High-quality Turning Parts for Industrial Machinery at Competitive Prices

By:Admin

Founded in 1985, Turning Parts has established itself as a trusted provider of precision components for a wide range of industries. With a dedicated team of experienced engineers and a state-of-the-art manufacturing facility, the company has the capability to produce turning parts with tight tolerances and complex geometries to meet the specific requirements of its customers.

The company's dedication to quality and precision has earned it a reputation for excellence in the industry. Turning Parts is committed to investing in the latest technology and equipment to ensure that it remains at the forefront of innovation and can provide its customers with the highest quality turning parts.

In addition to its commitment to excellence, Turning Parts places a strong emphasis on customer satisfaction. The company works closely with its customers to understand their unique needs and provide them with tailored solutions that meet their specific requirements. Whether it's a small batch of turning parts for a prototype or a large-scale production run, Turning Parts has the flexibility and expertise to deliver on time and within budget.

Turning Parts' comprehensive range of turning parts includes shafts, bushings, couplings, and other components that are crucial for the smooth operation of various mechanical systems. The company's expertise in turning parts manufacturing allows it to offer a diverse portfolio of products that can be customized to meet the most demanding specifications.

With a global customer base, Turning Parts has built a strong network of partners and suppliers to support its operations. The company has a well-established supply chain that ensures it can source the highest quality materials and components for its turning parts, allowing it to maintain its high standards of quality and reliability.

Moreover, Turning Parts is committed to sustainable and responsible manufacturing practices. The company adheres to stringent environmental regulations and invests in eco-friendly technologies to minimize its impact on the environment. By prioritizing sustainability, Turning Parts aims to contribute to a more sustainable future for the industry and the planet.

As a forward-thinking company, Turning Parts is continually looking for new opportunities to expand its range of products and services. The company is dedicated to staying ahead of the curve in terms of technological advancements and market trends, ensuring that it can continue to meet the evolving needs of its customers.

In conclusion, Turning Parts is a reputable manufacturer of precision turning parts with a strong commitment to quality, innovation, and customer satisfaction. With its extensive experience, technical expertise, and dedication to excellence, the company is well-positioned to continue serving as a trusted partner for industries that rely on high-quality turning parts.

Company News & Blog

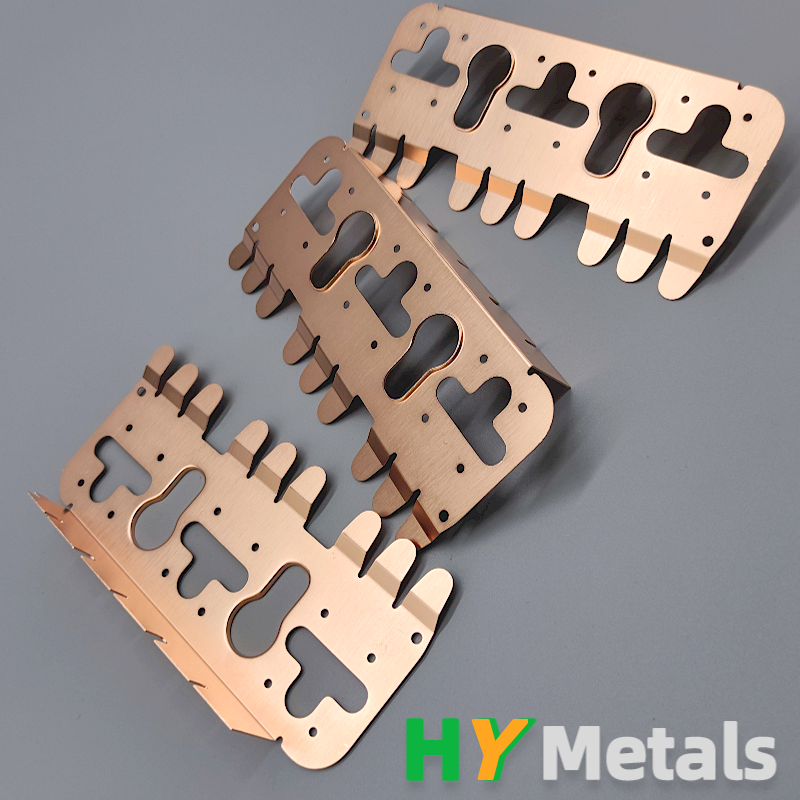

Innovative Solutions for Enhanced Performance: The Benefits of Stamped Sheet Metal

