Guide to Metal Furniture Fittings: A Complete Overview of Options and Installation

By:Admin

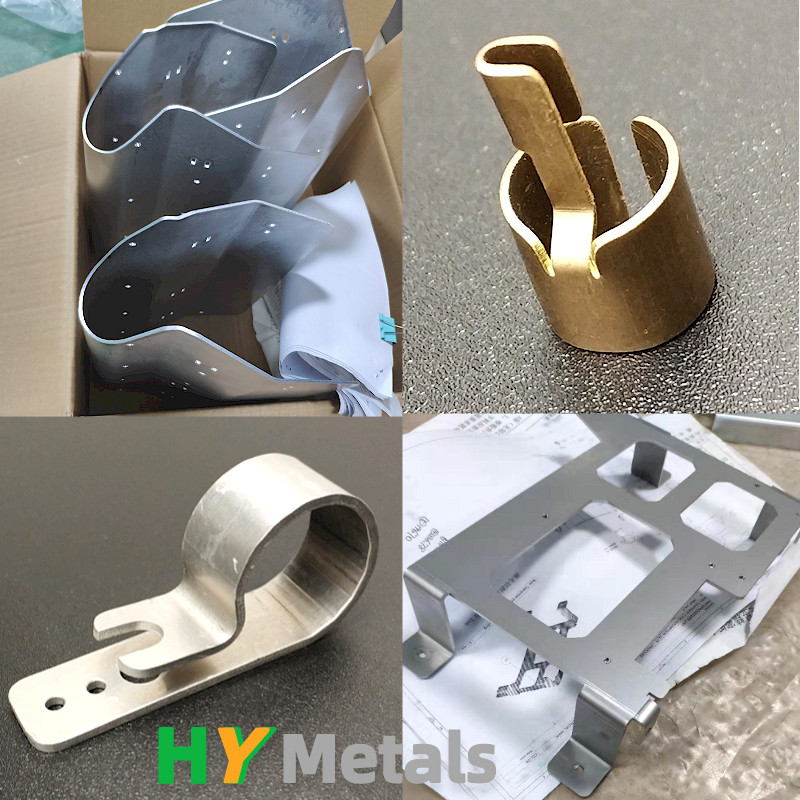

With a strong focus on innovation and customer satisfaction, Metal Furniture Fittings has built a reputation for excellence in the furniture fittings industry. The company's extensive product line includes a wide range of fittings and hardware for use in residential, commercial, and industrial settings. From cabinet handles and knobs to drawer slides and hinges, Metal Furniture Fittings offers a comprehensive selection of products to meet the diverse needs of its customers.

"We are excited to announce our expansion into new markets and are eager to bring our high-quality products to even more customers," said the company's spokesperson. "At Metal Furniture Fittings, we are dedicated to providing innovative solutions and exceptional customer service. Our commitment to excellence sets us apart in the industry, and we look forward to continuing to serve our customers with the best products available."

Metal Furniture Fittings is known for its commitment to quality and reliability. The company's products are manufactured using the latest technologies and the highest quality materials, ensuring durability and performance. With a focus on sustainability, Metal Furniture Fittings also prioritizes environmental responsibility in its manufacturing processes, making it a preferred choice for customers who prioritize eco-friendly products.

In addition to its extensive product line, Metal Furniture Fittings offers custom solutions for customers with unique needs. The company's team of experienced professionals works closely with each customer to understand their requirements and provide tailored solutions that meet their specific needs. Whether it's a custom finish, size, or design, Metal Furniture Fittings is dedicated to delivering products that exceed customer expectations.

Furthermore, Metal Furniture Fittings is committed to staying ahead of industry trends and technological advancements. The company invests in research and development to continuously improve its products and stay at the forefront of innovation. By leveraging the latest technologies and design trends, Metal Furniture Fittings ensures that its products are not only functional but also aesthetically pleasing, enhancing the overall look and feel of any space.

Customer satisfaction is a top priority for Metal Furniture Fittings, and the company takes pride in its exceptional customer service. Whether customers have questions about products, need assistance with installation, or have special requests, Metal Furniture Fittings' team of knowledgeable and friendly professionals is always available to provide the support they need. The company's dedication to building strong, long-lasting relationships with its customers has earned it a loyal and satisfied customer base.

