How to Bend Sheet Metal By Hand: Step-by-Step Guide

By:Admin

Hand bending sheet metal requires a high level of expertise and precision, as the metal must be carefully manipulated to achieve the desired shape and angle. This method is often preferred for smaller production runs or for creating prototypes, as it allows for greater flexibility and customization.

One company that has truly mastered the art of hand bending sheet metal is {Company Name}. With a long-standing reputation for excellence in metal fabrication, {Company Name} has been at the forefront of the industry for over 30 years. Specializing in precision sheet metal bending and forming, they have earned the trust and respect of their clients through their unwavering commitment to quality and craftsmanship.

Led by a team of highly skilled craftsmen and engineers, {Company Name} has the expertise and knowledge to tackle even the most complex sheet metal bending projects. Their state-of-the-art facility is equipped with the latest technology and machinery, allowing them to produce precise and intricate bends with unparalleled accuracy.

What sets {Company Name} apart from their competitors is their dedication to the art of hand bending sheet metal. While many other companies have shifted to automated or robotic bending processes, {Company Name} continues to uphold the tradition of hand craftsmanship. This approach allows them to offer a level of customization and attention to detail that is simply unmatched in the industry.

By combining traditional techniques with modern technology, {Company Name} is able to deliver superior results for their clients. Whether it's creating custom components for aerospace applications or producing specialty parts for the automotive industry, their team has the expertise and capabilities to meet the unique needs of each project.

Furthermore, {Company Name} places a strong emphasis on quality control and precision. Every piece of sheet metal that comes through their facility is carefully inspected and measured to ensure that it meets the highest standards of accuracy and consistency. This commitment to quality has earned them a reputation as a trusted partner for businesses across a wide range of industries.

In addition to their exceptional sheet metal bending capabilities, {Company Name} also offers a comprehensive range of metal fabrication services. From laser cutting and welding to finishing and assembly, they have the expertise and resources to handle every aspect of the manufacturing process. This turnkey approach allows their clients to streamline their production and reduce lead times, ultimately saving time and money.

As the manufacturing industry continues to evolve, {Company Name} remains dedicated to upholding the tradition of hand bending sheet metal. By combining time-honored techniques with cutting-edge technology, they continue to set the standard for quality and precision in the world of metal fabrication. With a commitment to excellence and a passion for craftsmanship, {Company Name} is poised to lead the industry for years to come.

Company News & Blog

Top Quality Extruded Aluminum Heatsinks for Efficient Heat Dissipation

Extruded Aluminum Heatsink Takes the Heat Away, Making Electronic Devices More EfficientAs the technology develops, electronic devices are becoming more advanced, powerful, and compact, which is great news for consumers who demand more functionality and convenience. However, this trend also poses a challenge for manufacturers who need to dissipate the heat generated by these devices. Without proper cooling, electronic components can overheat and fail, compromising the performance, safety, and reliability of the product. That's where an extruded aluminum heatsink comes into play, providing an effective and efficient way to transfer heat away from electronic devices.An extruded aluminum heatsink is a passive component that is attached to the electronic device to absorb and dissipate the heat generated by it. It works by increasing the surface area available to dissipate heat through the use of fins, which are thin and elongated projections that extend from the heatsink's base. These fins expose more of the heatsink's surface to the surrounding air, increasing the rate of heat transfer by convection. In addition, the heatsink's base is in contact with the heat source, such as a CPU, GPU, or power converter, which conducts the heat away from the source and spreads it out across the heatsink's surface. Finally, the heatsink dissipates the heat into the ambient air, which carries it away from the device.An extruded aluminum heatsink is an ideal solution for many electronic devices because of its low cost, lightweight, and easy customization. It can be designed to fit a specific device or application, with different sizes, shapes, and fin densities to optimize the performance and minimize the size and weight of the heatsink. Moreover, an extruded aluminum heatsink is durable, corrosion-resistant, and can withstand high temperatures, making it suitable for harsh environments and industrial applications.One company that specializes in extruded aluminum heatsinks is (need to remove brand name). Founded in (year), the company has over (number) years of experience in designing and manufacturing heatsinks for various industries, including computer, communication, lighting, transportation, power, and aerospace. (Remove brand name) offers a wide range of heatsink products, from standard extrusions to custom designs, with different materials, finishes, and assembly options.According to (CEO name), (remove brand name)'s CEO, the company's success lies in its commitment to quality, innovation, and customer service. "We take pride in delivering effective and efficient thermal solutions that exceed our customers' expectations," he said. "We use the latest technology and techniques to design and produce heatsinks that meet or exceed industry standards, and we work closely with our customers to understand their needs and provide personalized solutions."Some of (remove brand name)'s recent innovations in extruded aluminum heatsinks include:- Micro-fins: (remove brand name) has developed a new technique for producing micro-fins, which are very thin and closely spaced fins that increase the surface area of the heatsink without adding much weight or volume. Micro-fins are ideal for compact devices that require high performance and low profile, such as laptops, tablets, and smartphones.- Stack-fins: Another technique that (remove brand name) has pioneered is stack-fins, which are multiple sets of fins stacked on top of each other, like a sandwich. Stack-fins can increase the heat transfer rate by up to 50% compared to conventional fins, making them suitable for high-power applications and environments with limited airflow.- Heat-pipes: (remove brand name) has integrated heat-pipes into some of its heatsinks, which are sealed tubes filled with a liquid or gas that absorbs and transfers heat through a phase-change process. Heat-pipes can improve the thermal performance of a heatsink by several times, making it possible to cool even the hottest components.- Surface treatments: (remove brand name) offers a variety of surface treatments for its heatsinks, such as anodizing, painting, powder coating, and polishing, to enhance their aesthetics, corrosion resistance, and thermal conductivity. Surface treatments can also provide additional functions, such as electromagnetic shielding, insulation, and light reflection.With its expertise in extruded aluminum heatsinks and its commitment to innovation and quality, (remove brand name) is poised to meet the challenges of the growing electronics industry and provide reliable and effective thermal solutions to its customers. If you have a thermal management challenge, why not contact (remove brand name) for a consultation and see how they can help you?

