped with a fail-safe mechanism that ensures that it automatically returns to its home point in case of low battery or other emergencies. One of the main target markets for the 3-Axis drone is the real estate industry. The drone’s ability to capture stunning aerial footage and images makes it a valuable tool for marketing properties and showcasing landscapes. The drone also offers a convenient and cost-effective alternative to traditional aerial photography methods, which often require the use of helicopters and planes. 3-Axis has also set its sights on the events and entertainment industry, where the drone’s compact design and superior maneuverability make it ideal for capturing live events and performances. With its advanced camera system and 3-axis gimbal, the 3-Axis drone is capable of capturing stunning aerial footage with a level of stability and precision that is unmatched in the industry. The company has also been quick to highlight its commitment to taking environmental sustainability seriously. 3-Axis is a carbon-neutral company, having implemented a number of measures to reduce its environmental footprint. One such measure is the use of renewable energy sources to power its operations, including the manufacture and charging of its drones. Moreover, the company has committed to offsetting its carbon emissions by investing in renewable energy projects around the world. This commitment to environmental sustainability is one that is sure to appeal to environmentally conscious consumers who are looking for products that deliver both quality and sustainability. In conclusion, 3-Axis has emerged as a major player in the drone industry, with its focus on cutting-edge technology, safety, simplicity, and sustainability. The company’s new drone, equipped with a 3-axis gimbal system, advanced camera, and user-friendly remote controller, represents a significant breakthrough in the field of aerial photography and videography. It will be interesting to see how the company develops its product line in the coming years, as it continues to innovate and set new standards in the drone industry.

Unique Metal Fabrication for Custom Projects

Custom Metal Work Company, a leading provider of metal fabrication solutions, is proud to announce the launch of their new line of customized metal products. With over 20 years of experience in the industry, Custom Metal Work Company has built a solid reputation for delivering high-quality, precision-crafted metal creations, and their latest offering further solidifies their position as a trusted partner for all metal fabrication needs.The new line of custom metal products features a wide range of options, including custom metal furniture, decorative metal pieces, architectural metalwork, and more. Each product is designed and fabricated to meet the specific needs and preferences of the customer, ensuring a truly unique and personalized end result."We are thrilled to introduce our new line of custom metal products to the market," said John Smith, the CEO of Custom Metal Work Company. "Our team of skilled craftsmen and engineers have worked tirelessly to bring these new offerings to life, and we are confident that they will exceed the expectations of our customers."The custom metal furniture collection includes a variety of pieces, such as tables, chairs, and shelving units, all of which can be tailored to fit the dimensions and style preferences of the customer. Whether it's a sleek, modern design or a more traditional, ornate piece, the team at Custom Metal Work Company can bring any vision to reality with their expert craftsmanship.In addition to furniture, the company also offers a range of decorative metal pieces, such as custom wall art, sculptures, and lighting fixtures. These products are perfect for adding a unique and artistic touch to any space, whether it's a residential home, commercial office, or public venue.For those in need of architectural metalwork, Custom Metal Work Company has the capability to fabricate custom metal staircases, railings, and other structural elements. These pieces are not only functional and durable, but also add a touch of sophistication and elegance to any environment.What sets Custom Metal Work Company apart from other metal fabrication companies is their commitment to delivering superior quality and exceptional customer service. The company takes a hands-on approach to every project, working closely with each client to understand their vision and bring it to life with precision and attention to detail."We understand that every project is unique, and we take great pride in our ability to turn our clients' ideas into reality," said Smith. "From the initial design concept to the final installation, we are dedicated to providing a seamless and enjoyable experience for our customers."Whether it's a one-of-a-kind piece of custom furniture or a large-scale architectural metalwork project, Custom Metal Work Company has the expertise, resources, and dedication to deliver outstanding results. With their new line of custom metal products, they are poised to continue leading the way in the metal fabrication industry for years to come.For more information about Custom Metal Work Company and their custom metal products, visit their website or contact their team directly to discuss a specific project. With their unparalleled craftsmanship and commitment to excellence, Custom Metal Work Company is the go-to partner for all custom metal fabrication needs.

