High Precision CNC Lathe Parts: Key Factors to Consider

By:Admin

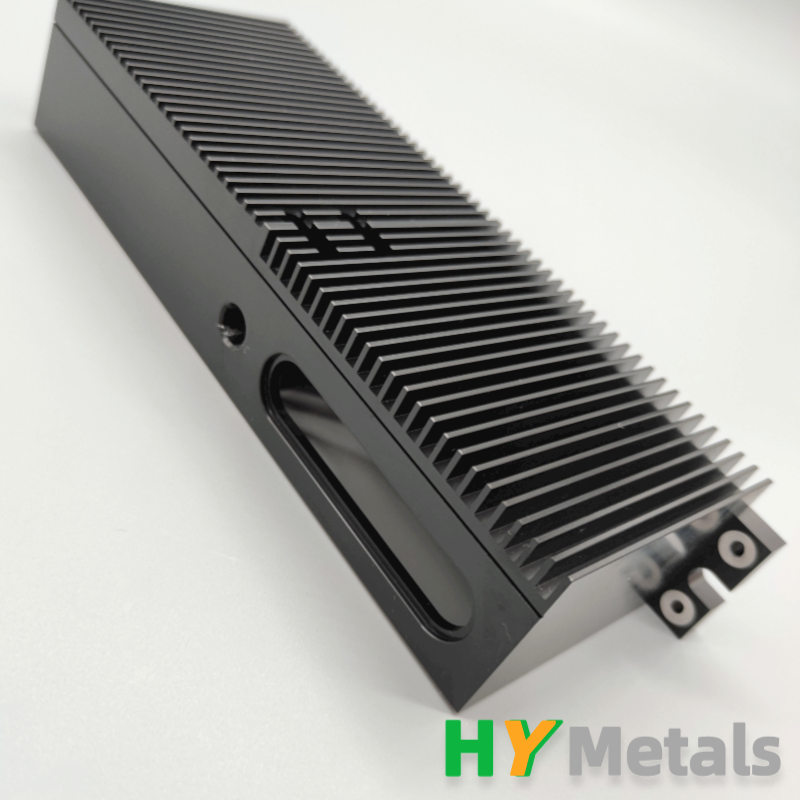

In the world of manufacturing, precision is everything. The ability to create intricate and accurately sized components is essential for a wide range of industries, from aerospace to automotive and everything in between. This is where CNC lathe precision parts come into play – these components are the hallmark of quality manufacturing and are essential for creating high-performance products.

One company that has made a name for itself in the world of CNC lathe precision parts is {company name removed}. With years of experience and a commitment to excellence, they have become a trusted name in the industry. Their dedication to quality and innovation has allowed them to thrive in an increasingly competitive market.

{company name removed} specializes in the production of CNC lathe precision parts, using the latest technology and cutting-edge techniques to create components that meet the highest standards of quality and accuracy. Their skilled team of engineers and technicians work tirelessly to ensure that every part they produce is flawless, meeting the exact specifications of their customers.

Their state-of-the-art facility is equipped with the latest CNC lathes, allowing them to produce a wide range of precision parts with incredible speed and accuracy. From simple components to complex and intricate designs, {company name removed} has the capability to handle any project, no matter how challenging.

One of the key factors that sets {company name removed} apart from their competitors is their unwavering commitment to quality. Every part that leaves their facility is subjected to rigorous quality control measures to ensure that it meets their strict standards. This dedication to excellence has earned them a reputation for reliability and consistency, making them the go-to choice for customers who demand nothing but the best.

In addition to their commitment to quality, {company name removed} also prides themselves on their ability to provide exceptional customer service. They work closely with their clients to understand their specific needs and requirements, offering custom solutions that are tailored to their individual needs. This personalized approach has allowed them to forge strong and lasting partnerships with a wide range of customers, from small businesses to multinational corporations.

Another key factor in {company name removed}'s success is their continuous investment in research and development. They are constantly seeking out new technologies and techniques to improve their production processes and stay ahead of the curve. This commitment to innovation has allowed them to remain at the forefront of the industry, setting new standards for quality and performance.

Looking to the future, {company name removed} remains committed to their core values of quality, innovation, and customer service. They continue to invest in the latest technology and talent, ensuring that they remain a top choice for customers who demand the best. With their unwavering dedication to excellence, they are well positioned to continue their success and remain a trusted name in the world of CNC lathe precision parts.

