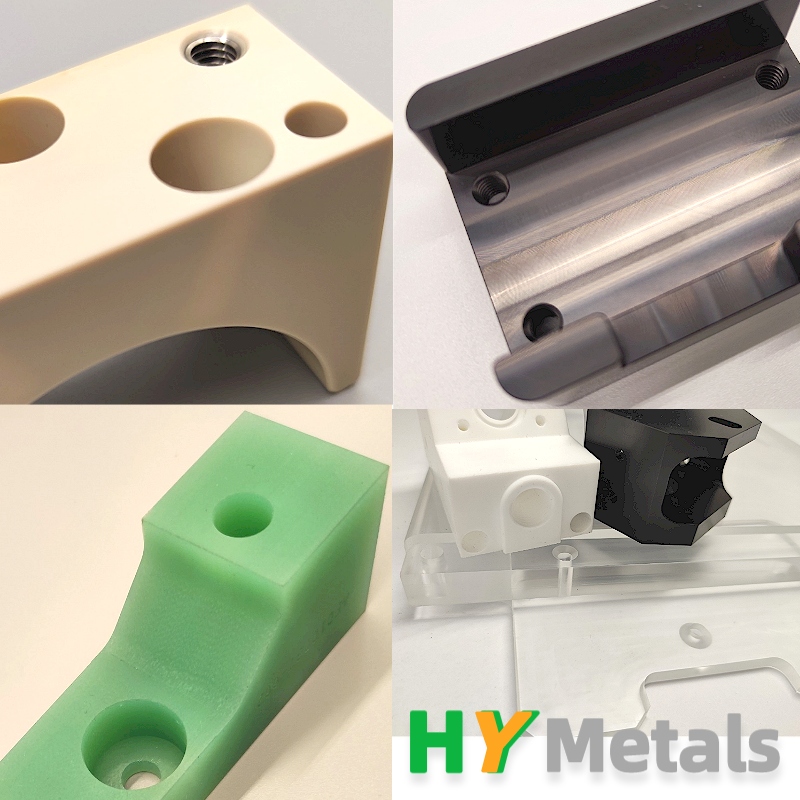

Durable Custom Metal Parts for Various Industries

By:Admin

{City, Date}--Custom metal parts supplier {Company} is celebrating its expansion and growth as it continues to meet the needs of its diverse customer base. With a focus on precision and quality, {Company} has been able to provide custom metal parts for a wide range of industries, including automotive, aerospace, and medical.

Founded in {year}, {Company} has built a reputation for excellence in the custom metal parts industry. With a team of highly skilled engineers and technicians, the company is able to create custom metal parts that meet the exact specifications of its customers. Whether it is a complex metal component for an aerospace application or a precision part for a medical device, {Company} has the expertise and capabilities to deliver high-quality products.

In recent years, {Company} has seen significant growth in its customer base, as more companies recognize the value of custom metal parts that are tailored to their specific needs. This increased demand has led to the expansion of {Company}'s manufacturing facilities, allowing the company to increase its production capacity and offer a wider range of custom metal parts to its customers.

"We are thrilled to see the continued success and growth of {Company}," said {Spokesperson}, a representative of the company. "Our team has worked hard to build a reputation for excellence in the custom metal parts industry, and it is rewarding to see the positive impact that we are having on our customers and the industries we serve."

{Company} is committed to staying at the forefront of technology and innovation in the custom metal parts industry. The company has invested in state-of-the-art manufacturing equipment and advanced quality control processes to ensure that its products meet the highest standards. Additionally, {Company} continues to invest in research and development to explore new materials and techniques that can further enhance the quality and performance of its custom metal parts.

The expansion of {Company}'s manufacturing facilities is an exciting development for the company and its customers. With increased production capacity, {Company} is now able to take on larger orders and offer shorter lead times, allowing it to better meet the needs of its customers. In addition, the company has expanded its product line to include a wider range of custom metal parts, giving customers even more options to choose from.

"We are proud of the growth and expansion that {Company} has experienced in recent years," said {Spokesperson}. "Our dedicated team has been the driving force behind our success, and we are excited to continue serving our customers with the highest quality custom metal parts."

