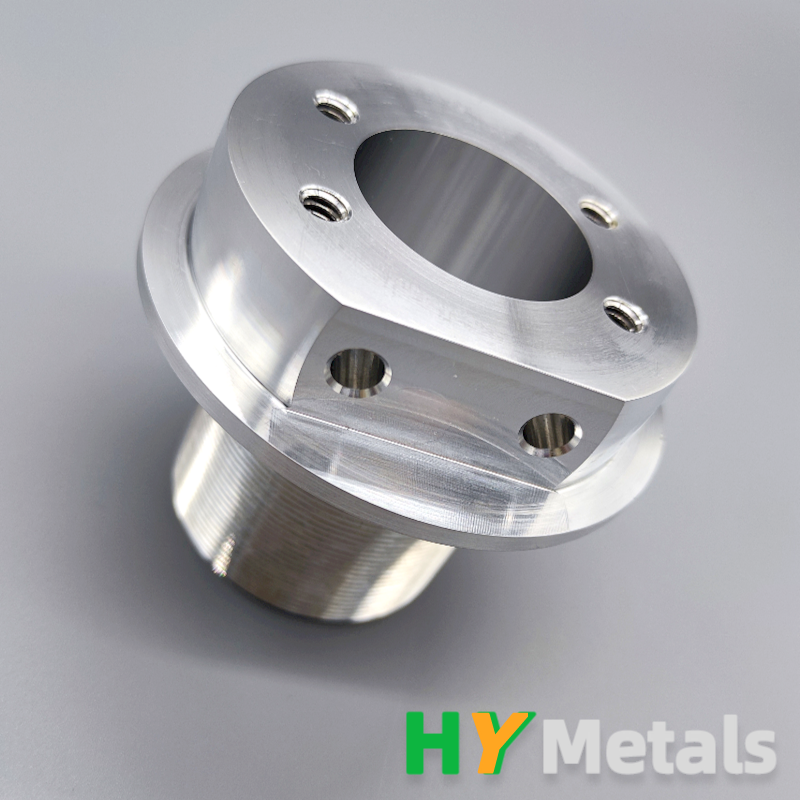

We are proud that we have invested heavily in manufacturing equipment and facilities, including 60 lathes and over 150 CNC mills, as well as grinding machines. With these capabilities, we can produce without compromise in precision or quality all types of metals including steel, stainless steel, tool steel, aluminum alloy, brass, zinc alloys and many types of plastics such as PC, Nylon, POM, PTFE and PEEK. One of the main advantages of CNC turning is that it is very efficient and flexible, allowing us to produce parts of various shapes, sizes and complexities. In addition, CNC lathes are highly automated, reducing the risk of error. As a result, we can achieve extremely close tolerances and fine surface finishes with repeatable accuracy, even on very complex parts. In our CNC turning process, we focus on optimizing our external thread production techniques, ensuring that all threads are precisely shaped, cut at the correct pitch diameter, and have the correct lead angle. These critical parameters ensure a precise fit with mating components and enhance the mechanical properties of the final product. We use advanced programming software to input precise cut dimensions, ensuring the final product meets all customer specifications. At HY Metals, we understand the importance of quality, precision and meeting deadlines. We strive to deliver all products on time and to the highest standards. Committed to excellent customer service, we work closely with customers to ensure final parts meet all specifications and needs. HY Metals is your one stop shop if you need CNC machined parts with external threaded components. We have the expertise, experience and technology to produce precision, high-quality parts with finely machined surfaces. We only offer the best cutting edge CNC turning and milling, you won't be disappointed. Contact us today for a custom quote or to learn more about our CNC machining services.

