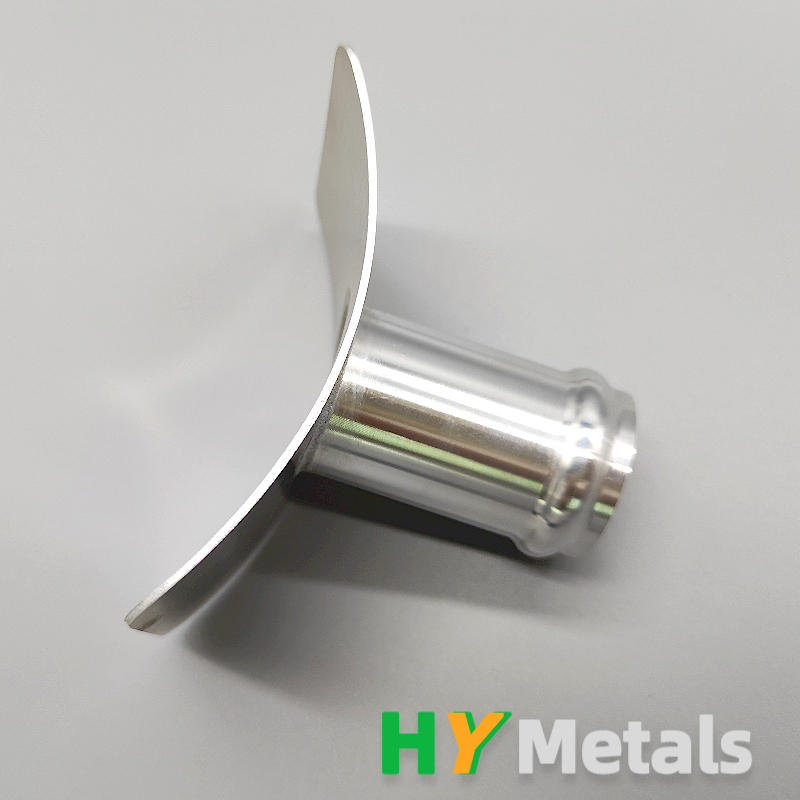

Top Quality Milling Components for Your Industrial Needs

By:Admin

Milling Components, a leading manufacturer of precision milling machinery and components, has recently launched an innovative new product line that is expected to revolutionize the industry. This new line of products combines cutting-edge technology with the company's decades of expertise in the field of milling and machining, providing customers with solutions that are more precise, efficient, and cost-effective than ever before.

The company, headquartered in [Location], has been at the forefront of the milling industry since its founding in [Year]. With a strong focus on research and development, [Brand name]'s team of engineers and technicians have consistently pushed the boundaries of what is possible in terms of milling technology. The result is a product line that is highly regarded for its precision, reliability, and durability, making [Brand name] a trusted partner for businesses in a wide range of industries.

The newest addition to [Brand name]'s product lineup is a series of advanced milling components that have been designed to meet the diverse needs of modern manufacturing operations. These components are built to the highest standards of quality and are capable of delivering exceptional performance in a wide range of applications, from small-scale precision machining to heavy-duty industrial production.

One of the key features of this new product line is its focus on versatility and adaptability. The components have been engineered to be highly customizable, allowing customers to tailor their milling setups to their specific requirements. This level of flexibility not only enhances the efficiency of the milling process but also reduces the need for costly and time-consuming retooling.

In addition to their customizable nature, the new milling components also incorporate the latest advancements in digital and automation technologies. This allows for seamless integration with other machinery and systems, creating a more streamlined and interconnected manufacturing environment. By leveraging these technologies, customers can improve their overall productivity and reduce the risk of errors and downtime.

The launch of this new product line represents a significant milestone for [Brand name]. As a company that has always been committed to innovation, [Brand name] is proud to offer its customers a range of milling components that are truly at the cutting edge of technological advancement. This commitment to excellence has earned [Brand name] a reputation as a forward-thinking and reliable provider of milling solutions.