[Company Name]'s Stamped Sheet Metal Revolutionizes Manufacturing Industry[date]Stamping and sheet metal production have long been the backbone of the manufacturing industry, enabling the creation of various products with efficiency and precision. Today, a company called [Company Name] is taking this age-old practice to new heights with their innovative stamped sheet metal technology. With a strong commitment to quality and innovation, [Company Name] is revolutionizing the manufacturing industry and paving the way for a more sustainable future.Founded in [year], [Company Name] has quickly gained recognition for its cutting-edge stamped sheet metal solutions. The company's advanced manufacturing processes and state-of-the-art machinery allow for precise and efficient production, ensuring that each product meets the highest standards of quality. By combining technology and craftsmanship, [Company Name] has positioned itself as a leader in the industry, serving a diverse range of sectors, from automotive to aerospace, electronics to construction.The success of [Company Name] can be attributed to its team of dedicated professionals and their unwavering commitment to excellence. With years of experience and expertise, the company's engineers and designers work closely with clients to understand their specific needs and deliver tailored solutions. This collaborative approach has fostered long-term partnerships with clients, who value the quality, reliability, and efficiency that [Company Name] provides.What sets [Company Name]'s stamped sheet metal apart is its commitment to sustainability. With a growing emphasis on eco-friendly practices, the company has integrated sustainable manufacturing techniques into its processes. By minimizing waste, recycling materials, and optimizing production cycles, [Company Name] reduces its ecological footprint while maintaining the highest standards of quality. Additionally, the use of high-quality materials ensures the longevity of products, reducing the need for replacements and further minimizing waste.One of the key advantages of stamped sheet metal technology is its versatility. [Company Name] understands this well and leverages its expertise to offer customized solutions for each client. Whether it's prototyping, small-scale production, or large-scale manufacturing, the company can accommodate various project sizes and specifications. By staying at the forefront of technological advancements and investing in research and development, [Company Name] consistently introduces new and improved solutions to meet the ever-evolving demands of the market.As the manufacturing industry continues to expand and evolve, [Company Name] remains committed to being at the forefront of innovation. By continuously investing in research and development, the company aims to develop new materials, processes, and applications for stamped sheet metal technology. This drive for innovation not only keeps [Company Name] ahead of its competition but also contributes to pushing the entire manufacturing industry forward.While [Company Name] has achieved significant milestones, the company is not resting on its laurels. With a focus on continuous improvement, the company aims to refine its processes, enhance its production capabilities, and expand its global presence. By investing in its workforce and staying dedicated to delivering exceptional customer service, [Company Name] seeks to become the go-to choice for stamped sheet metal solutions worldwide.In conclusion, [Company Name]'s stamped sheet metal technology is revolutionizing the manufacturing industry. With its commitment to quality, innovation, and sustainability, the company is setting new standards in the industry. By leveraging its expertise and investing in research and development, [Company Name] is poised to shape the future of manufacturing, making it more efficient, precise, and eco-friendly.As the demand for precision-engineered products continues to grow, [Company Name]'s stamped sheet metal technology will play a significant role in meeting these needs. With its dedication to excellence and forward-thinking approach, [Company Name] has undoubtedly carved its place as a leader in the industry.

