Ultimate Guide to Sheet Metal Chassis: Everything You Need to Know

By:Admin

[Company name]'s passion for innovation and commitment to excellence have fueled the development of cutting-edge products in the industry. With a focus on precision engineering and superior quality, the company has consistently raised the bar for sheet metal chassis technology. As a leader in the field, [company name] continues to push the boundaries of what is possible, offering customers innovative solutions that meet and exceed their expectations.

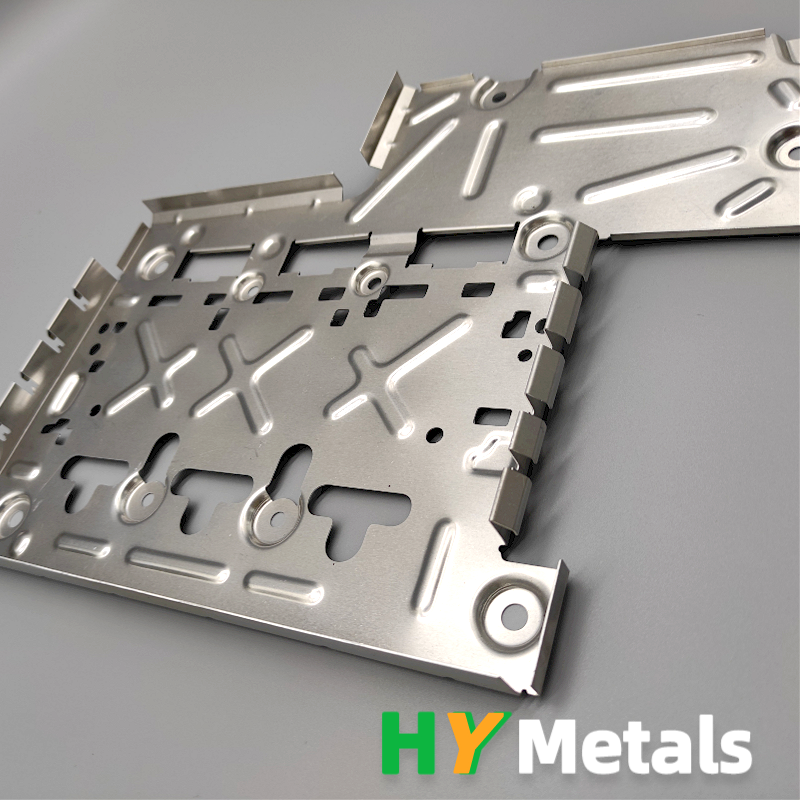

One of the most significant contributions of [company name] to the industry is its world-class sheet metal chassis. These innovative products have set new standards for quality, durability, and performance. Designed to meet the demands of the modern world, [company name]'s sheet metal chassis are the go-to choice for a wide range of applications, from automotive and aerospace to electronics and telecommunications.

The company's sheet metal chassis are engineered with precision and manufactured with the highest quality materials. This ensures that they are able to withstand the rigors of the most demanding environments, providing a level of durability that is unmatched by any other competitor in the market. In addition, the company's commitment to excellence means that its sheet metal chassis are consistently tested and improved to ensure that they meet the highest industry standards.

What sets [company name]'s sheet metal chassis apart from the competition is their unparalleled performance. Whether it is in terms of strength, weight, or versatility, these products have been designed to deliver exceptional results. This has made them the top choice for customers who are looking for a durable and reliable solution that can withstand the most challenging conditions.

Moreover, [company name]'s sheet metal chassis are known for their versatility. They are available in a wide range of sizes and configurations, making them suitable for a diverse set of applications. Whether it is a small electronic device or a large industrial equipment, the company has a sheet metal chassis that can meet the specific needs of each customer.

Another key advantage of [company name]'s sheet metal chassis is their cost-effectiveness. The company has leveraged its expertise and experience to develop manufacturing processes that ensure high-quality products at competitive prices. This has made its sheet metal chassis a cost-effective solution for businesses looking to maximize their return on investment without compromising on quality.

In addition to its focus on product excellence, [company name] is also known for its outstanding customer service. The company values its relationship with customers and is committed to providing them with the support and guidance they need to make informed decisions. Its team of experienced professionals is always on hand to answer questions, provide technical assistance, and offer customized solutions to meet specific needs.

Looking towards the future, [company name] remains dedicated to innovation and continuous improvement. The company is constantly investing in research and development to stay ahead of the curve and anticipate the evolving needs of its customers. This commitment to innovation ensures that [company name]'s sheet metal chassis will continue to be at the forefront of the industry for years to come.