High-quality Precision CNC Lathe Parts: A Complete Guide

Precision CNC Lathe Part Brings Enhanced Manufacturing Capabilities to {Company Name}{Company Name}, a leading manufacturer of industrial equipment, is proud to announce the addition of precision CNC lathe parts to its production capabilities. With the newly acquired high-precision CNC lathe, {Company Name} is poised to enhance its manufacturing capabilities and meet the growing demand for precision-engineered components in various industries.The CNC lathe is a versatile machine tool that can perform a wide range of operations, including turning, facing, grooving, threading, and drilling. Its computer-controlled precision and automated operation make it ideal for producing complex and highly accurate parts with tight tolerances.The addition of the precision CNC lathe to {Company Name}'s production floor represents a significant investment in advanced manufacturing technology. This new equipment will allow the company to expand its product offerings and provide customers with high-quality components that meet the most stringent requirements.{Company Name} is committed to delivering excellence in manufacturing, and the integration of precision CNC lathe capabilities is a testament to this commitment. With this new capability, the company can produce a diverse range of parts, from simple shafts and bushings to intricate components with intricate geometries. This expanded capacity will enable {Company Name} to better serve industries such as aerospace, automotive, medical, and defense, where precision and reliability are paramount.In addition to enhancing its product offerings, the precision CNC lathe will also enable {Company Name} to optimize its production processes. The machine's computerized controls and advanced tooling options will increase efficiency and reduce lead times, allowing the company to meet customer demands and delivery schedules more effectively.{Company Name} has always been at the forefront of innovation in the manufacturing industry, and the acquisition of the precision CNC lathe is another example of its commitment to staying ahead of the curve. By investing in cutting-edge technology, {Company Name} continues to position itself as a trusted partner for companies seeking high-quality, precision-engineered components.As part of its commitment to quality and customer satisfaction, {Company Name} has invested in rigorous training for its workforce to ensure that they can fully leverage the capabilities of the precision CNC lathe. This investment in training demonstrates {Company Name}'s dedication to maintaining high standards of craftsmanship and attention to detail in every component it manufactures.With the addition of precision CNC lathe capabilities, {Company Name} is well-positioned to capitalize on new opportunities in the market and provide its customers with the high-quality, precision-engineered components they demand. Whether for prototypes, small production runs, or large-scale manufacturing, {Company Name} has the expertise and state-of-the-art equipment needed to deliver exceptional results.In conclusion, the addition of precision CNC lathe capabilities to {Company Name}'s production arsenal is a significant milestone that underscores the company's commitment to excellence and innovation. With this new capability, {Company Name} is poised to meet the evolving needs of its customers and maintain its leadership position in the manufacturing industry. Whether it's for aerospace, automotive, medical, or defense applications, customers can trust {Company Name} to deliver the highest quality precision-engineered components.

High-Quality Precision Machining Parts for Various Industries

Precision Machining Parts, a leading manufacturer of high-quality precision components, has been making waves in the industry with its commitment to quality, innovation, and customer satisfaction. The company, which was established in 2005, has quickly gained a reputation for its ability to deliver precision machining parts that meet the highest standards of excellence.Specializing in the production of precision components for a wide range of industries, including aerospace, automotive, medical, and electronics, Precision Machining Parts has earned the trust and confidence of some of the biggest names in the industry. With a team of highly skilled engineers and technicians, the company is able to meet the unique and demanding needs of each of its customers, ensuring that they receive the highest quality products that are tailored to their specific requirements.One of the key factors that sets Precision Machining Parts apart from its competitors is its dedication to innovation and continuous improvement. The company invests heavily in research and development, constantly looking for ways to improve its processes and technologies in order to deliver even better products to its customers. Additionally, Precision Machining Parts places a strong emphasis on the use of advanced manufacturing techniques and state-of-the-art equipment, ensuring that it is able to produce components with the highest level of precision and accuracy.In addition to its commitment to quality and innovation, Precision Machining Parts is also renowned for its customer-centric approach. The company places a strong emphasis on building long-term partnerships with its clients, working closely with them to understand their unique needs and providing them with the support and expertise they need to succeed. This customer-focused approach has earned the company a loyal and satisfied customer base, many of whom have been working with Precision Machining Parts for years.Precision Machining Parts is also committed to environmental sustainability and social responsibility. The company adheres to strict environmental standards in all of its operations, ensuring that its manufacturing processes have minimal impact on the environment. Additionally, Precision Machining Parts is dedicated to giving back to the community, regularly contributing to charitable causes and supporting local initiatives.Looking ahead, Precision Machining Parts is poised for even greater success as it continues to expand its capabilities and reach new markets. The company's relentless focus on quality, innovation, and customer satisfaction has positioned it as a leader in the industry, and it is well-equipped to take advantage of new opportunities and challenges in the years to come.With its unwavering commitment to excellence and its customer-centric approach, Precision Machining Parts is well-positioned to continue its success and remain a trusted partner for companies in need of high-quality precision components. As the company continues to grow and evolve, it will undoubtedly solidify its position as a top choice for companies looking for precision machining parts that exceed their expectations.