As {Company} celebrates its expansion and growth, the company is also looking ahead to the future. With a strong focus on innovation and customer satisfaction, {Company} is poised to continue its leadership in the custom metal parts industry, providing high-quality products and exceptional service to its customers.

For more information about {Company} and its custom metal parts, visit {website} or contact {contact information}.

About {Company}:

{Company} is a leading supplier of custom metal parts for a wide range of industries. With a focus on precision and quality, the company has built a reputation for excellence in the custom metal parts industry. Through its commitment to innovation and customer satisfaction, {Company} continues to provide high-quality products and exceptional service to its customers.

Company News & Blog

Precision Grinding of CNC Machined Parts for Increased Durability and Performance

Title: Advancements in CNC Machined Parts Grinding: Delivering Precision and EfficiencyIntroduction (approx. 80 words):In the fast-paced world of manufacturing, the demand for precision-engineered components is at an all-time high. Addressing this need, a leading company in the field has made significant breakthroughs in CNC Machined Parts Grinding. By combining cutting-edge technology and industry expertise, they are revolutionizing the production of machined parts, offering unparalleled precision, efficiency, and reliability. With the ability to remove imperfections with remarkable accuracy, their advanced grinding techniques enhance product quality, reduce production time, and maximize cost-effectiveness.Innovation in CNC Machined Parts Grinding (approx. 200 words):Building on decades of experience and a commitment to continuous innovation, the company has introduced state-of-the-art advancements in CNC Machined Parts Grinding. By leveraging advanced robotic systems, high-precision tools, and computer numerical control (CNC) technology, they have transformed the grinding process, setting new standards in the industry.The integration of robotic systems has enabled precise handling and positioning of components, ensuring consistent grinding quality. This automation enhances productivity, eliminates human error, and optimizes production throughput. Additionally, it allows for multitasking capabilities, enabling simultaneous grinding of multiple parts, saving valuable time without compromising precision.Furthermore, the utilization of high-precision tools and cutting-edge abrasives guarantees the removal of imperfections with exceptional accuracy. By employing a combination of grinding wheels, belts, and discs designed for specific applications, the company ensures the highest level of precision, ensuring superior surface finishes and dimensional accuracy.To enhance the grinding process's efficiency, the company has incorporated CNC technology into their machining centers. This allows for seamless coordination between various machining operations, eliminating the need for multiple setups and tool changes. The result is faster cycle times, reduced downtime, and improved overall productivity.Benefits and Applications (approx. 250 words):The advancements in CNC Machined Parts Grinding have numerous benefits that make them indispensable for various manufacturing industries. The precision achieved through these techniques ensures the exact dimensions and tolerances required, eliminating the risk of errors and rework. By improving product quality and reducing rejects, manufacturers can establish a reputation for delivering superior components consistently.Moreover, these advancements have considerably reduced production time. With increased automation, multitasking capabilities, and efficient integration of CNC technology, companies can significantly improve throughput. This accelerates the delivery of finished parts, enabling manufacturers to meet tight deadlines without compromising quality.The cost-effectiveness of CNC Machined Parts Grinding is another crucial advantage. By streamlining processes and minimizing waste, manufacturers can optimize resource utilization and reduce production costs. In addition, the ability to complete complex grinding operations in a single setup reduces labor costs and machine downtime.The applications for CNC Machined Parts Grinding span various industries, including aerospace, automotive, robotics, medical, and more. In the aerospace sector, for instance, the precision grinding techniques are indispensable for creating intricate components that withstand the extreme demands of aircraft engines. Similarly, in the medical field, these advancements enable the production of high-precision parts for surgical instruments and prosthetics, ensuring utmost reliability and patient safety.Conclusion (approx. 70 words):Through their relentless pursuit of innovation, the company has transformed CNC Machined Parts Grinding, positioning themselves as industry leaders. With a focus on precision, efficiency, and cost-effectiveness, their advanced grinding techniques have revolutionized the manufacturing sector. By embracing these advancements, manufacturers can forge a path towards increased productivity, improved quality, and enhanced competitiveness in the global market.