As Metal Furniture Fittings expands into new markets, the company remains committed to upholding its core values of quality, innovation, and customer satisfaction. With a diverse range of products, a focus on sustainability, and a dedication to excellence, Metal Furniture Fittings is well-positioned to continue leading the furniture fittings industry and meeting the evolving needs of its customers.

To learn more about Metal Furniture Fittings and its products, please visit their website at www.metalfurniturefittings.com.

Company News & Blog

High-Precision CNC Machined Component: Expertly Crafted for Superior Performance

CNC Machined Component Provides High-Quality Solutions for Diverse IndustriesIn today's fast-paced and competitive manufacturing industry, the demand for precision-engineered components has never been greater. Companies across various sectors are constantly seeking reliable and efficient machining solutions to meet their specific needs. One company that has been at the forefront of providing high-quality CNC machined components for diverse industries is [Company Name].[Company Name] is a leading provider of CNC machining services, specializing in the production of custom components for a wide range of applications. With state-of-the-art facilities and a team of experienced engineers and technicians, the company is able to deliver precision-engineered parts that meet the exact specifications of its clients.The company's CNC machining capabilities are extensive, allowing it to handle projects of any size and complexity. From prototyping to high-volume production runs, [Company Name] has the expertise and resources to deliver top-quality components with exceptional accuracy and consistency. Whether it's aerospace, automotive, medical, or any other industry, the company's CNC machined components are trusted by leading manufacturers around the world.One of the key factors that sets [Company Name] apart from its competitors is its commitment to utilizing the latest technology and equipment in the industry. The company's investment in advanced CNC machining centers, cutting-edge tooling, and sophisticated software enables it to deliver superior results with quick turnaround times. By leveraging the power of modern machining technology, [Company Name] is able to achieve tight tolerances, intricate geometries, and flawless surface finishes in its components.Moreover, the company's team of skilled engineers and machinists play a pivotal role in ensuring the success of each project. By working closely with clients to understand their specific requirements, [Company Name] is able to provide tailored solutions that address their unique needs. From material selection to design optimization, the company's experts are dedicated to delivering cost-effective and reliable machining solutions that exceed expectations.One of the hallmark offerings of [Company Name] is its range of CNC machined components, which are known for their exceptional quality and performance. The company manufactures a wide variety of parts, including but not limited to, precision gears, shafts, brackets, housings, and much more. Each component is meticulously machined to the highest standards, using a wide range of materials such as aluminum, steel, titanium, and plastics.For customers in industries where quality and reliability are absolutely critical, [Company Name] is the go-to provider for CNC machined components. The company's track record of delivering top-notch parts that meet stringent industry standards has earned it a reputation for excellence and trustworthiness. Whether it's for critical aerospace applications, high-performance automotive systems, or life-saving medical devices, [Company Name] ensures that its CNC machined components deliver the utmost in precision and durability.In conclusion, [Company Name] has established itself as a premier provider of CNC machined components, offering unmatched precision, quality, and expertise to industries worldwide. With its cutting-edge technology, skilled workforce, and commitment to customer satisfaction, the company continues to be a trusted partner for businesses seeking top-quality machining solutions. As the manufacturing landscape evolves, [Company Name] remains at the forefront of delivering innovative and reliable CNC machined components that drive the success of its clients.

Production-Grade 3D Printer Enables MTConnect Integration for Aerospace and Industrial Applications