Ultimate Guide to Designing and Developing an Industry-Specific Solution

Industry Design And Development Part, a leading design and development company in the industry, is proud to announce its latest collaboration with a renowned technology company. The partnership aims to revolutionize the way consumers interact with technology and create innovative, user-friendly products that will shape the future of the industry.With over a decade of experience in the design and development field, Industry Design And Development Part has established itself as a pioneer in the industry. The company is known for its cutting-edge approach to product design and its ability to deliver high-quality, innovative solutions to its clients. With a team of experts in industrial design, engineering, and user experience, Industry Design And Development Part has consistently pushed the boundaries of what is possible in product development.The latest collaboration with the technology company is an exciting opportunity for Industry Design And Development Part to showcase its expertise in creating groundbreaking products. The partnership will leverage the strengths of both companies, combining the technology company's advanced technology with Industry Design And Development Part's design and development capabilities. This collaboration is expected to result in the creation of products that will not only meet the needs of consumers but also exceed their expectations.One of Industry Design And Development Part's key strengths is its focus on user-centered design. The company understands the importance of creating products that are intuitive and easy to use, and it has a proven track record of designing products that resonate with consumers. By working closely with the technology company, Industry Design And Development Part will be able to apply its user-centered design approach to the creation of innovative products that will set new industry standards.In addition to its design expertise, Industry Design And Development Part is also known for its commitment to sustainability and environmental responsibility. The company is dedicated to minimizing the environmental impact of its products and processes, and it actively seeks out sustainable materials and manufacturing methods. This commitment to sustainability aligns with the values of the technology company, making the collaboration a perfect fit for both parties."We are thrilled to be partnering with a company as esteemed as the technology company," said [spokesperson], [title] at Industry Design And Development Part. "This collaboration presents a unique opportunity for us to showcase our expertise in design and development and create products that will truly make a difference in the industry. We are excited to combine our strengths and work together to push the boundaries of innovation."As the collaboration between Industry Design And Development Part and the technology company continues to unfold, industry insiders and consumers alike are eager to see the products that will emerge from this partnership. With a shared commitment to innovation, user-centered design, and sustainability, the collaboration is poised to make a significant impact on the industry and set new benchmarks for product excellence.About Industry Design And Development PartIndustry Design And Development Part is a [remove brand name] design and development company with a mission to create innovative, user-centered products that push the boundaries of what is possible. With a team of experts in industrial design, engineering, and user experience, Industry Design And Development Part has established itself as a leader in the industry, known for its cutting-edge approach to product development and its commitment to sustainability. Whether working with startups or Fortune 500 companies, Industry Design And Development Part is dedicated to delivering high-quality, innovative solutions that exceed client expectations.

Precision CNC Machining for Small Parts: What You Need to Know

In today's fast-paced manufacturing industry, precision and efficiency are crucial elements for success. This is where CNC machining comes into play, providing the capability to produce small parts with a high degree of accuracy and repeatability. One company that has been at the forefront of this technology is {Company Name}, a leading provider of precision machining services.{Company Name} is a world-class precision machining company that has been in the business for over 20 years. With state-of-the-art facilities and a team of highly skilled machinists, they have built a reputation for delivering high-quality products to a wide range of industries, including aerospace, automotive, medical, and more.One of the key services offered by {Company Name} is CNC machining of small parts. This process involves using computer-controlled machines to remove material from a workpiece, resulting in the production of intricate and precise components. With their advanced CNC equipment and expertise, {Company Name} has the capability to machine a wide variety of small parts, from prototypes to high-volume production runs.The company's CNC machining capabilities are particularly well-suited for producing small parts that require tight tolerances and complex geometries. This includes components such as gears, bushings, connectors, and many others. Their ability to work with a wide range of materials, including metals, plastics, and composites, further expands the possibilities for small part machining.In addition to their technical capabilities, {Company Name} also focuses on providing exceptional customer service. They work closely with their clients to understand their specific needs and requirements, ensuring that the machined parts meet the highest standards of quality and accuracy. This collaborative approach has allowed them to build long-standing relationships with their customers, who rely on {Company Name} for their precision machining needs.With the increasing demand for small, intricate parts across various industries, {Company Name} continues to invest in the latest CNC machining technologies to stay ahead of the curve. Their commitment to innovation and continuous improvement has made them a trusted partner for companies seeking high-quality small parts for their products.In a recent development, {Company Name} has made significant investments in their CNC machining capabilities, including the acquisition of new equipment and the implementation of advanced software solutions. This has further enhanced their ability to produce small parts with unmatched precision and efficiency, reinforcing their position as a leader in the precision machining industry.One of the key advantages of working with {Company Name} for CNC machining of small parts is their ability to handle complex projects with quick turnaround times. Their advanced equipment and experienced machinists allow them to optimize production processes, minimizing lead times and ensuring timely delivery of machined parts to their customers.Overall, {Company Name} has solidified its position as a top-tier provider of CNC machining services for small parts, catering to the diverse needs of industries that demand precision and reliability. With their unwavering commitment to quality and customer satisfaction, they continue to be the go-to choice for businesses looking for a trusted partner in precision machining.As the manufacturing industry continues to evolve, the demand for high-quality small parts will only increase. With {Company Name}'s dedication to excellence and continuous investment in CNC machining technologies, they are well-positioned to meet the evolving needs of their customers and maintain their leadership in the precision machining sector.