We are proud that we have invested heavily in manufacturing equipment and facilities, including 60 lathes and over 150 CNC mills, as well as grinding machines. With these capabilities, we can produce without compromise in precision or quality all types of metals including steel, stainless steel, tool steel, aluminum alloy, brass, zinc alloys and many types of plastics such as PC, Nylon, POM, PTFE and PEEK. One of the main advantages of CNC turning is that it is very efficient and flexible, allowing us to produce parts of various shapes, sizes and complexities. In addition, CNC lathes are highly automated, reducing the risk of error. As a result, we can achieve extremely close tolerances and fine surface finishes with repeatable accuracy, even on very complex parts. In our CNC turning process, we focus on optimizing our external thread production techniques, ensuring that all threads are precisely shaped, cut at the correct pitch diameter, and have the correct lead angle. These critical parameters ensure a precise fit with mating components and enhance the mechanical properties of the final product. We use advanced programming software to input precise cut dimensions, ensuring the final product meets all customer specifications. At HY Metals, we understand the importance of quality, precision and meeting deadlines. We strive to deliver all products on time and to the highest standards. Committed to excellent customer service, we work closely with customers to ensure final parts meet all specifications and needs. HY Metals is your one stop shop if you need CNC machined parts with external threaded components. We have the expertise, experience and technology to produce precision, high-quality parts with finely machined surfaces. We only offer the best cutting edge CNC turning and milling, you won't be disappointed. Contact us today for a custom quote or to learn more about our CNC machining services.High precision CNC turning parts with machined external threads

We are a factory that specializes in high precision CNC turning parts with machined external threads. Our products are accurately made to meet your specifications and needs.

Request a QuotePRODUCTS DETAILS

We are proud that we have invested heavily in manufacturing equipment and facilities, including 60 lathes and over 150 CNC mills, as well as grinding machines. With these capabilities, we can produce without compromise in precision or quality all types of metals including steel, stainless steel, tool steel, aluminum alloy, brass, zinc alloys and many types of plastics such as PC, Nylon, POM, PTFE and PEEK. One of the main advantages of CNC turning is that it is very efficient and flexible, allowing us to produce parts of various shapes, sizes and complexities. In addition, CNC lathes are highly automated, reducing the risk of error. As a result, we can achieve extremely close tolerances and fine surface finishes with repeatable accuracy, even on very complex parts. In our CNC turning process, we focus on optimizing our external thread production techniques, ensuring that all threads are precisely shaped, cut at the correct pitch diameter, and have the correct lead angle. These critical parameters ensure a precise fit with mating components and enhance the mechanical properties of the final product. We use advanced programming software to input precise cut dimensions, ensuring the final product meets all customer specifications. At HY Metals, we understand the importance of quality, precision and meeting deadlines. We strive to deliver all products on time and to the highest standards. Committed to excellent customer service, we work closely with customers to ensure final parts meet all specifications and needs. HY Metals is your one stop shop if you need CNC machined parts with external threaded components. We have the expertise, experience and technology to produce precision, high-quality parts with finely machined surfaces. We only offer the best cutting edge CNC turning and milling, you won't be disappointed. Contact us today for a custom quote or to learn more about our CNC machining services.

We are proud that we have invested heavily in manufacturing equipment and facilities, including 60 lathes and over 150 CNC mills, as well as grinding machines. With these capabilities, we can produce without compromise in precision or quality all types of metals including steel, stainless steel, tool steel, aluminum alloy, brass, zinc alloys and many types of plastics such as PC, Nylon, POM, PTFE and PEEK. One of the main advantages of CNC turning is that it is very efficient and flexible, allowing us to produce parts of various shapes, sizes and complexities. In addition, CNC lathes are highly automated, reducing the risk of error. As a result, we can achieve extremely close tolerances and fine surface finishes with repeatable accuracy, even on very complex parts. In our CNC turning process, we focus on optimizing our external thread production techniques, ensuring that all threads are precisely shaped, cut at the correct pitch diameter, and have the correct lead angle. These critical parameters ensure a precise fit with mating components and enhance the mechanical properties of the final product. We use advanced programming software to input precise cut dimensions, ensuring the final product meets all customer specifications. At HY Metals, we understand the importance of quality, precision and meeting deadlines. We strive to deliver all products on time and to the highest standards. Committed to excellent customer service, we work closely with customers to ensure final parts meet all specifications and needs. HY Metals is your one stop shop if you need CNC machined parts with external threaded components. We have the expertise, experience and technology to produce precision, high-quality parts with finely machined surfaces. We only offer the best cutting edge CNC turning and milling, you won't be disappointed. Contact us today for a custom quote or to learn more about our CNC machining services.Hot Products