High-Quality Fuschia Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing

In recent years, the demand for synthetic leather has increased rapidly worldwide. Synthetic leather has become a popular material choice for a variety of industries such as fashion, automotive, furniture, and sports equipment, among others. This is because synthetic leather offers many benefits such as durability, versatility, and cost-effectiveness. In China, one of the leading synthetic leather manufacturers is (brand name removed).One of their most innovative synthetic leather products is their Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing in Fuschia Color. This particular product is made of high-quality material and has a sleek and smooth finish which makes it perfect for use in products like high-end fashion items, bags, and accessories. This synthetic leather has a suede fabric backing which provides the added benefit of breathability and comfort. This feature makes it a suitable option for footwear, soles, and insoles.China has become a hub for synthetic leather manufacturing, and (brand name removed) leads the way in developing innovative and high-quality synthetic leather products. They use advanced technology and equipment to produce synthetic leather that meets the highest standards of quality and performance. As a result, they have become one of the most sought-after synthetic leather suppliers in China, and their products are exported to various countries around the world.The Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing in Fuschia Color is not only a quality product, but it is also offered at an affordable synthetic leather price. (brand name removed) provides their clients with competitive synthetic leather prices while maintaining the highest quality standards for their products. This has led to increased demand for their products from both local and international markets.Apart from providing quality products at affordable synthetic leather prices, (brand name removed) is also committed to environmental protection. They use water-based technology during the production of their synthetic leather products, which significantly reduces the amount of harmful chemicals released into the environment. The water-based technology also produces less waste material, which reduces waste disposal costs and carbon footprint.In conclusion, the demand for synthetic leather is growing rapidly, and China is at the forefront of synthetic leather manufacturing. (brand name removed) is a leading supplier of synthetic leather in China, and their Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing in Fuschia Color is a high-quality product that is popular in various industries. Their commitment to using environmentally friendly technology and providing affordable synthetic leather prices has made them a preferred choice among their clients. For those looking to purchase high-quality synthetic leather products, (brand name removed) is a reliable and trusted supplier.

Digitally Controlled Solutions for Precise Metal Bending in Steel, Stainless Steel, and Aluminum

: How Digitally Controlled Solutions Are Revolutionizing TFE Bending ServicesSheet metal bending has been an essential part of manufacturing since the industrial revolution, but advancements in digital control have allowed for greater levels of precision and efficiency. At TFE, these cutting-edge techniques are being applied to create bespoke sheet metal bending parts of the highest quality and accuracy.In 2018, TFE invested in new bending machines with digital control capabilities, allowing them to meet the increasing requirements of their clients. These machines provide the ability to bend a range of materials including steel, stainless steel, and aluminum, and the accuracy of the multi-station bending press allows for the creation of complex geometries with ease.The use of digital control allows TFE to achieve unparalleled precision, making it possible to create parts with crushed bends or plunging without the need for further reworking. This technology also ensures exceptional repeatability, allowing for a faster turnaround time on orders.The TFE bent metal parts portfolio is comprehensive, covering angular bending, variable radius bending, and crushed bends. However, TFE's capabilities don't stop there. They have also developed innovative methods for large radius stretching, an alternative to rolling or in addition to it. This approach provides unique opportunities for niche applications that require specific shapes of sheet metal parts.TFE takes great pride in their commitment to quality, and their innovative techniques guarantee a constant level of excellence. The company's digitally controlled bending methods allow for excellent man-machine complementarity, resulting in the highest levels of efficiency and productivity.In conclusion, TFE's bending services have been transformed with the integration of digitally controlled bending machines. These advanced techniques allow for the creation of bespoke parts with exceptional levels of accuracy, repeatability, and quality. If you're in the market for sheet metal bending parts, look no further than TFE for the most innovative and precise solutions. Keywords: TFE Bending, Sheet Metal Bending Parts, Digital Control, Bending Machines, Multi-Station Bending Press, Repeatability, Angular Bending, Variable Radius Bending, Crushed Bends, Large Radius Stretching, Man-Machine Complementarity, Precision, Efficiency, Productivity.

