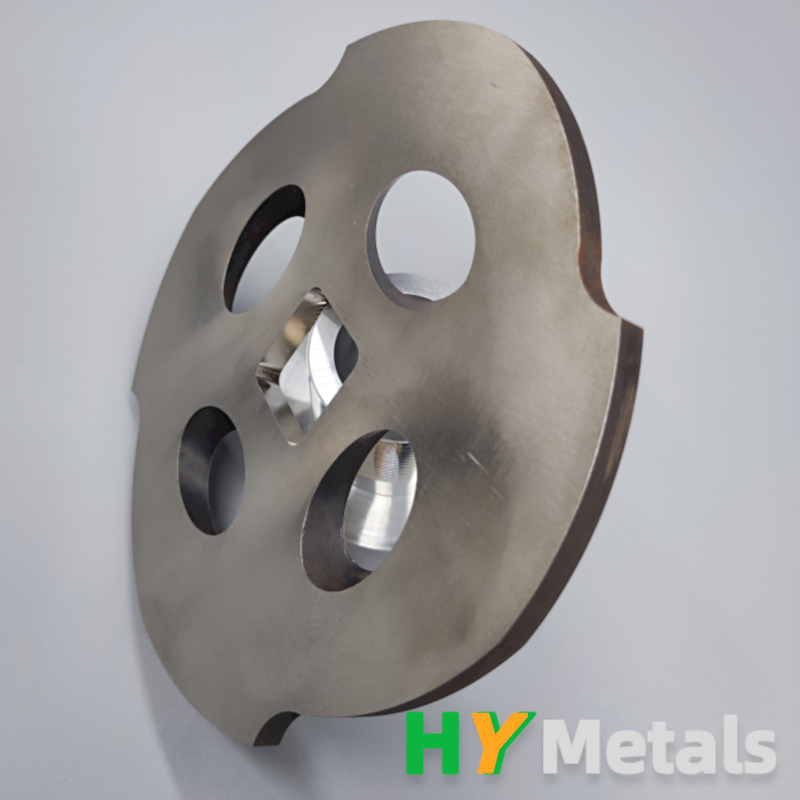

High Quality Sheet Metal Prototype Parts for Your Products

By:Admin

With state-of-the-art equipment and a team of skilled technicians, the company is able to produce prototype parts with exceptional accuracy and craftsmanship. Whether it's a custom design or a standard part, they have the expertise to deliver results that meet the highest industry standards.

The company's commitment to quality is evident in every aspect of their operation. From the selection of materials to the final finishing touches, their team takes pride in their work and strives to exceed customer expectations. This dedication to excellence has made them a trusted partner for businesses in a variety of sectors, including aerospace, automotive, electronics, and more.

In addition to their focus on quality, the company is also dedicated to providing exceptional customer service. Their team works closely with clients to understand their specific needs and ensure that the final product meets or exceeds their requirements. This approach has earned them a loyal customer base and a reputation for reliability and professionalism.

One of the company's key strengths is their ability to provide fast turnaround times without compromising on quality. Their streamlined production process and efficient workflow allow them to complete projects quickly and efficiently, helping clients meet tight deadlines and stay on schedule.

Furthermore, the company is constantly investing in new technologies and techniques to stay at the forefront of the industry. They understand the importance of staying ahead of the curve and are committed to keeping up with the latest advancements in sheet metal fabrication.

The company's dedication to innovation and excellence has earned them numerous accolades and certifications. They are proud to hold various industry certifications, including ISO [insert number] and [other relevant certifications]. These achievements serve as a testament to their ongoing commitment to quality and continuous improvement.

The company's impressive track record of success is a testament to their expertise and dedication to excellence. They have earned the trust and loyalty of countless clients by consistently delivering top-quality sheet metal prototype parts that meet their exacting standards.

Moving forward, the company is poised for continued growth and success. They are fully committed to maintaining their position as a leader in the industry and will continue to invest in their people, processes, and technologies to ensure that they remain at the forefront of sheet metal fabrication for years to come.

In conclusion, the company's dedication to precision, quality, and customer satisfaction sets them apart as a leader in the field of sheet metal prototype parts. With a proven track record of success and a commitment to ongoing innovation, they are well-positioned for continued growth and are a trusted partner for businesses in a variety of industries.