3D printing service for rapid prototype parts

High precision CNC turning parts with machined external threads

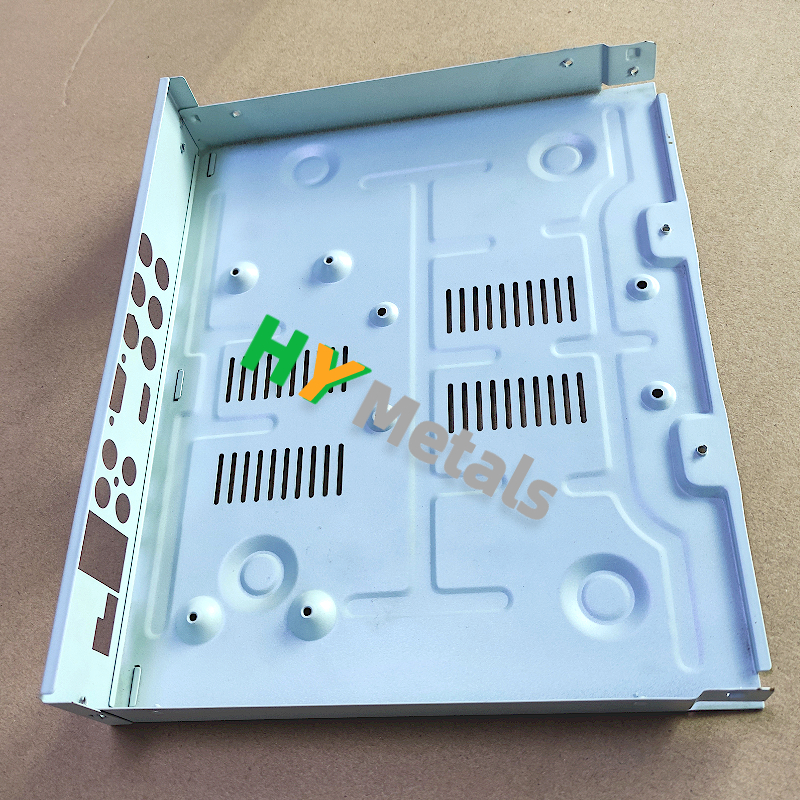

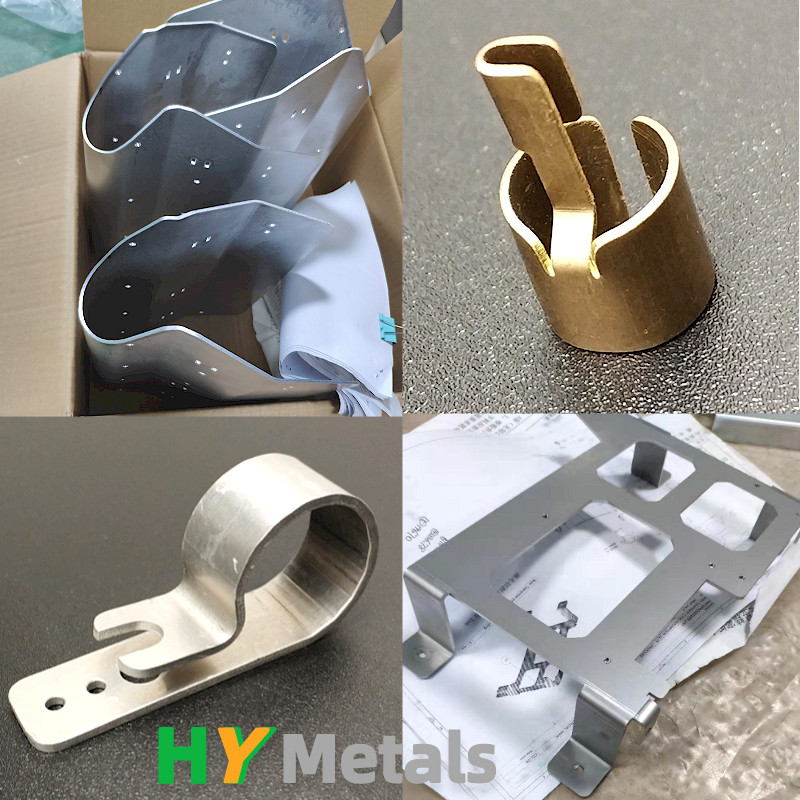

High-precision sheet metal prototype parts aluminum welding parts

Sheet metal prototype with short turnaround