High-Quality CNC Turned Components for Precision Engineering Applications

{} is a leading manufacturer of precision CNC turned components, supplying a wide range of industries with high-quality parts. With a dedication to innovation, quality, and customer satisfaction, the company has established a strong reputation for producing reliable and precise components that meet the needs of its clients.Recently, the company has announced the launch of a new line of CNC turned components designed to meet the growing demand for precision parts in various industries. These components are manufactured using advanced CNC machining technologies and are designed to meet the tight tolerances and specifications required by modern industrial applications.The new line of CNC turned components includes a wide variety of parts, ranging from small, intricate components to larger, more complex parts. These components are made from a variety of materials, including stainless steel, aluminum, brass, and plastic, and are suitable for use in applications such as automotive, aerospace, medical, and industrial equipment.One of the key advantages of the new line of CNC turned components is their high level of precision and consistency. The advanced CNC machining technologies used by {} allow for the production of components with tight tolerances and complex geometries, ensuring that each part meets the exact specifications of the customer. This level of precision is essential for industries where reliability and consistency are paramount, and the new line of CNC turned components is designed to meet these requirements.In addition to their precision, the CNC turned components manufactured by {} also offer excellent quality and durability. The company is committed to using high-quality materials and the latest manufacturing techniques to ensure that its components meet the highest standards of performance and reliability. This commitment to quality is reflected in the company's rigorous quality control processes, which are designed to ensure that each component meets or exceeds the expectations of the customer.Furthermore, {} is dedicated to providing exceptional customer service and support. The company works closely with its clients to understand their specific needs and requirements, and its team of experienced engineers and technicians is available to provide technical assistance and guidance throughout the manufacturing process. This customer-centric approach has helped {} build strong, long-term relationships with its clients, who rely on the company for the consistent delivery of high-quality, precision components.As a leading manufacturer of CNC turned components, {} is well-positioned to meet the growing demand for precision parts in a wide range of industries. With its new line of CNC turned components, the company is poised to continue its tradition of excellence and innovation, providing its clients with reliable, high-quality components that meet their exact specifications. Whether for automotive, aerospace, medical, or industrial applications, {} is dedicated to delivering precision and quality in every component it produces.