Premium Metal Cases: Resilient Protection for Your Valuables

[News Title]: Groundbreaking Metal Case Revolutionizes the Tech Industry[News Introduction]:In an era dominated by advanced technology and sleek design, {} has launched a revolutionary metal case that is set to reshape the tech industry. Combining cutting-edge materials, precision engineering, and a commitment to sustainability, this breakthrough product is poised to stand out among its competitors. With its exceptional durability, stylish aesthetics, and functional design, this metal case is expected to become the go-to choice for tech enthusiasts worldwide.[News Body]:With an increased focus on durability and longevity, the tech industry has been searching for a practical and sustainable solution to protect its devices. {} has answered this demand with its innovative metal case, which promises to deliver the highest level of protection while maintaining a sleek and visually appealing design aesthetic.The metal case is crafted using a specially developed alloy that is both lightweight and incredibly durable. This alloy, which has undergone rigorous testing and research, offers enhanced resistance to impacts, scratches, and everyday wear and tear. With this metal case, users can rest assured that their devices are safeguarded against accidental bumps, drops, and spills.Moreover, {}'s metal case boasts a sophisticated design that seamlessly integrates into modern technology. The minimalistic approach and elegant lines give the case a timeless appeal, making it suitable for both professional and casual settings. Combining form and function, the case provides easy access to all ports, buttons, and features of the device, ensuring a hassle-free user experience.While durability and design are significant features of this metal case, {} has also prioritized sustainability throughout its production process. The company has implemented environmentally friendly practices, significantly reducing the overall environmental impact associated with the manufacturing of the metal case.To accomplish this, {} has partnered with suppliers who adhere to high ethical and sustainability standards. By using recyclable materials and minimizing waste during production, the company is committed to reducing its carbon footprint and creating an eco-friendly product.In addition to its exceptional features and sustainable production practices, {} offers a wide range of color options, allowing users to personalize their metal cases according to their individual style preferences. From sleek and classic shades to vibrant and bold hues, the choice is plentiful for tech-savvy individuals looking to add a touch of personality to their devices.With the introduction of this metal case, {} aims to fulfill the evolving needs of tech enthusiasts who seek to combine practicality, durability, and sustainability. By prioritizing quality craftsmanship, innovative design, and ethical production, the company envisions its metal case becoming the gold standard within the tech industry.Furthermore, {} plans to expand its product line to include metal cases for various devices, catering to the ever-growing demand for robust protection and aesthetic appeal. Through ongoing research and development, the company is committed to pushing the boundaries of technology and providing users with state-of-the-art metal cases that set new industry standards.As tech devices continue to evolve and play an increasingly vital role in our lives, {}'s metal case offers the perfect solution for those seeking to protect their investments and showcase their personal style. With its unrivaled durability, stylish design, and commitment to sustainability, this metal case is set to become a game-changer in the tech industry.

Listen to a New Track called Spinning by an Artist on SoundCloud

article about a new sound dynamic software and its benefits for music producers.In today's music industry, the need to innovate and explore new ways of creating sounds has never been greater. While traditional software and hardware tools have their advantages, they can sometimes fall short when it comes to creating complex and dynamic sounds that stand out in today's crowded market. That's where the new sound dynamic software, developed by a leading audio software company, comes in.The new software, which has been in development for over two years, introduces a new way of creating soundscapes that is different from anything else on the market. Unlike traditional software which is linear, the new software is spherical in nature, allowing for a much greater degree of freedom when it comes to creating and manipulating sound.So how does it work? The software uses a series of spherical coordinates to create a three-dimensional soundscape. Sound sources can be added in any position, and the software allows for complete control over the distance, direction and intensity of each source. This means that music producers can create complex and dynamic soundscapes that are not limited by traditional linear software.The benefits of this new software are numerous. For one, it allows producers to create truly unique and immersive soundscapes that can help their music stand out in a crowded market. The spherical nature of the software also makes it much easier to work with than traditional linear software, as it allows producers to work with sounds in a more intuitive and natural way.Perhaps the biggest benefit of this new software, however, is in its ability to create truly dynamic soundscapes. Traditional software can sometimes struggle when it comes to creating sounds that change in intensity or direction over time. The new software, however, allows for complete control over every aspect of the soundscape, which means that producers can create sounds that evolve and change in ways that were simply not possible with traditional software.The development of this new software has been a long and arduous process, but the results speak for themselves. Industry insiders have been raving about the software, with many calling it a game-changer for the industry. Music producers who have had the chance to use the software have been equally impressed, with many saying that it has revolutionized the way they create sound.The new software is also highly customizable, allowing producers to tailor it to their specific needs. This means that it can be used in a wide variety of genres, from electronic dance music to classical orchestration. The software is also compatible with a wide range of hardware and software setups, making it a valuable addition to any producer's toolbox."It's amazing to think that just a few years ago, this kind of technology was simply not possible," said one industry insider. "But now, thanks to the hard work of this software company, we have a game-changing tool that is going to change the face of music production."Overall, the new sound dynamic software is a must-have for any music producer looking to create unique and dynamic soundscapes. It represents a significant leap forward in technology and is sure to be a game-changer for the industry.