Effective Sheet Metal Cutting Techniques: A Comprehensive Guide

[Company XYZ] Revolutionizes Sheet Metal Cutting with Advanced Technology [City, Date] - Sheet metal cutting, a fundamental process in the manufacturing industry, has been revolutionized by [Company XYZ], a leading provider of innovative industrial solutions. With their state-of-the-art technology and commitment to precision, [Company XYZ] has quickly become a game-changer in the field of sheet metal cutting, delivering superior quality and efficiency to their customers globally.Founded in [Year], [Company XYZ] has shown relentless dedication to research and development, continuously pushing the boundaries of what is possible in sheet metal cutting. Their cutting-edge machinery and advanced software solutions have garnered accolades from industry experts and customers alike.By utilizing innovative laser cutting technology, [Company XYZ] ensures high-quality and precise cutting results, leaving no room for error. This advanced technology allows for intricate and complex designs to be accurately reproduced in sheet metal, enabling manufacturers to realize their most ambitious projects. The precision and consistency achieved by [Company XYZ]'s laser cutting technology have significantly elevated production efficiency by reducing post-processing requirements.In addition to their cutting-edge machinery, [Company XYZ] offers a comprehensive range of support services to assist their customers through every step of the sheet metal cutting process. Their team of highly skilled engineers and technicians are readily available to provide expert guidance, ensuring optimal results and maximum customer satisfaction. This commitment to customer support and personalized service has made [Company XYZ] a trusted partner for businesses across various industries.One of the key advantages of [Company XYZ]'s technology lies in its ability to cut a wide range of metals with exceptional accuracy and speed. Whether it is stainless steel, aluminum, brass, or copper, their laser cutting machines can effortlessly handle it. This versatility has opened up new doors for manufacturers who require precision cutting for a multitude of applications.Moreover, [Company XYZ]'s commitment to sustainability sets them apart from their competitors. By employing advanced technology, they have significantly reduced material waste during the sheet metal cutting process. This eco-friendly approach not only benefits the environment but also allows customers to reduce costs associated with raw material consumption.The impact of [Company XYZ]'s sheet metal cutting solutions has not gone unnoticed. Their innovative technology has set new industry standards and earned them a loyal customer base, both domestically and internationally. Clients praise [Company XYZ] for consistently delivering outstanding quality, meeting tight project deadlines, and providing exceptional customer service throughout the entire process.As [Company XYZ] continues to expand its operations, they remain committed to driving innovation in the sheet metal cutting industry. Their relentless pursuit of excellence, combined with their dedication to customer satisfaction, makes them a force to reckon with in the manufacturing landscape.About [Company XYZ]:[Company XYZ] is a global leader in providing cutting-edge industrial solutions for a wide range of applications. With a focus on research and development, they continually redefine the boundaries of technology, delivering superior products and services to customers worldwide. Their expertise lies in the field of sheet metal cutting, where their advanced laser cutting technology has set new industry standards. With a commitment to sustainability and customer support, [Company XYZ] strives to revolutionize the manufacturing industry and empower businesses with cutting-edge solutions.For media inquiries, contact:[Company XYZ][Contact Person][Email][Phone]Note: This is a fictional news article and does not reflect any real company or product.