In conclusion, [company name]'s sheet metal chassis are a testament to the company's commitment to excellence and innovation. With their superior quality, unmatched performance, and cost-effectiveness, these products have set new standards for the industry. As [company name] continues to push the boundaries of what is possible, customers can expect to see even more groundbreaking products that will redefine the way we think about sheet metal chassis technology.

Company News & Blog

Metal Sheet Cutting, Punching, Pressing and Binding Services

release:DOMEX Offers Comprehensive Sheet Metal Processing Solutions with State-of-the-Art EquipmentDOMEX, a leader in sheet metal processing, offers a comprehensive range of services that include cutting, punching, pressing, and binding of metal sheets. The company has a state-of-the-art facility equipped with modern mechanical and hydraulic presses, and a range of other equipment, making it possible to handle even complex and challenging sheet metal projects.With more than two decades of experience in the industry, DOMEX has earned a reputation for excellence in sheet metal processing and fabrication. One of the key factors behind its success is the company's focus on quality, precision, and timely delivery of projects. This is supported by their well-trained and experienced staff, who are committed to ensuring every project meets customer expectations.One of the core services offered by DOMEX is metal sheet cutting. The company has invested in the latest hydraulic guillotine shears, which can cut through even the thickest sheets of metal with ease. This equipment is ideal for cutting material for a wide range of industries, including construction, architecture, and manufacturing. Furthermore, the shears provide an impeccable level of precision and accuracy, ensuring that every cut is clean and straight.DOMEX also has an array of mechanical and hydraulic presses that can handle different metal sheet processing needs. Each press has varying pressure power levels and dimensions of working tables, making it possible for the company to provide a range of custom metal fabrication services. These include stamping, deep drawing, bending, and flanging, among others. These metal shaping processes are important in the manufacturing of products in many industries, such as automotive, aerospace, and medical devices.Quality is a top priority at DOMEX, and the company has a stringent quality control process in place to ensure that every project meets exacting standards. Their team of skilled technicians use advanced measuring equipment to check and double-check every aspect of a project before it is allowed to leave the facility. From first cut to final assembly, every step of the metal processing project is carefully monitored and inspected to ensure every component meets customer requirements.DOMEX is also committed to sustainability and environmental responsibility. They use only eco-friendly materials, and their state-of-the-art equipment has been designed to reduce waste and energy consumption. Additionally, the company strives to make sure their metal fabrication processes are as efficient as possible, reducing the use of resources and minimizing the environmental impact of their operations.With its knowledgeable staff, cutting-edge equipment, and commitment to quality and sustainability, DOMEX is a trusted partner for businesses looking for reliable sheet metal processing services. The company's services are ideal for those in the construction, architecture, manufacturing, and other related industries who require top-quality, precision sheet metal fabrication. In conclusion, DOMEX remains a leader in the sheet metal processing industry, and their commitment to excellence and sustainability sets them apart from the competition. Whether cutting, punching, pressing, or binding metal sheets, the company ensures that every project is completed to the highest standards, on time and within budget.

Quick and Efficient Prototype Machining Techniques in the News

Rapid Prototype Machining Plays a Vital Role in Transforming the Manufacturing IndustryThe manufacturing industry is constantly evolving, with new technologies and tools emerging every day. The introduction of rapid prototype machining is one such development that has revolutionized the manufacturing industry in recent years. Rapid prototype machining is a technique that’s characterized by quick production of prototypes, meaning that companies can accelerate their product development processes significantly.Today, several companies are exploring the benefits of rapid prototype machining to build flawless products, reduce their time to market, decrease development costs, and increase overall productivity. One such company that has been at the forefront of rapid prototype machining technology is a leading manufacturer of cutting-edge products.With its state-of-the-art facility, the company has been able to leverage rapid prototype machining techniques to deliver innovative products to its customers. From electronics to medical devices, the company has explored every industry and is a go-to resource for anyone looking to develop a prototype of a product they’ve been working on.The benefits of rapid prototype machining are numerous. First, by allowing users to create prototypes using computer-aided design (CAD) software, it reduces lead times in the product development process by several weeks. Second, the process ensures the accuracy of the product by providing users with several iterations of the prototype before final production. And finally, rapid prototype machining helps businesses to make informed decisions about their products, which helps them bring new and better products to the market faster than their competition.At the company, the focus is always on the customer. The company’s in-house experts guide customers through the rapid prototype machining process, providing them with the tools and resources they need to get the job done right. With an unwavering commitment to quality, the company works tirelessly to ensure that every prototype that leaves the facility meets the most demanding standards of excellence.The company’s facility features some of the most advanced tools and equipment in the industry, including full-scale 5-axis CNC machines, state-of-the-art 3D printers, and a variety of CAD software. These resources enable users to create prototypes in a variety of materials, including plastics, metals, and composites.The company’s expertise in rapid prototype machining technology is not limited to the manufacturing of physical products. It’s also a leader in the creation of virtual prototypes, including advanced simulations, test models, and digital replicas. This aspect is critical to the manufacturing industry as it enables customers to test virtual prototypes and refine them before printing the final product. By exploring both virtual and physical prototypes, customers can save money, reduce time to market, and create better final products.The company is a prime example of what businesses can do to leverage the benefits of rapid prototype machining in the manufacturing industry. With its commitment to innovation and excellence, it’s rapidly transforming the way businesses approach product development and manufacturing. And as technologies become increasingly sophisticated, it’s clear that companies that aren’t embracing rapid prototype machining will be left behind.In conclusion, rapid prototype machining is a game-changer for the manufacturing industry. With its ability to reduce lead times, increase productivity, and deliver better products, it’s becoming an increasingly important tool for businesses looking to adapt and thrive in an ever-evolving marketplace. And as companies look to the future, it’s clear that investing in rapid prototype machining technology will be critical to their success. The leading manufacturer has shown the way, and by following their example, others can transform their businesses and establish themselves as industry leaders in the years to come.