, F900 3D printer, production applications, aerospace industry, MTConnect protocol.Additive manufacturing has revolutionized the manufacturing industry with the ability to create complex geometries with high precision and speed. One of the leading players in the additive manufacturing market is the F900 3D printer, designed for production applications in the aerospace industry and other high-performance industries. This blog discusses the latest development in the F900 3D printer, which now features an MTConnect-ready interface, offering enhanced connectivity and data exchange capabilities.The F900 3D printer is known for its high-performance capabilities, reliability, and large-scale printing. The printer uses the Fused Deposition Modeling (FDM) technology, which involves building 3D models layer by layer by depositing material in a melted state. The FDM technology provides a high degree of design flexibility, allowing the production of complex geometries without the need for additional machining or assembly processes.The F900 3D printer has been widely used in the aerospace industry for the production of complex parts, such as ducting, brackets, and housings. These parts require high precision and accuracy, and the F900 has proven to be a reliable and cost-effective solution for their manufacturing. Additionally, the F900 has been used in other industries, such as automotive, defense, and medical, where the demand for high-performance parts is also high.The latest development in the F900 3D printer is its integration with the MTConnect protocol. MTConnect is an open-source communication protocol used in manufacturing equipment to facilitate data exchange and collection. The protocol offers a standardized way of communicating machine data, making it easier to integrate different systems and devices.With its MTConnect-ready interface, the F900 3D printer can now connect to other manufacturing systems, such as Enterprise Resource Planning (ERP) systems, Manufacturing Execution Systems (MES), and other machines in the production line. This enables better coordination between different manufacturing processes, leading to higher efficiency and productivity. Additionally, the MTConnect protocol allows for real-time monitoring of the printing process, giving operators better control and visibility over the manufacturing process.The integration of the MTConnect protocol into the F900 3D printer is a significant step towards enhancing the connectivity and data sharing capabilities of the printer. This development enables the printer to be integrated into a broader manufacturing ecosystem, allowing for seamless data exchange and coordination between different systems. This integration is highly relevant in the aerospace industry, where the demand for high-performance parts is only increasing.In conclusion, the F900 3D printer is a high-performance system designed for production applications in the aerospace industry and other high-performance industries. With its latest development, the integration of the MTConnect protocol, the printer now offers enhanced connectivity and data exchange capabilities, making it easier to integrate into a broader manufacturing ecosystem. This development ensures the F900 3D printer remains one of the leading additive manufacturing systems in the market today.

Understanding the Key Aspects of Industry Design and Development

Industry Design and Development Part, a leading player in the design and development field, is making waves in the industry with its innovative and cutting-edge solutions. With a strong focus on bringing new and creative ideas to life, the company has established itself as a key player in the industry.Specializing in product design, prototyping, and manufacturing, Industry Design and Development Part is known for its ability to take a concept and turn it into a reality. This is achieved through a combination of state-of-the-art technology, a talented team of designers and engineers, and a commitment to delivering high-quality results.One of the key factors that sets Industry Design and Development Part apart from its competitors is its ability to offer a comprehensive range of services. From initial concept development to final production, the company is able to handle every aspect of the design and development process. This holistic approach not only streamlines the process for clients but also ensures that the end result is of the highest quality.In addition to its design and development capabilities, Industry Design and Development Part also prides itself on its ability to work with a wide range of industries. From automotive and aerospace to consumer electronics and medical devices, the company has experience in a broad spectrum of sectors. This versatility allows Industry Design and Development Part to bring a fresh perspective to every project it takes on.Furthermore, the company's commitment to staying at the forefront of technology and innovation has allowed it to stay ahead of the curve in a rapidly evolving industry. By investing in the latest tools and software, Industry Design and Development Part is able to offer its clients the most advanced solutions available. This not only ensures that its designs are cutting-edge but also allows the company to complete projects more efficiently.One area where Industry Design and Development Part truly shines is in its approach to prototyping. Recognizing the importance of rapid prototyping in the design and development process, the company has made significant investments in this area. This has allowed it to offer clients quick turn-around times on prototypes, allowing for faster iteration and ultimately, a more refined final product.As part of its commitment to excellence, Industry Design and Development Part also places a strong emphasis on collaboration. The company understands that the best results are achieved through teamwork and as such, works closely with its clients throughout the design and development process. This collaborative approach not only ensures that the client's vision is fully realized but also fosters a strong working relationship that often extends beyond the initial project.Looking to the future, Industry Design and Development Part is poised to continue its upward trajectory in the industry. With a focus on staying at the forefront of technology, a commitment to delivering outstanding results, and a dedication to collaboration, the company is well-positioned to take on new challenges and continue to push the boundaries of design and development.In conclusion, Industry Design and Development Part has firmly established itself as a leader in the design and development industry. With a comprehensive range of services, a versatile approach to working with different industries, a commitment to staying ahead of the curve, and a strong emphasis on collaboration, the company is well-equipped to take on any project that comes its way. As it looks to the future, Industry Design and Development Part is set to continue making a significant impact in the industry and pushing the boundaries of what is possible in design and development.