In conjunction with the release of the new product line, [Brand name] is also reinforcing its dedication to customer service and support. The company's team of experts is available to provide guidance and assistance to customers as they integrate the new milling components into their operations. This commitment to customer satisfaction is a cornerstone of [Brand name]'s business philosophy, and it is one of the reasons why the company has maintained long-standing relationships with many of its clients.

Looking ahead, the future appears bright for [Brand name] and its innovative new product line. With a strong foundation of expertise and a focus on continuous improvement, [Brand name] is well-positioned to remain a leader in the milling industry for years to come. By staying at the forefront of technological advancements and maintaining its commitment to customer satisfaction, [Brand name] is poised to continue providing its customers with the highest quality milling components and machinery.

Overall, the launch of this new product line is a testament to [Brand name]'s dedication to pushing the boundaries of what is possible in the milling and machining industry. With its combination of advanced technology, customizable solutions, and unparalleled customer support, [Brand name] is setting a new standard for excellence in the field of milling components.

Company News & Blog

New Stamping Cut Process Streamlines Manufacturing Efficiency and Reduces Costs

[Company Name], a leading company in the manufacturing industry, has announced the implementation of stamping cut technology to enhance its production process. The company has been at the forefront of innovation, constantly seeking new and improved methods to increase efficiency and quality of their products.Stamping cut, also known as blanking or punching, is a method used to cut or shape metal sheets into a desired form. It is a widely used manufacturing process in various industries, including automotive, aerospace, electronics, and more. By introducing this technology into their production line, [Company Name] aims to further improve the precision and consistency of their products.With the implementation of stamping cut technology, [Company Name] will be able to streamline their manufacturing process and reduce lead times. This will not only help in meeting the growing demand for their products but also enable them to keep up with the ever-changing market trends. By reducing the time and effort required for manual cutting and shaping of metal sheets, [Company Name] can also significantly cut down on production costs, which could ultimately result in more competitive pricing for their customers.In addition to the improved efficiency, stamping cut technology will also enhance the quality of [Company Name]'s products. The precise and accurate cutting achieved through this method will ensure that each component meets the required specifications, ultimately leading to better performance and longevity of the final products. This, in turn, will further solidify the company's reputation for delivering high-quality and reliable products to their customers.[Company Name] has always been committed to investing in the latest technologies and equipment to stay ahead in the industry. The introduction of stamping cut technology is just one of the many steps the company has taken to achieve this goal. By continuously modernizing their production processes, [Company Name] is positioning itself as a leader in the manufacturing sector and is ready to meet the demands of the future.The company's dedication to innovation and quality has not gone unnoticed. [Company Name] has garnered a strong reputation for its commitment to excellence and has built enduring relationships with its customers and partners. The implementation of stamping cut technology is yet another testament to the company's unwavering dedication to providing the best products and services to the market.As [Company Name] moves forward with the integration of stamping cut technology into its production process, it is clear that the company is committed to driving progress and delivering value to its customers. The move is not only a significant step forward for the company but also signals its readiness to embrace new technologies and adapt to the evolving needs of the market.In conclusion, the implementation of stamping cut technology by [Company Name] is a testament to the company's commitment to innovation, efficiency, and quality. As the company continues to invest in advanced technologies, it is poised to maintain its position as a leading manufacturer in the industry and meet the demands of the market. With its strong focus on delivering value to its customers, [Company Name] is well-positioned to thrive in the ever-changing manufacturing landscape.