In conclusion, CNC lathe precision parts are essential for creating high-quality products, and {company name removed} has established themselves as a leader in the industry. Their commitment to quality, innovation, and customer service has allowed them to thrive in a competitive market, and they are well positioned to continue their success in the future. With their state-of-the-art facility and skilled team, they are the go-to choice for customers who demand nothing but the best.

Company News & Blog

Precision Sheet Metal Brackets Made with Advanced Manufacturing Techniques

: A Comprehensive Guide for Your Manufacturing NeedsSheet metal brackets are an integral part of any manufacturing process that requires the use of metal sheets. In industries that require immense precision and accuracy, the bracket systems ensure that the metal’s shape and structure are maintained throughout the process. With the advancements in modern CNC manufacturing processes, the quality of these bracket systems has improved significantly. The use of advanced automation tools has led to more efficient and precise manufacturing methods.Sheet metal brackets are widely used in various industries such as Aerospace, Medical, Automotive, Construction, and Electronics. In construction, sheet metal brackets are used to provide support to the structural systems, and in electronics, they secure electronic components in place. With their versatility, sheet metal brackets are an essential component in several processes and products.Here is a comprehensive guide to sheet metal brackets for all your manufacturing needs:Types of Sheet Metal Brackets1. Angle Brackets: These are brackets that are bent to 90-degree angles to create perpendicular structural joints. They are commonly used in construction to ensure that the structures maintain their shape and stability.2. U Brackets: These brackets have a U-shaped cross-section that is used to create a mounting point for objects. They are commonly used to mount objects onto walls and other surfaces.3. L Brackets: These are brackets that are bent to form an L-shape. They are used in most applications requiring reinforcement to prevent structural deformation.4. Z Brackets: These are brackets that are bent to form a ‘Z’ shape. They are used in construction to provide additional support to the structural systems.5. T Brackets: These are brackets that are bent to form a T-shape. They are commonly used to attach objects onto walls or other surfaces.Applications of Sheet Metal BracketsSheet metal brackets are used in various applications, including:AerospaceIn the aerospace industry, brackets are used to mount different types of equipment and systems such as electronics, fuel systems, engines, and landing gear. The brackets are usually made from lightweight materials like aluminum to minimize weight.AutomotiveIn the automotive industry, brackets are essential in holding the structural components of the car together. They are also used in securing electrical components in place.ConstructionSheet metal brackets are used extensively in the construction industry for many different applications, such as securing wall studs and reinforcing roof structures.ElectronicsIn the electronics industry, sheet metal brackets are used to secure electronic components in place. They are also used in creating housing systems for electrical components.MedicalSheet metal brackets are used in medical equipment and devices to support and hold various pieces of equipment such as monitors, IV poles, and other medical components in place.Manufacturing ProcessWith advancements in modern CNC manufacturing processes, sheet metal brackets can be precisely and efficiently manufactured. The manufacturing process for sheet metal brackets includes the following stages:1. Material Selection: The sheets of metal used in creating the brackets are usually made from various metals such as Stainless Steel, Carbon Steel, and Aluminum, and copper.2. Laser Cutting: The sheets of metal are cut using laser cutting machines to create the individual brackets' required shapes and sizes.3. Bending: The cut sheet metal is then bent using precision bending machines to create the desired shape of the bracket.4. Welding or Fixing: After bending the metal, the bracket components are welded or fixed together to create a final product.5. Finishing: The finished brackets are sandblasted or painted to give it a final finish.ConclusionSheet metal brackets are a vital part of many manufacturing processes. They provide structural support, aid in mounting equipment and components, and ensure precise manufacturing processes. The modern CNC manufacturing processes have significantly improved the manufacturing process of sheet metal brackets, leading to more efficient, accurate, and high-quality products. If you need sheet metal brackets for your manufacturing processes, ensure that you engage a reputable and experienced manufacturer who can deliver the desired results.