Company News & Blog

Top Auto Parts to Enhance Your Vehicle's Performance

Title: Transforming the Automotive Industry: Auto Parts Company Revolutionizes Vehicle PerformanceIntroduction:Innovation is the driving force behind the thriving automotive industry, constantly pushing the boundaries of technology and challenging conventional practices. Auto Parts, a leading player in the market, has emerged as a trailblazer, revolutionizing the way vehicles perform. With their cutting-edge solutions and commitment to excellence, Auto Parts continues to impress both consumers and industry experts alike.Body:1. History and Accomplishments:Auto Parts, founded in {year}, has garnered a stellar reputation for providing high-quality automotive components over the years. Their commitment to innovation and superior performance has set them apart from their competitors, propelling them to the forefront of the industry. With a strong focus on research and development, Auto Parts has consistently introduced groundbreaking technologies to enhance vehicle performance, reliability, and safety.2. Industry-Leading Research and Development:By investing heavily in research and development, Auto Parts has been able to set new benchmarks in the automotive industry. Their state-of-the-art facilities and dedicated team of engineers and scientists continually strive to improve existing products and develop new, game-changing solutions. This commitment to innovation has resulted in the introduction of several disruptive technologies that have transformed the automotive landscape.3. Advanced Material Science:One of the key areas where Auto Parts excels is in the field of advanced material science. They have developed proprietary materials that offer unparalleled strength, durability, and lightweight properties. These materials enhance the performance of various automotive components, such as engine parts, suspension systems, and exhaust systems, leading to improved fuel efficiency, reduced emissions, and enhanced overall vehicle performance.4. Transformative Fuel Efficiency Solutions:Auto Parts has pioneered numerous fuel efficiency solutions that have significantly reduced the carbon footprint of vehicles. Their advanced fuel injection systems and engine management technologies have not only boosted performance but have also optimized fuel consumption. By harnessing the power of cutting-edge electronics, Auto Parts has played a pivotal role in achieving higher mileage and reducing harmful emissions.5. Safety Innovations:Safety is a top priority in the automotive industry, and Auto Parts has continually developed groundbreaking technologies to enhance vehicle safety. They have introduced advanced braking systems, collision avoidance systems, and sensor technologies that provide drivers with an added layer of protection on the road. These safety innovations have not only helped to prevent accidents but have also contributed to saving countless lives.6. Commitment to Sustainability:Auto Parts understands the importance of environmental sustainability and has taken significant steps to reduce their ecological impact. They have implemented eco-friendly manufacturing processes, reducing waste generation and improving energy efficiency. Auto Parts also actively collaborates with other industry partners and regulatory bodies to develop greener solutions and promote sustainable practices across the automotive sector.7. Global Presence and Recognition:Auto Parts has successfully established a global presence, catering to a diverse range of markets. Their commitment to excellence and relentless pursuit of innovation has earned them widespread recognition within the industry. The company has received numerous accolades, including multiple awards for product excellence and sustainability initiatives. Their products are trusted by leading automotive manufacturers worldwide, making Auto Parts a preferred choice in the market.Conclusion:Auto Parts' unwavering dedication to innovation has set new industry standards, transforming the automotive landscape. With their trailblazing research and development efforts, advanced material science, fuel efficiency solutions, safety innovations, and commitment to sustainability, Auto Parts continues to make its mark in the industry. As vehicles become smarter, greener, and safer, Auto Parts remains at the forefront, driving the future of automotive excellence.