How to Build a Heavy CNC Milling Machine: 18 Steps with Pictures

Machine, Instructables, heavy CNC milling, epoxy granite, linear guides, building processCNC Milling Machine: A Comprehensive Guide to Building Your OwnBuilding a heavy-duty CNC milling machine is not a task for the faint-hearted. It requires a lot of different working steps and careful planning to ensure that you end up with a machine that can deliver precise and accurate results. In this blog post, we will take a closer look at the steps involved in building a big CNC machine with good milling performance, as well as the materials and equipment needed for the project.Step 1: Design and PlanningThe first step in building a CNC milling machine is to design and plan the machine. This involves deciding on the size of the machine, the materials to be used, the type of milling machine to be used, and the features and capabilities that the machine should have. It is important to have a clear understanding of the requirements before starting the project to avoid any costly mistakes down the line.Step 2: Building the MoldThe next step is to build a big and accurate mold for casting the epoxy granite. Epoxy granite is a popular material for building milling machines due to its sturdiness and vibration damping properties. The mold should be designed to ensure that it is rigid and can create a smooth surface finish. The casting process should be done carefully to avoid any air bubbles or voids that can cause inaccuracies in the finished cast.Step 3: Aligning the Linear GuidesThe linear guides play a crucial role in the accuracy and precision of the milling machine. They are responsible for guiding the cutting tool along a straight and consistent path. The linear guides should be aligned carefully to ensure that they are in perfect alignment with the cutting tool. This requires careful attention to detail and the use of precision measuring tools.Step 4: Building the Machine FrameThe frame of the milling machine should be built to be strong and rigid. The use of high-quality materials such as aluminum or steel is recommended. The frame should be designed with sufficient clearance to accommodate the linear guides and other machine components.Step 5: Assembling the MachineOnce all the components of the milling machine have been prepared, it is time to start assembling the machine. This requires careful attention to detail and a lot of patience. Each component should be installed carefully and securely to ensure that the machine is stable and can deliver precise and accurate results.ConclusionBuilding a heavy CNC milling machine is a challenging task that requires a lot of time and effort. However, with careful planning and attention to detail, it is possible to build a machine that can deliver precise and accurate results. The use of high-quality materials and precision measuring tools is essential to ensure that the machine is built to the required specifications. With the right approach, anyone can build their own CNC milling machine and take their machining capabilities to the next level.