Top Quality Extruded Aluminum Heatsinks for Efficient Heat Dissipation

Extruded Aluminum Heatsink Takes the Heat Away, Making Electronic Devices More EfficientAs the technology develops, electronic devices are becoming more advanced, powerful, and compact, which is great news for consumers who demand more functionality and convenience. However, this trend also poses a challenge for manufacturers who need to dissipate the heat generated by these devices. Without proper cooling, electronic components can overheat and fail, compromising the performance, safety, and reliability of the product. That's where an extruded aluminum heatsink comes into play, providing an effective and efficient way to transfer heat away from electronic devices.An extruded aluminum heatsink is a passive component that is attached to the electronic device to absorb and dissipate the heat generated by it. It works by increasing the surface area available to dissipate heat through the use of fins, which are thin and elongated projections that extend from the heatsink's base. These fins expose more of the heatsink's surface to the surrounding air, increasing the rate of heat transfer by convection. In addition, the heatsink's base is in contact with the heat source, such as a CPU, GPU, or power converter, which conducts the heat away from the source and spreads it out across the heatsink's surface. Finally, the heatsink dissipates the heat into the ambient air, which carries it away from the device.An extruded aluminum heatsink is an ideal solution for many electronic devices because of its low cost, lightweight, and easy customization. It can be designed to fit a specific device or application, with different sizes, shapes, and fin densities to optimize the performance and minimize the size and weight of the heatsink. Moreover, an extruded aluminum heatsink is durable, corrosion-resistant, and can withstand high temperatures, making it suitable for harsh environments and industrial applications.One company that specializes in extruded aluminum heatsinks is (need to remove brand name). Founded in (year), the company has over (number) years of experience in designing and manufacturing heatsinks for various industries, including computer, communication, lighting, transportation, power, and aerospace. (Remove brand name) offers a wide range of heatsink products, from standard extrusions to custom designs, with different materials, finishes, and assembly options.According to (CEO name), (remove brand name)'s CEO, the company's success lies in its commitment to quality, innovation, and customer service. "We take pride in delivering effective and efficient thermal solutions that exceed our customers' expectations," he said. "We use the latest technology and techniques to design and produce heatsinks that meet or exceed industry standards, and we work closely with our customers to understand their needs and provide personalized solutions."Some of (remove brand name)'s recent innovations in extruded aluminum heatsinks include:- Micro-fins: (remove brand name) has developed a new technique for producing micro-fins, which are very thin and closely spaced fins that increase the surface area of the heatsink without adding much weight or volume. Micro-fins are ideal for compact devices that require high performance and low profile, such as laptops, tablets, and smartphones.- Stack-fins: Another technique that (remove brand name) has pioneered is stack-fins, which are multiple sets of fins stacked on top of each other, like a sandwich. Stack-fins can increase the heat transfer rate by up to 50% compared to conventional fins, making them suitable for high-power applications and environments with limited airflow.- Heat-pipes: (remove brand name) has integrated heat-pipes into some of its heatsinks, which are sealed tubes filled with a liquid or gas that absorbs and transfers heat through a phase-change process. Heat-pipes can improve the thermal performance of a heatsink by several times, making it possible to cool even the hottest components.- Surface treatments: (remove brand name) offers a variety of surface treatments for its heatsinks, such as anodizing, painting, powder coating, and polishing, to enhance their aesthetics, corrosion resistance, and thermal conductivity. Surface treatments can also provide additional functions, such as electromagnetic shielding, insulation, and light reflection.With its expertise in extruded aluminum heatsinks and its commitment to innovation and quality, (remove brand name) is poised to meet the challenges of the growing electronics industry and provide reliable and effective thermal solutions to its customers. If you have a thermal management challenge, why not contact (remove brand name) for a consultation and see how they can help you?