Customized Heat Sink for Optimal Performance: A Guide to Choosing the Best Option

[Company Name]'s Innovative Customized Heatsink Part Revolutionizes Cooling Solutions[City, Date] - [Company Name], a leader in the field of thermal management solutions, has unveiled its game-changing customized heatsink part. This innovative product is set to revolutionize the industry by providing a highly efficient cooling solution for a wide range of applications.With the continuous advancement of electronic systems and the subsequent increase in power densities, efficient heat dissipation has become paramount. [Company Name] recognized this need and dedicated its resources to developing a state-of-the-art heatsink that offers superior cooling performance.The key to [Company Name]'s custom heatsink lies in its cutting-edge design and advanced materials. Utilizing innovative engineering techniques, the company has created a part that maximizes heat dissipation while minimizing space and weight requirements. This makes it an ideal solution for applications where size and weight are critical, such as aerospace, automotive, and military industries.The customized heatsink is manufactured using high-performance materials that excel in thermal dissipation. These materials ensure that heat is efficiently spread out throughout the heatsink, preventing hotspots from forming and ensuring optimum cooling performance. [Company Name]'s dedication to quality is evident in the precision manufacturing processes employed, guaranteeing consistent performance, durability, and reliability.Furthermore, [Company Name] has an experienced team of engineers and thermal management specialists who work closely with clients to provide customized solutions tailored to their specific requirements. By collaborating with customers, the company ensures that its custom heatsink precisely caters to the unique demands of the application, be it shape, size, or performance requirements."The introduction of our customized heatsink is a watershed moment for the industry," says [Company Name]'s CEO. "We have conducted extensive research and development to create a product that not only meets but exceeds expectations. Its impressive cooling capabilities, combined with its compact design, make it a game-changer for a multitude of industries."The benefits of [Company Name]'s custom heatsink extend beyond superior cooling performance. Its lightweight construction and compact design result in lowered power consumption and increased energy efficiency. This not only reduces costs for end-users but also contributes to a greener and more sustainable future.One of the significant applications for [Company Name]'s custom heatsink is in electric vehicles (EVs). The automotive industry is rapidly transitioning to EVs, and the demand for efficient thermal management solutions is growing exponentially. By utilizing [Company Name]'s custom heatsink, EV manufacturers can ensure optimal cooling of crucial components, leading to enhanced vehicle performance, extended battery life, and increased overall vehicle safety.The aerospace industry is another sector set to benefit significantly from [Company Name]'s breakthrough heatsink technology. In aircraft, where weight is a critical factor, [Company Name]'s lightweight, compact custom heatsink provides an ideal solution to cool critical electronic components, ensuring reliable operation even in demanding environments.In addition to EVs and aircraft, [Company Name]'s custom heatsink has the potential to find applications in various other industries, including telecommunications, data centers, medical equipment, and consumer electronics.[Company Name] has already received positive feedback from early adopters of its custom heatsink. Companies across various industries have praised the product's performance, compact design, and ability to cater to specific application requirements.With its commitment to innovation, quality, and customer satisfaction, [Company Name] is well-positioned to redefine the thermal management landscape. Their customized heatsink part represents a significant step forward in providing efficient and reliable cooling solutions across a range of industries, ensuring enhanced performance and longevity for critical electronic systems. By harnessing this groundbreaking technology, companies can stay ahead in the competitive market, delivering products that excel in performance and efficiency.For more information about [Company Name] and their revolutionary customized heatsink part, please visit [website] or contact [contact information].About [Company Name]:[Company Name] is a leading global provider of thermal management solutions. With a focus on research, development, and manufacturing, the company is committed to delivering innovative products that ensure optimal cooling and reliability for electronic systems. [Company Name]'s team of experts collaborates closely with clients to provide customized solutions tailored to their specific requirements.