Top Tips for Rapid Die And Molding in Manufacturing Industry

Rapid Die And Molding, a leading manufacturing company in the injection molding industry, has made significant advancements in their production processes to meet the growing demand for high-quality plastic parts.Established in 1998, Rapid Die And Molding has been at the forefront of innovation and technological advancements in injection molding. Since its inception, the company has continuously invested in state-of-the-art equipment, cutting-edge technology, and highly skilled employees to ensure the highest level of quality and efficiency in their manufacturing processes.With a strong emphasis on continuous improvement, Rapid Die And Molding has developed a reputation for delivering precision-engineered plastic parts to a wide range of industries, including automotive, aerospace, medical devices, and consumer goods.The company's commitment to excellence is evident in their dedication to providing exceptional customer service, innovative solutions, and a relentless pursuit of perfection in every aspect of their operations.Rapid Die And Molding recently announced a series of upgrades to their production facilities, including the acquisition of new injection molding machines with advanced automation capabilities. These state-of-the-art machines have significantly increased the company's production capacity, allowing them to fulfill larger orders with shorter lead times while maintaining the highest level of quality and consistency.Furthermore, Rapid Die And Molding has implemented the latest software for process monitoring and quality control, enabling real-time data analysis and predictive maintenance to minimize downtime and maximize efficiency. These technological advancements have resulted in improved product quality, reduced waste, and enhanced overall productivity.In addition to their investment in equipment and technology, Rapid Die And Molding has also focused on the development of their workforce. The company regularly provides specialized training and development programs for their employees, ensuring that they are equipped with the most up-to-date knowledge and skills to operate the new equipment and deliver the best results.Furthermore, Rapid Die And Molding places a strong emphasis on sustainability and environmental responsibility. The company has implemented eco-friendly manufacturing practices and continuously seeks ways to minimize their environmental impact through recycling and waste reduction initiatives.As a result of these investments and initiatives, Rapid Die And Molding has successfully elevated its position as a leading provider of precision plastic parts in the industry. The company's dedication to innovation and excellence has earned them a stellar reputation among their clients and partners, solidifying their position as a go-to partner for all injection molding needs.With their enhanced production capabilities and unwavering commitment to quality, Rapid Die And Molding is poised to continue its trajectory of growth and success in the injection molding industry. Their relentless pursuit of excellence, coupled with their investment in state-of-the-art technology and skilled workforce, sets them apart as an industry leader and ensures they remain at the forefront of innovation for years to come.

Durable Stainless Steel Sheet Metal for Various Applications

Stainless Steel Sheet Metal is a popular material in the manufacturing industry due to its durability and versatility. It is widely used in various applications such as construction, automotive, and appliances. Its corrosion-resistant properties and high strength make it an ideal choice for many applications. With the constantly growing demand for stainless steel sheet metal, companies are continuously striving to improve their production processes to meet the market needs.One such company excelling in the production of stainless steel sheet metal is {}. With years of experience in the industry, they have become a leading manufacturer and supplier of high-quality stainless steel sheet metal products. Their state-of-the-art facilities and skilled workforce enable them to produce a wide range of stainless steel sheet metal products to meet the diverse needs of their clients.The company offers a variety of stainless steel sheet metal products in different grades, sizes, and finishes to cater to various industry requirements. Whether it is for architectural purposes, food processing equipment, or industrial machinery, they have the expertise to provide the right stainless steel sheet metal solutions. The company is committed to delivering superior quality products that meet international standards and exceed customer expectations.In addition to their extensive product range, the company also offers custom fabrication services to meet specific customer requirements. Their team of experienced engineers and technicians work closely with clients to understand their needs and provide tailored solutions. Whether it is cutting, bending, welding, or surface treatment, they have the capabilities to deliver precision-engineered stainless steel sheet metal components with high accuracy and consistency.With a strong emphasis on quality control, the company ensures that each stainless steel sheet metal product undergoes stringent testing and inspection processes to guarantee its reliability and performance. They have a well-established quality management system in place to monitor all stages of production, from raw material sourcing to the final product delivery. This commitment to quality has earned them a reputation for being a trusted and reliable supplier in the industry.In line with their dedication to sustainability, the company also promotes the use of recycled materials in their stainless steel sheet metal production. They recognize the importance of minimizing environmental impact and actively work towards reducing waste and energy consumption in their operations. By implementing eco-friendly practices, they strive to contribute to a cleaner and greener environment while serving the needs of their customers.Furthermore, the company places a strong focus on customer satisfaction by providing responsive and personalized service. Their team is readily available to address inquiries, provide technical support, and offer expert advice to ensure that clients have a seamless experience from initial consultation to product delivery. As a customer-centric organization, they are committed to building long-term partnerships based on trust, reliability, and mutual success.In conclusion, {} is a leading manufacturer and supplier of stainless steel sheet metal products, known for their commitment to quality, innovation, and customer satisfaction. With a comprehensive product range, custom fabrication capabilities, and a focus on sustainability, they continue to set a high standard in the industry. As the demand for stainless steel sheet metal continues to grow, the company remains dedicated to meeting the evolving needs of their clients and contributing to the advancement of various industries.