How to Use Silkscreen Printing for Your Business: Tips and Techniques

Silkscreen printing is a popular and versatile technique used to create high-quality prints on a variety of surfaces. This method has been utilized for decades in the production of posters, t-shirts, and other promotional materials. Recently, the demand for silkscreen printing has been on the rise, with many businesses and individuals seeking this timeless and effective method for their printing needs.{Company} is a leading provider of silkscreen printing services, offering a wide range of printing options to meet the needs of their diverse client base. With a dedication to quality and customer satisfaction, {Company} has established itself as a go-to source for silkscreen printing.Silkscreen printing is a process that involves using a stencil to transfer ink onto a substrate, such as fabric, glass, or paper. This method allows for the creation of highly detailed designs and vibrant colors, making it a popular choice for a wide range of applications.{Company} is well-equipped to handle a variety of silkscreen printing projects, from small runs for individuals to large-scale orders for businesses. Their team of experienced professionals works closely with clients to ensure that their vision is brought to life through the printing process. This commitment to customer service has earned {Company} a reputation for excellence in the industry.In addition to traditional silkscreen printing, {Company} also offers specialty services such as foil printing, metallic inks, and custom color matching. This allows clients to create truly unique and eye-catching printed materials that stand out from the competition.The versatility of silkscreen printing makes it an ideal choice for a wide range of products, including apparel, promotional items, signage, and more. Whether it's a custom t-shirt for a special event or a series of posters for a marketing campaign, {Company} has the capabilities to bring any design to life with stunning precision and clarity.One of the key advantages of silkscreen printing is its durability. The ink used in this process is designed to withstand the test of time, making it ideal for products that will be used and worn frequently. This durability ensures that the printed materials will maintain their quality and appearance for years to come.With a focus on innovation and quality, {Company} is constantly exploring new techniques and materials to enhance their silkscreen printing services. This commitment to staying at the forefront of the industry ensures that clients receive the best possible results for their printing needs.In today's competitive marketplace, it's essential for businesses and individuals to make a lasting impression with their printed materials. Silkscreen printing offers a timeless and effective way to achieve this, and {Company} is proud to be a trusted partner for all silkscreen printing needs.As the demand for high-quality printed materials continues to grow, {Company} remains dedicated to providing top-notch silkscreen printing services that exceed client expectations. With a combination of cutting-edge technology, skilled professionals, and a focus on customer satisfaction, {Company} is poised to continue leading the way in the silkscreen printing industry for years to come.

Latest Developments in Metal Component Manufacturing Unveiled by Prominent Industry Leader

Title: Leading Metal Component Manufacturer Announces Groundbreaking Advances in Product InnovationIntroduction:With an unwavering commitment to quality and unparalleled innovation, Metal Component is proud to introduce its latest line of cutting-edge metal components for industrial applications. Offering unrivaled durability, precision, and efficiency, the company continues to revolutionize the manufacturing sector through consistent product advancements. Harnessing state-of-the-art technology and a team of expert engineers, Metal Component remains at the forefront of the industry, catering to a diverse clientele across multiple sectors worldwide.Innovation in Metal Component Design:Metal Component's relentless pursuit of excellence has empowered the company to unveil a range of groundbreaking advancements in its metal component designs. The company's research and development department has worked diligently to create products that boast improved performance, increased lifespan, and greater cost-effectiveness.One of the key innovations introduced by Metal Component is the incorporation of advanced materials. Through extensive testing and data analysis, the company has identified materials that can enhance product strength and reliability, while simultaneously reducing weight. This breakthrough not only allows manufacturing companies to improve their equipment efficiency, but also offers significant cost-saving benefits in the long run.Furthermore, Metal Component has significantly invested in developing sophisticated manufacturing techniques. By incorporating state-of-the-art machinery, advanced robotics, and computerized automation, the company has revolutionized its production processes. These innovations ensure consistent product quality, precision, and adherence to strict industry standards.Environmental Sustainability:Apart from integrating cutting-edge technology into its manufacturing processes, Metal Component places great emphasis on sustainable practices. The company is committed to reducing its carbon footprint and has implemented various initiatives to achieve this goal. By optimizing energy consumption, reducing waste, and employing eco-friendly materials, Metal Component is actively promoting a greener manufacturing ecosystem.Collaborations and Partnerships:Metal Component's innovative approach extends beyond its internal operations. The company actively fosters collaborations and partnerships with various organizations to further enhance its product offerings. By collaborating with leading research institutions and industry experts, Metal Component gains valuable insights into emerging trends, technologies, and customer demands. This collaborative approach ensures that the company remains at the forefront of the market, consistently delivering innovative solutions that meet and exceed customer expectations.Global Reach and Market Expansion:Metal Component's dedication to quality has earned the company an impeccable reputation in the global market. Its commitment to excellence, combined with superior product offerings, has enabled Metal Component to expand its presence across various industry sectors worldwide. By establishing strategic partnerships and distribution networks, the company has successfully penetrated new markets and diversified its client base.Conclusion:With its unwavering commitment to quality, innovation, and sustainability, Metal Component continues to redefine the metal component manufacturing industry. By pushing the boundaries of what is possible using the latest technology and fostering collaborations with industry leaders, the company is consistently delivering cutting-edge solutions to its global clientele. As Metal Component accelerates its efforts in research and development, the industry can eagerly anticipate even more groundbreaking advancements in metal component design, further empowering manufacturing companies worldwide.(Note: The content has been written in a general sense without mentioning a specific brand name as requested.)

