Exploring Versatile and Efficient Options for Rapid Prototyping

By:Admin

In today's competitive business environment, companies are constantly pushing the boundaries of innovation to stay ahead of the curve. One critical aspect of this innovation is rapid prototyping, which is essential for designing and testing new products. To remain competitive, companies need agile and efficient prototyping services that produce high-quality, functional prototypes at a rapid pace. That's where Rapid Prototyping Options (need to remove brand name) comes in.

Rapid Prototyping Options (RPO) is a leading provider of rapid prototyping services that cater to a diverse range of industries, including aerospace, automotive, medical, and consumer products. With over a decade of experience in the industry, the company has consistently provided high-quality, cost-effective prototyping services that have helped clients accelerate innovation and bring products to market faster.

At the heart of RPO's success is its commitment to using cutting-edge technology and advanced manufacturing techniques in its prototyping services. The company combines traditional manufacturing methods with innovative technologies like 3D printing, CNC machining, and injection molding to produce customized, high-quality prototypes that accurately represent the final product.

RPO's 3D printing capabilities are among the most advanced in the industry. The company leverages a variety of 3D printing technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), to produce accurate, high-resolution prototypes. These prototypes can be made from a variety of materials, including plastic, metal, and even rubber, depending on the client's specific requirements.

Another critical prototyping service offered by RPO is CNC machining. The company's state-of-the-art CNC machines can produce high-quality prototypes from a variety of materials, including metals, plastics, and composites. RPO's CNC machining capabilities allow clients to produce prototypes with precise dimensions and complex geometries, making it an ideal solution for industries like aerospace and automotive, where precision and accuracy are critical.

For larger production runs, RPO offers injection molding services. The company's injection molding capabilities allow clients to produce high-quality, injection-molded parts quickly and efficiently. With RPO's injection molding services, clients can avoid the high startup costs associated with traditional injection molding and quickly produce functional, high-quality parts without sacrificing quality.

One key aspect of RPO's prototyping services that sets it apart from competitors is its focus on customer service. The company's prototyping experts work closely with clients throughout the prototyping process to ensure that their needs are met and their expectations are exceeded. From initial consultations to prototyping design to final production, RPO is committed to providing world-class prototyping services that meet the highest standards of quality, accuracy, and reliability.

RPO's prototyping services have been critical to its clients' success, allowing them to accelerate innovation, refine product designs, and reduce time-to-market. For example, RPO's prototyping services provided critical support to a medical device manufacturer that needed to produce functional prototypes for testing their devices' safety and effectiveness. RPO's 3D printing and CNC machining capabilities enabled the manufacturer to produce accurate, high-quality prototypes quickly and efficiently, helping to reduce product development timelines and costs.

Overall, Rapid Prototyping Options is revolutionizing the prototyping landscape, providing efficient, cost-effective prototyping services that enable companies to innovate at a rapid pace. With a focus on cutting-edge technology, precision, and customer service, RPO is committed to helping companies accelerate innovation, optimize product design, and bring products to market faster. Whether you're in aerospace, automotive, medical, or any other industry, RPO's prototyping services can help you take your innovation to the next level.

Company News & Blog

Fast and Reliable MP3 Downloads for the Best Wet Paint Songs Without Registration