High-quality Turning Parts for Industrial Machinery at Competitive Prices

Turning Parts is a leading manufacturer of precision components serving a variety of industries, including automotive, aerospace, and medical. The company specializes in the production of high-quality turning parts that are essential for the functioning of mechanical systems in various applications.Founded in 1985, Turning Parts has established itself as a trusted provider of precision components for a wide range of industries. With a dedicated team of experienced engineers and a state-of-the-art manufacturing facility, the company has the capability to produce turning parts with tight tolerances and complex geometries to meet the specific requirements of its customers.The company's dedication to quality and precision has earned it a reputation for excellence in the industry. Turning Parts is committed to investing in the latest technology and equipment to ensure that it remains at the forefront of innovation and can provide its customers with the highest quality turning parts.In addition to its commitment to excellence, Turning Parts places a strong emphasis on customer satisfaction. The company works closely with its customers to understand their unique needs and provide them with tailored solutions that meet their specific requirements. Whether it's a small batch of turning parts for a prototype or a large-scale production run, Turning Parts has the flexibility and expertise to deliver on time and within budget.Turning Parts' comprehensive range of turning parts includes shafts, bushings, couplings, and other components that are crucial for the smooth operation of various mechanical systems. The company's expertise in turning parts manufacturing allows it to offer a diverse portfolio of products that can be customized to meet the most demanding specifications.With a global customer base, Turning Parts has built a strong network of partners and suppliers to support its operations. The company has a well-established supply chain that ensures it can source the highest quality materials and components for its turning parts, allowing it to maintain its high standards of quality and reliability.Moreover, Turning Parts is committed to sustainable and responsible manufacturing practices. The company adheres to stringent environmental regulations and invests in eco-friendly technologies to minimize its impact on the environment. By prioritizing sustainability, Turning Parts aims to contribute to a more sustainable future for the industry and the planet.As a forward-thinking company, Turning Parts is continually looking for new opportunities to expand its range of products and services. The company is dedicated to staying ahead of the curve in terms of technological advancements and market trends, ensuring that it can continue to meet the evolving needs of its customers.In conclusion, Turning Parts is a reputable manufacturer of precision turning parts with a strong commitment to quality, innovation, and customer satisfaction. With its extensive experience, technical expertise, and dedication to excellence, the company is well-positioned to continue serving as a trusted partner for industries that rely on high-quality turning parts.

High-Quality Fuschia Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing

In recent years, the demand for synthetic leather has increased rapidly worldwide. Synthetic leather has become a popular material choice for a variety of industries such as fashion, automotive, furniture, and sports equipment, among others. This is because synthetic leather offers many benefits such as durability, versatility, and cost-effectiveness. In China, one of the leading synthetic leather manufacturers is (brand name removed).One of their most innovative synthetic leather products is their Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing in Fuschia Color. This particular product is made of high-quality material and has a sleek and smooth finish which makes it perfect for use in products like high-end fashion items, bags, and accessories. This synthetic leather has a suede fabric backing which provides the added benefit of breathability and comfort. This feature makes it a suitable option for footwear, soles, and insoles.China has become a hub for synthetic leather manufacturing, and (brand name removed) leads the way in developing innovative and high-quality synthetic leather products. They use advanced technology and equipment to produce synthetic leather that meets the highest standards of quality and performance. As a result, they have become one of the most sought-after synthetic leather suppliers in China, and their products are exported to various countries around the world.The Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing in Fuschia Color is not only a quality product, but it is also offered at an affordable synthetic leather price. (brand name removed) provides their clients with competitive synthetic leather prices while maintaining the highest quality standards for their products. This has led to increased demand for their products from both local and international markets.Apart from providing quality products at affordable synthetic leather prices, (brand name removed) is also committed to environmental protection. They use water-based technology during the production of their synthetic leather products, which significantly reduces the amount of harmful chemicals released into the environment. The water-based technology also produces less waste material, which reduces waste disposal costs and carbon footprint.In conclusion, the demand for synthetic leather is growing rapidly, and China is at the forefront of synthetic leather manufacturing. (brand name removed) is a leading supplier of synthetic leather in China, and their Waterborne 0.60mm PU Synthetic Leather with Suede Fabric Backing in Fuschia Color is a high-quality product that is popular in various industries. Their commitment to using environmentally friendly technology and providing affordable synthetic leather prices has made them a preferred choice among their clients. For those looking to purchase high-quality synthetic leather products, (brand name removed) is a reliable and trusted supplier.

