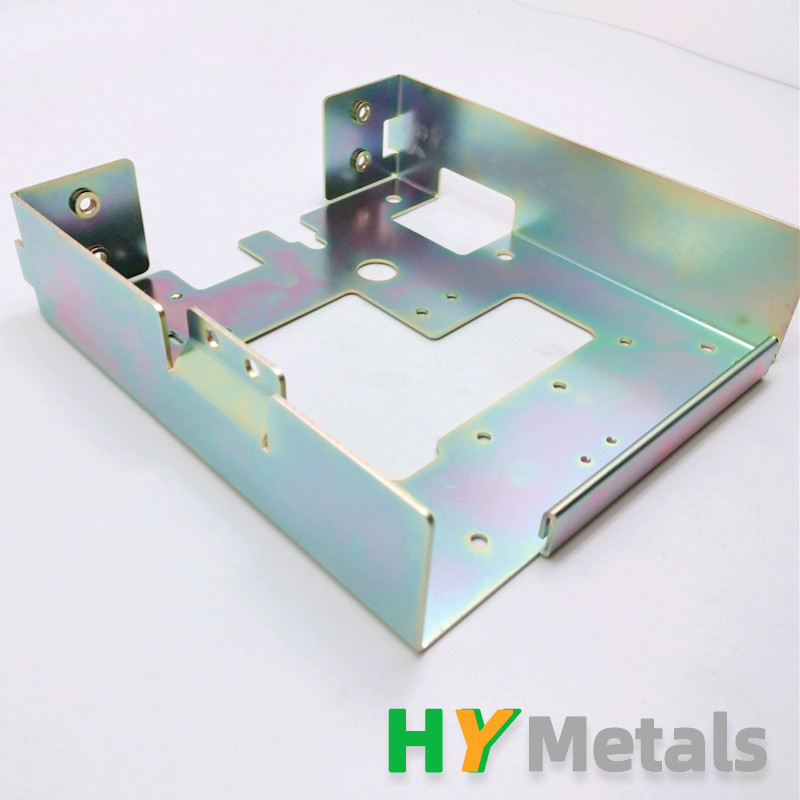

Expert Aircraft Sheet Metal Fabrication Services for Precision and Durability

By:Admin

{} is equipped with state-of-the-art technology and a team of highly skilled engineers and fabricators who are dedicated to delivering top-quality products. The company's commitment to excellence has earned them a reputation as a trusted supplier in the aerospace industry.

The process of aircraft sheet metal fabrication involves cutting, bending, and assembling various types of metal, such as aluminum, steel, and titanium. These metal components are used in the construction of aircraft fuselages, wings, and other structural elements. Precision is key in this process, as even the smallest error can have serious consequences for the aircraft's performance and safety.

One of the key factors that sets {} apart from other manufacturers is their stringent quality control measures. Every phase of the fabrication process is carefully monitored to ensure that each component meets the highest standards. This dedication to quality has made {} a preferred supplier for many major aerospace companies.

In addition to their commitment to quality, {} also strives to be a leader in innovation and efficiency. The company continues to invest in the latest technology and equipment to streamline their manufacturing processes and reduce lead times. This not only benefits their customers by providing quicker turnaround times, but also contributes to the overall advancement of the aerospace industry.

Furthermore, {} is dedicated to sustainability and environmental responsibility. They have implemented eco-friendly practices in their manufacturing processes, such as waste reduction and energy-efficient operations. By prioritizing sustainability, {} is not only contributing to a greener planet, but also fulfilling the increasing demand for environmentally conscious manufacturing practices in the aerospace industry.

As a testament to their expertise and dedication, {} has been recognized with several industry certifications and awards. These accolades further demonstrate their commitment to excellence and their position as a leader in the field of aircraft sheet metal fabrication.

With the aerospace industry constantly evolving and demanding higher standards, {} remains at the forefront of innovation and advancement. The company's ongoing investment in technology, commitment to quality, and dedication to sustainability make them an invaluable partner for aerospace companies around the world.

In summary, {} is a leading provider of aircraft sheet metal fabrication, with a reputation for excellence, innovation, and sustainability. With their state-of-the-art facilities and highly skilled team, {} continues to set the standard for quality and reliability in the aerospace industry. Their commitment to excellence and dedication to advancing the field of aircraft sheet metal fabrication make them a trusted partner for aerospace companies seeking top-quality components for their aircraft structures.