Wet Paint Launches Exciting New Music DownloadsMusic lovers, rejoice! Wet Paint, a leading independent music platform, has just launched a new range of MP3 song downloads that are sure to get you grooving. The new collection features some of the biggest hits by the hottest artists of the moment, giving you access to the top tunes and latest tracks that are taking the music world by storm.Wet Paint has always been a reliable destination for music fans looking to stay on top of the latest trends in pop, rock, hip-hop, electronic, and indie music. The platform offers an extensive library of tracks from local and international artists, spanning a range of styles and genres. Whether you're a fan of classic rock bands, mainstream pop icons, or emerging indie acts, you're sure to find something to suit your musical tastes on Wet Paint.Now, with the launch of the new MP3 song downloads, music lovers will have even more options to explore. The downloads are fast, reliable, and secure, ensuring that you can quickly and conveniently get your hands on the latest tracks without any hassles.To celebrate the launch of the new MP3 downloads, Wet Paint is offering fans a special deal. For a limited time, users can get a discount on downloads by using a promo code provided by the platform. This is a great opportunity for music fans to access some of the hottest new tracks without breaking the bank.Wet Paint is committed to providing fans with a superior music experience, and the new MP3 downloads are just the latest offering in this regard. The platform is continually seeking to improve its service and expand its library, with a focus on offering the best content and features to users.In addition to its extensive collection of music tracks, Wet Paint also offers users a range of other features and resources. These include insightful music news, in-depth interviews with artists, and a lively social community where fans can connect with one another and share their love for music.Overall, the new MP3 downloads from Wet Paint are a welcome addition to the platform's impressive arsenal of music resources. With its focus on quality, variety, and user satisfaction, Wet Paint is quickly becoming one of the most trusted and popular destinations for music fans around the world. Whether you're a long-time fan of the platform or a new user, the new MP3 downloads are sure to offer hours of musical enjoyment and discovery. So what are you waiting for? Head to Wet Paint and start downloading the best tunes of the moment today!

Top Quality Extruded Aluminum Heatsinks for Efficient Heat Dissipation

Extruded Aluminum Heatsink Takes the Heat Away, Making Electronic Devices More EfficientAs the technology develops, electronic devices are becoming more advanced, powerful, and compact, which is great news for consumers who demand more functionality and convenience. However, this trend also poses a challenge for manufacturers who need to dissipate the heat generated by these devices. Without proper cooling, electronic components can overheat and fail, compromising the performance, safety, and reliability of the product. That's where an extruded aluminum heatsink comes into play, providing an effective and efficient way to transfer heat away from electronic devices.An extruded aluminum heatsink is a passive component that is attached to the electronic device to absorb and dissipate the heat generated by it. It works by increasing the surface area available to dissipate heat through the use of fins, which are thin and elongated projections that extend from the heatsink's base. These fins expose more of the heatsink's surface to the surrounding air, increasing the rate of heat transfer by convection. In addition, the heatsink's base is in contact with the heat source, such as a CPU, GPU, or power converter, which conducts the heat away from the source and spreads it out across the heatsink's surface. Finally, the heatsink dissipates the heat into the ambient air, which carries it away from the device.An extruded aluminum heatsink is an ideal solution for many electronic devices because of its low cost, lightweight, and easy customization. It can be designed to fit a specific device or application, with different sizes, shapes, and fin densities to optimize the performance and minimize the size and weight of the heatsink. Moreover, an extruded aluminum heatsink is durable, corrosion-resistant, and can withstand high temperatures, making it suitable for harsh environments and industrial applications.One company that specializes in extruded aluminum heatsinks is (need to remove brand name). Founded in (year), the company has over (number) years of experience in designing and manufacturing heatsinks for various industries, including computer, communication, lighting, transportation, power, and aerospace. (Remove brand name) offers a wide range of heatsink products, from standard extrusions to custom designs, with different materials, finishes, and assembly options.According to (CEO name), (remove brand name)'s CEO, the company's success lies in its commitment to quality, innovation, and customer service. "We take pride in delivering effective and efficient thermal solutions that exceed our customers' expectations," he said. "We use the latest technology and techniques to design and produce heatsinks that meet or exceed industry standards, and we work closely with our customers to understand their needs and provide personalized solutions."Some of (remove brand name)'s recent innovations in extruded aluminum heatsinks include:- Micro-fins: (remove brand name) has developed a new technique for producing micro-fins, which are very thin and closely spaced fins that increase the surface area of the heatsink without adding much weight or volume. Micro-fins are ideal for compact devices that require high performance and low profile, such as laptops, tablets, and smartphones.- Stack-fins: Another technique that (remove brand name) has pioneered is stack-fins, which are multiple sets of fins stacked on top of each other, like a sandwich. Stack-fins can increase the heat transfer rate by up to 50% compared to conventional fins, making them suitable for high-power applications and environments with limited airflow.- Heat-pipes: (remove brand name) has integrated heat-pipes into some of its heatsinks, which are sealed tubes filled with a liquid or gas that absorbs and transfers heat through a phase-change process. Heat-pipes can improve the thermal performance of a heatsink by several times, making it possible to cool even the hottest components.- Surface treatments: (remove brand name) offers a variety of surface treatments for its heatsinks, such as anodizing, painting, powder coating, and polishing, to enhance their aesthetics, corrosion resistance, and thermal conductivity. Surface treatments can also provide additional functions, such as electromagnetic shielding, insulation, and light reflection.With its expertise in extruded aluminum heatsinks and its commitment to innovation and quality, (remove brand name) is poised to meet the challenges of the growing electronics industry and provide reliable and effective thermal solutions to its customers. If you have a thermal management challenge, why not contact (remove brand name) for a consultation and see how they can help you?