Durable and Versatile Aluminum Bending Bracket for Various Applications

Aluminum Bending Bracket Supplier Reaches New MilestoneIn the world of manufacturing, precision is key. Every detail matters, and every part must be crafted with care and expertise. This is especially true in the aerospace and automotive industries, where the demand for high-quality components is at an all-time high.One company that has been meeting and exceeding these demands is [Company Name]. With a proven track record of providing top-notch aluminum bending brackets to some of the biggest names in the industry, [Company Name] has recently reached a new milestone in their journey towards manufacturing excellence.Specializing in the production of aluminum bending brackets, [Company Name] has been a major player in the manufacturing industry for many years. Their parts are known for their precision, durability, and reliability, making them the go-to choice for companies in need of high-quality components.The team at [Company Name] is made up of dedicated professionals who are passionate about their work. With a commitment to delivering the best possible products to their customers, they have built a reputation for excellence and reliability. This has allowed them to forge strong partnerships with some of the most respected companies in the industry, cementing their status as a leading supplier of aluminum bending brackets.Their manufacturing process is second to none, with a focus on quality and precision at every step. From the initial design phase to the final inspection, every part is meticulously crafted to ensure that it meets the highest standards. This dedication to quality has set [Company Name] apart from the competition, making them a trusted name in the industry.Recently, [Company Name] announced that they have reached a new milestone in their production capabilities. Thanks to their continued investment in cutting-edge technology and their unwavering commitment to excellence, they have expanded their manufacturing capacity, allowing them to produce even more high-quality aluminum bending brackets than ever before.This milestone is a testament to [Company Name]'s dedication to innovation and progress. By investing in state-of-the-art equipment and staying ahead of the curve when it comes to manufacturing techniques, they have positioned themselves as a leader in the industry. This expanded capacity will allow them to better serve their customers and meet the growing demand for their products.In addition to their commitment to quality and innovation, [Company Name] also prioritizes sustainability in their manufacturing processes. They understand the importance of minimizing their environmental impact and have taken steps to ensure that their operations are as eco-friendly as possible. This dedication to sustainability has not gone unnoticed, and has further solidified [Company Name]'s reputation as a responsible and forward-thinking supplier.As the demand for high-quality aluminum bending brackets continues to grow, [Company Name] is well-positioned to meet and exceed the needs of their customers. With their expanded production capacity and unwavering commitment to excellence, they are ready to take on new challenges and continue to provide top-notch components to the aerospace and automotive industries.In conclusion, [Company Name] has reached a new milestone in their journey towards manufacturing excellence. With a focus on quality, innovation, and sustainability, they have solidified their position as a leading supplier of aluminum bending brackets. Their dedication to precision and their commitment to meeting the needs of their customers make them a trusted partner for companies in need of high-quality components. As they continue to invest in their capabilities and expand their production capacity, [Company Name] is poised to remain at the forefront of the industry for years to come.

Durable and Versatile Sheet Metal Flat for Various Applications

Sheet Metal Flat is a leading provider of high-quality sheet metal products to a wide range of industries. With a strong focus on customer satisfaction and cutting-edge technology, the company has established itself as a trusted partner for businesses looking for precision-engineered metal components.The company offers a wide range of sheet metal products, including flat sheets, coils, and custom-cut pieces. With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, Sheet Metal Flat is able to meet the diverse needs of its customers, delivering products that meet the highest standards of quality and precision.One of the key strengths of Sheet Metal Flat is its ability to work with a variety of materials, including stainless steel, aluminum, and carbon steel. This versatility allows the company to cater to the unique requirements of different industries, from automotive and aerospace to construction and electronics.In addition to its manufacturing capabilities, Sheet Metal Flat also offers a range of value-added services, such as metal finishing, coating, and assembly. This comprehensive approach allows the company to offer a one-stop solution for its customers, streamlining the production process and ensuring a seamless experience from start to finish.Furthermore, the company prides itself on its commitment to sustainability and environmentally friendly practices. Sheet Metal Flat has invested in advanced technologies and processes to minimize waste and reduce its carbon footprint, ensuring that its operations are as eco-friendly as possible.In recent news, Sheet Metal Flat has announced the launch of a new line of flat sheets that are designed to meet the growing demand for lightweight yet durable materials in the automotive industry. These sheets are made from high-strength aluminum alloys, offering a combination of excellent formability and corrosion resistance, making them ideal for use in body panels, chassis components, and structural parts."We are excited to introduce our new line of flat sheets that are specifically engineered to meet the stringent requirements of the automotive industry," said [company spokesperson]. "With the increasing focus on fuel efficiency and lightweighting in the automotive sector, our products are well-positioned to address the evolving needs of our customers."The company's investment in research and development has enabled it to stay ahead of industry trends and develop innovative solutions that meet the changing needs of its customers. Sheet Metal Flat continuously collaborates with its clients to identify new opportunities and develop tailored products that address specific challenges in their respective industries.In addition to its focus on product innovation, Sheet Metal Flat also places a strong emphasis on customer service and satisfaction. The company's team of dedicated professionals works closely with clients to understand their requirements and provide personalized solutions that meet their exact specifications.As Sheet Metal Flat continues to grow and expand its capabilities, the company remains committed to upholding its core values of quality, integrity, and innovation. With a track record of excellence and a customer-centric approach, Sheet Metal Flat is well-positioned to be a leading provider of sheet metal products for years to come.