Precision Machined Parts for Aerospace Industry

Machined Aerospace Parts plays a critical role in the aviation industry. The leading company has a longstanding reputation for providing high-quality aviation components to airlines and aircraft manufacturers. It boasts a significant market share in the aerospace industry and prides itself on a variety of CNC machining capabilities to deliver exceptional results.The company's proven track record of delivering parts that meet military and commercial aviation standards has made it a trusted supplier in the aviation industry. Customers who partner with Machined Aerospace Parts appreciate the company's focus on innovation, quality, and superior customer service. These are the essential qualities that have propelled the company to the top of the industry.Machined Aerospace Parts' capabilities are vast and diversified to meet the constantly evolving needs of the industry. The company has an array of precision equipment and utilizes the latest tools and technologies to produce a range of components. Whether it's machining parts from solid materials, producing small or large components, or creating complex structures, Machined Aerospace Parts has the expertise to get the job done.The company has a team of highly skilled professionals who are experts in the field of aviation. From engineers to production managers, all staff members are deeply passionate about the industry and take pride in their work. The team is focused on creating efficient, cost-effective solutions that meet customers' unique needs.One of the reasons Machined Aerospace Parts is a preferred supplier in the aviation industry is due to its exceptional quality control process. The company ensures that every component is subject to rigorous testing to meet the strict standards of the industry. The quality control process begins with design reviews and ends with a final inspection of finished products. These stringent checks ensure that all parts meet exacting requirements, and nothing leaves the factory until it meets the company's high standards.Machined Aerospace Parts is committed to continuous improvement, and that includes investing in cutting-edge technology and equipment. The company recently added several new machines to its assembly line, expanding its CNC machining capabilities. The machines allow the company to operate faster, which ensures quicker lead times for customers.Despite the challenges posed by the COVID-19 pandemic, Machined Aerospace Parts has continued to thrive. It has remained committed to serving its customers' needs and has adapted well to the changing landscape. The company maintains safe working conditions and adheres to all regulations and health guidelines to ensure the safety of employees and customers.As a company committed to excellence, Machined Aerospace Parts invests significantly in its people. The company has a rigorous training program that ensures all staff members are up-to-date on the latest industry developments and are equipped with the skills necessary to meet customers' needs. The company also offers training and apprenticeships to young people who want to learn about the aviation industry. By investing in young talent, the company is securing the future of the industry.In conclusion, Machined Aerospace Parts is a well-established, reputable, and innovative aviation company. With its advanced technology, highly skilled workforce, and exceptional quality control, it is no surprise that it continues to succeed in the industry. The company's commitment to providing cost-effective, efficient solutions to customers has propelled it to the top of the industry, and it remains a preferred supplier for many airlines and aircraft manufacturers. In a constantly evolving industry, Machined Aerospace Parts is poised for growth, and its future looks exceedingly bright.