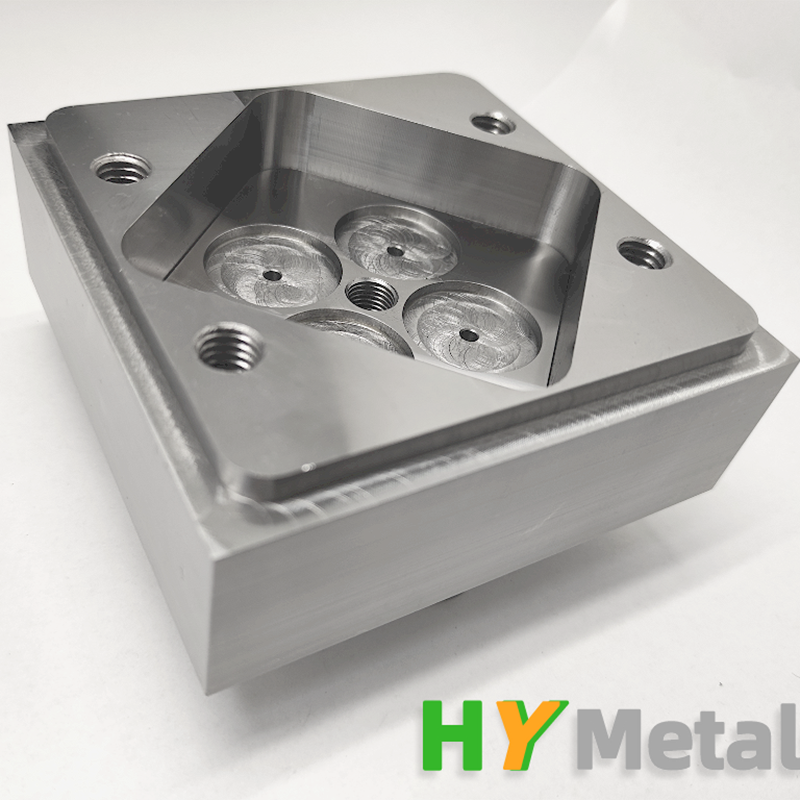

High-Quality Precision Milling Parts for Various Industries

Milling Parts is a leading multinational corporation that specializes in producing and supplying high-quality mechanical parts for various industries such as automotive, aerospace, medical, and more. The company has a mission to meet the needs of its customers by providing the best products and services possible. Milling Parts has recently announced a significant expansion of its operations, which will enable the company to enhance its production capacity and supply chain efficiency. This expansion includes the construction of a new state-of-the-art plant that will be equipped with advanced technologies to enable the production of more complex and high-quality parts. According to the company officials, this new plant will be the largest Milling Parts production facility, and it will be strategically located to serve both domestic and international customers. The facility will include multiple production lines, quality control and testing facilities, warehouses, and administrative offices. The CEO of Milling Parts stated that this expansion is part of the company's long-term growth strategy, and it reflects the commitment to meeting the increasing demands of its customers. He further added that the company aims to increase its market share and become a key player in the global mechanical parts industry. Milling Parts is known for its innovative and customer-focused approach to business. The company has an experienced team of engineers and technicians who work closely with customers to understand their needs and provide customized solutions. The company also invests heavily in research and development to stay at the forefront of technological advancements in the industry. Milling Parts is committed to ensuring the highest quality standards in all its products and services. The company has implemented a comprehensive quality management system that includes strict adherence to international standards such as ISO 9001 and AS9100. This ensures that all products and services meet or exceed customer expectations and comply with regulatory requirements. Milling Parts has a strong presence in the global market and serves customers in more than 50 countries. The company has established a network of partners and distributors worldwide, which enables it to provide efficient logistics and supply chain services. Milling Parts is also committed to sustainability and operates with a focus on minimizing its environmental impact. The company has implemented various initiatives to reduce energy consumption, waste generation, and carbon emissions. Milling Parts has a positive reputation in the industry, and it has received numerous awards and certifications for its excellence in quality, innovation, and customer service. The company has also been recognized for its role in creating job opportunities and contributing to economic growth in the regions where it operates. The expansion of Milling Parts operations is expected to create additional job opportunities and contribute to the development of the local economy. The company has stated that it will prioritize the recruitment of local talent and provide training and career development opportunities. In conclusion, Milling Parts is a leading mechanical parts manufacturer with a commitment to innovation, quality, and customer service. The company's expansion of operations is a reflection of its long-term growth strategy and commitment to meeting the needs of its customers. The new state-of-the-art plant will enable Milling Parts to enhance production capacity, supply chain efficiency, and become a key player in the global mechanical parts industry.