High-quality Turning Parts for Industrial Machinery at Competitive Prices

Turning Parts is a leading manufacturer of precision components serving a variety of industries, including automotive, aerospace, and medical. The company specializes in the production of high-quality turning parts that are essential for the functioning of mechanical systems in various applications.Founded in 1985, Turning Parts has established itself as a trusted provider of precision components for a wide range of industries. With a dedicated team of experienced engineers and a state-of-the-art manufacturing facility, the company has the capability to produce turning parts with tight tolerances and complex geometries to meet the specific requirements of its customers.The company's dedication to quality and precision has earned it a reputation for excellence in the industry. Turning Parts is committed to investing in the latest technology and equipment to ensure that it remains at the forefront of innovation and can provide its customers with the highest quality turning parts.In addition to its commitment to excellence, Turning Parts places a strong emphasis on customer satisfaction. The company works closely with its customers to understand their unique needs and provide them with tailored solutions that meet their specific requirements. Whether it's a small batch of turning parts for a prototype or a large-scale production run, Turning Parts has the flexibility and expertise to deliver on time and within budget.Turning Parts' comprehensive range of turning parts includes shafts, bushings, couplings, and other components that are crucial for the smooth operation of various mechanical systems. The company's expertise in turning parts manufacturing allows it to offer a diverse portfolio of products that can be customized to meet the most demanding specifications.With a global customer base, Turning Parts has built a strong network of partners and suppliers to support its operations. The company has a well-established supply chain that ensures it can source the highest quality materials and components for its turning parts, allowing it to maintain its high standards of quality and reliability.Moreover, Turning Parts is committed to sustainable and responsible manufacturing practices. The company adheres to stringent environmental regulations and invests in eco-friendly technologies to minimize its impact on the environment. By prioritizing sustainability, Turning Parts aims to contribute to a more sustainable future for the industry and the planet.As a forward-thinking company, Turning Parts is continually looking for new opportunities to expand its range of products and services. The company is dedicated to staying ahead of the curve in terms of technological advancements and market trends, ensuring that it can continue to meet the evolving needs of its customers.In conclusion, Turning Parts is a reputable manufacturer of precision turning parts with a strong commitment to quality, innovation, and customer satisfaction. With its extensive experience, technical expertise, and dedication to excellence, the company is well-positioned to continue serving as a trusted partner for industries that rely on high-quality turning parts.

Exploring the Tremendous Benefits of Fast Prototyping in Modern Industries

Title: Revolutionary Prototyping Technology Unveiled by Industry LeaderSubtitle: Pioneering the Future of Product Development and InnovationDate: [Date][City], [State] - [Company Name], a renowned leader in the field of prototyping and product development, has introduced an innovative and ground-breaking technology that is set to revolutionize the industry. The company is changing the game with its cutting-edge Fast Prototyping, a process that enables businesses to bring their ideas to life quicker and more efficiently than ever before.With a knack for pushing boundaries and an unwavering commitment to excellence, [Company Name] has always been at the forefront of technological advancements. The introduction of their Fast Prototyping technology is yet another testament to their status as industry leaders.Fast Prototyping is a game-changer in the product development world, allowing businesses to rapidly iterate and refine their designs in order to accelerate the time-to-market. This technology enables companies to transform their concept into a physical prototype within a matter of days, significantly reducing the time and cost associated with traditional prototyping methods.The key to Fast Prototyping lies in its use of cutting-edge 3D printing technologies. By harnessing the power of additive manufacturing, [Company Name] can create highly intricate and accurate prototypes directly from digital designs. This removes the need for costly and time-consuming manual modeling and machining processes, streamlining the entire development cycle.Furthermore, [Company Name] has developed advanced materials specifically tailored for Fast Prototyping. These materials possess exceptional strength, durability, and surface finish properties, ensuring that the prototypes accurately represent the final product. This allows companies to make critical design decisions early on and avoid costly errors down the line.The benefits of Fast Prototyping are not limited to design iteration speed and cost reduction. By quickly obtaining physical prototypes, businesses can test their products' ergonomics, functionality, and market appeal, gaining valuable insights that can inform further development iterations. This agile approach to product development empowers companies to meet customer demands swiftly and stay ahead of the competition.In addition to their state-of-the-art technology, [Company Name] boasts a highly skilled team of engineers and designers who work closely with clients throughout the prototyping process. Their expertise and collaborative approach ensure that the envisioned product is accurately translated into physical form, guaranteeing customer satisfaction."Our innovation-driven approach has always been centered around helping businesses transform their ideas into tangible realities," said [Company Name]'s CEO. "With Fast Prototyping, we are enabling companies to prototype and iterate at an unprecedented pace, unlocking the potential for faster time-to-market and competitive advantage."The applications of Fast Prototyping are vast and diverse. From aerospace to automotive, consumer electronics to medical devices, [Company Name] is committed to supporting a wide range of industries in their pursuit of innovation and excellence. Their technology will undoubtedly empower businesses to reimagine what is possible and bring their concepts to fruition in record time.For companies looking to harness the power of Fast Prototyping, [Company Name] offers tailored solutions and comprehensive support throughout the entire prototyping process. This includes design optimization, material selection, and seamless integration with existing product development workflows.As an industry leader and innovator, [Company Name] continues to revolutionize the field of product development. With Fast Prototyping, they are pioneering a new era of rapid, efficient, and cost-effective innovation, allowing businesses to turn their ideas into reality with unparalleled speed and precision.About [Company Name]:[Company Name] is a globally recognized leader in advanced product development and prototyping. With a team of highly skilled engineers and designers, they have been at the forefront of technological innovation for over [number of years] years. Their commitment to excellence and passion for driving innovation have cemented their position as a trusted partner for businesses across various industries.