K-pop Group Member Involved in Physical Altercation Raises Concerns

NCT, the world-renowned punching machine manufacturer, has recently unveiled a new range of products, making a grand entry into the global market. Founded in 1970 and headquartered in Japan, the company has been one of the major players in the metal-forming industry for more than five decades. The company's huge success has been built on continuous innovation, research, and development of its products. With a keen focus on delivering the most advanced machinery to meet the needs of the modern world, NCT has been lauded for producing cutting-edge technology punching machines.The NCT punching machine's range is optimized for clients who seek to achieve high-precision sheet metal fabrication. Along with this, these machines offer superior speed and excellent durability, positioning them as a product of choice for clients in need of a reliable and quality-driven machine. The company's new line of punching machines is geared towards offering customized solutions that cater to both small-scale and large-scale industries. Clients can choose from various models, which have been specifically designed to cater to different needs, budgets, and production volumes.NCT's recent entry into the global marketplace has garnered much attention, owing to the company's longstanding reputation in the metal-forming machinery industry. The company's machines are known for their unparalleled precision and speed, combined with their ability to handle a wide variety of metals. The company's newest range of products is ideal for a wide range of punching applications used in several industries, including automobile, aerospace, electrical, and electronics.With the ever-growing demand for high-quality punching machines, NCT's entry into the global market promises to offer a much-needed boost to the metal-forming industry. The company's punching machines are designed to optimize time, effort, and cost, which are the most significant concerns of clients seeking these machines. The company's innovative and highly efficient punching machines set themselves apart from their competition, offering clients benefits such as increased productivity, higher precision, and lower cost per punch.The punching industry has evolved significantly over the years, and the demand for high-quality punching machines is higher than ever. NCT's large-scale entry into the market makes it evident that the company identifies the growing demand and is committed to providing the best solutions to clients worldwide. By offering a wide range of customized machinery, the company caters to clients of all sizes and industries, which ensures that clients can find the most suitable punching machine for their unique requirements.In conclusion, NCT's recent unveiling of their new range of punching machines marks the company's entry into the global market, and it is set to revolutionize the metal-forming industry. With superior speed, precision, and durability, NCT's machines offer unprecedented levels of productivity, providing clients with cost-effective solutions that optimize time and effort. The company's commitment to research and development has enabled it to deliver advanced and customized machinery, satisfying the needs of clients worldwide. With NCT, clients are guaranteed an unparalleled experience, and they can rest assured that they are investing in the best and most innovative punching machines on the market.