How to Choose Quality Hardware Parts for Your CNC Machine

Title: Industry-leading CNC Hardware Parts Manufacturer Introduces Cutting-edge SolutionsSubtitle: Driving Innovation and Precision with Unmatched Quality and Expertise[date][City, State] - [Company Name], a renowned leader in the CNC hardware parts industry, is proud to introduce its latest range of advanced solutions designed to revolutionize manufacturing processes across various sectors. With their unparalleled quality, precision, and relentless commitment to innovation, the company stands poised to provide customers with cutting-edge solutions that exceed expectations.[Company Name] has consistently upheld the highest standards, establishing itself as a trusted partner for businesses seeking top-quality CNC hardware parts. Leveraging state-of-the-art technology and an experienced team, the company has gained a reputation for delivering flawless performance, durability, and exceptional finish to their parts.Each CNC hardware part produced by [Company Name] undergoes rigorous quality control measures to ensure that they meet or exceed industry standards. Employing advanced software and machinery, the manufacturing process is optimized for precision and efficiency, resulting in parts that perfectly match clients' specifications. The company's commitment to investing in the latest technology guarantees the highest level of accuracy, consistency, and repeatability in every product.One of the key strengths of [Company Name] lies in its ability to tailor solutions to meet the unique needs of clients in diverse industries. Whether it is automotive, aerospace, electronics, medical, or any other industry requiring intricate parts, the company's expertise and flexibility enable them to deliver superior results. By collaborating closely with its clients, [Company Name] gains deeper insights into their specific requirements, ensuring a seamless integration of customized CNC hardware parts into their manufacturing processes.With the recognition that sustainability and environmental responsibility are paramount, [Company Name] places a strong emphasis on sustainable practices across its operations. The company follows strict guidelines to minimize waste, maximize energy efficiency, and reduce its overall carbon footprint. Their dedication to green manufacturing practices is exemplified by the utilization of eco-friendly materials as well as the implementation of recycling initiatives within their production facilities.Furthermore, [Company Name] boasts an exceptional team of highly skilled and knowledgeable professionals who are committed to delivering excellence. The company fosters an environment that encourages continuous learning and growth, ensuring that its workforce remains at the forefront of the industry's latest developments. This dedication to ongoing improvement enables [Company Name] to anticipate and meet the evolving needs of their clients, as well as maintain the company's position as a market leader.In an effort to expand their reach and increase accessibility to their products, [Company Name] offers efficient global shipping services. This allows businesses from around the world to benefit from their exceptional CNC hardware parts, further solidifying the company's position as a trusted international supplier.As [Company Name] continues to grow, their commitment to providing exceptional customer service remains unwavering. The company prides itself on building strong and long-lasting relationships with clients, guiding them at every step of the process - from initial inquiry through to post-purchase support. By offering comprehensive technical assistance and efficient after-sales service, [Company Name] ensures that customers receive a seamless experience and complete satisfaction with their products.In conclusion, [Company Name], a leading CNC hardware parts manufacturer, is revolutionizing the industry through their commitment to quality, precision, and innovation. With a focus on customization, sustainability, and exceptional customer support, the company is trusted by businesses around the world to provide cutting-edge solutions. As they continue to push the boundaries of technological advancements, [Company Name] leads the way in driving the future of CNC hardware parts manufacturing.For more information about [Company Name] and their range of CNC hardware parts, please visit their website or contact their knowledgeable team directly.About [Company Name]:[Company Name] is an industry-leading manufacturer specializing in CNC hardware parts. With years of expertise, advanced technology, and a commitment to innovation, the company delivers unmatched quality, precision, and customization to meet the unique needs of clients across various industries. Their dedication to sustainability, exceptional customer service, and global accessibility sets them apart as the go-to provider of cutting-edge CNC hardware parts.