Precision Machined Parts for Aerospace Industry

Machined Aerospace Parts plays a critical role in the aviation industry. The leading company has a longstanding reputation for providing high-quality aviation components to airlines and aircraft manufacturers. It boasts a significant market share in the aerospace industry and prides itself on a variety of CNC machining capabilities to deliver exceptional results.The company's proven track record of delivering parts that meet military and commercial aviation standards has made it a trusted supplier in the aviation industry. Customers who partner with Machined Aerospace Parts appreciate the company's focus on innovation, quality, and superior customer service. These are the essential qualities that have propelled the company to the top of the industry.Machined Aerospace Parts' capabilities are vast and diversified to meet the constantly evolving needs of the industry. The company has an array of precision equipment and utilizes the latest tools and technologies to produce a range of components. Whether it's machining parts from solid materials, producing small or large components, or creating complex structures, Machined Aerospace Parts has the expertise to get the job done.The company has a team of highly skilled professionals who are experts in the field of aviation. From engineers to production managers, all staff members are deeply passionate about the industry and take pride in their work. The team is focused on creating efficient, cost-effective solutions that meet customers' unique needs.One of the reasons Machined Aerospace Parts is a preferred supplier in the aviation industry is due to its exceptional quality control process. The company ensures that every component is subject to rigorous testing to meet the strict standards of the industry. The quality control process begins with design reviews and ends with a final inspection of finished products. These stringent checks ensure that all parts meet exacting requirements, and nothing leaves the factory until it meets the company's high standards.Machined Aerospace Parts is committed to continuous improvement, and that includes investing in cutting-edge technology and equipment. The company recently added several new machines to its assembly line, expanding its CNC machining capabilities. The machines allow the company to operate faster, which ensures quicker lead times for customers.Despite the challenges posed by the COVID-19 pandemic, Machined Aerospace Parts has continued to thrive. It has remained committed to serving its customers' needs and has adapted well to the changing landscape. The company maintains safe working conditions and adheres to all regulations and health guidelines to ensure the safety of employees and customers.As a company committed to excellence, Machined Aerospace Parts invests significantly in its people. The company has a rigorous training program that ensures all staff members are up-to-date on the latest industry developments and are equipped with the skills necessary to meet customers' needs. The company also offers training and apprenticeships to young people who want to learn about the aviation industry. By investing in young talent, the company is securing the future of the industry.In conclusion, Machined Aerospace Parts is a well-established, reputable, and innovative aviation company. With its advanced technology, highly skilled workforce, and exceptional quality control, it is no surprise that it continues to succeed in the industry. The company's commitment to providing cost-effective, efficient solutions to customers has propelled it to the top of the industry, and it remains a preferred supplier for many airlines and aircraft manufacturers. In a constantly evolving industry, Machined Aerospace Parts is poised for growth, and its future looks exceedingly bright.

Discover the Advantages of In-House Metal Fabrication for Quality and Timely Delivery