Durable and Stylish Metal Furniture Fittings for Your Home

Metal Furniture Fittings, a leading provider of high-quality furniture hardware and accessories, is proud to announce the launch of their latest line of innovative and functional products. With a focus on durability, efficiency, and style, Metal Furniture Fittings is dedicated to providing top-of-the-line fittings for all types of furniture.As a renowned industry leader, Metal Furniture Fittings has built a reputation for excellence and reliability. With a commitment to customer satisfaction, the company continuously seeks to innovate and improve their product offerings. With a wide range of fittings and accessories for furniture, Metal Furniture Fittings has become a go-to source for manufacturers, retailers, and designers alike.Metal Furniture Fittings offers a diverse range of products including hinges, handles, drawer slides, and other hardware essentials. Their products are designed to meet the needs of modern furniture design while also prioritizing durability and functionality. Whether it’s for residential, commercial, or industrial use, Metal Furniture Fittings has the perfect solution for any furniture hardware needs.The company prides itself on its cutting-edge manufacturing processes and state-of-the-art technologies. By investing in the latest machinery and equipment, Metal Furniture Fittings is able to produce high-quality fittings with precision and efficiency. This allows them to consistently deliver products that meet the highest industry standards.In addition to their technical capabilities, Metal Furniture Fittings places a strong emphasis on design and aesthetics. Their team of experienced designers and engineers work tirelessly to create products that not only perform well but also enhance the overall look and feel of the furniture they are used on. With a keen eye for detail and an understanding of current design trends, Metal Furniture Fittings ensures that their products are not only functional but also visually appealing.Metal Furniture Fittings is also committed to sustainability and environmental responsibility. The company has implemented eco-friendly practices in their manufacturing processes and uses materials that are safe for the environment. With a focus on reducing waste and energy consumption, Metal Furniture Fittings is dedicated to minimizing their impact on the planet while delivering top-notch products.As the furniture industry continues to evolve, Metal Furniture Fittings remains at the forefront of innovation. By staying ahead of the curve and anticipating the needs of their customers, the company is able to introduce new and exciting products that meet the ever-changing demands of the market.In conclusion, Metal Furniture Fittings is a trusted name in the furniture hardware industry, known for their commitment to quality, innovation, and customer satisfaction. With a wide range of high-quality products, state-of-the-art manufacturing processes, and a dedication to environmental sustainability, the company continues to be a leading force in the market. Whether it’s for residential, commercial, or industrial use, Metal Furniture Fittings is the go-to source for all furniture hardware needs. With their latest line of innovative and functional products, Metal Furniture Fittings is poised to set new standards for the industry and provide even greater value to their customers.