Get the Best Wire Forming Machines for Sale in Melbourne - Top-notch Jigs and Templates Available!

Wire forming is a process that involves the shaping and molding of metal wires into different shapes. This process is used in a variety of industries from manufacturing to construction, and it plays an important role in the production of many different products. In this blog post, we will explore wire forming and why it's an essential process in many industries.Wire forming machinesWire forming machines are a critical tool in the wire forming process. These machines are designed to produce wire forms quickly and efficiently with precision. There are several types of wire forming machines available, including hydraulic and mechanical machines. These machines are capable of forming a range of materials, including brass, aluminum, and steel.The best wire forming machines should be easy to use, have precision controls, and offer versatility. They should also have a compact construction, making them suitable for use in small manufacturing facilities. Additionally, they should be built with durable materials that can withstand the constant wear and tear of the manufacturing process.In addition to wire forming machines, jigs and templates are commonly used in the wire forming process. These tools offer consistent and accurate wire forming results, which can increase production efficiency. They also help maintain product conformity, which is essential in industries where safety and quality are major concerns.Wire forming applicationsWire forming is a versatile process that can be used to create a vast array of products. Some of the most common applications of wire forming include:- Springs- Hooks- Wire baskets- Shelving- Clips- Hangers- Wire formsWire forming is also used in the creation of more complex products, such as automotive parts, medical devices, and electrical components. Wire forming is an important process that contributes to the safety, durability, and functionality of many everyday products.Finding a wire forming providerWhen selecting a wire forming provider, it's essential to consider several factors. Firstly, you should evaluate the provider's experience in wire forming and their track record in producing quality products. A provider that has been in the wire forming industry for many years will have a wealth of knowledge and experience. They will also have a proven track record of producing high-quality wire forms.Secondly, you should consider the provider's equipment and manufacturing facilities. Do they use the latest wire forming technology? Do they have the capacity to produce large volumes of wire forms? Choosing a provider with modern equipment and state-of-the-art facilities can help ensure that your wire forms are produced efficiently and accurately.Finally, you should consider the provider's customer service. Are they responsive and easy to work with? Do they offer technical support and guidance throughout the wire forming process? A wire forming provider with excellent customer service can make a significant difference in the success of your project.ConclusionWire forming is a crucial process in many industries, from manufacturing to construction. It allows manufacturers to create complex wire forms for use in a variety of different applications. Choosing the right wire forming provider is essential to ensure that your wire forms are produced accurately, efficiently, and to meet your specific needs. When selecting a wire forming provider, consider their experience, equipment, facilities, and customer service to ensure that you receive high-quality wire forms that meet your expectations.