Sheet Metal Panel Fabrication – The Ultimate Solution to All Metal Fabrication NeedsSheet metal fabrication has come a long way since its inception. It has become an indispensable part of various industries and is used extensively for a multitude of purposes. Be it aerospace, automotive, construction, or any other industry – sheet metal fabrication is crucial in all of them.Although there are numerous methods of sheet metal fabrication, sheet metal panel fabrication has gained immense popularity among manufacturers. The primary reason for its popularity is the accuracy and precision it offers while fabricating metal panels.Let's delve deeper into the aspects of sheet metal panel fabrication and understand how it can help manufacturers in their metal fabrication needs.What is Sheet Metal Panel Fabrication?Sheet metal panel fabrication is a process that involves cutting, folding, and shaping sheet metal into panels. These panels can be of various shapes and sizes, and the fabrication process can be customized as per the requirement.Sheet metal panel fabrication involves using various tools such as laser cutting machines, CNC punching machines, and hydraulic press brakes. These machines are highly efficient and can provide accurate and precise output with utmost consistency.Advantages of Sheet Metal Panel Fabrication1. Precision – As stated earlier, sheet metal panel fabrication provides a high degree of precision and accuracy. The cutting and folding are done with utmost care and attention to detail, ensuring that the metal panels meet the required specifications.2. Customization – Sheet metal panel fabrication can be customized to cater to the specific needs of the manufacturer. This versatility allows manufacturers to produce metal panels of various shapes, sizes, and thicknesses. This flexibility is not present in other methods of metal fabrication.3. Efficiency – Sheet metal panel fabrication is highly efficient and can deliver output at a much quicker rate than other methods of metal fabrication. The use of advanced machines enhances the efficiency of the process, making it an ideal choice for manufacturers who want to increase their production speed.4. Cost-Effective – Sheet metal panel fabrication can be cost-effective in the long run. The high degree of precision and accuracy results in minimal wastage of material, making it a cost-effective method for manufacturers who want to cut down on their raw material costs.ConclusionSheet metal panel fabrication has become an integral part of various industries. It offers precision, customization, efficiency, and cost-effectiveness, making it the ultimate solution for all metal fabrication needs. If you want to streamline your metal fabrication process and improve your production speed, sheet metal panel fabrication is an ideal choice.So, if you are looking for a reliable metal fabrication service provider, look no further than sheet metal panel fabrication experts. They can help you with all your metal fabrication needs, ensuring that the end product meets your specifications.

High-Quality Fuschia Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing

In recent years, the demand for synthetic leather has increased rapidly worldwide. Synthetic leather has become a popular material choice for a variety of industries such as fashion, automotive, furniture, and sports equipment, among others. This is because synthetic leather offers many benefits such as durability, versatility, and cost-effectiveness. In China, one of the leading synthetic leather manufacturers is (brand name removed).One of their most innovative synthetic leather products is their Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing in Fuschia Color. This particular product is made of high-quality material and has a sleek and smooth finish which makes it perfect for use in products like high-end fashion items, bags, and accessories. This synthetic leather has a suede fabric backing which provides the added benefit of breathability and comfort. This feature makes it a suitable option for footwear, soles, and insoles.China has become a hub for synthetic leather manufacturing, and (brand name removed) leads the way in developing innovative and high-quality synthetic leather products. They use advanced technology and equipment to produce synthetic leather that meets the highest standards of quality and performance. As a result, they have become one of the most sought-after synthetic leather suppliers in China, and their products are exported to various countries around the world.The Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing in Fuschia Color is not only a quality product, but it is also offered at an affordable synthetic leather price. (brand name removed) provides their clients with competitive synthetic leather prices while maintaining the highest quality standards for their products. This has led to increased demand for their products from both local and international markets.Apart from providing quality products at affordable synthetic leather prices, (brand name removed) is also committed to environmental protection. They use water-based technology during the production of their synthetic leather products, which significantly reduces the amount of harmful chemicals released into the environment. The water-based technology also produces less waste material, which reduces waste disposal costs and carbon footprint.In conclusion, the demand for synthetic leather is growing rapidly, and China is at the forefront of synthetic leather manufacturing. (brand name removed) is a leading supplier of synthetic leather in China, and their Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing in Fuschia Color is a high-quality product that is popular in various industries. Their commitment to using environmentally friendly technology and providing affordable synthetic leather prices has made them a preferred choice among their clients. For those looking to purchase high-quality synthetic leather products, (brand name removed) is a reliable and trusted supplier.