Discover the Latest News on Precision CNC Machining Parts

article:CNC Machining Parts Proves to be an Essential Resource for Precision EngineeringFor many decades, the manufacturing industry has relied on CNC machines to produce high-quality end products with a precision-level of accuracy. Among these machines, CNC Machining Parts have become a fundamental resource to aid in the production of high-performance products that meet strict manufacturing specifications. In today's competitive market, achieving success in precision engineering depends on having access to the latest cutting-edge technology. This is where CNC Machining Parts come in, proving to be an essential resource that has transformed the manufacturing industry, providing a step up in the production of the highest-grade products.CNC Machining Parts are CNC-machined components that have been specifically designed to meet the stringent demands of various industries. They are produced to the most exacting standards of quality and durability, ensuring that they offer the best performance under tough and demanding circumstances. These parts are made from high-quality materials like metals, plastics, and composites that ensure that they can withstand the pressures of modern production environments.CNC Machining Parts have been designed to operate with a high degree of precision, accuracy, and reliability. CNC machines, which produce these parts, are run by computers, delivering the highest level of control and accuracy over the manufacturing process. They are programmed to perform a series of highly precise movements that create the desired end product, guaranteeing the highest levels of quality in every component produced. The CNC production process is incredibly fast and efficient, allowing for the manufacturing of large quantities of parts in a short amount of time.The CNC Machining Parts produced by {} are some of the most sophisticated and advanced in the industry. Featuring cutting-edge technology and materials, these parts have been developed to withstand the most demanding of conditions and environments. The company's production process involves the use of state-of-the-art computer-controlled machinery. The automation of this manufacturing process ensures that each part produced is a high-quality, durable component that meets the strictest demands of the manufacturing industry.CNC Machining Parts have a broad scope of applications across a range of industries. They are used in many diverse fields such as aerospace, electronics, automotive, marine, and medical industries, to mention a few. In the aerospace industry, for instance, these parts are used in the manufacture of aircraft parts, ensuring that they are highly durable and can withstand the rigors of high-altitude flight. In the automotive industry, CNC Machining Parts are used in the production of engine components, ensuring that they are efficient and can withstand high temperatures and robust driving conditions.In the medical industry, CNC Machining Parts have become instrumental in the production of high-quality medical devices and equipment. These machines produce precision components for use in surgical instruments, prosthetics, hearing aids, and other medical devices that require precise measurements. The efficiency of CNC Machining Parts has made the production of these components more accessible, cheaper, and faster, thereby improving the medical industry's level of quality.CNC Machining Parts have become essential in modern-day manufacturing. They have transformed the way manufacturing is done, offering higher levels of precision, reliability, and consistency, resulting in better-performing products. The CNC Machining Parts produced by {} are some of the best in the business and come highly recommended by satisfied customers. The company's emphasis on quality, value, and customer service has made them a leader in the industry. By utilizing cutting-edge technology, top-quality materials, and a team of skilled engineers, the company has set itself apart from its competitors, providing superior CNC Machining Parts that meet the stringent demands of various industries.In conclusion, CNC Machining Parts have become an essential resource for precision engineering. They have revolutionized the manufacturing industry by offering the highest level of precision, accuracy, and consistency, thereby producing the highest quality products. The CNC Machining Parts produced by {} are among the best on the market, utilizing state-of-the-art technology, efficient production processes, and high-quality materials. The company's focus on quality, customer service, and innovation has made it a standout performer in the industry, providing the best products and services that meet the needs of customers around the world.

Precision CNC Machining Services Offered by Chinese Factory

CNC machining has revolutionized the manufacturing industry, enabling companies to produce high-quality precision parts with speed and accuracy. One of the leading CNC machining factories in China offers custom precision CNC machining services, including CNC milling, CNC turning, and CNC machining. Whether you need steel machined parts or other materials, this factory can provide you with the precision parts you need.At this CNC machining factory, they use advanced technologies and state-of-the-art machines to manufacture precision parts. They have a team of highly skilled engineers and technicians who have extensive experience in manufacturing all types of precision parts. Their engineers can work with you to develop customized parts that fit your specific requirements.One of the advantages of CNC machining is that it allows for the production of complex shapes and designs with ease. The CNC machines are capable of working with a wide range of materials, including metals, plastics, and composites. The CNC machines can perform a range of operations, such as cutting, drilling, and milling, with remarkable accuracy.The factory's CNC milling services are ideal for manufacturing precise parts with complex geometries. They can produce parts up to 1 meter in length and 500mm in diameter. The CNC turning services are perfect for manufacturing precision parts with tight tolerances. They can produce parts up to 500mm in diameter and 1 meter in length.Whether you need steel machined parts for automotive applications, aerospace, medical, or any other industry, this factory can provide you with high-quality parts, precisely machined to your specifications. They use the latest technologies to accurately measure the parts and ensure that they are within the required tolerances.In addition to steel machined parts, they can provide custom CNC machining services for a wide range of materials, including aluminum, brass, titanium, and high-temperature alloys. They can also provide surface treatments, such as anodizing and painting, to give the parts the required finish.Moreover, the CNC machining factory in China offers competitive pricing for their precision CNC machining services. They have a fast turnaround time, so you can have your parts manufactured and delivered within a short time. They are committed to providing their customers with the highest quality parts and the best customer service.In conclusion, if you need steel machined parts or any other precision parts, consider working with this CNC machining factory in China. They have the expertise, technology, and equipment to manufacture high-quality precision parts to your exact specifications. They offer competitive pricing, fast turnaround time, and excellent customer service. Contact them today to learn more about their CNC machining services.