Precision Grinding of CNC Machined Parts for Increased Durability and Performance

Title: Advancements in CNC Machined Parts Grinding: Delivering Precision and EfficiencyIntroduction (approx. 80 words):In the fast-paced world of manufacturing, the demand for precision-engineered components is at an all-time high. Addressing this need, a leading company in the field has made significant breakthroughs in CNC Machined Parts Grinding. By combining cutting-edge technology and industry expertise, they are revolutionizing the production of machined parts, offering unparalleled precision, efficiency, and reliability. With the ability to remove imperfections with remarkable accuracy, their advanced grinding techniques enhance product quality, reduce production time, and maximize cost-effectiveness.Innovation in CNC Machined Parts Grinding (approx. 200 words):Building on decades of experience and a commitment to continuous innovation, the company has introduced state-of-the-art advancements in CNC Machined Parts Grinding. By leveraging advanced robotic systems, high-precision tools, and computer numerical control (CNC) technology, they have transformed the grinding process, setting new standards in the industry.The integration of robotic systems has enabled precise handling and positioning of components, ensuring consistent grinding quality. This automation enhances productivity, eliminates human error, and optimizes production throughput. Additionally, it allows for multitasking capabilities, enabling simultaneous grinding of multiple parts, saving valuable time without compromising precision.Furthermore, the utilization of high-precision tools and cutting-edge abrasives guarantees the removal of imperfections with exceptional accuracy. By employing a combination of grinding wheels, belts, and discs designed for specific applications, the company ensures the highest level of precision, ensuring superior surface finishes and dimensional accuracy.To enhance the grinding process's efficiency, the company has incorporated CNC technology into their machining centers. This allows for seamless coordination between various machining operations, eliminating the need for multiple setups and tool changes. The result is faster cycle times, reduced downtime, and improved overall productivity.Benefits and Applications (approx. 250 words):The advancements in CNC Machined Parts Grinding have numerous benefits that make them indispensable for various manufacturing industries. The precision achieved through these techniques ensures the exact dimensions and tolerances required, eliminating the risk of errors and rework. By improving product quality and reducing rejects, manufacturers can establish a reputation for delivering superior components consistently.Moreover, these advancements have considerably reduced production time. With increased automation, multitasking capabilities, and efficient integration of CNC technology, companies can significantly improve throughput. This accelerates the delivery of finished parts, enabling manufacturers to meet tight deadlines without compromising quality.The cost-effectiveness of CNC Machined Parts Grinding is another crucial advantage. By streamlining processes and minimizing waste, manufacturers can optimize resource utilization and reduce production costs. In addition, the ability to complete complex grinding operations in a single setup reduces labor costs and machine downtime.The applications for CNC Machined Parts Grinding span various industries, including aerospace, automotive, robotics, medical, and more. In the aerospace sector, for instance, the precision grinding techniques are indispensable for creating intricate components that withstand the extreme demands of aircraft engines. Similarly, in the medical field, these advancements enable the production of high-precision parts for surgical instruments and prosthetics, ensuring utmost reliability and patient safety.Conclusion (approx. 70 words):Through their relentless pursuit of innovation, the company has transformed CNC Machined Parts Grinding, positioning themselves as industry leaders. With a focus on precision, efficiency, and cost-effectiveness, their advanced grinding techniques have revolutionized the manufacturing sector. By embracing these advancements, manufacturers can forge a path towards increased productivity, improved quality, and enhanced competitiveness in the global market.