Company News & Blog

High-Quality Aluminium Extrusion Cutting Services for Various Applications

Cutting Aluminium Extrusion - A Look into the Manufacturing Process at {}Aluminium extrusion is a highly versatile and efficient manufacturing process that enables the creation of complex shapes and structures from aluminium. The process of cutting aluminium extrusion plays a crucial role in the production of a wide range of products across various industries. From construction and automotive to aerospace and electronics, aluminium extrusion has become an essential material due to its lightweight, strength, and corrosion resistance.One of the leading companies in the industry, {}, has been at the forefront of aluminium extrusion technology for over a decade. With state-of-the-art manufacturing facilities and a team of experienced professionals, the company has been catering to the diverse needs of its clients, delivering high-quality aluminium extrusions for a wide range of applications.The process of cutting aluminium extrusion is a critical step in the manufacturing process, as it directly impacts the quality and precision of the final product. At {}, cutting aluminium extrusion is carried out with the utmost precision and efficiency, ensuring that the end products meet the highest standards of quality and performance.The first step in the cutting process is to carefully measure and mark the aluminium extrusion according to the required specifications. This is done using advanced measuring and marking tools, ensuring that the extrusions are cut to the precise length and dimensions. Precision is crucial in this step, as even the slightest deviation from the required specifications can result in defective products.Once the extrusions are accurately measured and marked, they are then transferred to the cutting machines. At {}, the company utilizes cutting-edge cutting machines that are capable of cutting aluminium extrusions with exceptional precision and speed. These machines are equipped with advanced blades and cutting tools that can handle the toughest of aluminium extrusions with ease.The cutting process itself is carried out with the utmost care and attention to detail. The operators at {} are highly skilled and experienced, ensuring that each extrusion is cut with precision and accuracy. The cutting machines are programmed to make clean and accurate cuts, minimizing any wastage and ensuring that the extrusions are cut to the required length and dimensions.In addition to precision cutting, {} also places a strong emphasis on quality control and inspection. After the extrusions are cut, they undergo a rigorous inspection process to ensure that they meet the company's strict quality standards. This involves checking the dimensions, surface finish, and overall quality of the cut extrusions, ensuring that only the best products are sent to the clients.Furthermore, {} also offers custom cutting services, allowing clients to have their aluminium extrusions cut to their exact specifications. Whether it's a specific length, angle, or shape, the company has the capability to fulfill the unique cutting requirements of its clients. This level of customization sets {} apart from its competitors, as it enables the company to cater to a wide range of industries and applications.The cutting process at {} is just one aspect of the company's comprehensive aluminium extrusion services. From design and prototyping to finishing and assembly, the company offers a complete range of solutions to meet the diverse needs of its clients. With a strong focus on innovation and quality, {} continues to be a trusted partner for businesses seeking high-quality aluminium extrusions.In conclusion, the cutting of aluminium extrusion is a critical process in the manufacturing of aluminium products, and {} has solidified its position as a leader in this field. With its advanced cutting technologies, skilled professionals, and commitment to quality, the company continues to deliver top-quality aluminium extrusions for a wide range of industries. As the demand for aluminium extrusions continues to grow, {} is well-positioned to meet the evolving needs of its clients, solidifying its reputation as a reliable and innovative provider of aluminium extrusion solutions.