China-Based Manufacturer Offers Precision CNC Machined Parts

Wintec Precision Machining Co., Ltd: Your One-Stop Solution for CNC Precision Machined ComponentsWintec Precision Machining Co., Ltd is a leading OEM/ODM manufacturer of CNC precision machined components in China. With years of experience in the industry, Wintec has emerged as a reliable and trustworthy machining partner for businesses across the globe. Our team of highly skilled engineers and technicians, along with state-of-the-art infrastructure and advanced technology, enable us to deliver high-quality machined products that are second to none.At Wintec, we operate with a customer-first approach where customer satisfaction is our top priority. We work closely with our clients to understand their specific requirements and offer customized solutions that meet their needs. We have an extensive range of machining capabilities, including CNC turning, CNC milling, and CNC grinding, to provide accurate and precise parts that meet our client's specifications.Our CNC precision machined components are made using strict quality control measures that ensure superior product performance and reliability. We use only the highest quality raw materials that are sourced from reputable suppliers to ensure that our products meet stringent industry standards. Our commitment to quality is demonstrated by our ISO 9001:2015 certification, a testament that we deliver quality products consistently.At Wintec, we offer a broad range of CNC precision machined components, including shafts, sleeves, gears, housings, and more. We specialize in producing quality parts that cater to a wide range of industries, including the automotive, aerospace, medical, and energy sectors. Our machining capabilities allow us to create parts with intricate designs, intricate surface finishes, and tight tolerances that meet our client's exacting requirements.As a China-based manufacturer, Wintec offers our clients a cost-effective solution that does not compromise on quality. We have an extensive network of suppliers that allows us to source the best raw materials at a competitive price, passing on the savings to our clients. Our commitment to delivering cost-effective solutions makes us an attractive partner for businesses looking to reduce their production costs without sacrificing quality.In conclusion, Wintec Precision Machining Co., Ltd is a reliable partner for businesses in need of CNC precision machined components. We offer quality products, customized solutions, and cost-effective services that meet our clients' requirements. Our commitment to customer satisfaction, quality, and integrity makes us the ideal choice for your machining needs. Contact us today to learn more about our products and services.

CNC Turning Services for High-Quality Lathe Turned Parts

Service, Lathe Turned Production Parts, Prototyping, CNC Machined Parts, Manufacturing Partners, Instant CNC Turning Quote.CNC Turning Service: Your One-Stop Solution for All Your Lathe NeedsIn today's fast-paced manufacturing industry, the demand for precision and accuracy in parts production is more important than ever. Thanks to advances in technology, the CNC turning service has emerged as the go-to solution for manufacturing high-quality lathe-turned production parts. CNC Turning, with its precision, speed, and flexibility, has revolutionized the world of manufacturing and has become an essential part of modern-day production processes.At CNC Turning Service, we understand the importance of getting it right the first time, which is why we offer an exceptional range of services dedicated to providing our clients with the best possible results. Our services provide complete end-to-end solutions, from prototyping to CNC machined parts, and we deliver them with unbeatable speed, quality, and price.Our Global Network of Certified Manufacturing PartnersCNC Turning Service is proud to have a global network of 25 certified manufacturing partners, enabling us to offer our clients the best CNC turning services available. These partners have over 100 CNC turning machines, allowing us to produce everything from simple to complex parts. Our partners undergo a rigorous selection process to ensure they meet our exacting standards of quality, consistency, and efficiency. As a result, our clients benefit significantly from increased savings, faster lead times, and access to a wider range of capabilities.The Most Cost-Effective Solution for PrototypingAt CNC Turning Service, we understand that prototyping is an essential part of the production process. As such, we offer our clients the most cost-effective solution for creating high-quality prototypes. Our CNC turning service gives our clients the ability to produce prototypes that are identical to the final product in terms of specifications, tolerances, and material, which reduces the risk of design errors and allows for necessary modifications before the final production.CNC Machined Parts With Unbeatable Quality and SpeedCNC Turning Service produces CNC machined parts with unbeatable speed and quality. Our partners' CNC turning machines produce precise and accurate parts with precise tolerances, finishes, and features. Whether you need single parts or thousands, our CNC turning service can provide you with the most efficient and cost-effective production.Instant CNC Turning QuoteCNC Turning Service offers an instant CNC turning quote to our clients. Our online quote system is user-friendly, simple, and straightforward to use. Our clients can upload their designs, specify their requirements, and receive a quote instantly. With our instant quote system, our clients can access real-time pricing information and plan their production processes accordingly.ConclusionAt CNC Turning Service, we provide our clients with a complete end-to-end solution for all their lathe-turned production parts needs. Our global network of certified manufacturing partners, our cost-effective prototyping solutions, and our unbeatable quality and speed in producing CNC machined parts, make us the go-to solution for manufacturing high-quality parts. Contact us today and experience the benefits of our CNC turning services.