The Ultimate Guide to Anodizing: Everything You Need to Know

Title: Advancing Surface Technology: Anodizing Expands HorizonsSubtitle: (Company Name) Pioneers Innovations in Surface-Enhancing TechniquesDate: [Insert Date][City], [Country] - In a world where aesthetics and functionality play a pivotal role in various industries, finding innovative ways to enhance the durability and appearance of products has become a top priority for manufacturers. As the demand for advanced surface technology continues to grow, (Company Name) emerges as a prominent industry leader, leveraging the art of anodizing to provide unprecedented solutions that revolutionize various sectors. With an extensive range of products and a commitment to excellence, (Company Name) is making significant strides towards advancing surface technology, leaving a lasting impact on multiple industries.Founded in [Year], (Company Name) has been at the forefront of surface enhancement technologies, aiming to perfect the anodizing process by delivering unparalleled results to its customers. Guided by a passion for innovation and attention to detail, the company has garnered a reputation for reliability, precision, and efficiency in the anodizing industry. Combining cutting-edge machinery, state-of-the-art techniques, and a team of highly skilled professionals, (Company Name) has successfully established itself as an industry-leading player.Anodizing, the primary specialty of (Company Name), is an electrochemical process that significantly improves the surface characteristics of metals, particularly aluminum. By creating a protective layer of oxide on the surface, anodizing enhances the metal's corrosion resistance, durability, and appearance. This process involves immersing the aluminum material in an electrolyte bath and applying an electrical current, leading to the formation of an oxide layer that is integral to the material itself. (Company Name) has honed this technique to perfection.One of the key advantages of anodizing is the ability to apply various finishes, resulting in an extensive array of textures, colors, and patterns, which are both pleasing to the eye and highly functional. Industries ranging from automotive and architecture to aerospace and consumer electronics rely on anodizing to deliver products with enhanced durability, strength, and aesthetics. (Company Name) takes pride in harnessing the versatility of anodizing to provide tailored solutions to meet the specific requirements of its diverse client base.With an unwavering dedication to quality, (Company Name) employs stringent quality control measures throughout the anodizing process. By closely monitoring the composition of the electrolyte bath, the applied voltage, and the duration of treatment, the company ensures consistent results that meet or exceed industry standards. (Company Name) also emphasizes environmental sustainability by utilizing eco-friendly chemicals and implementing efficient waste management practices, minimizing its ecological footprint.As a testament to its commitment to innovation, (Company Name) consistently invests in research and development, seeking to push the boundaries of anodizing technology. By staying up to date with the latest advancements and trends, the company is able to offer cutting-edge solutions that meet the evolving needs of its customers. (Company Name) understands that each industry has unique challenges, and through continuous improvement and adaptability, the company remains a trusted partner for businesses across various sectors.Looking to the future, (Company Name) has ambitious expansion plans to solidify its position as a global leader in surface-enhancing solutions. The company aims to establish strategic partnerships, expand its geographical reach, and explore emerging markets. By introducing new anodizing techniques, optimizing production processes, and fostering innovation, (Company Name) is poised to reshape the surface technology landscape and pave the way for a new era of enhanced product aesthetics and performance.In conclusion, (Company Name) stands at the forefront of the anodizing revolution, revolutionizing the way surface technology is approached. With its extensive expertise, dedication to excellence, and commitment to innovation, (Company Name) is poised to unlock the true potential of anodizing, bringing remarkable value to industries worldwide. As demands for advanced surface technologies continue to rise, (Company Name) remains the go-to partner for businesses seeking cutting-edge innovation, improved aesthetics, and unmatched product durability.

Top Quality Extruded Aluminum Heatsinks for Efficient Heat Dissipation

Extruded Aluminum Heatsink Takes the Heat Away, Making Electronic Devices More EfficientAs the technology develops, electronic devices are becoming more advanced, powerful, and compact, which is great news for consumers who demand more functionality and convenience. However, this trend also poses a challenge for manufacturers who need to dissipate the heat generated by these devices. Without proper cooling, electronic components can overheat and fail, compromising the performance, safety, and reliability of the product. That's where an extruded aluminum heatsink comes into play, providing an effective and efficient way to transfer heat away from electronic devices.An extruded aluminum heatsink is a passive component that is attached to the electronic device to absorb and dissipate the heat generated by it. It works by increasing the surface area available to dissipate heat through the use of fins, which are thin and elongated projections that extend from the heatsink's base. These fins expose more of the heatsink's surface to the surrounding air, increasing the rate of heat transfer by convection. In addition, the heatsink's base is in contact with the heat source, such as a CPU, GPU, or power converter, which conducts the heat away from the source and spreads it out across the heatsink's surface. Finally, the heatsink dissipates the heat into the ambient air, which carries it away from the device.An extruded aluminum heatsink is an ideal solution for many electronic devices because of its low cost, lightweight, and easy customization. It can be designed to fit a specific device or application, with different sizes, shapes, and fin densities to optimize the performance and minimize the size and weight of the heatsink. Moreover, an extruded aluminum heatsink is durable, corrosion-resistant, and can withstand high temperatures, making it suitable for harsh environments and industrial applications.One company that specializes in extruded aluminum heatsinks is (need to remove brand name). Founded in (year), the company has over (number) years of experience in designing and manufacturing heatsinks for various industries, including computer, communication, lighting, transportation, power, and aerospace. (Remove brand name) offers a wide range of heatsink products, from standard extrusions to custom designs, with different materials, finishes, and assembly options.According to (CEO name), (remove brand name)'s CEO, the company's success lies in its commitment to quality, innovation, and customer service. "We take pride in delivering effective and efficient thermal solutions that exceed our customers' expectations," he said. "We use the latest technology and techniques to design and produce heatsinks that meet or exceed industry standards, and we work closely with our customers to understand their needs and provide personalized solutions."Some of (remove brand name)'s recent innovations in extruded aluminum heatsinks include:- Micro-fins: (remove brand name) has developed a new technique for producing micro-fins, which are very thin and closely spaced fins that increase the surface area of the heatsink without adding much weight or volume. Micro-fins are ideal for compact devices that require high performance and low profile, such as laptops, tablets, and smartphones.- Stack-fins: Another technique that (remove brand name) has pioneered is stack-fins, which are multiple sets of fins stacked on top of each other, like a sandwich. Stack-fins can increase the heat transfer rate by up to 50% compared to conventional fins, making them suitable for high-power applications and environments with limited airflow.- Heat-pipes: (remove brand name) has integrated heat-pipes into some of its heatsinks, which are sealed tubes filled with a liquid or gas that absorbs and transfers heat through a phase-change process. Heat-pipes can improve the thermal performance of a heatsink by several times, making it possible to cool even the hottest components.- Surface treatments: (remove brand name) offers a variety of surface treatments for its heatsinks, such as anodizing, painting, powder coating, and polishing, to enhance their aesthetics, corrosion resistance, and thermal conductivity. Surface treatments can also provide additional functions, such as electromagnetic shielding, insulation, and light reflection.With its expertise in extruded aluminum heatsinks and its commitment to innovation and quality, (remove brand name) is poised to meet the challenges of the growing electronics industry and provide reliable and effective thermal solutions to its customers. If you have a thermal management challenge, why not contact (remove brand name) for a consultation and see how they can help you?