Exploring the Tremendous Benefits of Fast Prototyping in Modern Industries

Title: Revolutionary Prototyping Technology Unveiled by Industry LeaderSubtitle: Pioneering the Future of Product Development and InnovationDate: [Date][City], [State] - [Company Name], a renowned leader in the field of prototyping and product development, has introduced an innovative and ground-breaking technology that is set to revolutionize the industry. The company is changing the game with its cutting-edge Fast Prototyping, a process that enables businesses to bring their ideas to life quicker and more efficiently than ever before.With a knack for pushing boundaries and an unwavering commitment to excellence, [Company Name] has always been at the forefront of technological advancements. The introduction of their Fast Prototyping technology is yet another testament to their status as industry leaders.Fast Prototyping is a game-changer in the product development world, allowing businesses to rapidly iterate and refine their designs in order to accelerate the time-to-market. This technology enables companies to transform their concept into a physical prototype within a matter of days, significantly reducing the time and cost associated with traditional prototyping methods.The key to Fast Prototyping lies in its use of cutting-edge 3D printing technologies. By harnessing the power of additive manufacturing, [Company Name] can create highly intricate and accurate prototypes directly from digital designs. This removes the need for costly and time-consuming manual modeling and machining processes, streamlining the entire development cycle.Furthermore, [Company Name] has developed advanced materials specifically tailored for Fast Prototyping. These materials possess exceptional strength, durability, and surface finish properties, ensuring that the prototypes accurately represent the final product. This allows companies to make critical design decisions early on and avoid costly errors down the line.The benefits of Fast Prototyping are not limited to design iteration speed and cost reduction. By quickly obtaining physical prototypes, businesses can test their products' ergonomics, functionality, and market appeal, gaining valuable insights that can inform further development iterations. This agile approach to product development empowers companies to meet customer demands swiftly and stay ahead of the competition.In addition to their state-of-the-art technology, [Company Name] boasts a highly skilled team of engineers and designers who work closely with clients throughout the prototyping process. Their expertise and collaborative approach ensure that the envisioned product is accurately translated into physical form, guaranteeing customer satisfaction."Our innovation-driven approach has always been centered around helping businesses transform their ideas into tangible realities," said [Company Name]'s CEO. "With Fast Prototyping, we are enabling companies to prototype and iterate at an unprecedented pace, unlocking the potential for faster time-to-market and competitive advantage."The applications of Fast Prototyping are vast and diverse. From aerospace to automotive, consumer electronics to medical devices, [Company Name] is committed to supporting a wide range of industries in their pursuit of innovation and excellence. Their technology will undoubtedly empower businesses to reimagine what is possible and bring their concepts to fruition in record time.For companies looking to harness the power of Fast Prototyping, [Company Name] offers tailored solutions and comprehensive support throughout the entire prototyping process. This includes design optimization, material selection, and seamless integration with existing product development workflows.As an industry leader and innovator, [Company Name] continues to revolutionize the field of product development. With Fast Prototyping, they are pioneering a new era of rapid, efficient, and cost-effective innovation, allowing businesses to turn their ideas into reality with unparalleled speed and precision.About [Company Name]:[Company Name] is a globally recognized leader in advanced product development and prototyping. With a team of highly skilled engineers and designers, they have been at the forefront of technological innovation for over [number of years] years. Their commitment to excellence and passion for driving innovation have cemented their position as a trusted partner for businesses across various industries.

Production-Grade 3D Printer Enables MTConnect Integration for Aerospace and Industrial Applications

, F900 3D printer, production applications, aerospace industry, MTConnect protocol.Additive manufacturing has revolutionized the manufacturing industry with the ability to create complex geometries with high precision and speed. One of the leading players in the additive manufacturing market is the F900 3D printer, designed for production applications in the aerospace industry and other high-performance industries. This blog discusses the latest development in the F900 3D printer, which now features an MTConnect-ready interface, offering enhanced connectivity and data exchange capabilities.The F900 3D printer is known for its high-performance capabilities, reliability, and large-scale printing. The printer uses the Fused Deposition Modeling (FDM) technology, which involves building 3D models layer by layer by depositing material in a melted state. The FDM technology provides a high degree of design flexibility, allowing the production of complex geometries without the need for additional machining or assembly processes.The F900 3D printer has been widely used in the aerospace industry for the production of complex parts, such as ducting, brackets, and housings. These parts require high precision and accuracy, and the F900 has proven to be a reliable and cost-effective solution for their manufacturing. Additionally, the F900 has been used in other industries, such as automotive, defense, and medical, where the demand for high-performance parts is also high.The latest development in the F900 3D printer is its integration with the MTConnect protocol. MTConnect is an open-source communication protocol used in manufacturing equipment to facilitate data exchange and collection. The protocol offers a standardized way of communicating machine data, making it easier to integrate different systems and devices.With its MTConnect-ready interface, the F900 3D printer can now connect to other manufacturing systems, such as Enterprise Resource Planning (ERP) systems, Manufacturing Execution Systems (MES), and other machines in the production line. This enables better coordination between different manufacturing processes, leading to higher efficiency and productivity. Additionally, the MTConnect protocol allows for real-time monitoring of the printing process, giving operators better control and visibility over the manufacturing process.The integration of the MTConnect protocol into the F900 3D printer is a significant step towards enhancing the connectivity and data sharing capabilities of the printer. This development enables the printer to be integrated into a broader manufacturing ecosystem, allowing for seamless data exchange and coordination between different systems. This integration is highly relevant in the aerospace industry, where the demand for high-performance parts is only increasing.In conclusion, the F900 3D printer is a high-performance system designed for production applications in the aerospace industry and other high-performance industries. With its latest development, the integration of the MTConnect protocol, the printer now offers enhanced connectivity and data exchange capabilities, making it easier to integrate into a broader manufacturing ecosystem. This development ensures the F900 3D printer remains one of the leading additive manufacturing systems in the market today.