High-quality Custom Heatsink Solutions for Optimal Thermal Management

Custom Heatsink Innovations: Enhancing Performance and ReliabilityIn the fast-paced and rapidly evolving world of technology, the demand for high-performance electronic devices continues to grow. From computers and smartphones to servers and gaming consoles, the need for efficient heating solutions is paramount. Custom heatsinks have become an essential component for ensuring the optimal performance and reliability of these devices.One company at the forefront of custom heatsink innovations is {}. With a strong commitment to research and development, they have been pioneering cutting-edge thermal management solutions for a wide range of industries and applications.Established in {}, {} has quickly gained recognition for its expertise in designing and manufacturing custom heatsinks that are tailored to meet the specific requirements of their clients. Their team of skilled engineers and technicians work closely with customers to develop bespoke cooling solutions that address the unique thermal challenges faced by their electronic devices.One of the key factors that sets {} apart from its competitors is its focus on utilizing advanced materials and manufacturing processes to create heatsinks that offer superior thermal performance. By leveraging state-of-the-art technology, {} is able to deliver innovative cooling solutions that effectively dissipate heat and prolong the lifespan of electronic components.One of the latest advancements from {} is the development of a custom heatsink that incorporates a groundbreaking thermal design. This new heatsink is engineered to maximize surface area and optimize airflow, resulting in significantly improved heat dissipation. By customizing the heatsink's design to suit the specific dimensions and thermal requirements of the target device, {} is able to provide a tailored cooling solution that enhances overall performance and reliability.In addition to their technical expertise, {} is also dedicated to ensuring the quality and performance of their custom heatsinks through rigorous testing and validation. Their in-house testing facilities allow them to evaluate the thermal characteristics of their heatsinks under various operating conditions, ensuring that they meet the highest standards of performance and reliability.Furthermore, {} takes a holistic approach to thermal management by offering comprehensive design and engineering support to their clients. By collaborating closely with customers from the initial concept phase through to final production, {} is able to develop bespoke heatsink solutions that are fully optimized for the specific requirements of each application.The impact of custom heatsinks from {} is felt across a wide range of industries, including telecommunications, automotive, aerospace, and consumer electronics. Whether it's improving the efficiency of power electronics in electric vehicles or enhancing the thermal performance of high-powered processors in data centers, {}'s custom heatsinks play a critical role in enabling the reliable operation of electronic devices in diverse environments.Looking ahead, {} is committed to driving further innovations in custom heatsink technology, with a focus on pushing the boundaries of thermal management to meet the evolving needs of the electronics industry. By continuing to invest in research and development, and by collaborating closely with their customers, {} is poised to remain a leader in delivering high-performance custom heatsinks that set new standards for efficiency and reliability.In conclusion, custom heatsinks from {} are playing a pivotal role in advancing the performance and reliability of electronic devices across various industries. Through their dedication to innovation, quality, and customer collaboration, {} is transforming the landscape of thermal management and setting the benchmark for custom heatsink solutions.

Sheet Metal Bending Tools: Dies, Press Brakes, Tube & Wire Bending

Sheet metal bending is a process that involves creating a bend in a metal sheet to give it a certain shape or form. This process is done using specialized tools and equipment such as bending dies, press brakes, and tube & wire bending machines.Bending dies are the main tool used for sheet metal bending. They are used to apply force to the metal to create a bend. These dies come in different shapes and sizes depending on the shape and size of the bend required. The dies can be used with a stamping press or press brakes.Stamping presses are machines that are used to apply pressure to the metal sheet to create the desired shape. The press brake is another machine that is used for sheet metal bending. It is a large machine that uses a hydraulic system to apply force to the metal sheet. The press brake can create several bends in the metal sheet at once.There are several types of bending dies that can be used for sheet metal bending. The most common type of bending die is the progressive bending die. This die allows multiple bends to be created simultaneously, which makes the process faster and more efficient. Other types of bending dies include the wiping die, rotary die, and the air-bending die.Wire bending machines are used to create bends in wire or rod-shaped materials. These machines use specialized dies to create precise bends in the wire. The bending process is done using a combination of force and heat to create the desired shape.Tube bending machines are used for creating bends in tubes and pipes. These machines use mandrels and dies to create precise bends in the tube. The mandrel is a rod that is placed inside the tube to prevent it from collapsing during the bending process.When it comes to sheet metal bending, it is important to use the right tools and equipment to ensure that the sheet metal is bent correctly. Bending dies and tools are crucial in this process. With the right tools and equipment, it is possible to create precise bends that will meet the desired requirements.In conclusion, sheet metal bending is a complex process that requires specialized tools and equipment like bending dies, press brakes, tube & wire bending machines. Each of these pieces of equipment plays a crucial role in the bending process and is designed to create precise bends. When used correctly, these tools can help you achieve the desired shape and form for your sheet metal project.