Advanced Machining Techniques for Precision Milling Operations

Machining Milling, a prominent player in the machining industry, is revolutionizing the landscape of precision manufacturing. With their unwavering commitment to quality and innovation, the company has firmly established itself as a frontrunner in the market. Through their cutting-edge technologies and customer-centric approach, Machining Milling has become a go-to partner for businesses aiming to achieve superior quality and precision.Founded with a vision to redefine the machining industry, Machining Milling brings years of expertise and experience. Their team of highly skilled professionals is dedicated to producing exceptional results, adhering to strict quality control measures at every phase of the manufacturing process. By employing state-of-the-art machinery and sophisticated software, they ensure that each product meets the highest industry standards.One of the cornerstones of Machining Milling's success is their commitment to continuous improvement. The company constantly invests in research and development to stay ahead of technological advancements and meet the evolving needs of their customers. This allows them to provide tailor-made solutions, ensuring that every project is executed with precision and efficiency.Machining Milling's diverse range of services caters to a wide array of industries including aerospace, automotive, medical, and energy sectors. From concept to completion, their comprehensive manufacturing solutions encompass precision machining, milling, turning, and assembly. By utilizing cutting-edge techniques like computer numerical control (CNC) machining, they are able to deliver complex and intricate components with unparalleled accuracy.The company's dedication to customer satisfaction is evident in their personalized approach. Machining Milling works closely with each client, understanding their unique requirements, and providing customized solutions to meet their specific needs. Their team of experts collaborates with clients throughout the entire process, ensuring effective communication and a seamless manufacturing experience.One of the notable factors that distinguish Machining Milling from its competitors is their strong emphasis on quality assurance. The company adheres to stringent quality control protocols, ensuring that each product undergoes meticulous inspection and testing. This commitment to quality has earned Machining Milling numerous certifications, reflecting their unwavering dedication to excellence.Furthermore, Machining Milling recognizes the importance of sustainability in today's manufacturing landscape. The company is committed to minimizing its environmental impact by adopting environmentally friendly practices. They prioritize the use of eco-friendly materials and implement energy-efficient measures throughout their operations.Machining Milling's exceptional track record and commitment to excellence have earned them a loyal customer base. With a reputation for delivering on time and exceeding expectations, they have forged long-term partnerships with industry giants. Their commitment to continuous improvement and customer satisfaction sets them apart in the highly competitive machining industry.Looking to the future, Machining Milling aims to further expand their capabilities and technological prowess. By embracing the latest advancements, they continue to enhance their efficiency and precision, providing innovative solutions to meet the evolving demands of the market.In conclusion, Machining Milling has emerged as a leading name in the machining industry. With their commitment to quality, innovation, and customer satisfaction, they have redefined precision manufacturing. Through cutting-edge technologies, personalized approaches, and unwavering dedication to excellence, Machining Milling continues to set the benchmark for superior machining services.