High-Quality Precision Milling Parts for Various Industries

Milling Parts is a leading multinational corporation that specializes in producing and supplying high-quality mechanical parts for various industries such as automotive, aerospace, medical, and more. The company has a mission to meet the needs of its customers by providing the best products and services possible. Milling Parts has recently announced a significant expansion of its operations, which will enable the company to enhance its production capacity and supply chain efficiency. This expansion includes the construction of a new state-of-the-art plant that will be equipped with advanced technologies to enable the production of more complex and high-quality parts. According to the company officials, this new plant will be the largest Milling Parts production facility, and it will be strategically located to serve both domestic and international customers. The facility will include multiple production lines, quality control and testing facilities, warehouses, and administrative offices. The CEO of Milling Parts stated that this expansion is part of the company's long-term growth strategy, and it reflects the commitment to meeting the increasing demands of its customers. He further added that the company aims to increase its market share and become a key player in the global mechanical parts industry. Milling Parts is known for its innovative and customer-focused approach to business. The company has an experienced team of engineers and technicians who work closely with customers to understand their needs and provide customized solutions. The company also invests heavily in research and development to stay at the forefront of technological advancements in the industry. Milling Parts is committed to ensuring the highest quality standards in all its products and services. The company has implemented a comprehensive quality management system that includes strict adherence to international standards such as ISO 9001 and AS9100. This ensures that all products and services meet or exceed customer expectations and comply with regulatory requirements. Milling Parts has a strong presence in the global market and serves customers in more than 50 countries. The company has established a network of partners and distributors worldwide, which enables it to provide efficient logistics and supply chain services. Milling Parts is also committed to sustainability and operates with a focus on minimizing its environmental impact. The company has implemented various initiatives to reduce energy consumption, waste generation, and carbon emissions. Milling Parts has a positive reputation in the industry, and it has received numerous awards and certifications for its excellence in quality, innovation, and customer service. The company has also been recognized for its role in creating job opportunities and contributing to economic growth in the regions where it operates. The expansion of Milling Parts operations is expected to create additional job opportunities and contribute to the development of the local economy. The company has stated that it will prioritize the recruitment of local talent and provide training and career development opportunities. In conclusion, Milling Parts is a leading mechanical parts manufacturer with a commitment to innovation, quality, and customer service. The company's expansion of operations is a reflection of its long-term growth strategy and commitment to meeting the needs of its customers. The new state-of-the-art plant will enable Milling Parts to enhance production capacity, supply chain efficiency, and become a key player in the global mechanical parts industry.

Precision CNC Machined Parts for Corn and Grain Agriculture Products – Manufacturer in China

CNC machining is a widely-used technology in various industries, including agriculture. Specifically, CNC machined parts are essential in corn and grain harvesting and processing activities. In Senorok.com, we offer precision CNC machined parts that provide outstanding performance and optimal efficiency. Our expert manufacturing team uses the latest technology and an extensive range of raw materials to produce high-quality machined parts for different industries.One of our most popular CNC machined parts is the SS-03,05 model, which is made of high-quality steel. Steel is a durable and robust material that can withstand extreme conditions, making it ideal for use in agricultural machinery. With our precise CAD/CAM techniques and cutting-edge CNC technology, we can manufacture highly accurate and precise machined parts that meet our clients' unique demands.Our CNC machined parts are available at a reasonable price, and we offer competitive rates that make us a reliable partner for different types of businesses. Our team has years of experience in delivering top-quality CNC machined parts, and we understand the importance of delivering products that match our clients' expectations.Apart from steel, we can also manufacture CNC milled plastic parts that are highly effective in various applications. Plastic parts are preferred in some cases because they are lightweight, affordable, and can be quickly produced in large volumes. Our CNC machines are optimized to work with different types of plastics, and we can provide custom-made solutions that suit our clients' requirements.In conclusion, CNC machining is an essential technology that contributes significantly to the agricultural sector. At Senorok.com, we are committed to delivering top-quality CNC machined parts that provide superior performance and durability. Our products are reliable, competitively priced, and manufactured with precision to meet our clients' unique needs. Please contact us today to learn more about our CNC machining services and how we can help your business succeed.