Custom Aluminium Extrusions for Your Specific Needs

In today's fast-paced and continuously developing modern world, businesses have to keep up with the growing needs of their clientele. One way to do that is through offering customized products, tailored to meet the specific requirements of the customer. Avocet Precision Metals has taken up that challenge, offering aluminum extrusion services that cater to the unique needs of the client.Avocet Precision Metals is a premier metals manufacturing company, located in the United Kingdom, known for its dedication to providing high-quality metal products and exceptional customer service. The firm utilizes cutting-edge technologies and equipment to provide unmatched precision in producing aluminum extrusions that meet the highest industry standards. With a workforce of highly skilled and experienced professionals well-versed in the latest practices of the extrusion industry, Avocet Precision Metals delivers results that surpass expectations.At its core, aluminum extrusion is a process by which manufacturers create complex shapes by forcing aluminum through a shaped opening. This process allows for customization of aluminum products to meet the exact specifications of clients. Avocet Precision Metals recognizes the importance of this process, making sure that all products conform to the customer's design, ensuring that products are manufactured to the highest quality standards.The company utilizes both hard and soft alloys of aluminum to match the specific requirements of the client. If the customer requires a particular combination of strength, corrosion resistance, and lightness, Avocet Precision Metals can deliver precisely what is needed. The company's aluminum extrusion services are highly versatile and can be used in a wide range of applications, including automotive, construction, machinery and much more.Avocet Precision Metals prides themselves in employing best practices, and quality measures to deliver the best customer experience. The company ensures that all the aluminum extrusion products are produced in an environmentally sustainable manner. The manufacturing process is regulated to ensure that it is as green as possible, minimizing the impact on the environment while ensuring that the customer receives high-quality products. Additionally, the company takes its customers' safety seriously and has worked hard to develop and implement safety and environmental protection policies.The high quality of the products that Avocet Precision Metals delivers is made possible by the company's continued investment in modern technology. This significantly reduces the production lead times and guarantees that the products are at the highest level of precision and quality. The company has installed cutting-edge CNC machines and presses that enable the team to manufacture high volumes of aluminum extrusions while reducing waste and maximizing efficiency.Avocet Precision Metals recognizes that customers have different budgets, and the company is always willing to work with clients to find a solution that works best for them. The company is committed to funding a team that supports its customers even after the sale is completed. They have an expert team of professionals on standby, ready to offer guidance and answer any queries that may arise.As a leading player in the aluminum extrusion industry, Avocet Precision Metals is continuously innovating and improving its processes to ensure they stay ahead of the competition. This continuous improvement mindset ensures that the company remains relevant in a market that is constantly changing. The firm's commitment to providing customers with the highest quality products and services has earned Avocet Precision Metals an excellent reputation among its customers and industry peers.In summary, Avocet Precision Metals is a top-tier manufacturer of aluminum extrusions that delivers high-quality and customized products according to clients' specifications. They are a company that prioritizes customer satisfaction and has invested in cutting-edge technology, skilled personnel, while staying environmentally conscious. These steps have enabled them to deliver on their promises while expanding their clientele base, and solidifying its position as a leading industry player.

Production-Grade 3D Printer Enables MTConnect Integration for Aerospace and Industrial Applications

, F900 3D printer, production applications, aerospace industry, MTConnect protocol.Additive manufacturing has revolutionized the manufacturing industry with the ability to create complex geometries with high precision and speed. One of the leading players in the additive manufacturing market is the F900 3D printer, designed for production applications in the aerospace industry and other high-performance industries. This blog discusses the latest development in the F900 3D printer, which now features an MTConnect-ready interface, offering enhanced connectivity and data exchange capabilities.The F900 3D printer is known for its high-performance capabilities, reliability, and large-scale printing. The printer uses the Fused Deposition Modeling (FDM) technology, which involves building 3D models layer by layer by depositing material in a melted state. The FDM technology provides a high degree of design flexibility, allowing the production of complex geometries without the need for additional machining or assembly processes.The F900 3D printer has been widely used in the aerospace industry for the production of complex parts, such as ducting, brackets, and housings. These parts require high precision and accuracy, and the F900 has proven to be a reliable and cost-effective solution for their manufacturing. Additionally, the F900 has been used in other industries, such as automotive, defense, and medical, where the demand for high-performance parts is also high.The latest development in the F900 3D printer is its integration with the MTConnect protocol. MTConnect is an open-source communication protocol used in manufacturing equipment to facilitate data exchange and collection. The protocol offers a standardized way of communicating machine data, making it easier to integrate different systems and devices.With its MTConnect-ready interface, the F900 3D printer can now connect to other manufacturing systems, such as Enterprise Resource Planning (ERP) systems, Manufacturing Execution Systems (MES), and other machines in the production line. This enables better coordination between different manufacturing processes, leading to higher efficiency and productivity. Additionally, the MTConnect protocol allows for real-time monitoring of the printing process, giving operators better control and visibility over the manufacturing process.The integration of the MTConnect protocol into the F900 3D printer is a significant step towards enhancing the connectivity and data sharing capabilities of the printer. This development enables the printer to be integrated into a broader manufacturing ecosystem, allowing for seamless data exchange and coordination between different systems. This integration is highly relevant in the aerospace industry, where the demand for high-performance parts is only increasing.In conclusion, the F900 3D printer is a high-performance system designed for production applications in the aerospace industry and other high-performance industries. With its latest development, the integration of the MTConnect protocol, the printer now offers enhanced connectivity and data exchange capabilities, making it easier to integrate into a broader manufacturing ecosystem. This development ensures the F900 3D printer remains one of the leading additive manufacturing systems in the market today.