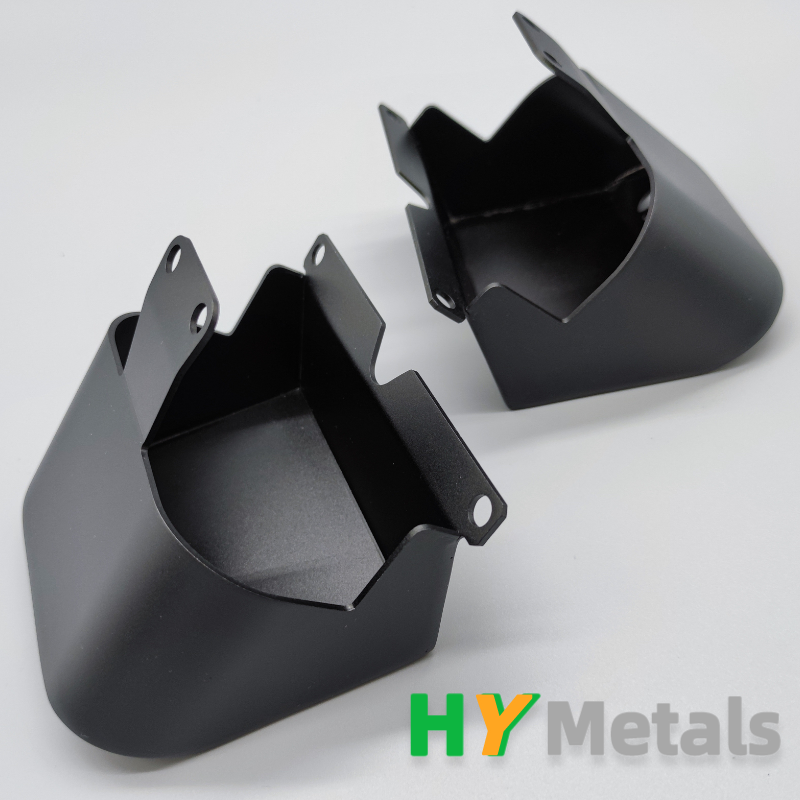

High precision sheet metal formed part that features powder coating and screen printing

Custom Manufacturing service for Sheet Metal Prototype parts aluminum auto parts

Sheet Metal parts made from Galvanized steel & sheet metal parts with zinc plating