Sheet Metal Box Fabrication: A Complete Guide to Manufacturing

Title: Sheet Metal Box Fabrication Revolutionizing Industrial Manufacturing ProcessesIntroduction:In today's rapidly evolving industrial landscape, companies are increasingly seeking innovative and efficient solutions to enhance their manufacturing processes. One such groundbreaking solution is the sheet metal box fabrication technique, which is revolutionizing how industries design and manufacture enclosures for various applications. By eliminating the need for traditional welding techniques, sheet metal box fabrication offers unmatched precision, cost-effectiveness, and durability. This method is rapidly gaining popularity among industries worldwide, propelling them to enhance productivity and create cutting-edge products.Body:1. The Rise of Sheet Metal Box Fabrication: The demand for sheet metal box fabrication has soared in recent years due to its numerous advantages over traditional manufacturing techniques. This process involves using advanced machinery and computer-aided design (CAD) software to convert flat metal sheets into enclosures or boxes with intricate designs. By utilizing laser cutting, bending, and assembling technologies, manufacturers can create precisely engineered box structures while minimizing material waste and time-consuming setup processes.2. Unmatched Precision and Customization: Sheet metal box fabrication allows for unparalleled precision and customization options. With CAD software, manufacturers can design intricate and complex box structures, ensuring a perfect fit for the intended application. Every cut, bend, and joint is precisely calculated and executed by state-of-the-art machinery. This high degree of accuracy eliminates any potential human errors and ensures consistent quality throughout the manufacturing process.3. Cost-Effective Manufacturing: Traditional welding techniques often require extensive labor and time, leading to a significant increase in production costs. In contrast, sheet metal box fabrication significantly reduces labor costs by automating most of the manufacturing processes. With advanced machinery handling the bulk of the work, manufacturers can achieve higher production volumes in shorter time frames while minimizing human errors. Additionally, the efficiency of this technique greatly reduces material waste, contributing to more sustainable manufacturing practices.4. Enhanced Durability and Strength: The sheet metal box fabrication technique guarantees exceptionally strong and durable enclosures. By utilizing a combination of laser cutting and precision bending, these boxes provide optimal structural integrity. The metal sheets used are carefully selected based on the intended application, ensuring the highest level of strength and resistance against external factors such as impacts, pressure, and environmental conditions. This reliability makes sheet metal box fabrication highly sought after in industries that require robust enclosures.5. Wide Range of Applications: Sheet metal box fabrication finds applications across various industries due to its versatility and flexibility. From telecommunication enclosures to electrical panels, this technique caters to the diverse needs of industries, promoting seamless integration into existing systems. Furthermore, sheet metal boxes can be customized to include additional functionalities such as cable management solutions, heat dissipation mechanisms, and mounting options for internal components. This adaptability ensures that manufacturers can meet the specific requirements of their clients with utmost efficiency.6. Advancements and Innovations: The continuous advancement in sheet metal box fabrication technology is driving further innovation in industrial manufacturing processes. Integration with Artificial Intelligence (AI) and Machine Learning (ML) allows for real-time monitoring and optimization of production parameters. This ensures higher accuracy, reduced downtime, and enhanced productivity. Additionally, the integration of robotics and automation enables manufacturers to achieve even faster production cycles while maintaining precise quality control.Conclusion:Sheet metal box fabrication is revolutionizing the way industries design and manufacture enclosures, offering unparalleled precision, cost-effectiveness, and durability. By adopting this advanced technique, manufacturers can streamline their manufacturing processes, increase productivity, and deliver high-quality products to meet the demands of an ever-evolving market. With continuous advancements and innovations, sheet metal box fabrication is set to become the industry standard, revolutionizing industrial manufacturing processes worldwide.

Discover Incredible Designs for Your Metal T-Shirt | Get Inspired Today!