Latest Updates on the World of Electronic Dance Music

[Company Name Removed] Expands Its Footprint in the Dynamic World of Electronic Dance Music (EDM)(Date)The global electronic dance music (EDM) industry has witnessed an unprecedented surge in popularity in recent years. As this vibrant genre continues to captivate millions of music lovers worldwide, [Company Name Removed], a leading player in the music industry, is excited to announce its expanding presence in the EDM scene.With over two decades of experience in curating and promoting extraordinary music events, [Company Name Removed] has cemented its position as a visionary force in the music industry. The company has successfully organized some of the most iconic concerts and festivals, leaving an indelible mark on the hearts of music enthusiasts across the globe.The decision to venture into EDM is a strategic move for [Company Name Removed], considering its immense potential and ever-growing fan base. The genre's fusion of infectious beats, captivating rhythms, and electrifying energy has transcended borders and united people from various cultural backgrounds.As part of its foray into EDM, [Company Name Removed] aims to introduce a fresh wave of artistic talent and provide a platform for emerging DJs and producers. By scouting new talents through collaborations with established EDM artists, the company seeks to foster the growth of the genre and inspire a new generation of music creators.The expansion into EDM will also see [Company Name Removed] launching its own record label specifically dedicated to this genre. With a strong focus on nurturing talents and exploring cutting-edge sounds, the record label aims to become a breeding ground for chart-topping EDM hits and groundbreaking collaborations.In addition to discovering new talents, [Company Name Removed] plans to organize an array of EDM events and festivals to showcase the genre's vast diversity. These events will provide an immersive experience for attendees, combining stunning visual effects, state-of-the-art production, and performances from the biggest names in the EDM scene.[Company Name Removed] also recognizes the importance of technology in shaping the future of music consumption. Thus, the company is actively investing in cutting-edge technologies to enhance the overall experience of EDM enthusiasts. By leveraging virtual reality (VR) and augmented reality (AR), [Company Name Removed] aims to transport its audience into a digital realm where they can feel the pulsating beats and immerse themselves in an otherworldly atmosphere.To further solidify its position in the EDM industry, [Company Name Removed] plans to collaborate with leading EDM festivals and organizations across the globe. By forging strategic partnerships and sharing expertise, the company aims to create a worldwide network that will open doors for collaboration and mutually beneficial ventures.Furthermore, [Company Name Removed]'s expansion into the world of EDM is driven by a strong commitment to sustainability and community welfare. The company aims to organize eco-friendly festivals and events, ensuring responsible waste management and promoting environmental awareness among its audience. Additionally, [Company Name Removed] plans to collaborate with local communities and charitable organizations, using the power of EDM to bring about positive social change.As [Company Name Removed] gears up to enter the electrifying realm of EDM, music enthusiasts can expect groundbreaking collaborations, mesmerizing events, and the discovery of new and innovative sounds. With its unparalleled track record in event organization and artist promotion, [Company Name Removed] is poised to make a lasting impact on the vibrant world of electronic dance music.