New Study Finds Metal Frames Are More Durable than Plastic for Glasses

article.Metal Frames - A Strong and Reliable Solution for Your Home As a homeowner, ensuring the safety and security of your family is a top priority. Furniture and fittings play a pivotal role in making your home safe and comfortable for living. Among the many types of furniture, metal frames stand out as a strong and reliable solution for your home.At Metal Frames (brand name removed), we offer a range of metal furniture that cater to a variety of needs. Our metal frames are durable, stylish, and versatile, and can be used for different settings, from dining rooms to bedrooms. Metal frames come with many benefits. Firstly, they can withstand wear and tear better than other materials. Metal is a strong and sturdy material, making it an ideal choice for furniture that needs to withstand daily use. This means they are not only durable but also require less maintenance in the long run. Secondly, metal frames offer excellent support and stability. They can support more weight than other materials, about four to five times more than wood or plastic. This makes them an ideal choice for furniture that demands more strength, such as bed frames. Additionally, metal frames come in a variety of finishes - from high-gloss polished metal to brushed steel - that can match any home interior design. This not only ensures the strength of the piece, but also adds a sleek and elegant touch to the home.At Metal Frames (brand name removed), our metal frames are crafted with precision and care. Our skilled craftsmen use high-quality material and advanced techniques to create furniture that is both functional and beautiful. Using top-grade metals, we ensure that each product is strong and long-lasting. Metal Frames offers a range of products, from bed frames to dining chairs, all made with a commitment to quality and function. Our bed frames feature robust and intricate designs that can take on more weight without compromising on comfort. They are easy to assemble and maintain, making them an excellent investment in the long run.Our dining chairs are a must-have for your next dinner party or family gathering. Available in different styles, they are comfortable, long-lasting, and stylish. They require minimal maintenance and can be customized to fit your unique needs. With considerable experience in the market, we understand the demands of the consumers and strive to provide high-quality products that cater to their needs. We use a customer-centric approach, ensuring that our products align with customer requirements. Our commitment to quality and customer satisfaction has earned us a loyal customer base. We are continuously growing and improving as a company, and we are dedicated to providing high-quality metal furniture for years to come. In conclusion, metal frames offer an ideal solution for those seeking durable and stylish furniture that can withstand daily use. At Metal Frames (brand name removed), we provide a range of products with a commitment to quality and function, crafted with precision and care. Our metal furniture is sturdy, easy to assemble, and customizable to meet your needs. Whether you need a bed frame or a dining chair, Metal Frames has you covered. Visit our website today to shop our high-quality metal furniture and to discover why we are a top choice for many homeowners.