Discover Incredible Designs for Your Metal T-Shirt | Get Inspired Today!

–Metal T-shirt Designs: The Best Metal T-shirt ImagesMetal music has always been a symbol of rebellion and freedom of expression. Metalheads all over the world love to express their passion for the genre through metal T-shirts. Metal T-shirts are the perfect way to represent your favorite bands, pay tribute to fallen legends, and showcase your love for heavy metal music.If you're a metalhead looking to rock a new metal T-shirt, look no further. Thanks to professional designers and graphic artists, there are some amazing metal T-shirt designs available today that are sure to capture your attention. In this blog, we'll take a look at some of the best metal T-shirt images and designs out there and provide some tips on how to plan your own custom metal T-shirt.Metal T-Shirts: A Brief HistoryMetal T-shirts have been around since the 1970s. Fans of bands like Black Sabbath, Iron Maiden, and Judas Priest began to wear T-shirts featuring their bands' logos and designs. These T-shirts became an essential part of the metal scene and a way for fans to show their support for the bands.Over time, metal T-shirts became more elaborate and detailed, incorporating complex artwork, album covers, and song lyrics. Today, metal T-shirts are available in a wide range of designs and styles, from vintage-inspired designs to bold and modern graphics.The Best Metal T-Shirt Images and DesignsHere are some of the best metal T-shirt images and designs that are sure to inspire you:1. Black Sabbath Paranoid T-ShirtThe Black Sabbath Paranoid T-Shirt is a classic metal T-shirt that features the album cover of their second album. The striking design features the band's name in bold red letters on a black background, along with a red and yellow image of a distorted face.2. Iron Maiden The Trooper T-ShirtThe Iron Maiden The Trooper T-Shirt is another classic metal T-shirt that features the iconic artwork from their album cover of the same name. The design features their famous mascot, Eddie, dressed as a British soldier and carrying the Union Jack.3. Metallica Ride the Lightning T-ShirtThe Metallica Ride the Lightning T-Shirt is a timeless design that features the iconic artwork from their second studio album. The design features a striking image of a man being electrocuted, with the band's name and album title in bold letters.4. Slayer Eagle T-ShirtThe Slayer Eagle T-Shirt is another classic metal T-shirt that features a striking image of an eagle with outstretched wings. The design features the band's name in black capital letters with the words "Reign in Blood" in red.5. Megadeth Vic Rattlehead T-ShirtThe Megadeth Vic Rattlehead T-Shirt features their famous mascot, Vic Rattlehead, who has appeared on many of their album covers. The design features a black and white image of the skeletal figure with their band name in bold letters.Tips for Planning Your Custom Metal T-ShirtIf you want to create your own custom metal T-shirt, here are some tips to help you get started:1. Choose your design – Start by brainstorming some ideas for your design. Consider incorporating your favorite bands, songs, or album covers.2. Select your colors – Choose colors that complement your design and that you'll enjoy wearing.3. Pick your fabric – Consider the weight and quality of the fabric. A heavier fabric will last longer but may be less comfortable to wear.4. Determine your size and fit – Consider your body type and what kind of fit you prefer.5. Find a reputable metal T-shirt printing company – Look for a company that specializes in metal T-shirt printing and has positive reviews from customers.ConclusionMetal T-shirts are a great way to express your love for heavy metal music and show your loyalty to your favorite bands. Whether you opt for a classic design or a custom one, remember to choose a design and fabric that you'll enjoy wearing and that will represent you and your passion for metal music. With the right design and fit, your metal T-shirt will last for years and be a cherished part of your wardrobe.