China's Reliable Suppliers of High-Quality Machined Parts for Worldwide Buyers

: Why sourcing from China is a popular choice?When it comes to Machining Components, sourcing from China has been an increasingly popular choice, and with good reason. China has quickly become a manufacturing hub, with a large portion of the world's products being produced there. From machined parts to electronics, China has become a global leader in production and manufacturing. In this blog, we will delve into why sourcing from China is a popular choice for Machining Components.Cost-EffectiveOne of the main reasons businesses choose to source from China is the cost-effectiveness. The cost of manufacturing in China is significantly lower than in other countries. This is because the cost of labor is lower in China, making it cheaper to produce machined parts. Additionally, China has well-established manufacturing infrastructure and access to raw materials, which lowers production costs.Quality and ReliabilityChina's manufacturing industry has come a long way in terms of quality and reliability. With many manufacturers adopting ISO certification and implementing quality control measures, you can expect to receive high-quality machined parts from China. When you work with reliable suppliers, you can be certain that the products manufactured are up to international standards.Advanced TechnologyThe manufacturing industry has also been rapidly advancing in China, with many companies investing in advanced technology. This has enabled them to produce high-quality Machining Components and reduce production time while maintaining consistent quality. With advanced technology and equipment, the lead time for products can be significantly reduced, resulting in a faster turnaround time.Large Supplier BaseChina has a vast manufacturing industry, which has resulted in a large supplier base. This is beneficial for businesses as they can easily source the products they require. Moreover, with so many suppliers competing for business, the prices are often competitive, resulting in cost savings for businesses.Customizable ProductsChina is well-equipped to manufacture customized products. Manufacturers can easily tailor their products to meet the specific needs of their customers. Whether it's the dimensions or materials used, manufacturers can create a customized solution that meets your specifications. With customization options available, businesses can have machined parts that are exactly what they need.ConclusionIn conclusion, sourcing from China is a popular choice for Machining Components because of its cost-effectiveness, quality and dependability, advanced technology, large supplier base, and customization options. With these advantages and the continued growth of the manufacturing industry in China, businesses can expect to continue sourcing high-quality machined parts at reasonable prices.

Discover the Amazing Art of Metal Bending Techniques

Metal Bending, a leading manufacturer in the metal fabrication industry, has recently announced the launch of their innovative new product line. The company, known for its high-quality and precision metal bending services, is excited to introduce this new line of products to meet the evolving needs of their customers.With over 20 years of experience in the industry, Metal Bending has built a reputation for excellence in metal fabrication. Their state-of-the-art facility is equipped with the latest technology and machinery, allowing them to provide a wide range of metal bending services to industries such as aerospace, automotive, construction, and more.The new product line will further expand Metal Bending's offerings, allowing them to serve a broader range of customers and industries. The company's dedication to innovation and quality is evident in their commitment to staying at the forefront of the metal fabrication industry.In addition to their new product line, Metal Bending also offers custom metal bending services, allowing customers to request specific designs and shapes for their projects. From simple bends to complex geometries, the company's team of highly skilled engineers and technicians can deliver precision results for any metal bending need.Metal Bending's dedication to customer satisfaction is a driving force behind their success. The company prides itself on providing top-notch customer service, working closely with clients to understand their unique requirements and delivering solutions that meet and exceed their expectations.Furthermore, Metal Bending is committed to sustainability and environmental responsibility. The company adheres to strict environmental regulations and utilizes eco-friendly practices in their operations. They also strive to minimize waste and optimize energy efficiency in their manufacturing processes.As Metal Bending continues to grow and expand its product offerings, the company remains dedicated to maintaining its core values of integrity, quality, and innovation. With a focus on delivering exceptional results and exceeding customer expectations, Metal Bending is poised to continue its leadership in the metal fabrication industry.The company's dedication to excellence has earned them a loyal customer base and a strong reputation in the industry. Metal Bending's products and services are trusted by businesses across various sectors, and their new product line is anticipated to further solidify their position as a go-to source for all metal bending needs.As the demand for metal fabrication services continues to grow, Metal Bending is well-positioned to meet the needs of diverse industries with their unmatched expertise and commitment to quality. The company's new product line is a testament to their ongoing dedication to innovation and customer satisfaction, and it is sure to make a significant impact in the metal fabrication industry.With a proven track record of success and a forward-thinking approach to business, Metal Bending is set to continue its impressive growth and maintain its position as a leader in the metal fabrication industry. The company's new product line is an exciting development that speaks to their ongoing commitment to excellence and innovation, and it is sure to be well-received by their customers.