Beginner's Guide to 3D Printing and Prototyping: Everything You Need to Know

3D Printing And Prototyping Revolutionize Manufacturing IndustryIn the ever-evolving landscape of technology and innovation, 3D printing and prototyping have emerged as game-changers in the manufacturing industry. These cutting-edge technologies have paved the way for efficient and cost-effective production processes, allowing companies to bring their designs to life in a fraction of the time and cost compared to traditional manufacturing methods.One company at the forefront of this revolution is [Company Name], a leading provider of 3D printing and prototyping solutions. With a strong commitment to innovation and customer satisfaction, [Company Name] has established itself as a trusted partner for businesses looking to harness the power of 3D printing and prototyping.Utilizing state-of-the-art 3D printing technology, [Company Name] offers a wide range of services, including rapid prototyping, custom production, and additive manufacturing. Their team of experts works closely with clients to understand their unique requirements and deliver high-quality, precision-engineered products that meet and exceed their expectations.The benefits of 3D printing and prototyping are numerous and far-reaching. By using digital models to create physical objects, manufacturers can significantly reduce the time and resources required for product development and testing. This streamlined approach not only accelerates the production cycle but also enables companies to bring new products to market faster, giving them a competitive edge in today's fast-paced business environment.Moreover, 3D printing and prototyping offer unparalleled design freedom, allowing companies to create complex and intricate shapes that would be impossible to achieve using traditional manufacturing methods. This level of customization and flexibility empowers businesses to explore new ideas, iterate on designs, and refine their products with unmatched precision and efficiency.The environmental benefits of 3D printing and prototyping cannot be understated. Unlike subtractive manufacturing, where material is removed from a solid block, 3D printing builds objects layer by layer, resulting in minimal waste and eco-friendly production processes. This sustainable approach aligns with the growing demand for greener, more eco-conscious manufacturing practices, positioning 3D printing and prototyping as a key driver of positive change in the industry.As the demand for 3D printing and prototyping continues to grow, [Company Name] remains dedicated to pushing the boundaries of what is possible in additive manufacturing. By investing in the latest technology and expanding their capabilities, [Company Name] is poised to meet the evolving needs of their clients and deliver innovative solutions that drive business success.In conclusion, 3D printing and prototyping have revolutionized the manufacturing industry, offering a host of benefits including faster production cycles, enhanced design possibilities, and sustainable manufacturing practices. With their commitment to innovation and customer satisfaction, [Company Name] is at the forefront of this transformation, empowering businesses to bring their ideas to life with unmatched precision and efficiency. As the industry continues to embrace these groundbreaking technologies, the future of manufacturing looks brighter than ever before.

High-Quality Custom Radiator Parts for Your Vehicle

Custom Radiator Part: A Perfect Solution for Your Heating NeedsCustom radiator parts have become an essential component for the heating industry, offering personalized solutions for various heating systems. These parts are specifically designed to fit and function perfectly within a specific radiator system, providing better efficiency and performance. In this regard, {Company Name} has been at the forefront of delivering high-quality custom radiator parts to meet the diverse needs of its customers.{Company Name} is an industry-leading manufacturer and supplier of custom radiator parts, specializing in designing and producing tailored solutions for both residential and commercial heating applications. With years of experience and expertise in the heating industry, the company has established a solid reputation for delivering top-notch products that meet the highest standards of quality and reliability.The custom radiator parts offered by {Company Name} are meticulously engineered to align with the specific requirements of different heating systems. Whether it's a unique design, specific dimensions, or special materials, the company can cater to a wide range of customizations to ensure a perfect fit and seamless integration with the existing heating infrastructure. This level of customization not only enhances the performance of the heating system but also ensures a more efficient and cost-effective solution for the end-user.One of the key advantages of opting for custom radiator parts from {Company Name} is the ability to address complex heating challenges with tailored solutions. The company's team of skilled engineers and technicians work closely with the customers to understand their specific needs and develop customized parts that effectively meet those requirements. This collaborative approach ensures that the custom radiator parts not only enhance the overall performance of the heating system but also contribute to energy savings and reduced maintenance costs in the long run.Another noteworthy aspect of the custom radiator parts offered by {Company Name} is their exceptional durability and reliability. The company is committed to using high-quality materials and advanced manufacturing processes to ensure that every custom part is built to last. This level of attention to detail and quality control not only instills confidence in the customers but also reflects the company's dedication to delivering long-term value through its products.Furthermore, {Company Name} prides itself on its ability to provide quick turnaround times for custom radiator parts without compromising on quality. The company understands the importance of timely solutions in the heating industry and has streamlined its manufacturing processes to meet the demands of its customers efficiently. This agility in production, combined with the company's unwavering commitment to excellence, has positioned {Company Name} as a trusted partner for custom radiator solutions.In conclusion, the demand for custom radiator parts continues to grow as heating systems become more sophisticated and diverse. {Company Name} has emerged as a reliable source for high-quality custom radiator parts, offering tailored solutions to address the unique requirements of its customers. With a focus on precision engineering, durability, and timely delivery, the company has solidified its position as a preferred partner for custom radiator solutions in the heating industry. Whether it's a residential upgrade or a commercial project, {Company Name} is well-equipped to deliver custom radiator parts that exceed expectations and elevate the performance of any heating system.