Discover the Art of Shaping Sheet Metal: A Comprehensive Guide

Title: Industry Leader Revolutionizes Sheet Metal ManufacturingIntroduction:In an era of constant innovation and advancement, the sheet metal manufacturing industry continues to evolve. One company, known for its groundbreaking techniques and commitment to excellence, has significantly contributed to the advancements of this sector. With their state-of-the-art production methods and cutting-edge technology, they have revolutionized the sheet metal manufacturing process, ensuring high-quality products and enhanced efficiency. Here, we delve into the key elements that make this company a leader in the industry.Research and Development:At the forefront of the company's success lies its relentless pursuit of research and development. By investing heavily in this area, they have been able to continuously discover and implement novel techniques and technologies into their manufacturing process. With an in-house team of highly skilled engineers and technicians, they consistently break new ground in the sheet metal industry. This dedication to R&D has allowed them to offer innovative solutions to their clients, overcoming challenges and meeting the ever-changing demands of the market.Advanced Machinery and Equipment:The company's commitment to cutting-edge technology is evident in its extensive use of advanced machinery and equipment. The production floor is equipped with high-precision lasers, computer numerical control (CNC) machines, and automated robotics, ensuring accuracy and consistency in every step of the manufacturing process. The integration of such advanced technology not only enhances the quality of the products but also improves overall operational efficiency, reducing production time and costs.Skilled Workforce:A company is only as good as its employees, and this industry leader understands the significance of a skilled workforce. They have assembled a team of highly trained professionals with extensive experience in sheet metal manufacturing. From machine operators and welders to quality control specialists and project managers, their employees possess the necessary expertise to meet the diverse needs of their clients. The company promotes a culture of continuous learning and advancement, providing regular training programs to keep pace with the ever-evolving industry requirements.Quality Assurance and Certifications:The company takes pride in its commitment to delivering the highest quality sheet metal products to its customers. Stringent quality control measures are in place throughout the manufacturing process to ensure that each product meets or exceeds industry standards. By employing cutting-edge inspection techniques and quality assurance protocols, they guarantee the durability, reliability, and precision of their sheet metal products. Additionally, the company holds various certifications, such as ISO 9001:2015 and ISO 14001:2015, further demonstrating their dedication to meeting global quality and environmental standards.Eco-Friendly Practices:In addition to quality manufacturing, the company prioritizes sustainability and environmental responsibility in its operations. By implementing eco-friendly practices, such as the use of energy-efficient machinery and recycling programs, they aim to minimize their carbon footprint. They continuously explore new ways to reduce waste and optimize resource utilization, contributing to a cleaner and greener planet while manufacturing superior sheet metal products.Customer-Centric Approach:Unlike many others in the industry, this company places a strong emphasis on building long-term relationships with its clients. They understand that each customer has unique requirements and tailor their services accordingly. By actively involving clients in the design process and offering personalized solutions, they ensure customer satisfaction throughout every project. The company's dedication to customer service has earned them a loyal clientele, with many returning for repeat business and referrals.Conclusion:In conclusion, this industry-leading company has revolutionized the sheet metal manufacturing industry through its commitment to research and development, advanced machinery, highly skilled workforce, quality assurance, sustainable practices, and customer-centric approach. By continually pushing the boundaries of innovation, they have set themselves apart as pioneers in the field. With their unmatched expertise and unwavering dedication to superior quality, this company will undoubtedly continue to shape the future of sheet metal manufacturing.

High-quality precision components for CNC machining.