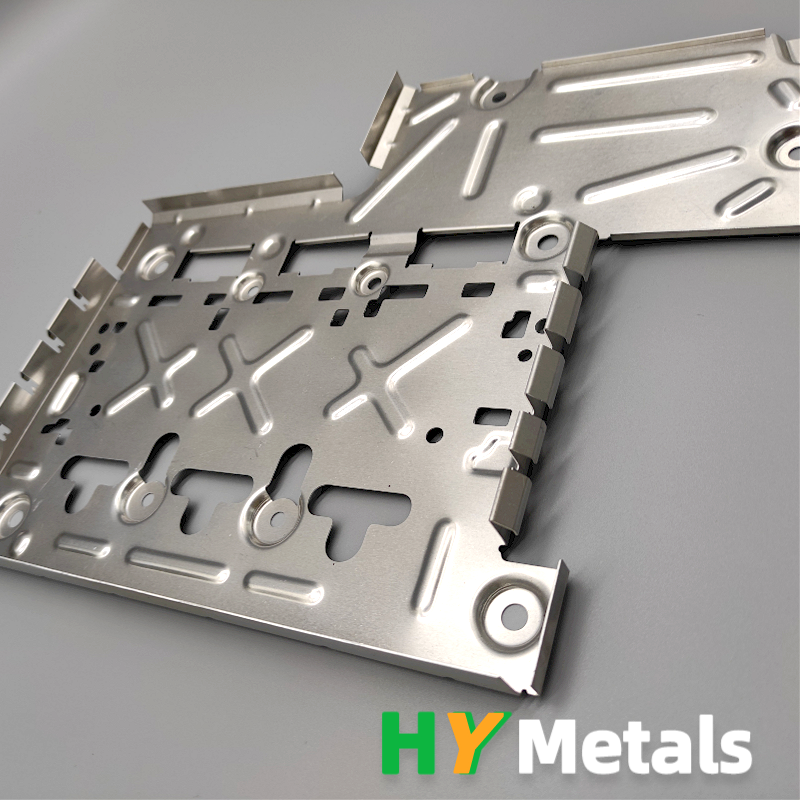

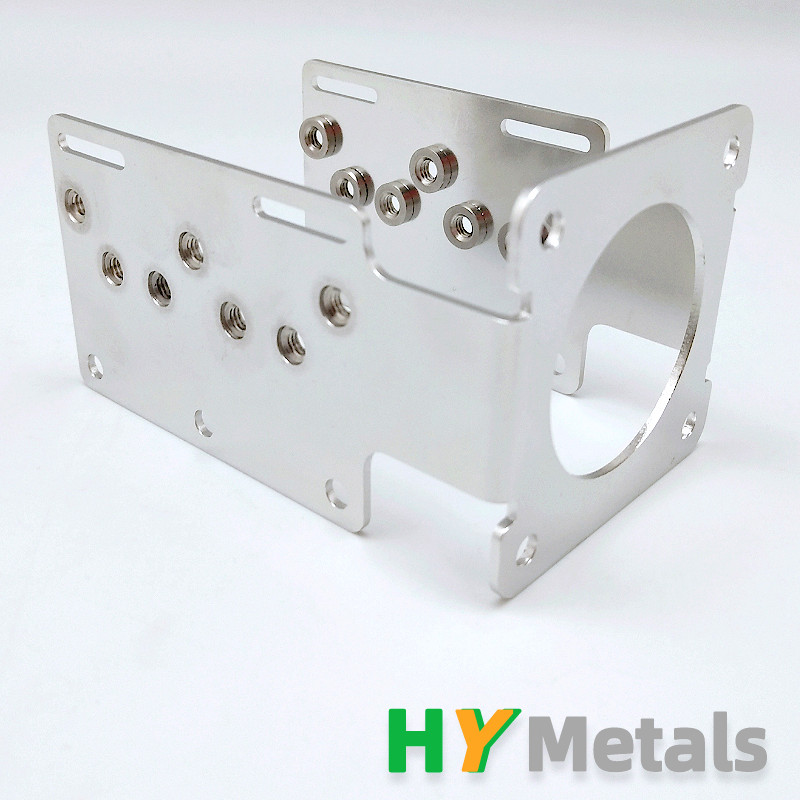

Precision Sheet metal bending and forming process

Custom sheet metal welding and assembly

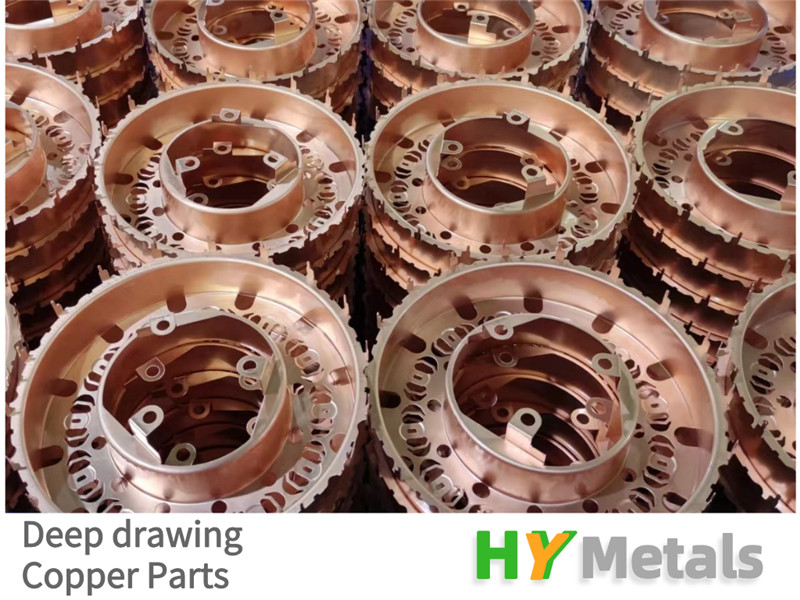

High precision metal stamping work include Stamping, Punching and Deep-Drawing

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours