High-Quality Metal Stamping Services for Precision Manufacturing

By:Admin

Specializing in precision metal stamping, the company offers a comprehensive range of services, including design, engineering, prototyping, and full-scale production. With state-of-the-art facilities and a team of experienced professionals, Precision Metal Stamping prides itself on delivering top-notch products that meet the highest quality standards.

One of the key factors that sets Precision Metal Stamping apart from its competitors is its commitment to innovation. The company continually invests in the latest technology and equipment to ensure that it stays ahead of the curve and can offer its clients the most advanced solutions. From complex, multi-stage progressive die stamping to simple blanking operations, Precision Metal Stamping has the capabilities to handle a wide range of projects with precision and efficiency.

Furthermore, the company is dedicated to maintaining the highest levels of quality and consistency. With rigorous quality control processes in place, Precision Metal Stamping ensures that every product that leaves its facilities meets or exceeds customer expectations. This commitment to excellence has earned the company a stellar reputation and a loyal customer base.

In addition to its technical prowess, Precision Metal Stamping also places a strong emphasis on customer service. The company works closely with its clients to understand their specific needs and develop tailored solutions that meet their requirements. With a focus on collaboration and communication, Precision Metal Stamping fosters strong, long-term relationships with its customers, providing them with the support and guidance they need to succeed.

As part of its ongoing commitment to excellence, Precision Metal Stamping recently announced the expansion of its facilities. The company has invested in a new, state-of-the-art manufacturing plant that will significantly increase its production capacity and allow for even greater operational efficiency. This expansion will also enable Precision Metal Stamping to take on larger and more complex projects, further solidifying its position as a leader in the industry.

"We are thrilled to announce the expansion of our facilities," said the CEO of Precision Metal Stamping. "This investment represents our dedication to meeting the growing needs of our customers and further establishing ourselves as a premier provider of metal stamping solutions. With our expanded capabilities, we look forward to taking on new challenges and delivering even greater value to our clients."

The expansion of its facilities is just one example of how Precision Metal Stamping is continually striving to improve and evolve. The company is always looking for new opportunities to enhance its processes and capabilities, ensuring that it remains at the forefront of the industry.

Looking ahead, Precision Metal Stamping is committed to maintaining its position as a leader in the metal stamping industry. With its focus on innovation, quality, and customer service, the company is well-positioned to continue delivering exceptional results for its clients and driving the industry forward.

In conclusion, Precision Metal Stamping has proven itself to be a force to be reckoned with in the metal stamping industry. With its advanced technology, unwavering commitment to quality, and dedication to customer satisfaction, the company has established itself as a trusted partner for businesses across various sectors. As it continues to expand and evolve, Precision Metal Stamping is poised to set new standards for excellence in the industry and remain a top choice for metal stamping solutions.

Company News & Blog

Expert Guide to CNC Turning: Everything You Need to Know

The precision engineering company, [], is making waves in the industry with its cutting-edge CNC Turning capabilities. With a focus on delivering high-quality, complex components for a range of industries, [] has established itself as a leader in the field of precision engineering. The company's commitment to investing in the latest technology, including state-of-the-art CNC Turning equipment, has set it apart from its competitors and positioned it as a go-to partner for businesses seeking reliable and efficient manufacturing solutions.CNC Turning is a manufacturing process that involves the use of computer numerical control (CNC) machines to produce components by rotating a workpiece while cutting tools are used to remove material. This process allows for the production of highly precise and complex components with tight tolerances, making it an essential capability for many industries, including aerospace, automotive, and medical.[]'s CNC Turning capabilities are a key part of its overall service offering, allowing the company to meet the diverse needs of its customers. The company's CNC Turning services are well-suited for the production of a wide range of components, including shafts, bushings, pulleys, and more. This versatility, combined with []'s commitment to quality and precision, makes it a trusted partner for businesses looking to outsource their manufacturing needs.One of the key advantages of CNC Turning is its ability to produce components with a high level of accuracy and consistency. By using computer-controlled machines, [] is able to achieve unparalleled precision in the production of components, ensuring that each part meets the exact specifications of the customer. This level of precision is essential for industries where even the smallest deviation can have significant consequences, such as aerospace and medical devices.In addition to precision, CNC Turning also offers increased efficiency and cost-effectiveness. By automating the machining process, [] is able to produce components at a faster rate and with minimal human intervention. This not only reduces the risk of errors but also allows for quicker turnaround times, enabling [] to meet tight production deadlines and deliver results to its customers in a timely manner.The investment in CNC Turning technology is just one example of []'s commitment to staying at the forefront of the industry. The company continually seeks to improve and expand its capabilities, ensuring that it can meet the evolving needs of its customers and remain competitive in the market. This dedication to innovation has been a driving force behind []'s success and has helped the company earn a reputation as a reliable and forward-thinking partner for precision engineering solutions.With its state-of-the-art CNC Turning capabilities, [] is well-positioned to continue serving a diverse range of industries and meeting the demand for high-quality, precision-engineered components. As the company looks to the future, it remains focused on investing in the latest technology and expanding its capabilities to ensure that it can continue to exceed the expectations of its customers.In conclusion, CNC Turning is a crucial aspect of []'s service offering, allowing the company to deliver precision-engineered components to a range of industries. By investing in the latest technology and prioritizing quality and efficiency, [] has solidified its position as a leader in the field of precision engineering. With its commitment to innovation and customer satisfaction, [] is well-equipped to meet the diverse and evolving needs of its clients and maintain its standing as a trusted partner in the industry.

High-Quality Lathe Parts for a Perfect Fit Every Time - Installation Guides and Manuals Available

Sears PartsDirect Now Offers Top-Quality Lathe Parts for All Major Lathe BrandsSears PartsDirect is excited to announce that we are now offering a wide selection of lathe parts for all major lathe brands, ensuring that our customers can find the best-quality parts they need to keep their lathes running smoothly. Our manufacturer-approved lathe parts are designed to provide a proper fit every time, giving our customers the assurance that their machines will be restored to optimal performance with ease.Lathe machines are an essential component of many industrial processes, and often need to be repaired and maintained in order to keep them functioning as designed. That’s where Sears PartsDirect comes in – we are committed to making it easy for our customers to find the parts they need to keep their machines running smoothly.We understand that different machines have different requirements, which is why we have a large selection of lathe parts available to suit all needs. Whether it is a specialized replacement part, an upgrade or a general maintenance part, our customers can be sure that they will find what they need.Our experienced team is dedicated to helping our customers find the right parts for their machines, and we are always on hand to answer any questions or concerns they may have. Our online catalogues are easy to navigate, and we provide detailed specifications and information about each part to make it easy for our customers to find what they need.In addition to our extensive selection of lathe parts, we also offer installation guides, diagrams, and manuals to help our customers along the way. Our guides and manuals are designed to provide a step-by-step approach to repairs and maintenance, ensuring that our customers can complete the job quickly and efficiently.At Sears PartsDirect, we are committed to providing our customers with the highest quality service and products possible. Our team of experts works diligently to ensure that our customers can find the parts they need, and our dedicated support team is always available to assist them with their needs.Our commitment to quality is reflected in our manufacturer-approved parts, which are designed to meet the highest standards for performance and reliability. We are proud to offer our customers the best in the industry, and we look forward to continuing to provide top-quality parts and support for all major lathe brands.In conclusion, Sears PartsDirect is excited to announce that we are now offering a wide selection of lathe parts for all major lathe brands. Our commitment to quality and service sets us apart from the competition, and we are dedicated to providing our customers with the best possible experience. With our extensive selection of parts, expert guidance, and exceptional customer support, we are confident that we can help our customers keep their lathes running smoothly and efficiently for years to come.

High-Quality Precision Milling Parts for Various Industries

Milling Parts is a leading multinational corporation that specializes in producing and supplying high-quality mechanical parts for various industries such as automotive, aerospace, medical, and more. The company has a mission to meet the needs of its customers by providing the best products and services possible. Milling Parts has recently announced a significant expansion of its operations, which will enable the company to enhance its production capacity and supply chain efficiency. This expansion includes the construction of a new state-of-the-art plant that will be equipped with advanced technologies to enable the production of more complex and high-quality parts. According to the company officials, this new plant will be the largest Milling Parts production facility, and it will be strategically located to serve both domestic and international customers. The facility will include multiple production lines, quality control and testing facilities, warehouses, and administrative offices. The CEO of Milling Parts stated that this expansion is part of the company's long-term growth strategy, and it reflects the commitment to meeting the increasing demands of its customers. He further added that the company aims to increase its market share and become a key player in the global mechanical parts industry. Milling Parts is known for its innovative and customer-focused approach to business. The company has an experienced team of engineers and technicians who work closely with customers to understand their needs and provide customized solutions. The company also invests heavily in research and development to stay at the forefront of technological advancements in the industry. Milling Parts is committed to ensuring the highest quality standards in all its products and services. The company has implemented a comprehensive quality management system that includes strict adherence to international standards such as ISO 9001 and AS9100. This ensures that all products and services meet or exceed customer expectations and comply with regulatory requirements. Milling Parts has a strong presence in the global market and serves customers in more than 50 countries. The company has established a network of partners and distributors worldwide, which enables it to provide efficient logistics and supply chain services. Milling Parts is also committed to sustainability and operates with a focus on minimizing its environmental impact. The company has implemented various initiatives to reduce energy consumption, waste generation, and carbon emissions. Milling Parts has a positive reputation in the industry, and it has received numerous awards and certifications for its excellence in quality, innovation, and customer service. The company has also been recognized for its role in creating job opportunities and contributing to economic growth in the regions where it operates. The expansion of Milling Parts operations is expected to create additional job opportunities and contribute to the development of the local economy. The company has stated that it will prioritize the recruitment of local talent and provide training and career development opportunities. In conclusion, Milling Parts is a leading mechanical parts manufacturer with a commitment to innovation, quality, and customer service. The company's expansion of operations is a reflection of its long-term growth strategy and commitment to meeting the needs of its customers. The new state-of-the-art plant will enable Milling Parts to enhance production capacity, supply chain efficiency, and become a key player in the global mechanical parts industry.

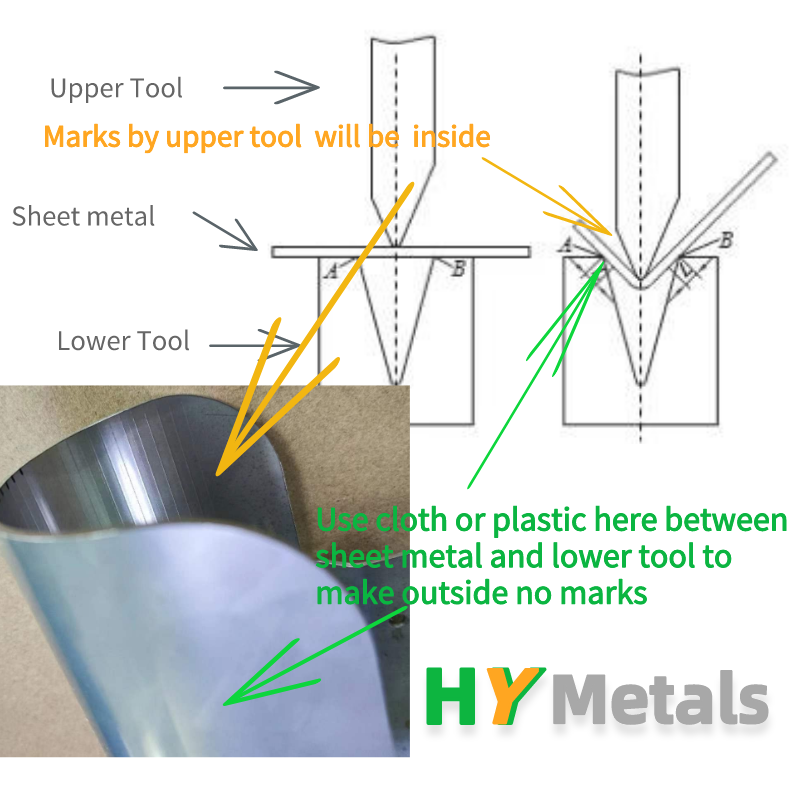

Sheet Metal Bending Tools: Dies, Press Brakes, Tube & Wire Bending

Sheet metal bending is a process that involves creating a bend in a metal sheet to give it a certain shape or form. This process is done using specialized tools and equipment such as bending dies, press brakes, and tube & wire bending machines.Bending dies are the main tool used for sheet metal bending. They are used to apply force to the metal to create a bend. These dies come in different shapes and sizes depending on the shape and size of the bend required. The dies can be used with a stamping press or press brakes.Stamping presses are machines that are used to apply pressure to the metal sheet to create the desired shape. The press brake is another machine that is used for sheet metal bending. It is a large machine that uses a hydraulic system to apply force to the metal sheet. The press brake can create several bends in the metal sheet at once.There are several types of bending dies that can be used for sheet metal bending. The most common type of bending die is the progressive bending die. This die allows multiple bends to be created simultaneously, which makes the process faster and more efficient. Other types of bending dies include the wiping die, rotary die, and the air-bending die.Wire bending machines are used to create bends in wire or rod-shaped materials. These machines use specialized dies to create precise bends in the wire. The bending process is done using a combination of force and heat to create the desired shape.Tube bending machines are used for creating bends in tubes and pipes. These machines use mandrels and dies to create precise bends in the tube. The mandrel is a rod that is placed inside the tube to prevent it from collapsing during the bending process.When it comes to sheet metal bending, it is important to use the right tools and equipment to ensure that the sheet metal is bent correctly. Bending dies and tools are crucial in this process. With the right tools and equipment, it is possible to create precise bends that will meet the desired requirements.In conclusion, sheet metal bending is a complex process that requires specialized tools and equipment like bending dies, press brakes, tube & wire bending machines. Each of these pieces of equipment plays a crucial role in the bending process and is designed to create precise bends. When used correctly, these tools can help you achieve the desired shape and form for your sheet metal project.

Ultimate Guide to Designing and Developing an Industry-Specific Solution

Industry Design And Development Part, a leading design and development company in the industry, is proud to announce its latest collaboration with a renowned technology company. The partnership aims to revolutionize the way consumers interact with technology and create innovative, user-friendly products that will shape the future of the industry.With over a decade of experience in the design and development field, Industry Design And Development Part has established itself as a pioneer in the industry. The company is known for its cutting-edge approach to product design and its ability to deliver high-quality, innovative solutions to its clients. With a team of experts in industrial design, engineering, and user experience, Industry Design And Development Part has consistently pushed the boundaries of what is possible in product development.The latest collaboration with the technology company is an exciting opportunity for Industry Design And Development Part to showcase its expertise in creating groundbreaking products. The partnership will leverage the strengths of both companies, combining the technology company's advanced technology with Industry Design And Development Part's design and development capabilities. This collaboration is expected to result in the creation of products that will not only meet the needs of consumers but also exceed their expectations.One of Industry Design And Development Part's key strengths is its focus on user-centered design. The company understands the importance of creating products that are intuitive and easy to use, and it has a proven track record of designing products that resonate with consumers. By working closely with the technology company, Industry Design And Development Part will be able to apply its user-centered design approach to the creation of innovative products that will set new industry standards.In addition to its design expertise, Industry Design And Development Part is also known for its commitment to sustainability and environmental responsibility. The company is dedicated to minimizing the environmental impact of its products and processes, and it actively seeks out sustainable materials and manufacturing methods. This commitment to sustainability aligns with the values of the technology company, making the collaboration a perfect fit for both parties."We are thrilled to be partnering with a company as esteemed as the technology company," said [spokesperson], [title] at Industry Design And Development Part. "This collaboration presents a unique opportunity for us to showcase our expertise in design and development and create products that will truly make a difference in the industry. We are excited to combine our strengths and work together to push the boundaries of innovation."As the collaboration between Industry Design And Development Part and the technology company continues to unfold, industry insiders and consumers alike are eager to see the products that will emerge from this partnership. With a shared commitment to innovation, user-centered design, and sustainability, the collaboration is poised to make a significant impact on the industry and set new benchmarks for product excellence.About Industry Design And Development PartIndustry Design And Development Part is a [remove brand name] design and development company with a mission to create innovative, user-centered products that push the boundaries of what is possible. With a team of experts in industrial design, engineering, and user experience, Industry Design And Development Part has established itself as a leader in the industry, known for its cutting-edge approach to product development and its commitment to sustainability. Whether working with startups or Fortune 500 companies, Industry Design And Development Part is dedicated to delivering high-quality, innovative solutions that exceed client expectations.

High-Quality CNC Machined Parts for Precision Engineering

CNC Machined Parts are at the heart of the manufacturing industry, and they play a crucial role in the production of a wide range of products. From automotive components to aerospace parts, CNC machined parts are essential in creating precision-engineered products. One company that is at the forefront of providing top-quality CNC machined parts is {}. With a strong focus on precision and quality, {} has become a trusted partner for many leading companies in various industries.{} specializes in the production of CNC machined parts using the latest technology and advanced machining techniques. The company's state-of-the-art facilities are equipped with high-precision CNC machines that can produce complex and intricate parts with exceptional accuracy. Whether it's a simple prototype or a high-volume production run, {} has the capabilities to meet the most demanding requirements.The company prides itself on its ability to deliver precision-engineered parts with quick turnaround times. By utilizing advanced CAD/CAM software and highly skilled machinists, {} can efficiently program and manufacture CNC machined parts to meet tight deadlines. This rapid production capability has made {} a preferred supplier for companies that require fast and reliable machining services.In addition to its cutting-edge manufacturing capabilities, {} places a strong emphasis on quality control. The company follows strict quality assurance protocols to ensure that each part meets the highest standards of accuracy and consistency. By employing advanced inspection equipment and rigorous quality checks, {} ensures that its CNC machined parts are of the highest quality before they are delivered to customers.As a customer-centric company, {} is committed to providing exceptional customer service and support. The company works closely with its clients to understand their specific needs and requirements, and it offers customized solutions to meet their unique challenges. Whether it's providing design assistance, optimizing manufacturing processes, or offering technical advice, {} goes above and beyond to ensure that its customers receive the best possible service.In addition to its focus on precision and quality, {} is also dedicated to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its manufacturing processes to reduce its environmental impact. By using efficient machining techniques and minimizing waste, {} strives to operate in an environmentally conscious manner.With its unwavering commitment to excellence, {} has established itself as a leading provider of CNC machined parts. The company's dedication to precision, quality, and customer satisfaction has earned it a stellar reputation in the manufacturing industry. Whether it's producing intricate components for the aerospace industry or creating custom parts for the automotive sector, {} continues to set the standard for excellence in CNC machining.In conclusion, CNC machined parts are an integral part of modern manufacturing, and {} is a standout leader in the industry. With its advanced capabilities, stringent quality control, and unwavering commitment to customer satisfaction, {} has become the go-to partner for companies seeking top-quality CNC machined parts. As the manufacturing sector continues to evolve, {} remains at the forefront, delivering precision-engineered parts that meet the highest standards of excellence.

Durable and Versatile Aluminum Extrusion Profiles for Various Applications

Aluminum Extrusion Profiles are a key component in various industries, including construction, transportation, and manufacturing. These profiles are versatile and can be customized to fit a wide range of applications, making them an essential material for many businesses. One company that has been leading the way in the production of Aluminum Extrusion Profiles is {}.{} is a renowned manufacturer of aluminum extrusion profiles, with a strong focus on innovation and quality. With state-of-the-art facilities and a dedicated team of experts, {} has been at the forefront of the industry, providing high-quality and customizable aluminum profiles to meet the needs of their clients.The company's commitment to excellence is evident in their wide range of products, which include standard and custom extrusions, as well as value-added services such as precision cutting and machining. {}'s ability to offer tailor-made solutions has made them a preferred partner for businesses across various sectors.One of the key advantages of {}'s Aluminum Extrusion Profiles is their durability and strength. Aluminum is known for its lightweight yet robust properties, making it an ideal material for applications that require both strength and flexibility. This makes {}'s products an excellent choice for industries such as construction, automotive, and aerospace.Additionally, {} prioritizes sustainability in their production processes. Aluminum is a highly recyclable material, and {} is dedicated to reducing their environmental impact by implementing sustainable practices in their manufacturing operations. This commitment to sustainability has not only benefited the environment but has also positioned {} as a responsible and ethical business in the eyes of their clients and stakeholders.Furthermore, {}'s commitment to quality is reflected in their certifications and accreditations. The company adheres to strict industry standards and has obtained various certifications to ensure the reliability and performance of their products. This dedication to quality has earned them a strong reputation in the market, bolstering their position as a trusted supplier of aluminum extrusion profiles.In addition to their exceptional products, {} prides itself on providing excellent customer service. The company's team of professionals works closely with clients to understand their specific needs and deliver tailored solutions to meet their requirements. This customer-centric approach has been key to the company's success, fostering long-lasting relationships and earning repeat business from satisfied clients.Looking ahead, {} is poised for further growth and innovation in the aluminum extrusion industry. The company continues to invest in research and development to expand their product offerings and enhance their manufacturing processes. With a keen eye on market trends and customer needs, {} is well-positioned to remain a leader in the industry and meet the evolving demands of their clients.In conclusion, {} is a leading manufacturer of Aluminum Extrusion Profiles, known for their commitment to quality, sustainability, and customer satisfaction. With a focus on innovation and a dedication to meeting the unique requirements of their clients, {} has established itself as a trusted partner for businesses across various sectors. As they continue to grow and expand their capabilities, {} is poised to remain at the forefront of the aluminum extrusion industry, providing high-quality and customizable solutions for the evolving needs of their clients.

High-quality Sheet Metal Part for Precision Engineering Projects

Sheet Metal Part Company Provides High-Quality Components for Various IndustriesSince its establishment in 1998, Sheet Metal Part Company has been a leading manufacturer and supplier of precision sheet metal components for a wide range of industries. With a dedication to quality, innovation, and customer satisfaction, the company has built a solid reputation for producing high-quality parts that meet the specific requirements of its clients.The company's state-of-the-art manufacturing facility is equipped with advanced machinery and tools that enable the production of complex and precise sheet metal components. From intricate prototypes to large-scale production runs, Sheet Metal Part Company has the capabilities to handle diverse projects with efficiency and precision.One of the key strengths of Sheet Metal Part Company is its team of highly skilled engineers, technicians, and production staff. With years of experience and expertise in the field of sheet metal fabrication, the company's team members are committed to delivering top-notch solutions that exceed customer expectations. Whether it's custom enclosures for the electronics industry, precision components for the automotive sector, or specialized parts for the aerospace industry, the company's team is capable of meeting the unique demands of each customer.In addition to its commitment to quality and precision, Sheet Metal Part Company places a strong emphasis on innovation and continuous improvement. The company invests in research and development to stay at the forefront of technological advancements in the sheet metal fabrication industry. By embracing new techniques, processes, and materials, the company is able to offer innovative solutions that address the evolving needs of its customers.Furthermore, Sheet Metal Part Company takes pride in its strict adherence to industry standards and regulations. The company is certified to ISO 9001 standards, ensuring that its manufacturing processes and quality management systems are of the highest caliber. This dedication to quality and compliance has earned the company the trust and confidence of its customers, who rely on Sheet Metal Part Company for their most critical sheet metal component needs.With a strong focus on customer satisfaction, Sheet Metal Part Company works closely with its clients to understand their requirements and provide tailored solutions that meet their specific needs. The company's customer-centric approach, combined with its technical expertise and manufacturing capabilities, has resulted in long-term partnerships with a diverse range of customers across various industries.In recent news, Sheet Metal Part Company has introduced a new line of environmentally friendly sheet metal components that are designed to reduce waste and energy consumption in manufacturing processes. By utilizing sustainable materials and implementing eco-friendly production methods, the company aims to contribute to environmental conservation while meeting the needs of its customers.As Sheet Metal Part Company continues to expand its product offerings and reach new markets, the company remains committed to its founding principles of quality, innovation, and customer satisfaction. With a solid track record of delivering high-quality sheet metal components for diverse applications, the company is poised to remain a trusted partner for industries that require precision and reliability in their sheet metal parts.In conclusion, Sheet Metal Part Company stands as a leading provider of high-quality sheet metal components for a wide range of industries. With a focus on quality, innovation, and customer satisfaction, the company has established itself as a reliable partner for businesses seeking precision and reliability in their sheet metal parts. With a dedication to continuous improvement and environmental stewardship, Sheet Metal Part Company is well-positioned to meet the evolving needs of its customers and the market.