CNC Precision Components, a leading manufacturer in the field of precision machining, has recently announced its expansion plans to meet the growing demand for its products. The company, known for its high-quality components and superior customer service, is set to increase its production capacity and expand its global reach to better serve its customers.With over [number of years] of experience in the industry, CNC Precision Components has built a solid reputation for its ability to deliver precision-engineered parts to a wide range of industries including aerospace, automotive, medical, and defense. The company’s state-of-the-art facility is equipped with the latest CNC machines and advanced manufacturing technologies, allowing it to produce complex components with tight tolerances and exacting specifications.As part of its expansion plans, CNC Precision Components will be adding new machining centers, hiring additional skilled personnel, and implementing advanced quality control measures to ensure that its products meet the highest standards. This investment in new technology and talent will enable the company to increase its production capacity and reduce lead times, allowing it to better support its customers’ growing needs.In addition to expanding its production capabilities, CNC Precision Components is also focusing on strengthening its global presence. The company plans to establish strategic partnerships and distribution channels in key international markets to better serve its growing customer base. By building relationships with local partners, CNC Precision Components aims to provide localized support and faster turnaround times for its customers around the world.“We are excited about the opportunities that lie ahead for CNC Precision Components,” said [Spokesperson Name], [Job Title] of the company. “Our expansion plans will enable us to better meet the needs of our customers while solidifying our position as a leader in the precision machining industry. We are committed to maintaining the high quality and reliability that our customers have come to expect from us.”In addition to its expansion plans, CNC Precision Components is also dedicated to maintaining its commitment to sustainability and environmental responsibility. The company is continuously looking for ways to reduce its environmental footprint, minimize waste, and optimize its manufacturing processes to operate in an environmentally friendly manner.CNC Precision Components takes great pride in its ability to deliver high-quality precision components while maintaining a focus on sustainable and responsible business practices. By investing in the latest technology, expanding its production capacity, and enhancing its global reach, the company is well-positioned to continue meeting the evolving needs of its customers while maintaining its dedication to excellence.About CNC Precision Components:CNC Precision Components is a leading manufacturer specializing in the production of high-quality precision components for a wide range of industries. With a focus on quality, reliability, and customer satisfaction, the company has established itself as a trusted partner for businesses in need of precision-engineered parts. With its commitment to excellence and continuous improvement, CNC Precision Components is dedicated to meeting the evolving needs of its customers while upholding the highest standards of quality and service. For more information, please visit [company website].

Discover the Advantages of In-House Metal Fabrication for Quality and Timely Delivery

Sheet Metal Panel Fabrication – The Ultimate Solution to All Metal Fabrication NeedsSheet metal fabrication has come a long way since its inception. It has become an indispensable part of various industries and is used extensively for a multitude of purposes. Be it aerospace, automotive, construction, or any other industry – sheet metal fabrication is crucial in all of them.Although there are numerous methods of sheet metal fabrication, sheet metal panel fabrication has gained immense popularity among manufacturers. The primary reason for its popularity is the accuracy and precision it offers while fabricating metal panels.Let's delve deeper into the aspects of sheet metal panel fabrication and understand how it can help manufacturers in their metal fabrication needs.What is Sheet Metal Panel Fabrication?Sheet metal panel fabrication is a process that involves cutting, folding, and shaping sheet metal into panels. These panels can be of various shapes and sizes, and the fabrication process can be customized as per the requirement.Sheet metal panel fabrication involves using various tools such as laser cutting machines, CNC punching machines, and hydraulic press brakes. These machines are highly efficient and can provide accurate and precise output with utmost consistency.Advantages of Sheet Metal Panel Fabrication1. Precision – As stated earlier, sheet metal panel fabrication provides a high degree of precision and accuracy. The cutting and folding are done with utmost care and attention to detail, ensuring that the metal panels meet the required specifications.2. Customization – Sheet metal panel fabrication can be customized to cater to the specific needs of the manufacturer. This versatility allows manufacturers to produce metal panels of various shapes, sizes, and thicknesses. This flexibility is not present in other methods of metal fabrication.3. Efficiency – Sheet metal panel fabrication is highly efficient and can deliver output at a much quicker rate than other methods of metal fabrication. The use of advanced machines enhances the efficiency of the process, making it an ideal choice for manufacturers who want to increase their production speed.4. Cost-Effective – Sheet metal panel fabrication can be cost-effective in the long run. The high degree of precision and accuracy results in minimal wastage of material, making it a cost-effective method for manufacturers who want to cut down on their raw material costs.ConclusionSheet metal panel fabrication has become an integral part of various industries. It offers precision, customization, efficiency, and cost-effectiveness, making it the ultimate solution for all metal fabrication needs. If you want to streamline your metal fabrication process and improve your production speed, sheet metal panel fabrication is an ideal choice.So, if you are looking for a reliable metal fabrication service provider, look no further than sheet metal panel fabrication experts. They can help you with all your metal fabrication needs, ensuring that the end product meets your specifications.