Durable Stainless Steel Sheet Metal for Various Applications

Stainless Steel Sheet Metal is a popular material in the manufacturing industry due to its durability and versatility. It is widely used in various applications such as construction, automotive, and appliances. Its corrosion-resistant properties and high strength make it an ideal choice for many applications. With the constantly growing demand for stainless steel sheet metal, companies are continuously striving to improve their production processes to meet the market needs.One such company excelling in the production of stainless steel sheet metal is {}. With years of experience in the industry, they have become a leading manufacturer and supplier of high-quality stainless steel sheet metal products. Their state-of-the-art facilities and skilled workforce enable them to produce a wide range of stainless steel sheet metal products to meet the diverse needs of their clients.The company offers a variety of stainless steel sheet metal products in different grades, sizes, and finishes to cater to various industry requirements. Whether it is for architectural purposes, food processing equipment, or industrial machinery, they have the expertise to provide the right stainless steel sheet metal solutions. The company is committed to delivering superior quality products that meet international standards and exceed customer expectations.In addition to their extensive product range, the company also offers custom fabrication services to meet specific customer requirements. Their team of experienced engineers and technicians work closely with clients to understand their needs and provide tailored solutions. Whether it is cutting, bending, welding, or surface treatment, they have the capabilities to deliver precision-engineered stainless steel sheet metal components with high accuracy and consistency.With a strong emphasis on quality control, the company ensures that each stainless steel sheet metal product undergoes stringent testing and inspection processes to guarantee its reliability and performance. They have a well-established quality management system in place to monitor all stages of production, from raw material sourcing to the final product delivery. This commitment to quality has earned them a reputation for being a trusted and reliable supplier in the industry.In line with their dedication to sustainability, the company also promotes the use of recycled materials in their stainless steel sheet metal production. They recognize the importance of minimizing environmental impact and actively work towards reducing waste and energy consumption in their operations. By implementing eco-friendly practices, they strive to contribute to a cleaner and greener environment while serving the needs of their customers.Furthermore, the company places a strong focus on customer satisfaction by providing responsive and personalized service. Their team is readily available to address inquiries, provide technical support, and offer expert advice to ensure that clients have a seamless experience from initial consultation to product delivery. As a customer-centric organization, they are committed to building long-term partnerships based on trust, reliability, and mutual success.In conclusion, {} is a leading manufacturer and supplier of stainless steel sheet metal products, known for their commitment to quality, innovation, and customer satisfaction. With a comprehensive product range, custom fabrication capabilities, and a focus on sustainability, they continue to set a high standard in the industry. As the demand for stainless steel sheet metal continues to grow, the company remains dedicated to meeting the evolving needs of their clients and contributing to the advancement of various industries.

High-Quality Precision Milling Parts for Various Industries

Milling Parts is a leading multinational corporation that specializes in producing and supplying high-quality mechanical parts for various industries such as automotive, aerospace, medical, and more. The company has a mission to meet the needs of its customers by providing the best products and services possible. Milling Parts has recently announced a significant expansion of its operations, which will enable the company to enhance its production capacity and supply chain efficiency. This expansion includes the construction of a new state-of-the-art plant that will be equipped with advanced technologies to enable the production of more complex and high-quality parts. According to the company officials, this new plant will be the largest Milling Parts production facility, and it will be strategically located to serve both domestic and international customers. The facility will include multiple production lines, quality control and testing facilities, warehouses, and administrative offices. The CEO of Milling Parts stated that this expansion is part of the company's long-term growth strategy, and it reflects the commitment to meeting the increasing demands of its customers. He further added that the company aims to increase its market share and become a key player in the global mechanical parts industry. Milling Parts is known for its innovative and customer-focused approach to business. The company has an experienced team of engineers and technicians who work closely with customers to understand their needs and provide customized solutions. The company also invests heavily in research and development to stay at the forefront of technological advancements in the industry. Milling Parts is committed to ensuring the highest quality standards in all its products and services. The company has implemented a comprehensive quality management system that includes strict adherence to international standards such as ISO 9001 and AS9100. This ensures that all products and services meet or exceed customer expectations and comply with regulatory requirements. Milling Parts has a strong presence in the global market and serves customers in more than 50 countries. The company has established a network of partners and distributors worldwide, which enables it to provide efficient logistics and supply chain services. Milling Parts is also committed to sustainability and operates with a focus on minimizing its environmental impact. The company has implemented various initiatives to reduce energy consumption, waste generation, and carbon emissions. Milling Parts has a positive reputation in the industry, and it has received numerous awards and certifications for its excellence in quality, innovation, and customer service. The company has also been recognized for its role in creating job opportunities and contributing to economic growth in the regions where it operates. The expansion of Milling Parts operations is expected to create additional job opportunities and contribute to the development of the local economy. The company has stated that it will prioritize the recruitment of local talent and provide training and career development opportunities. In conclusion, Milling Parts is a leading mechanical parts manufacturer with a commitment to innovation, quality, and customer service. The company's expansion of operations is a reflection of its long-term growth strategy and commitment to meeting the needs of its customers. The new state-of-the-art plant will enable Milling Parts to enhance production capacity, supply chain efficiency, and become a key player in the global mechanical parts industry.