Top Auto Parts to Enhance Your Vehicle's Performance

Title: Transforming the Automotive Industry: Auto Parts Company Revolutionizes Vehicle PerformanceIntroduction:Innovation is the driving force behind the thriving automotive industry, constantly pushing the boundaries of technology and challenging conventional practices. Auto Parts, a leading player in the market, has emerged as a trailblazer, revolutionizing the way vehicles perform. With their cutting-edge solutions and commitment to excellence, Auto Parts continues to impress both consumers and industry experts alike.Body:1. History and Accomplishments:Auto Parts, founded in {year}, has garnered a stellar reputation for providing high-quality automotive components over the years. Their commitment to innovation and superior performance has set them apart from their competitors, propelling them to the forefront of the industry. With a strong focus on research and development, Auto Parts has consistently introduced groundbreaking technologies to enhance vehicle performance, reliability, and safety.2. Industry-Leading Research and Development:By investing heavily in research and development, Auto Parts has been able to set new benchmarks in the automotive industry. Their state-of-the-art facilities and dedicated team of engineers and scientists continually strive to improve existing products and develop new, game-changing solutions. This commitment to innovation has resulted in the introduction of several disruptive technologies that have transformed the automotive landscape.3. Advanced Material Science:One of the key areas where Auto Parts excels is in the field of advanced material science. They have developed proprietary materials that offer unparalleled strength, durability, and lightweight properties. These materials enhance the performance of various automotive components, such as engine parts, suspension systems, and exhaust systems, leading to improved fuel efficiency, reduced emissions, and enhanced overall vehicle performance.4. Transformative Fuel Efficiency Solutions:Auto Parts has pioneered numerous fuel efficiency solutions that have significantly reduced the carbon footprint of vehicles. Their advanced fuel injection systems and engine management technologies have not only boosted performance but have also optimized fuel consumption. By harnessing the power of cutting-edge electronics, Auto Parts has played a pivotal role in achieving higher mileage and reducing harmful emissions.5. Safety Innovations:Safety is a top priority in the automotive industry, and Auto Parts has continually developed groundbreaking technologies to enhance vehicle safety. They have introduced advanced braking systems, collision avoidance systems, and sensor technologies that provide drivers with an added layer of protection on the road. These safety innovations have not only helped to prevent accidents but have also contributed to saving countless lives.6. Commitment to Sustainability:Auto Parts understands the importance of environmental sustainability and has taken significant steps to reduce their ecological impact. They have implemented eco-friendly manufacturing processes, reducing waste generation and improving energy efficiency. Auto Parts also actively collaborates with other industry partners and regulatory bodies to develop greener solutions and promote sustainable practices across the automotive sector.7. Global Presence and Recognition:Auto Parts has successfully established a global presence, catering to a diverse range of markets. Their commitment to excellence and relentless pursuit of innovation has earned them widespread recognition within the industry. The company has received numerous accolades, including multiple awards for product excellence and sustainability initiatives. Their products are trusted by leading automotive manufacturers worldwide, making Auto Parts a preferred choice in the market.Conclusion:Auto Parts' unwavering dedication to innovation has set new industry standards, transforming the automotive landscape. With their trailblazing research and development efforts, advanced material science, fuel efficiency solutions, safety innovations, and commitment to sustainability, Auto Parts continues to make its mark in the industry. As vehicles become smarter, greener, and safer, Auto Parts remains at the forefront, driving the future of automotive excellence.