Ultimate Guide to Sheet Metal Forming Techniques for Manufacturing

article about the advancements in sheet metal forming technology.Sheet metal forming is a process used to transform flat metal sheets into various shapes and products through the application of force. This process is widely used in industries such as automotive, aerospace, construction, and manufacturing to create a wide range of products including car parts, machinery components, and household appliances.In recent years, there have been significant advancements in sheet metal forming technology that have led to improvements in efficiency, precision, and overall product quality. One company at the forefront of these advancements is {}.{} is a leading manufacturer of sheet metal forming equipment and has been instrumental in driving innovation in the industry. With a strong focus on research and development, the company has developed cutting-edge technologies that have revolutionized the sheet metal forming process.One of the key advancements that {} has introduced is the use of advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software to optimize the sheet metal forming process. This software allows manufacturers to create highly detailed and precise designs, which are then used to program the company's state-of-the-art sheet metal forming machines.In addition to software advancements, {} has also developed new techniques for controlling the temperature and pressure during the sheet metal forming process. These techniques have resulted in a more consistent and uniform shaping of the metal, leading to products with higher quality and durability.Furthermore, {} has invested heavily in automation and robotics to streamline the sheet metal forming process. By automating certain tasks, the company has been able to increase production speed and efficiency while reducing the margin of error.The advancements made by {} have not only improved the efficiency and precision of the sheet metal forming process, but they have also had a positive impact on sustainability. By optimizing the process and reducing waste, the company has been able to minimize its environmental footprint.In addition to technological advancements, {} has also focused on the training and development of its workforce. The company has a team of highly skilled engineers and technicians who are constantly pushing the boundaries of what is possible in sheet metal forming.Through their dedication to innovation and excellence, {} has solidified its position as a global leader in the sheet metal forming industry. The company's commitment to pushing the boundaries of what is possible has led to advancements that have transformed the industry and set new standards for quality and efficiency.Looking ahead, {} continues to invest in research and development to further advance sheet metal forming technology. With a focus on sustainability, efficiency, and precision, the company is poised to continue leading the way in the sheet metal forming industry.In conclusion, the advancements made by {} in sheet metal forming technology have had a profound impact on the industry. Through a combination of advanced software, temperature and pressure control techniques, automation, and a focus on sustainability, the company has raised the bar for efficiency, precision, and product quality in sheet metal forming. As {} continues to push the boundaries of what is possible, the future of sheet metal forming looks promising, with even more advancements on the horizon.

CNC Turning Services for High-Quality Lathe Turned Parts

Service, Lathe Turned Production Parts, Prototyping, CNC Machined Parts, Manufacturing Partners, Instant CNC Turning Quote.CNC Turning Service: Your One-Stop Solution for All Your Lathe NeedsIn today's fast-paced manufacturing industry, the demand for precision and accuracy in parts production is more important than ever. Thanks to advances in technology, the CNC turning service has emerged as the go-to solution for manufacturing high-quality lathe-turned production parts. CNC Turning, with its precision, speed, and flexibility, has revolutionized the world of manufacturing and has become an essential part of modern-day production processes.At CNC Turning Service, we understand the importance of getting it right the first time, which is why we offer an exceptional range of services dedicated to providing our clients with the best possible results. Our services provide complete end-to-end solutions, from prototyping to CNC machined parts, and we deliver them with unbeatable speed, quality, and price.Our Global Network of Certified Manufacturing PartnersCNC Turning Service is proud to have a global network of 25 certified manufacturing partners, enabling us to offer our clients the best CNC turning services available. These partners have over 100 CNC turning machines, allowing us to produce everything from simple to complex parts. Our partners undergo a rigorous selection process to ensure they meet our exacting standards of quality, consistency, and efficiency. As a result, our clients benefit significantly from increased savings, faster lead times, and access to a wider range of capabilities.The Most Cost-Effective Solution for PrototypingAt CNC Turning Service, we understand that prototyping is an essential part of the production process. As such, we offer our clients the most cost-effective solution for creating high-quality prototypes. Our CNC turning service gives our clients the ability to produce prototypes that are identical to the final product in terms of specifications, tolerances, and material, which reduces the risk of design errors and allows for necessary modifications before the final production.CNC Machined Parts With Unbeatable Quality and SpeedCNC Turning Service produces CNC machined parts with unbeatable speed and quality. Our partners' CNC turning machines produce precise and accurate parts with precise tolerances, finishes, and features. Whether you need single parts or thousands, our CNC turning service can provide you with the most efficient and cost-effective production.Instant CNC Turning QuoteCNC Turning Service offers an instant CNC turning quote to our clients. Our online quote system is user-friendly, simple, and straightforward to use. Our clients can upload their designs, specify their requirements, and receive a quote instantly. With our instant quote system, our clients can access real-time pricing information and plan their production processes accordingly.ConclusionAt CNC Turning Service, we provide our clients with a complete end-to-end solution for all their lathe-turned production parts needs. Our global network of certified manufacturing partners, our cost-effective prototyping solutions, and our unbeatable quality and speed in producing CNC machined parts, make us the go-to solution for manufacturing high-quality parts. Contact us today and experience the benefits of our CNC turning services.