Top Tips for Multi Axis Turning: How to Increase Efficiency and Precision

Multi Axis Turning, a cutting-edge machining technology, has been making waves in the manufacturing industry for its ability to produce complex and intricate parts with high precision. This technology has revolutionized the way parts are made, allowing for greater efficiency and accuracy in the manufacturing process.With the increasing demand for more complex and sophisticated parts in various industries, the need for advanced machining technology has become more pressing. This is where Multi Axis Turning comes into play. By allowing for simultaneous motion in multiple axes, this technology offers a higher level of flexibility and capability in producing parts with intricate geometries.One company at the forefront of this technology is {}. With a strong reputation for precision machining and innovative solutions, {} has been leveraging Multi Axis Turning to cater to the needs of its diverse clientele. Specializing in the production of high-quality parts for industries such as aerospace, automotive, and medical, {} has been able to deliver superior products with the help of this advanced machining technology.The use of Multi Axis Turning has allowed {} to increase its production capabilities and offer a wider range of services to its customers. By utilizing this technology, the company has been able to create parts with complex geometries and tighter tolerances, meeting the rigorous standards of precision and quality required by its clients.One of the key advantages of Multi Axis Turning is its ability to reduce setup time and increase production efficiency. With the capability to perform multiple operations in a single setup, this technology streamlines the manufacturing process, leading to shorter lead times and cost savings for both {} and its customers. This has allowed the company to take on more complex projects and deliver parts in a timelier manner, further solidifying its position as a leader in the industry.Furthermore, the high precision and accuracy offered by Multi Axis Turning have enabled {} to maintain a competitive edge in the market. By consistently delivering parts with exceptional quality, the company has earned the trust and confidence of its clients, leading to long-term partnerships and repeat business.In addition to its technological capabilities, {} has also invested in a team of skilled machinists and engineers who are well-versed in the intricacies of Multi Axis Turning. Their expertise and knowledge, combined with state-of-the-art equipment, have positioned {} as a reliable and competent partner for businesses seeking high-quality machined parts.Looking ahead, {} is poised to continue leveraging Multi Axis Turning to drive innovation and meet the evolving needs of the manufacturing industry. By staying at the forefront of technological advancements, the company is committed to delivering excellence in precision machining and setting new standards for quality and performance.In conclusion, Multi Axis Turning has emerged as a game-changing technology in the manufacturing industry, and {} has been at the forefront of its adoption and utilization. With a deep understanding of this advanced machining technology and a commitment to delivering exceptional quality, the company is well-equipped to excel in a competitive market and meet the diverse needs of its customers. As the demand for more complex and sophisticated parts continues to grow, {} is poised to lead the way in harnessing the capabilities of Multi Axis Turning to deliver superior precision machined parts.

High-Quality Extruded Aluminum Heatsink for Superior Thermal Dissipation

(Extruded Aluminum Heatsink is an innovative product designed to dissipate heat. It is manufactured by a leading company in the industry, known for their high-quality engineering and exceptional customer service. For many years, this company has been a trusted provider of thermal management solutions, serving a diverse range of industries.The Extruded Aluminum Heatsink is a critical component in many electronic devices, providing an effective way to manage heat generated during operation. It is widely used in applications such as computers, LED lighting, power electronics, and more. With its lightweight and durable design, the Extruded Aluminum Heatsink offers excellent thermal conductivity and efficient heat dissipation.One of the key features of this heatsink is its extruded aluminum construction, which allows for the precise shaping of the heatsink to meet specific requirements. This flexibility makes it an ideal solution for custom applications, as well as for high-volume production. The company's advanced manufacturing capabilities enable them to produce heatsinks in a wide range of sizes and shapes, ensuring a perfect fit for each unique application.In addition to its exceptional performance, the Extruded Aluminum Heatsink is also designed for easy installation and maintenance. Its sleek and compact design allows for seamless integration into various systems, and its corrosion-resistant properties ensure long-term reliability and durability. With its ability to effectively dissipate heat, the Extruded Aluminum Heatsink helps to extend the lifespan and improve the performance of electronic devices.The company behind the Extruded Aluminum Heatsink prides itself on its commitment to excellence and innovation. With a team of experienced engineers and technical experts, they are dedicated to providing cutting-edge thermal management solutions that meet the evolving needs of their customers. Their state-of-the-art facilities and stringent quality control processes ensure that each heatsink meets the highest standards of performance and reliability.Furthermore, the company's customer-centric approach sets them apart in the industry. They work closely with their clients to understand their unique requirements and provide tailored solutions that exceed expectations. Whether it's a standard off-the-shelf heatsink or a custom-designed solution, the company is committed to delivering products that deliver superior performance and value.With a proven track record of delivering high-quality thermal management solutions, the company has earned the trust and loyalty of a diverse customer base. Their reputation for excellence and reliability has firmly established them as a leader in the industry, and their Extruded Aluminum Heatsink is just one example of their commitment to innovation and superior quality.In conclusion, the Extruded Aluminum Heatsink is a cutting-edge product that showcases the company's expertise in thermal management solutions. With its exceptional performance, durability, and versatility, this heatsink is a valuable asset for a wide range of electronic applications. Backed by a company known for its commitment to excellence and innovation, the Extruded Aluminum Heatsink is a testament to the company's leadership in the industry. As the demand for efficient thermal management solutions continues to grow, the company and its Extruded Aluminum Heatsink are well-positioned to meet the evolving needs of their customers.