Discover the Latest Trends in Aluminum Extrusion Technology

Aluminum Extrusion Company Leads the Industry in Innovation and SustainabilityWith a commitment to innovation and sustainability, [Aluminum Extrusion Company] is leading the way in the aluminum extrusion industry. Their dedication to excellence has positioned them as a premier provider of high-quality aluminum extrusions for a wide range of applications.Founded in [year], [Aluminum Extrusion Company] has established itself as a leader in the industry, constantly pushing the boundaries of what is possible with aluminum extrusion. Their state-of-the-art manufacturing facilities and cutting-edge technology allow them to produce extrusions that meet the most stringent requirements and specifications.One of the key factors that set [Aluminum Extrusion Company] apart is their focus on sustainability. They are committed to reducing their environmental impact through the use of recycled materials and energy-efficient processes. This dedication to sustainability has not only earned them a reputation as an environmentally conscious company but has also opened up new business opportunities as more and more customers prioritize sustainable sourcing.In addition to their commitment to sustainability, [Aluminum Extrusion Company] is also at the forefront of innovation in the industry. They continuously invest in research and development to improve their products and processes, driving efficiency and creating new possibilities for their customers. This commitment to innovation has led to the creation of unique extrusion designs and the ability to produce custom extrusions that meet precise specifications.Another key area of focus for [Aluminum Extrusion Company] is their dedication to customer service. They work closely with their clients to understand their needs and provide tailored solutions that meet and exceed their expectations. Whether it's a custom extrusion for a specific application or a high-volume order for a specific industry, [Aluminum Extrusion Company] has the expertise and capabilities to deliver.As a testament to their commitment to excellence, [Aluminum Extrusion Company] has earned numerous certifications and accolades for their quality and performance. They adhere to strict industry standards and undergo regular audits to ensure that their products meet the highest levels of quality and consistency.With a proven track record of success and a strong reputation in the industry, [Aluminum Extrusion Company] continues to grow and expand its reach. Their dedication to innovation, sustainability, and customer service has allowed them to forge strong relationships with customers and partners, positioning them for continued success in the years to come.In an industry that is constantly evolving, [Aluminum Extrusion Company] has demonstrated a commitment to staying ahead of the curve and leading the way in the aluminum extrusion market. With a focus on sustainability, innovation, and customer service, they are well-positioned to continue setting the standard for excellence in the industry.In conclusion, [Aluminum Extrusion Company] is a company that is making a significant impact in the aluminum extrusion industry. Their commitment to sustainability, innovation, and customer service sets them apart as a leader in the field. With a dedication to excellence and a track record of success, [Aluminum Extrusion Company] is poised for continued growth and continued success in the years to come.

Revolutionizing Manufacturing: Streamline Production with Custom Industrial Design Parts

Build Parts For Industry Design Expands Its Capabilities to Serve Diverse Industrial SectorsBuild Parts For Industry Design, a leading provider of high-quality industrial parts and services, is proud to announce the expansion of its capabilities to better cater to the needs of diverse industrial sectors. With its state-of-the-art facilities and cutting-edge technology, the company aims to deliver innovative solutions and meet the demands of an ever-evolving market.Established in [year], Build Parts For Industry Design has become a trusted name in the industrial design and manufacturing industry. With a team of experienced engineers, designers, and technicians, the company has successfully served various clients across different sectors, including automotive, aerospace, electronics, and consumer goods.Understanding the changing dynamics of the industrial landscape, Build Parts For Industry Design has strategically invested in its facilities to ensure it remains at the forefront of innovation. By leveraging the latest technologies and continuously upgrading its equipment, the company is well-equipped to deliver parts that meet the highest industry standards.One of the key factors that sets Build Parts For Industry Design apart from its competitors is its commitment to precision and quality. The company follows rigorous quality control processes at every step of the manufacturing process to ensure that the parts it produces are of the finest quality. By adhering to industry-leading standards, Build Parts For Industry Design aims to provide its clients with reliable and durable parts that can withstand even the most demanding conditions.Build Parts For Industry Design also places great emphasis on customization and flexibility. The company understands that each industrial sector has its own unique needs and requirements. With its expanded capabilities, Build Parts For Industry Design can now offer tailor-made solutions to meet the specific demands of different industries. Whether it's designing intricate components for the aerospace industry or manufacturing precision parts for the automotive sector, the company has the expertise and resources to deliver exceptional results.In addition to its commitment to quality and customization, Build Parts For Industry Design is also dedicated to sustainable practices. The company recognizes the importance of minimizing its environmental impact and actively seeks out eco-friendly manufacturing processes. By investing in advanced technologies that reduce waste and optimize energy consumption, Build Parts For Industry Design ensures that its operations are as sustainable as possible.Customers of Build Parts For Industry Design can expect not only high-quality parts but also excellent customer service. The company takes pride in its responsive and efficient communication channels, ensuring that clients receive the support they need throughout their project. From initial design consultations to post-production assistance, Build Parts For Industry Design is committed to providing an unparalleled customer experience.As Build Parts For Industry Design expands its capabilities, it looks forward to forging new partnerships and collaborations across a wide range of industries. The company's dedication to innovation, quality, and sustainability positions it as an ideal partner for businesses looking to enhance their industrial design and manufacturing processes.With its state-of-the-art facilities and a team of skilled professionals, Build Parts For Industry Design is ready to take on new challenges and serve the diverse needs of the industrial sector. As the industry continues to evolve, the company remains committed to delivering cutting-edge solutions that drive innovation and economic growth.For more information about Build Parts For Industry Design and its range of services, please visit [website] or contact [email/phone].