Premium Metal Cases: Resilient Protection for Your Valuables

[News Title]: Groundbreaking Metal Case Revolutionizes the Tech Industry[News Introduction]:In an era dominated by advanced technology and sleek design, {} has launched a revolutionary metal case that is set to reshape the tech industry. Combining cutting-edge materials, precision engineering, and a commitment to sustainability, this breakthrough product is poised to stand out among its competitors. With its exceptional durability, stylish aesthetics, and functional design, this metal case is expected to become the go-to choice for tech enthusiasts worldwide.[News Body]:With an increased focus on durability and longevity, the tech industry has been searching for a practical and sustainable solution to protect its devices. {} has answered this demand with its innovative metal case, which promises to deliver the highest level of protection while maintaining a sleek and visually appealing design aesthetic.The metal case is crafted using a specially developed alloy that is both lightweight and incredibly durable. This alloy, which has undergone rigorous testing and research, offers enhanced resistance to impacts, scratches, and everyday wear and tear. With this metal case, users can rest assured that their devices are safeguarded against accidental bumps, drops, and spills.Moreover, {}'s metal case boasts a sophisticated design that seamlessly integrates into modern technology. The minimalistic approach and elegant lines give the case a timeless appeal, making it suitable for both professional and casual settings. Combining form and function, the case provides easy access to all ports, buttons, and features of the device, ensuring a hassle-free user experience.While durability and design are significant features of this metal case, {} has also prioritized sustainability throughout its production process. The company has implemented environmentally friendly practices, significantly reducing the overall environmental impact associated with the manufacturing of the metal case.To accomplish this, {} has partnered with suppliers who adhere to high ethical and sustainability standards. By using recyclable materials and minimizing waste during production, the company is committed to reducing its carbon footprint and creating an eco-friendly product.In addition to its exceptional features and sustainable production practices, {} offers a wide range of color options, allowing users to personalize their metal cases according to their individual style preferences. From sleek and classic shades to vibrant and bold hues, the choice is plentiful for tech-savvy individuals looking to add a touch of personality to their devices.With the introduction of this metal case, {} aims to fulfill the evolving needs of tech enthusiasts who seek to combine practicality, durability, and sustainability. By prioritizing quality craftsmanship, innovative design, and ethical production, the company envisions its metal case becoming the gold standard within the tech industry.Furthermore, {} plans to expand its product line to include metal cases for various devices, catering to the ever-growing demand for robust protection and aesthetic appeal. Through ongoing research and development, the company is committed to pushing the boundaries of technology and providing users with state-of-the-art metal cases that set new industry standards.As tech devices continue to evolve and play an increasingly vital role in our lives, {}'s metal case offers the perfect solution for those seeking to protect their investments and showcase their personal style. With its unrivaled durability, stylish design, and commitment to sustainability, this metal case is set to become a game-changer in the tech industry.

Latest Updates on the World of Electronic Dance Music

[Company Name Removed] Expands Its Footprint in the Dynamic World of Electronic Dance Music (EDM)(Date)The global electronic dance music (EDM) industry has witnessed an unprecedented surge in popularity in recent years. As this vibrant genre continues to captivate millions of music lovers worldwide, [Company Name Removed], a leading player in the music industry, is excited to announce its expanding presence in the EDM scene.With over two decades of experience in curating and promoting extraordinary music events, [Company Name Removed] has cemented its position as a visionary force in the music industry. The company has successfully organized some of the most iconic concerts and festivals, leaving an indelible mark on the hearts of music enthusiasts across the globe.The decision to venture into EDM is a strategic move for [Company Name Removed], considering its immense potential and ever-growing fan base. The genre's fusion of infectious beats, captivating rhythms, and electrifying energy has transcended borders and united people from various cultural backgrounds.As part of its foray into EDM, [Company Name Removed] aims to introduce a fresh wave of artistic talent and provide a platform for emerging DJs and producers. By scouting new talents through collaborations with established EDM artists, the company seeks to foster the growth of the genre and inspire a new generation of music creators.The expansion into EDM will also see [Company Name Removed] launching its own record label specifically dedicated to this genre. With a strong focus on nurturing talents and exploring cutting-edge sounds, the record label aims to become a breeding ground for chart-topping EDM hits and groundbreaking collaborations.In addition to discovering new talents, [Company Name Removed] plans to organize an array of EDM events and festivals to showcase the genre's vast diversity. These events will provide an immersive experience for attendees, combining stunning visual effects, state-of-the-art production, and performances from the biggest names in the EDM scene.[Company Name Removed] also recognizes the importance of technology in shaping the future of music consumption. Thus, the company is actively investing in cutting-edge technologies to enhance the overall experience of EDM enthusiasts. By leveraging virtual reality (VR) and augmented reality (AR), [Company Name Removed] aims to transport its audience into a digital realm where they can feel the pulsating beats and immerse themselves in an otherworldly atmosphere.To further solidify its position in the EDM industry, [Company Name Removed] plans to collaborate with leading EDM festivals and organizations across the globe. By forging strategic partnerships and sharing expertise, the company aims to create a worldwide network that will open doors for collaboration and mutually beneficial ventures.Furthermore, [Company Name Removed]'s expansion into the world of EDM is driven by a strong commitment to sustainability and community welfare. The company aims to organize eco-friendly festivals and events, ensuring responsible waste management and promoting environmental awareness among its audience. Additionally, [Company Name Removed] plans to collaborate with local communities and charitable organizations, using the power of EDM to bring about positive social change.As [Company Name Removed] gears up to enter the electrifying realm of EDM, music enthusiasts can expect groundbreaking collaborations, mesmerizing events, and the discovery of new and innovative sounds. With its unparalleled track record in event organization and artist promotion, [Company Name Removed] is poised to make a lasting impact on the vibrant world of electronic dance music.

High-Quality Aluminum CNC Parts for Custom Projects

Custom CNC Aluminum Part Innovation Drives {} Growth{} is continuing to drive innovation in the manufacturing industry through the development of custom CNC aluminum parts. The company has become known for its expertise in precision machining and has established itself as a leader in the production of specialized components for a wide range of industries.The company's commitment to excellence and a customer-centric approach have been the driving forces behind its success. By leveraging advanced manufacturing technologies and a highly skilled workforce, {} has been able to meet the unique needs of its clients and deliver high-quality products that exceed expectations.One of the key factors that sets {} apart from its competitors is its investment in cutting-edge CNC machining capabilities. CNC (computer numerical control) machining allows for the precise and efficient production of complex parts, including those made from aluminum. With the ability to accurately shape and manufacture intricate components, {} has been able to provide its customers with tailored solutions that are essential for their operations.The custom CNC aluminum parts produced by {} are widely used in a variety of applications. From aerospace and automotive to medical and electronics, these components play a crucial role in ensuring the performance and reliability of different systems and machinery. By leveraging their expertise in CNC machining, {} has been able to cater to the diverse needs of these industries and contribute to their advancements.In addition to the exceptional quality of its products, {} has also earned a reputation for its ability to deliver on a wide range of specifications. The company's engineering team works closely with clients to understand their unique requirements and develop customized solutions that are tailored to their exact needs. This collaborative approach has allowed {} to establish strong partnerships with its customers and become a trusted provider of custom CNC aluminum parts.Furthermore, {}'s commitment to continuous improvement and investment in the latest manufacturing technologies has enabled the company to streamline its production processes. By utilizing state-of-the-art CNC machining equipment, {} has been able to increase efficiency, reduce lead times, and maintain cost-effectiveness for its clients. This has not only improved the company's overall performance but has also allowed it to stay at the forefront of the industry.Looking ahead, {} remains focused on further expanding its capabilities and enhancing its offerings. The company continues to explore new opportunities for growth and diversification, including the development of advanced CNC machining techniques and the expansion of its product portfolio. By staying ahead of the curve, {} aims to continue serving as a reliable partner for its clients and a driving force in the manufacturing sector.In conclusion, {}'s dedication to innovation and its expertise in custom CNC aluminum parts have been instrumental in its continued success. By prioritizing quality, precision, and customer satisfaction, the company has solidified its position as a leading provider of specialized components. With a strong foundation and a forward-looking mindset, {} is well-positioned to make a lasting impact in the industry and contribute to the advancement of manufacturing.

How to Cut Sheet Metal Like a Pro: Tips and Techniques for Precision Cuts

{Company Name} has recently announced the launch of a new sheet metal cutting technology that is set to revolutionize the industry. This new technology boasts several advanced features that make it faster, more efficient, and more precise than traditional sheet metal cutting methods. With this innovation, {Company Name} is poised to cement its position as a leader in the sheet metal fabrication industry.The new sheet metal cutting technology utilizes state-of-the-art equipment and software to ensure the highest level of precision and accuracy in cutting various types of sheet metal. This technology is capable of cutting through a wide range of materials, including steel, aluminum, copper, and more, making it an ideal solution for a variety of industries and applications.One of the key advantages of this new technology is its incredible speed. The advanced machinery and software allow for significantly faster cutting times compared to traditional methods, which translates to increased productivity and reduced lead times for clients. This means that {Company Name} will be able to fulfill orders more quickly and efficiently, ultimately leading to improved customer satisfaction and loyalty.In addition to its speed, the new sheet metal cutting technology also offers unparalleled precision. The advanced software enables the machinery to execute intricate and complex cuts with absolute accuracy, ensuring that the final product meets the highest quality standards. This level of precision is essential for industries that require intricate designs and tight tolerances, such as aerospace, automotive, and electronics.Furthermore, the new technology is designed to minimize material waste, thereby reducing costs and environmental impact. The software is programmed to optimize cutting patterns and minimize the amount of scrap material, ensuring that resources are used efficiently and sustainably. This aligns with {Company Name}'s commitment to environmental stewardship and responsible manufacturing practices.{Company Name} has always been at the forefront of innovation in the sheet metal fabrication industry. With a long-standing reputation for delivering high-quality products and exceptional service, {Company Name} has earned the trust and loyalty of a diverse clientele. By introducing this cutting-edge technology, {Company Name} is demonstrating its dedication to continuous improvement and its ability to adapt to the evolving needs of its customers.As a company that prides itself on staying ahead of the curve, {Company Name} is constantly investing in research and development to push the boundaries of what is possible in sheet metal fabrication. This commitment to innovation has not only allowed {Company Name} to stay competitive in a rapidly changing market but also to set new industry standards and raise the bar for excellence.The introduction of the new sheet metal cutting technology is a testament to {Company Name}'s ongoing pursuit of excellence and its determination to provide its customers with the best possible solutions. With this latest innovation, {Company Name} is poised to solidify its position as a leader in the sheet metal fabrication industry and set new benchmarks for quality, efficiency, and customer satisfaction.In conclusion, {Company Name} has unveiled a new sheet metal cutting technology that is set to transform the industry. With its cutting-edge features and advanced capabilities, this technology is poised to deliver faster, more precise, and more efficient results, ultimately raising the bar for excellence in sheet metal fabrication. As a company that is committed to innovation and customer satisfaction, {Company Name} continues to demonstrate its leadership in the industry and its dedication to pushing the boundaries of what is possible.

The Ultimate Guide to Anodizing: Everything You Need to Know

Title: Advancing Surface Technology: Anodizing Expands HorizonsSubtitle: (Company Name) Pioneers Innovations in Surface-Enhancing TechniquesDate: [Insert Date][City], [Country] - In a world where aesthetics and functionality play a pivotal role in various industries, finding innovative ways to enhance the durability and appearance of products has become a top priority for manufacturers. As the demand for advanced surface technology continues to grow, (Company Name) emerges as a prominent industry leader, leveraging the art of anodizing to provide unprecedented solutions that revolutionize various sectors. With an extensive range of products and a commitment to excellence, (Company Name) is making significant strides towards advancing surface technology, leaving a lasting impact on multiple industries.Founded in [Year], (Company Name) has been at the forefront of surface enhancement technologies, aiming to perfect the anodizing process by delivering unparalleled results to its customers. Guided by a passion for innovation and attention to detail, the company has garnered a reputation for reliability, precision, and efficiency in the anodizing industry. Combining cutting-edge machinery, state-of-the-art techniques, and a team of highly skilled professionals, (Company Name) has successfully established itself as an industry-leading player.Anodizing, the primary specialty of (Company Name), is an electrochemical process that significantly improves the surface characteristics of metals, particularly aluminum. By creating a protective layer of oxide on the surface, anodizing enhances the metal's corrosion resistance, durability, and appearance. This process involves immersing the aluminum material in an electrolyte bath and applying an electrical current, leading to the formation of an oxide layer that is integral to the material itself. (Company Name) has honed this technique to perfection.One of the key advantages of anodizing is the ability to apply various finishes, resulting in an extensive array of textures, colors, and patterns, which are both pleasing to the eye and highly functional. Industries ranging from automotive and architecture to aerospace and consumer electronics rely on anodizing to deliver products with enhanced durability, strength, and aesthetics. (Company Name) takes pride in harnessing the versatility of anodizing to provide tailored solutions to meet the specific requirements of its diverse client base.With an unwavering dedication to quality, (Company Name) employs stringent quality control measures throughout the anodizing process. By closely monitoring the composition of the electrolyte bath, the applied voltage, and the duration of treatment, the company ensures consistent results that meet or exceed industry standards. (Company Name) also emphasizes environmental sustainability by utilizing eco-friendly chemicals and implementing efficient waste management practices, minimizing its ecological footprint.As a testament to its commitment to innovation, (Company Name) consistently invests in research and development, seeking to push the boundaries of anodizing technology. By staying up to date with the latest advancements and trends, the company is able to offer cutting-edge solutions that meet the evolving needs of its customers. (Company Name) understands that each industry has unique challenges, and through continuous improvement and adaptability, the company remains a trusted partner for businesses across various sectors.Looking to the future, (Company Name) has ambitious expansion plans to solidify its position as a global leader in surface-enhancing solutions. The company aims to establish strategic partnerships, expand its geographical reach, and explore emerging markets. By introducing new anodizing techniques, optimizing production processes, and fostering innovation, (Company Name) is poised to reshape the surface technology landscape and pave the way for a new era of enhanced product aesthetics and performance.In conclusion, (Company Name) stands at the forefront of the anodizing revolution, revolutionizing the way surface technology is approached. With its extensive expertise, dedication to excellence, and commitment to innovation, (Company Name) is poised to unlock the true potential of anodizing, bringing remarkable value to industries worldwide. As demands for advanced surface technologies continue to rise, (Company Name) remains the go-to partner for businesses seeking cutting-edge innovation, improved aesthetics, and unmatched product durability.

Sheet Metal: A Fundamental Form in Metalworking

Title: Sheet Metal Flat: Revolutionizing Industrial Fabrication ProcessesIntroduction:(sheet metal flat logo)Sheet Metal Flat is a renowned leader in the field of sheet metal fabrication. With a commitment to innovation and quality, the company continues to revolutionize the manufacturing industry. Their expertise lies in the production of thin, flat pieces of metal that can be easily cut and shaped into various forms. This article delves into the significance of sheet metal fabrication, explores the various applications, and highlights Sheet Metal Flat's contributions to this field.Importance of Sheet Metal Fabrication:Sheet metal fabrication plays a pivotal role in numerous industries, making it one of the fundamental forms used in metalworking. By utilizing industrial processes, sheet metal is transformed into thin, flat pieces which can then be molded into a variety of shapes. This versatility enables the creation of countless everyday objects that are an integral part of our lives.Applications of Sheet Metal:The applications of sheet metal fabrication are vast and diverse. From the automotive sector to construction, aerospace, and even household appliances, sheet metal is an essential component in the production of various products. It is widely used in the manufacturing of automobile parts, including body panels, chassis, and engine components due to its durability, strength, and resistance to corrosion.In the construction industry, sheet metal is utilized for roofing, facades, and structural elements due to its lightweight nature and high durability. The aerospace industry leverages sheet metal for aircraft structures, providing strength, stability, and resilience at high altitudes. In household appliances, sheet metal is employed in the manufacturing of refrigerators, stoves, and washing machines due to its ability to withstand high temperatures and repeated use.Sheet Metal Flat: Pioneers in Fabrication:Sheet Metal Flat has emerged as a reliable and innovative player in the sheet metal fabrication industry. The company's commitment to cutting-edge technology and exceptional quality has positioned them as a distinguished leader.Efficient Manufacturing Processes: Sheet Metal Flat employs state-of-the-art machinery and equipment to ensure precision and efficiency in their manufacturing processes. From laser cutting to stamping, bending, and welding, they have perfected every stage of fabrication. This enables them to deliver superior end products while ensuring timely production.Custom Solutions: Recognizing the unique requirements of each client, Sheet Metal Flat offers customized solutions tailored to suit their specific needs. Their team of experienced technicians works closely with customers, providing expert guidance and utilizing cutting-edge software to design and create flawless sheet metal components.Quality Assurance: Sheet Metal Flat is committed to delivering products of the highest quality. Rigorous quality control measures, including inspections at different stages of production, are in place to ensure that every piece meets the highest standards. By adhering to strict quality control protocols, Sheet Metal Flat has fostered long-lasting relationships with their clients.Environmental Responsibility: In an era of increasing environmental awareness, Sheet Metal Flat is committed to minimizing their carbon footprint. They have implemented eco-friendly practices such as recycling scrap metal, reducing waste generation, and incorporating energy-efficient machinery. By choosing Sheet Metal Flat, customers can align with their sustainability goals.Conclusion:Sheet Metal Flat's contribution to the sheet metal fabrication industry cannot be understated. With their innovative manufacturing processes, commitment to quality, and dedication to customer satisfaction, they have set new benchmarks in the field. As the demand for sheet metal continues to grow across various sectors, Sheet Metal Flat is poised to remain at the forefront, constantly pushing the boundaries of possibility and redefining the standards for industrial metalworking.