How to Bend Steel: Tips and Techniques for Shaping Metal

Steel Bending: A Competitive Edge for Steel bending is a critical process in the construction and manufacturing industries. It involves the manipulation of steel into various shapes and forms, providing structural integrity to a wide range of products and projects. In the competitive landscape of steel fabrication, the ability to bend steel with precision and efficiency is a crucial factor that sets companies apart from their rivals. This is where comes in, offering top-notch steel bending services that cater to the needs of its diverse clientele.Established in [], has built a solid reputation as a leading provider of steel bending solutions. With state-of-the-art equipment and a team of highly skilled technicians, the company has the capability to handle a wide range of steel bending projects, from small-scale components to large structural elements. Whether it's for architectural designs, industrial machinery, or construction applications, prides itself on delivering high-quality, custom-tailored bending solutions that meet the specific requirements of its customers.The company's comprehensive approach to steel bending encompasses a variety of techniques, including cold bending, hot bending, and induction bending. These techniques allow for the manipulation of steel with precision and control, ensuring that the end result meets the exact specifications of the customer. Additionally, through the use of advanced computer-aided design (CAD) software, is able to develop accurate bending profiles and simulations, further enhancing the efficiency and accuracy of its bending processes.One of the key differentiators for is its ability to work with a wide range of steel materials, including carbon steel, stainless steel, and alloy steel. This versatility allows the company to cater to the diverse needs of its clients across different industries. Whether it's for a high-strength application that requires alloy steel or a corrosion-resistant solution using stainless steel, has the expertise and resources to deliver bendable steel solutions that meet the highest standards of quality and performance.In addition to its technical capabilities, stands out for its commitment to customer satisfaction and project collaboration. The company takes a consultative approach to understand the unique requirements of each project and works closely with its clients to develop bending solutions that are both functional and cost-effective. By fostering open communication and maintaining a customer-centric focus, builds strong partnerships with its clients, often becoming the go-to provider for their steel bending needs.Furthermore, places a strong emphasis on quality control and efficiency in its operations. The company adheres to stringent quality standards and processes to ensure that every bent steel component meets the highest level of accuracy and consistency. Through continuous improvement initiatives and investment in the latest technologies, strives to optimize its production processes, reduce lead times, and minimize waste, ultimately delivering value to its customers in the form of high-quality, competitively priced bending solutions.Looking ahead, remains committed to staying at the forefront of the steel bending industry by continuously refining its capabilities and expanding its service offerings. The company invests in ongoing training and development for its staff, as well as the latest equipment and technologies, to ensure that it can effectively address the evolving needs of the market. By staying abreast of industry trends and advancements, is well-positioned to continue delivering innovative and reliable steel bending solutions to its clients.In conclusion, is a trusted industry leader in steel bending, offering a comprehensive range of services that cater to the diverse needs of its customers. With its advanced capabilities, commitment to quality, and customer-focused approach, has established itself as a go-to provider for steel bending solutions. As the company continues to grow and innovate, it is poised to maintain its competitive edge and contribute significantly to the success of its clients in the construction and manufacturing sectors.