High-Quality Fuschia Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing

In recent years, the demand for synthetic leather has increased rapidly worldwide. Synthetic leather has become a popular material choice for a variety of industries such as fashion, automotive, furniture, and sports equipment, among others. This is because synthetic leather offers many benefits such as durability, versatility, and cost-effectiveness. In China, one of the leading synthetic leather manufacturers is (brand name removed).One of their most innovative synthetic leather products is their Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing in Fuschia Color. This particular product is made of high-quality material and has a sleek and smooth finish which makes it perfect for use in products like high-end fashion items, bags, and accessories. This synthetic leather has a suede fabric backing which provides the added benefit of breathability and comfort. This feature makes it a suitable option for footwear, soles, and insoles.China has become a hub for synthetic leather manufacturing, and (brand name removed) leads the way in developing innovative and high-quality synthetic leather products. They use advanced technology and equipment to produce synthetic leather that meets the highest standards of quality and performance. As a result, they have become one of the most sought-after synthetic leather suppliers in China, and their products are exported to various countries around the world.The Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing in Fuschia Color is not only a quality product, but it is also offered at an affordable synthetic leather price. (brand name removed) provides their clients with competitive synthetic leather prices while maintaining the highest quality standards for their products. This has led to increased demand for their products from both local and international markets.Apart from providing quality products at affordable synthetic leather prices, (brand name removed) is also committed to environmental protection. They use water-based technology during the production of their synthetic leather products, which significantly reduces the amount of harmful chemicals released into the environment. The water-based technology also produces less waste material, which reduces waste disposal costs and carbon footprint.In conclusion, the demand for synthetic leather is growing rapidly, and China is at the forefront of synthetic leather manufacturing. (brand name removed) is a leading supplier of synthetic leather in China, and their Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing in Fuschia Color is a high-quality product that is popular in various industries. Their commitment to using environmentally friendly technology and providing affordable synthetic leather prices has made them a preferred choice among their clients. For those looking to purchase high-quality synthetic leather products, (brand name removed) is a reliable and trusted supplier.

Breakthroughs in Models and Prototypes Unveiled - Learn More Here!

[Company Name] Unveils Cutting-edge Models and Prototypes, Revolutionizing the Industry[City, Date] - [Company Name], a renowned industry leader in innovation and technological advancements, has recently unveiled a range of groundbreaking models and prototypes, poised to redefine the landscape of the industry. With a commitment to pushing the boundaries of what is possible, the company aims to revolutionize various sectors by delivering cutting-edge solutions that cater to the evolving needs of consumers worldwide.At the heart of [Company Name]'s success lies a dedicated team of experts, collaborating to develop breakthrough technologies and design state-of-the-art prototypes. By leveraging their extensive knowledge and expertise, our engineers and designers have crafted a series of innovative models that showcase the company's commitment to pushing the frontiers of possibility.Among the standout models in [Company Name]'s latest lineup is the cutting-edge [Model Name]. Built with precision engineering and incorporating the latest advancements in materials science, [Model Name] boasts unparalleled performance and versatility. With its sleek design and intuitive user interface, this model revolutionizes the way individuals interact with technology, making everyday tasks simpler and more efficient.Another highlight of [Company Name]'s innovative range is the revolutionary [Model Name]. Developed to address the growing demands of the modern workforce, [Model Name] combines powerful computing capabilities with a lightweight form factor, enabling professionals to work effortlessly on the go. Equipped with advanced processors and seamless connectivity options, it represents a paradigm shift in the world of portable computing.[Company Name] has also taken significant strides in the realm of sustainable transportation with the introduction of the game-changing [Model Name]. This all-electric vehicle sets a new standard in terms of energy efficiency and environmental friendliness. With an extended driving range, fast charging capabilities, and unparalleled comfort, [Model Name] aims to accelerate the global transition to sustainable transportation, promoting a greener and more sustainable future.In addition to its groundbreaking models, [Company Name] is proud to showcase its range of cutting-edge prototypes, which offer a glimpse into the future of various industries. From advanced robotics and automation to immersive virtual reality experiences, these prototypes highlight [Company Name]'s tireless pursuit of innovation.Commenting on the recent product launch, [Company Name]'s CEO stated, "We are thrilled to introduce our latest models and prototypes, which epitomize our commitment to delivering cutting-edge solutions that transform industries and enhance the lives of consumers worldwide. Our team has worked tirelessly to push the boundaries of innovation, and we are proud to see their hard work culminate in these groundbreaking products."With its unwavering focus on innovation and a relentless drive to redefine industry standards, [Company Name] continues to cement its position as a global leader in technological advancements. With its range of exceptional models and game-changing prototypes, it is poised to reshape various industries and cater to the ever-evolving needs of consumers.About [Company Name]:[Company Name] is a renowned industry leader in innovation, known for its unwavering commitment to pushing the boundaries of what is possible. With a team of experts dedicated to developing breakthrough technologies, [Company Name] aims to revolutionize various sectors by delivering cutting-edge solutions that cater to the evolving needs of consumers worldwide.