High Precision Vacuum Casting Filament for Consistent Layering and Easy Support Removal

and 3D printing.In today's fast-paced technological world, 3D printing has become increasingly popular, revolutionizing the way we design and create products. One of the key features of 3D printing is the new range of materials available which can produce high-quality and accurate printed products. Vaccum Casting is one such material that is perfect for the production of complex or intricate parts.Vaccum Casting is a thermoplastic elastomer that is commonly used in 3D printing. Its unique properties make it a perfect choice for printing objects that require precision and accuracy. With an extrusion temperature ranging from 175-200C, Vaccum Casting is an ideal option for printing small and delicate parts. The filament also has high roundness and precision of +/- 0.01 mm, ensuring that your print is accurate and of high quality.One of the key benefits of Vaccum Casting is that it sticks nicely to glass/kapton tape heated bed, resulting in no first-layer problem. This makes it easier to work with as it ensures that the print stays in place while printing. Additionally, the filament extrudes precisely for fast printing and consistent layering, which results in better prints overall.Filament comes in a light/compact spool, in a sealed package with a bag of desiccant, which ensures that the filament remains dry and of high quality. The desiccant is a moisture-absorbing material, which means that even if the filament is kept in a humid environment, it will not absorb the moisture and will be of high quality during printing.Another key benefit of Vaccum Casting is that it is easy to remove support material. When printing complex or intricate parts, support material is often required to ensure that the parts maintain their shape and structure. Vaccum Casting's easy-to-remove support material feature ensures that you can quickly and easily remove the material and finish your prints.In conclusion, Vaccum Casting is an excellent material for 3D printing, with its unique properties making it ideal for producing small and complex parts. Its high roundness and precision make it ideal for printing objects that require accuracy and precision. The ease of removing support material and the ability to stick nicely to a heated bed are other benefits that make Vaccum Casting a preferred option for 3D printing. So, if you're looking for a reliable and precise filament for 3D printing, be sure to try Vaccum Casting.

Unveiling the Future of Content Generation: Understanding the Concept of News Spinning