–Metal T-shirt Designs: The Best Metal T-shirt ImagesMetal music has always been a symbol of rebellion and freedom of expression. Metalheads all over the world love to express their passion for the genre through metal T-shirts. Metal T-shirts are the perfect way to represent your favorite bands, pay tribute to fallen legends, and showcase your love for heavy metal music.If you're a metalhead looking to rock a new metal T-shirt, look no further. Thanks to professional designers and graphic artists, there are some amazing metal T-shirt designs available today that are sure to capture your attention. In this blog, we'll take a look at some of the best metal T-shirt images and designs out there and provide some tips on how to plan your own custom metal T-shirt.Metal T-Shirts: A Brief HistoryMetal T-shirts have been around since the 1970s. Fans of bands like Black Sabbath, Iron Maiden, and Judas Priest began to wear T-shirts featuring their bands' logos and designs. These T-shirts became an essential part of the metal scene and a way for fans to show their support for the bands.Over time, metal T-shirts became more elaborate and detailed, incorporating complex artwork, album covers, and song lyrics. Today, metal T-shirts are available in a wide range of designs and styles, from vintage-inspired designs to bold and modern graphics.The Best Metal T-Shirt Images and DesignsHere are some of the best metal T-shirt images and designs that are sure to inspire you:1. Black Sabbath Paranoid T-ShirtThe Black Sabbath Paranoid T-Shirt is a classic metal T-shirt that features the album cover of their second album. The striking design features the band's name in bold red letters on a black background, along with a red and yellow image of a distorted face.2. Iron Maiden The Trooper T-ShirtThe Iron Maiden The Trooper T-Shirt is another classic metal T-shirt that features the iconic artwork from their album cover of the same name. The design features their famous mascot, Eddie, dressed as a British soldier and carrying the Union Jack.3. Metallica Ride the Lightning T-ShirtThe Metallica Ride the Lightning T-Shirt is a timeless design that features the iconic artwork from their second studio album. The design features a striking image of a man being electrocuted, with the band's name and album title in bold letters.4. Slayer Eagle T-ShirtThe Slayer Eagle T-Shirt is another classic metal T-shirt that features a striking image of an eagle with outstretched wings. The design features the band's name in black capital letters with the words "Reign in Blood" in red.5. Megadeth Vic Rattlehead T-ShirtThe Megadeth Vic Rattlehead T-Shirt features their famous mascot, Vic Rattlehead, who has appeared on many of their album covers. The design features a black and white image of the skeletal figure with their band name in bold letters.Tips for Planning Your Custom Metal T-ShirtIf you want to create your own custom metal T-shirt, here are some tips to help you get started:1. Choose your design – Start by brainstorming some ideas for your design. Consider incorporating your favorite bands, songs, or album covers.2. Select your colors – Choose colors that complement your design and that you'll enjoy wearing.3. Pick your fabric – Consider the weight and quality of the fabric. A heavier fabric will last longer but may be less comfortable to wear.4. Determine your size and fit – Consider your body type and what kind of fit you prefer.5. Find a reputable metal T-shirt printing company – Look for a company that specializes in metal T-shirt printing and has positive reviews from customers.ConclusionMetal T-shirts are a great way to express your love for heavy metal music and show your loyalty to your favorite bands. Whether you opt for a classic design or a custom one, remember to choose a design and fabric that you'll enjoy wearing and that will represent you and your passion for metal music. With the right design and fit, your metal T-shirt will last for years and be a cherished part of your wardrobe.

Latest 3D Printing Technology and its Impact on Manufacturing

[Insert Company Logo]Innovative 3D Printing Technology Revolutionizing Manufacturing Industry[City, Date] - As the manufacturing industry continues to evolve, a technological breakthrough has emerged that is changing the way products are designed and produced. 3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by layering materials such as plastics, metals, and ceramics based on a digital model. This revolutionary technology is being embraced by [Company Name], a leading company at the forefront of the 3D printing industry.Since its inception, [Company Name] has been dedicated to advancing 3D printing technology and providing cutting-edge solutions to its customers. The company's state-of-the-art 3D printers and advanced materials have enabled manufacturers to accelerate their product development cycle and create complex, high-quality parts with unparalleled precision.One of the key advantages of 3D printing is its ability to produce customized and intricate designs that traditional manufacturing methods may not be able to achieve. This flexibility and versatility have made 3D printing a game-changer for various industries, including aerospace, automotive, healthcare, and consumer goods.[Company Name] has been instrumental in driving the adoption of 3D printing across different sectors by offering a wide range of services, including prototyping, tooling, and low-volume production. The company's expertise in materials science and additive manufacturing processes has allowed it to develop innovative solutions that meet the specific needs of its customers.Moreover, [Company Name] is committed to sustainability and environmental responsibility. With 3D printing, the company has been able to reduce material waste and energy consumption, leading to a more sustainable and eco-friendly manufacturing process.In addition to its commitment to technological innovation, [Company Name] has also focused on providing comprehensive training and support to its clients. By offering workshops, seminars, and consulting services, the company has empowered its customers to harness the full potential of 3D printing and maximize their operational efficiency.Furthermore, [Company Name] has established strategic partnerships with leading organizations to further advance the adoption of 3D printing in various industries. These collaborations have enabled the company to broaden its market reach and leverage the expertise of industry leaders to drive innovation and growth.The impact of 3D printing on the manufacturing industry is undeniable, as it provides a cost-effective and efficient alternative to traditional manufacturing methods. As [Company Name] continues to push the boundaries of 3D printing technology, it is paving the way for a new era of manufacturing that is characterized by innovation, speed, and sustainability.The future of manufacturing is undoubtedly being shaped by 3D printing, and [Company Name] is at the forefront of this transformative revolution. With its unwavering commitment to excellence and its dedication to providing cutting-edge solutions, [Company Name] is poised to continue leading the way in the 3D printing industry and driving the next wave of innovation in manufacturing.For media inquiries, please contact:[Company Name][Contact Person][Email Address][Phone Number][Website][Company Address]