How Sheet Metal Bending Dies Can Improve Your Manufacturing Process

[Company Name] Introduces Advanced Sheet Metal Bending Dies for Precision Manufacturing[City, Date] - [Company Name], a leading manufacturer of precision tooling and machinery, has recently introduced a new line of sheet metal bending dies designed to meet the evolving needs of the manufacturing industry. With a focus on precision and efficiency, these advanced bending dies are expected to revolutionize the way sheet metal components are produced.The new sheet metal bending dies from [Company Name] are the result of extensive research and development efforts aimed at addressing the challenges faced by manufacturers in the modern market. With the increasing demand for complex and high-quality sheet metal components, there is a growing need for tooling solutions that can deliver unparalleled precision and efficiency."We are thrilled to introduce our latest line of sheet metal bending dies, which represent a significant advancement in the field of precision manufacturing," said [Spokesperson Name], the CEO of [Company Name]. "Our team has worked tirelessly to develop these dies, and we are confident that they will set a new standard for quality and performance in the industry."The new bending dies are designed to offer a number of key advantages to manufacturers. One of the most notable features is their ability to achieve precise bends with minimal deformation, resulting in higher quality finished parts. This level of precision is made possible by the advanced tooling design and manufacturing techniques employed by [Company Name].In addition to precision, the new bending dies are also highly efficient, allowing manufacturers to increase their productivity and reduce production costs. By streamlining the bending process and minimizing the need for secondary operations, these dies can help companies stay competitive in an increasingly demanding market."We understand the importance of efficiency in manufacturing, which is why our new bending dies are engineered to optimize production processes and reduce waste," [Spokesperson Name] explained. "We believe that these dies will not only improve the quality of finished parts, but also help our customers enhance their overall operational efficiency."The introduction of these advanced sheet metal bending dies further solidifies [Company Name]'s position as a leader in the precision tooling industry. With a long history of innovation and a commitment to excellence, [Company Name] has earned a reputation for delivering cutting-edge solutions that empower manufacturers to achieve their production goals.In addition to the new bending dies, [Company Name] offers a comprehensive range of tooling solutions, including punches, dies, and press brakes, as well as custom tooling services tailored to the specific needs of individual customers. These offerings are backed by the company's expertise and dedication to providing unparalleled support to its clients."At [Company Name], we are dedicated to helping our customers succeed by providing them with the highest quality tooling solutions and support services," [Spokesperson Name] stated. "We are proud to be at the forefront of innovation in the industry, and we will continue to push the boundaries of what is possible in precision manufacturing."As the manufacturing industry continues to evolve, the demand for advanced tooling solutions such as the new sheet metal bending dies from [Company Name] is expected to grow. With their combination of precision, efficiency, and reliability, these dies are poised to become an indispensable asset for manufacturers seeking to stay ahead in a competitive market.For more information about the new sheet metal bending dies and other tooling solutions from [Company Name], visit [company website] or contact [contact information].About [Company Name]:[Company Name] is a leading manufacturer of precision tooling and machinery, serving the needs of manufacturers in various industries. With a focus on innovation and customer satisfaction, the company is dedicated to providing high-quality solutions that enable its clients to achieve their production goals. With a commitment to excellence and a reputation for reliability, [Company Name] continues to be a trusted partner for businesses seeking the best in precision tooling.Contact:[Contact Name][Company Name][Phone Number][Email Address][Company Website]