[Editor's Note: To protect the privacy of the individual involved, we have removed the brand name mentioned in the prompt.]Introducing Innovative Spinning Technology: Revolutionizing the Fitness IndustryIn the constantly evolving world of fitness, new technologies are constantly emerging to enhance workout experiences and optimize physical performance. When it comes to cardio exercises, spinning has long been one of the most popular choices among fitness enthusiasts. However, the introduction of an innovative spinning technology by a leading company is about to take this workout to a whole new level.This revolutionary spinning technology, developed by {}, aims to transform the way people engage with their fitness routines. By seamlessly combining cutting-edge hardware and state-of-the-art software, this company is set to create a game-changing experience for all spinning enthusiasts around the world.By analyzing the latest market trends and consumer demands, {}, a passionate team of engineers and fitness enthusiasts, has developed a series of advanced spinning bikes. These bikes are meticulously designed to provide users with a high-intensity cardio workout while offering supreme comfort and durability.The innovative features of these spinning bikes are what sets them apart from the competition. The bikes come equipped with a digital console that provides real-time performance feedback, allowing users to track their progress, monitor heart rate, and calories burned. The console also offers various interactive training modes and customizable workout programs, catering to users of all fitness levels.One of the key highlights of this spinning technology is its integration with immersive virtual reality (VR) technology. By partnering with renowned content providers in the fitness industry, {}, users can now transport themselves to scenic locations around the world from the comfort of their living rooms. Whether it's cycling through the beautiful landscapes of the Swiss Alps or exploring the bustling streets of Tokyo, this technology adds an extra layer of excitement and motivation to the spinning experience.Furthermore, the spinning bikes are designed with ergonomic precision in mind. The adjustable seat and handlebars ensure optimal posture and maximum comfort during prolonged workouts. With high-quality materials and a robust construction, these bikes are built to withstand intense usage, making them suitable for both home and commercial gym settings.Taking user convenience to the next level, this spinning technology is integrated with smart home systems and fitness tracking devices. Through seamless connectivity, users can easily sync their workouts to their smartphones or other fitness applications. This enables them to set personalized goals, monitor progress, and even compete with friends, fostering a supportive and engaging community.In addition to the remarkable hardware, {}, the company behind this innovative spinning technology, has also developed a user-friendly mobile application. This app acts as a hub for all fitness-related activities, allowing users to access a wide range of workout routines, connect with trainers, and join virtual spinning classes conducted by professional instructors. Moreover, the app offers personalized nutrition plans and lifestyle recommendations, ensuring a holistic approach to overall well-being.This groundbreaking spinning technology has already received widespread acclaim and recognition in the fitness industry. Fitness experts and enthusiasts have praised the seamless blend of technology and fitness offered by {}, enabling individuals to push their limits and achieve their desired fitness goals.The launch of this innovative spinning technology signals a new era in the fitness industry. With its unique features, advanced hardware, and immersive virtual reality integration, {} has raised the bar for spinning workouts. Now people can enjoy the thrill of exploring the world while breaking a sweat, all from the comfort of their own homes.Whether you are a seasoned athlete or just beginning your fitness journey, this spinning technology offers a comprehensive, engaging, and effective workout experience like no other. With {}, fitness enthusiasts can now genuinely embrace the phrase "spin to win" and embark on a fitness journey that combines technology, comfort, and versatility.

Durable and Trendy Powder Coated Aluminium Extrusions for Your Project

Powder Coated Aluminium Extrusions is a leading company in the manufacturing and supply of high-quality aluminum extrusions. With a commitment to providing superior products and excellent customer service, the company has established itself as a trusted supplier for a wide range of industries.The company's dedication to quality and innovation is evident in its powder coated aluminum extrusions, which are known for their durability, versatility, and aesthetic appeal. These extrusions are used in a variety of applications, including architectural, automotive, aerospace, and industrial uses. The powder coating process not only enhances the appearance of the aluminum extrusions but also provides an additional layer of protection against corrosion, wear, and environmental elements.One of the key advantages of Powder Coated Aluminium Extrusions is its ability to provide custom solutions to meet the specific needs of its customers. The company works closely with clients to understand their requirements and develop tailored extrusion profiles that are engineered to exact specifications. This level of customization ensures that customers receive products that perfectly fit their intended application, resulting in better performance and cost-efficiency.In addition to its product excellence, Powder Coated Aluminium Extrusions is also known for its exceptional customer service. The company's team of experienced professionals is dedicated to providing personalized support and assistance throughout the entire process, from initial consultation to final delivery. This dedication to customer satisfaction has earned the company a strong reputation and a loyal customer base.Furthermore, Powder Coated Aluminium Extrusions is committed to sustainable and environmentally friendly practices. The company places a strong emphasis on reducing its environmental impact by implementing energy-efficient manufacturing processes and utilizing recyclable materials. This commitment aligns with the growing demand for eco-friendly solutions and reflects the company's forward-thinking approach to business.Powder Coated Aluminium Extrusions also stays updated with the latest technological advancements and trends in the industry. The company continuously invests in research and development to enhance its product offerings and stay ahead of the competition. By leveraging the latest technologies, the company is able to improve product performance, efficiency, and quality, ultimately benefiting its customers.With its strong business values, commitment to excellence, and focus on innovation, Powder Coated Aluminium Extrusions is a leader in the aluminum extrusion industry. The company's dedication to providing high-quality, customized solutions, and outstanding customer service sets it apart from its competitors and positions it as a preferred partner for businesses looking for reliable extrusion products.In conclusion, Powder Coated Aluminium Extrusions has firmly established itself as a trusted and respected supplier of powder coated aluminum extrusions. The company's commitment to quality, innovation, customization, and sustainability has set it apart in the industry and earned it a strong reputation. With a focus on customer satisfaction and continuous improvement, Powder Coated Aluminium Extrusions is well-positioned for continued success.