High-Quality Lighting Accessories for Your Home at Great Prices

Lighting Accessories, a leading provider of high-quality lighting solutions, has been serving the market for over two decades with its innovative and efficient products. The company specializes in a wide range of lighting accessories, including LED bulbs, fixtures, dimmers, and smart lighting solutions, catering to both residential and commercial customers.With a strong focus on sustainability and energy efficiency, Lighting Accessories has established itself as a pioneer in the industry, constantly pushing the boundaries of technology and design. The company's commitment to delivering cutting-edge solutions has earned it a solid reputation for reliability and excellence among its clientele.One of the key factors that set Lighting Accessories apart from its competitors is its dedication to research and development. The company continuously invests in the latest technologies and trends, ensuring that its products are always on the forefront of innovation. By staying ahead of the curve, Lighting Accessories has been able to anticipate and meet the evolving demands of the market, cementing its position as a market leader.In addition to its focus on innovation, Lighting Accessories is also known for its exceptional customer service. The company takes pride in its knowledgeable and friendly staff, who are always ready to assist clients with their lighting needs. Whether it's a new installation, a retrofit project, or a maintenance issue, Lighting Accessories is committed to providing prompt and effective support to ensure customer satisfaction.Furthermore, Lighting Accessories has a strong commitment to sustainability and environmental responsibility. The company offers a wide selection of energy-efficient LED lighting solutions, helping its customers reduce their carbon footprint and energy consumption. By promoting eco-friendly alternatives, Lighting Accessories is contributing to a greener and more sustainable future.Recently, Lighting Accessories introduced a new line of smart lighting products, designed to enhance convenience and efficiency for its customers. These products utilize cutting-edge technology to enable remote control and automation, allowing users to adjust their lighting settings with ease. With features such as dimming, scheduling, and integration with smart home systems, the new smart lighting solutions from Lighting Accessories offer a seamless and modern lighting experience.Furthermore, Lighting Accessories has expanded its reach by partnering with leading technology companies to integrate its smart lighting products with popular platforms and devices. This strategic collaboration has enabled Lighting Accessories to offer seamless compatibility and an enhanced user experience, further solidifying its position as an industry innovator.As part of its ongoing commitment to excellence, Lighting Accessories is constantly expanding its product range and exploring new opportunities in the lighting market. The company is dedicated to staying at the forefront of the industry, delivering exceptional products and services that exceed customer expectations.In conclusion, Lighting Accessories is a trusted provider of high-quality lighting solutions, known for its innovation, customer service, and commitment to sustainability. With a strong track record of success and a forward-thinking approach, the company continues to lead the way in the lighting industry, setting the standard for excellence and reliability. As the demand for efficient and intelligent lighting solutions continues to grow, Lighting Accessories is well-positioned to meet the needs of its customers and remain a driving force in the market.