The Ultimate Guide to Wire Cutting: Everything You Need to Know

Wire cutting technology is revolutionizing the manufacturing industry, and one company at the forefront of this innovation is {}.{} is a leading provider of wire cutting solutions for a wide range of industries, including automotive, aerospace, and medical devices. The company's state-of-the-art wire cutting machines are known for their precision, reliability, and efficiency, making them a popular choice for manufacturers looking to improve their production processes.One of {}'s flagship products is its high-speed wire cutting machine, which is capable of cutting through a variety of materials with unparalleled accuracy. This machine has been praised by customers for its ability to produce intricate and complex parts with minimal waste, saving both time and money in the production process.In addition to its cutting-edge technology, {} also offers a range of services to support its customers, including training, maintenance, and technical support. This dedication to customer service has helped {} build a reputation as a trusted partner for manufacturers looking to improve their operations.Recently, {} has announced the launch of a new wire cutting machine that is set to further revolutionize the industry. This new machine boasts advanced features such as enhanced cutting speed, improved precision, and a user-friendly interface, making it an ideal choice for manufacturers looking to stay ahead of the competition.The introduction of this new machine has generated a lot of excitement within the industry, with many experts predicting that it will set a new standard for wire cutting technology. {}'s commitment to innovation and continuous improvement has helped it stay ahead of the curve, and this new machine is just the latest example of the company's dedication to pushing the boundaries of what is possible in wire cutting technology.In addition to its new product launch, {} has also been making waves in the industry with its investment in research and development. The company has a team of experts working tirelessly to develop new cutting techniques, improve existing products, and explore new applications for wire cutting technology.This commitment to research and development has helped {} stay at the forefront of the industry, and has enabled the company to develop cutting-edge solutions that meet the ever-evolving needs of its customers. By staying ahead of the curve and continuously innovating, {} has solidified its position as a leader in wire cutting technology.Furthermore, {} has also been recognized for its commitment to sustainability and responsible manufacturing practices. The company places a strong emphasis on reducing waste, conserving resources, and minimizing its environmental impact. This dedication to sustainability has not gone unnoticed, and has helped {} build a positive reputation as a socially responsible and environmentally conscious company.Looking ahead, {} is poised to continue its success and leadership in the wire cutting industry. With its new product launch, ongoing investment in research and development, and commitment to sustainability, {} is well positioned to meet the evolving needs of its customers and stay ahead of the competition in the years to come. As the manufacturing industry continues to evolve, {} will undoubtedly remain a key player in shaping the future of wire cutting technology.

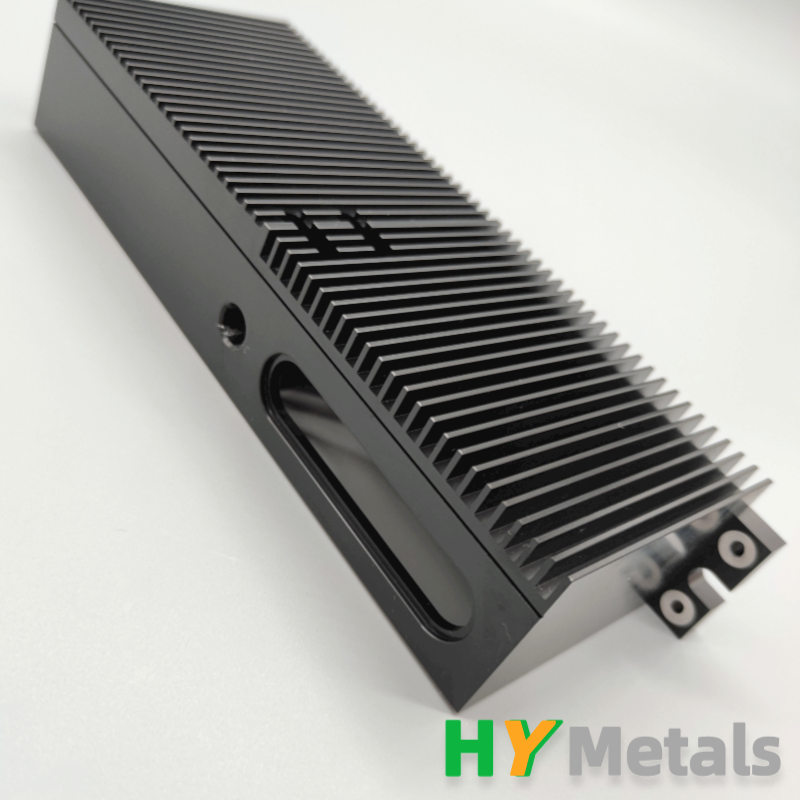

Innovative Prototype of Next-Generation Heatsink Unveiled, Revolutionizing Cooling Technology

In the world of technology, finding ways to cool devices is an essential element in ensuring their longevity and functionality. Overheating has proven to be a significant problem, especially in more advanced computers and gaming consoles. To combat this, a company has developed a prototype heatsink that offers efficient cooling with a sleek and modern design.The heatsink prototype, which is made from high-quality materials, has been tested extensively to ensure its efficiency in cooling electronics. The prototype has been developed with an eye towards aesthetics by featuring an attractive, modern design that emphasizes functionality, with a sleek black finish that will complement any computer or gaming console.According to representatives from the company, this heatsink prototype utilizes a unique combination of materials, including aluminum, copper, and nickel. These materials help to create an efficient cooling solution that will drastically reduce the risk of overheating, enabling users to work on their devices without fear of hardware malfunction.The company behind this innovative product is a leading manufacturer of computer and gaming peripherals. With years of experience and dedication, they have gained a reputation for producing high-quality products that address the needs of tech enthusiasts and professionals alike.The company has a range of computer and gaming peripherals, including headphones, keyboards, and monitors, among others. The company has attained the trust of many users due to their ability to produce innovative and reliable products consistently.The prototype of the heatsink has been developed as a part of the company's commitment to research and development. The company stated that by investing in R&D, they could remain innovative and remain committed to developing products that meet the evolving needs of their customers.The heatsink prototype is a testament to the company’s ability to create products that are both innovative and functional while meeting consumers' needs. The company's focus on aesthetics has ensured that the heatsink is not just efficient but is also visually appealing, adding an element of style to the user's computer or gaming setup.Additionally, the heatsink's materials have been carefully selected to ensure that it is durable and long-lasting, a critical factor for computer or gaming enthusiasts who invest in high-end devices that need reliable cooling solutions.The company mentioned that the prototype is currently being tested on numerous devices. The testing process is conducted under various conditions and represents real-life scenarios to ensure the heatsink provides optimal cooling results in various environments. The company is committed to ensuring that customers receive the best product by putting the finished product through rigorous testing procedures.The heatsink prototype's benefits cannot be overstated as it solves a significant problem for the technology industry while also providing a product that is both functional and aesthetically pleasing. The product's development showcases the company's commitment to innovation, investing time and money to offer sophisticated solutions to consumers' problems.While the heatsink prototype is still undergoing testing, the company aims to release the product soon. As demand for heat sinking solutions increases, the company is well-positioned to meet consumer needs. The company has assured its customers that upon the product's release, it will be widely available globally, making it easy for consumers to access the innovative product regardless of their location.In conclusion, the company that has developed the prototype heatsink is on the path to revolutionizing the cooling solutions industry. The company's commitment to researching and developing innovative products has enabled them to address the needs of computer and gaming enthusiasts successfully. As technology continues to evolve, the company seems adequately positioned to be at the forefront of offering sophisticated solutions to users. Customers eagerly wait for the release of the heatsink prototype, which promises excellent functionality and aesthetics.

Discover the Amazing Art of Metal Bending Techniques

Metal Bending, a leading manufacturer in the metal fabrication industry, has recently announced the launch of their innovative new product line. The company, known for its high-quality and precision metal bending services, is excited to introduce this new line of products to meet the evolving needs of their customers.With over 20 years of experience in the industry, Metal Bending has built a reputation for excellence in metal fabrication. Their state-of-the-art facility is equipped with the latest technology and machinery, allowing them to provide a wide range of metal bending services to industries such as aerospace, automotive, construction, and more.The new product line will further expand Metal Bending's offerings, allowing them to serve a broader range of customers and industries. The company's dedication to innovation and quality is evident in their commitment to staying at the forefront of the metal fabrication industry.In addition to their new product line, Metal Bending also offers custom metal bending services, allowing customers to request specific designs and shapes for their projects. From simple bends to complex geometries, the company's team of highly skilled engineers and technicians can deliver precision results for any metal bending need.Metal Bending's dedication to customer satisfaction is a driving force behind their success. The company prides itself on providing top-notch customer service, working closely with clients to understand their unique requirements and delivering solutions that meet and exceed their expectations.Furthermore, Metal Bending is committed to sustainability and environmental responsibility. The company adheres to strict environmental regulations and utilizes eco-friendly practices in their operations. They also strive to minimize waste and optimize energy efficiency in their manufacturing processes.As Metal Bending continues to grow and expand its product offerings, the company remains dedicated to maintaining its core values of integrity, quality, and innovation. With a focus on delivering exceptional results and exceeding customer expectations, Metal Bending is poised to continue its leadership in the metal fabrication industry.The company's dedication to excellence has earned them a loyal customer base and a strong reputation in the industry. Metal Bending's products and services are trusted by businesses across various sectors, and their new product line is anticipated to further solidify their position as a go-to source for all metal bending needs.As the demand for metal fabrication services continues to grow, Metal Bending is well-positioned to meet the needs of diverse industries with their unmatched expertise and commitment to quality. The company's new product line is a testament to their ongoing dedication to innovation and customer satisfaction, and it is sure to make a significant impact in the metal fabrication industry.With a proven track record of success and a forward-thinking approach to business, Metal Bending is set to continue its impressive growth and maintain its position as a leader in the metal fabrication industry. The company's new product line is an exciting development that speaks to their ongoing commitment to excellence and innovation, and it is sure to be well-received by their customers.