Effective Sheet Metal Cutting Techniques: A Comprehensive Guide

[Company XYZ] Revolutionizes Sheet Metal Cutting with Advanced Technology [City, Date] - Sheet metal cutting, a fundamental process in the manufacturing industry, has been revolutionized by [Company XYZ], a leading provider of innovative industrial solutions. With their state-of-the-art technology and commitment to precision, [Company XYZ] has quickly become a game-changer in the field of sheet metal cutting, delivering superior quality and efficiency to their customers globally.Founded in [Year], [Company XYZ] has shown relentless dedication to research and development, continuously pushing the boundaries of what is possible in sheet metal cutting. Their cutting-edge machinery and advanced software solutions have garnered accolades from industry experts and customers alike.By utilizing innovative laser cutting technology, [Company XYZ] ensures high-quality and precise cutting results, leaving no room for error. This advanced technology allows for intricate and complex designs to be accurately reproduced in sheet metal, enabling manufacturers to realize their most ambitious projects. The precision and consistency achieved by [Company XYZ]'s laser cutting technology have significantly elevated production efficiency by reducing post-processing requirements.In addition to their cutting-edge machinery, [Company XYZ] offers a comprehensive range of support services to assist their customers through every step of the sheet metal cutting process. Their team of highly skilled engineers and technicians are readily available to provide expert guidance, ensuring optimal results and maximum customer satisfaction. This commitment to customer support and personalized service has made [Company XYZ] a trusted partner for businesses across various industries.One of the key advantages of [Company XYZ]'s technology lies in its ability to cut a wide range of metals with exceptional accuracy and speed. Whether it is stainless steel, aluminum, brass, or copper, their laser cutting machines can effortlessly handle it. This versatility has opened up new doors for manufacturers who require precision cutting for a multitude of applications.Moreover, [Company XYZ]'s commitment to sustainability sets them apart from their competitors. By employing advanced technology, they have significantly reduced material waste during the sheet metal cutting process. This eco-friendly approach not only benefits the environment but also allows customers to reduce costs associated with raw material consumption.The impact of [Company XYZ]'s sheet metal cutting solutions has not gone unnoticed. Their innovative technology has set new industry standards and earned them a loyal customer base, both domestically and internationally. Clients praise [Company XYZ] for consistently delivering outstanding quality, meeting tight project deadlines, and providing exceptional customer service throughout the entire process.As [Company XYZ] continues to expand its operations, they remain committed to driving innovation in the sheet metal cutting industry. Their relentless pursuit of excellence, combined with their dedication to customer satisfaction, makes them a force to reckon with in the manufacturing landscape.About [Company XYZ]:[Company XYZ] is a global leader in providing cutting-edge industrial solutions for a wide range of applications. With a focus on research and development, they continually redefine the boundaries of technology, delivering superior products and services to customers worldwide. Their expertise lies in the field of sheet metal cutting, where their advanced laser cutting technology has set new industry standards. With a commitment to sustainability and customer support, [Company XYZ] strives to revolutionize the manufacturing industry and empower businesses with cutting-edge solutions.For media inquiries, contact:[Company XYZ][Contact Person][Email][Phone]Note: This is a fictional news article and does not reflect any real company or product.

What is Water-jet Technology? A Definition

Water-jet Technology Takes the Industrial World by StormWater-jet technology has been quietly revolutionizing the industrial world over the past decade. Driven by powerful streams of water and sometimes abrasive materials, water-jet cutting technology is quickly becoming the go-to cutting method for a variety of industries. From aerospace to the medical field, water-jet cutting is proving to be more precise and efficient than traditional cutting methods.A water-jet is a cutting tool that creates a high-velocity jet of water, usually mixed with an abrasive material. This creates a powerful cutting force that can cut through virtually any material with precision, including metal, stone, glass, and plastic. Water-jet cutting technology was developed in the 1950s, and since then, it has been continuously refined and improved, becoming one of the most versatile and effective cutting methods available today.One of the many benefits of water-jet cutting is its precision. Unlike traditional cutting methods that rely on brute force and sharp blades, water-jet cutting relies on a powerful stream of water to slice through materials with ease. This allows for incredibly intricate and precise cuts, even on difficult or complicated materials.Another benefit of water-jet cutting is its versatility. Water-jet cutters can handle a wide range of materials, from soft rubber to thick steel. This makes it an ideal choice for industries that require cutting precision on a variety of materials.The aerospace industry, for example, heavily relies on water-jet technology for the precision cutting of parts and components. With water-jet cutting, aerospace manufacturers can create intricate shapes out of tough materials such as titanium and composites, resulting in stronger, lighter-weight aircraft that perform better than ever before. Other industries, such as the medical field, also rely on water-jet cutting for precision cutting of surgical instruments and implantable devices.Water-jet cutting technology has also become more accessible in recent years, with more and more companies offering water-jet cutting services to a variety of industries. Companies like {} offer state-of-the-art water-jet cutting services that can handle large production runs or small, custom projects. By outsourcing their cutting needs, businesses can save time and money on equipment and maintenance costs while still enjoying the precision and versatility of water-jet cutting.Finally, water-jet cutting is also environmentally friendly. Unlike traditional cutting methods that produce harmful dust and debris, water-jet cutting creates minimal waste and leaves the material clean and untouched. This means less waste, fewer environmental hazards, and a safer workplace for employees.In conclusion, water-jet cutting technology is quickly becoming the go-to cutting method for businesses ranging from aerospace to medical manufacturing. With its precision, versatility, accessibility, and environmentally friendly benefits, water-jet cutting is the perfect solution for industries that require precise cutting of a variety of materials. As technology continues to improve, we can only expect to see water-jet cutting become even more essential to the industrial world.