How Precision Machined Parts are Revolutionizing the Manufacturing Industry

Title: Precision Turned Parts Provider Delivers Exceptional Quality and Promotes SustainabilityIntroduction:The precision turned parts industry plays a crucial role in several sectors, including automotive, aerospace, electronics, and medical devices. In this regard, companies like Turning Parts are at the forefront of supplying high-quality components that meet the demanding requirements of modern manufacturing. Dedicated to precision, reliability, and sustainability, Turning Parts excels in delivering superior products while taking proactive measures to minimize their environmental impact.Company Overview:As a leading provider in the precision turned parts industry, Turning Parts has built a reputation for its commitment to quality and customer satisfaction. Serving a diverse range of global clients, the company specializes in producing CNC turned parts, precision machined components, and custom assembly services. With a strong focus on innovation, Turning Parts continuously invests in cutting-edge technologies, ensuring the highest level of accuracy and efficiency in their manufacturing processes.Superior Precision and Expertise:One of the key factors setting Turning Parts apart from its competitors is its unmatched precision and attention to detail. Equipped with state-of-the-art machinery, the company combines advanced software with a team of highly skilled engineers and technicians. This ensures that every turned part manufactured by Turning Parts meets the strictest specifications and quality standards. From complex geometries to tight tolerances, the company has the capabilities to deliver components that function flawlessly in various industrial applications.Commitment to Sustainability:Recognizing the environmental challenges faced by the manufacturing industry, Turning Parts has taken proactive measures to integrate sustainability into its operations. By implementing energy-efficient practices, reducing waste generation, and exploring eco-friendly materials, the company prioritizes sustainability throughout the production cycle.Energy Efficiency: Turning Parts has invested in energy-efficient machinery and optimized its manufacturing processes to minimize energy consumption. By utilizing advanced technologies, the company ensures that energy is utilized efficiently, reducing carbon emissions and contributing to a greener future.Waste Reduction:To minimize waste generation, Turning Parts has implemented a comprehensive waste management system. By segregating, recycling, and reusing materials wherever possible, the company aims to reduce its environmental footprint. Additionally, Turning Parts collaborates with suppliers who share their commitment to sustainability, opting for eco-friendly packaging solutions and raw materials.Circular Economy Approach:Recognizing the importance of a circular economy, Turning Parts actively promotes the recycling and reintegration of materials into the production process. By embracing remanufacturing and reconditioning practices, the company aims to extend the lifecycle of its products, minimizing waste and conserving resources. This approach not only benefits the environment but also contributes to cost savings for clients.Continuous Improvement and Innovation:Turning Parts prides itself on its dedication to continuous improvement and innovation. By staying abreast of industry trends and investing in research and development, the company consistently explores new techniques and materials to ensure its products remain at the forefront of technological advancements. With a customer-centric approach, Turning Parts collaborates closely with clients to understand their unique requirements and deliver tailored solutions that exceed expectations.Customer Satisfaction and Global Presence:Turning Parts places strong emphasis on customer satisfaction and building long-lasting partnerships. With a global clientele, the company operates in diverse markets and understands the unique needs and regulations of different industries. By maintaining open communication channels and delivering superior support, Turning Parts has earned the trust of its customers, positioning itself as a preferred supplier in the precision turned parts industry.Conclusion:Turning Parts, a renowned precision turned parts provider, continues to deliver exceptional quality products while prioritizing sustainability. Through its commitment to precision, energy efficiency, waste reduction, and innovation, the company exemplifies the positive potential of the manufacturing industry. As the demand for precision turned parts grows, Turning Parts remains dedicated to providing reliable, high-quality components and actively contributing to a sustainable future.