High-Quality Metal Stamping Parts for Precision Applications

Precision Metal Stamping Parts (PMP) is a leading manufacturer of high-quality metal stamping parts for various industries. With their state-of-the-art facilities and advanced technology, they have been a trusted supplier for many companies worldwide. Their commitment to excellence and continuous innovation has set them apart in the industry.PMP specializes in the production of precision metal stamping parts for automotive, electronics, aerospace, and medical industries. They offer a wide range of services, including design and engineering, rapid prototyping, tooling, and production. Their expertise in stamping, forming, and assembly processes allows them to meet the most challenging requirements of their customers.The company's dedication to quality is evident in their rigorous quality control processes and certifications. They are ISO 9001 certified and adhere to strict quality assurance protocols to ensure that their products meet the highest standards. This commitment to quality has earned them a solid reputation as a reliable and trustworthy supplier.In addition to their commitment to quality, PMP is also dedicated to sustainability and environmental responsibility. They have implemented green manufacturing practices and are continuously seeking ways to reduce their environmental footprint. This commitment to sustainability has positioned them as a leader in environmentally-friendly manufacturing practices.PMP's success is driven by their team of highly skilled and experienced professionals. Their engineers and technicians are experts in their field and work closely with customers to develop innovative solutions to meet their specific needs. With their vast knowledge and experience, they have the capability to handle complex projects and deliver high-quality products on time and within budget.The company's investment in cutting-edge technology and equipment further enhances their ability to meet the demands of the industry. Their advanced machinery and tools enable them to produce precision metal stamping parts with unmatched accuracy and consistency. This technological advantage gives them a competitive edge and allows them to deliver superior products to their customers.The customer-centric approach of PMP is another key factor in their success. They prioritize customer satisfaction and work closely with their clients to understand their unique requirements. This collaborative approach has enabled them to build long-term relationships with their customers and become their trusted partner in metal stamping solutions.Looking ahead, PMP is committed to continued growth and innovation. They are continuously investing in research and development to expand their capabilities and offer new solutions to their customers. With their unwavering commitment to excellence, sustainability, and customer satisfaction, PMP is well-positioned to remain a leader in the metal stamping industry.In conclusion, Precision Metal Stamping Parts (PMP) is a reputable and reliable manufacturer of high-quality metal stamping parts for various industries. Their dedication to quality, sustainability, and customer satisfaction sets them apart in the industry. With their advanced technology, skilled team, and customer-centric approach, PMP is well-equipped to meet the ever-evolving needs of the industry and maintain their position as a leader in metal stamping solutions.

The Advantages of 3D Printing and Prototyping in Product Development

3D Printing And Prototyping Advancements Revolutionize Manufacturing ProcessThe manufacturing industry is continually evolving, and one of the most groundbreaking technologies to emerge in recent years is 3D printing and prototyping. This innovation has the potential to completely transform the way products are designed, developed, and manufactured. With its ability to create complex and customized parts, 3D printing has quickly become an essential tool for companies looking to stay ahead in the fiercely competitive market.[Company] is at the forefront of this revolution, leading the way with their cutting-edge 3D printing and prototyping solutions. With a strong emphasis on innovation and customer satisfaction, [Company] has quickly established itself as a leader in the industry. By combining advanced technology with years of expertise, they have been able to provide clients with high-quality, cost-effective 3D printing and prototyping services that have set new standards for the manufacturing sector.One of the key advantages of 3D printing is its ability to create complex and intricate designs that would be impossible to produce using traditional manufacturing methods. This has opened up a world of possibilities for product development, allowing companies to design and test prototypes quickly and efficiently. By using 3D printing, manufacturers can save time and money by avoiding the need for expensive tooling and mold-making processes, while also reducing waste and minimizing the environmental impact of production.In addition to rapid prototyping, 3D printing can also be used for small-batch manufacturing, allowing companies to produce limited quantities of custom-made products without the need for costly setup and production runs. This flexibility has made 3D printing an invaluable tool for companies looking to bring new products to market faster and more efficiently than ever before.[Company] has been at the forefront of this technology, offering a wide range of 3D printing and prototyping services to meet the diverse needs of their clients. Whether it's creating intricate prototypes for the aerospace industry or producing custom-designed parts for the automotive sector, [Company] has been able to deliver high-quality results that have exceeded their clients' expectations.With a dedicated team of experts and state-of-the-art equipment, [Company] has been able to tackle even the most challenging projects with ease. Their commitment to quality and innovation has set them apart in a highly competitive market, earning them a reputation as a trusted partner for companies looking to leverage the power of 3D printing and prototyping in their manufacturing processes.Looking ahead, the future of 3D printing and prototyping is filled with promise. As the technology continues to evolve, it is expected to become even more accessible and affordable, making it an essential tool for manufacturers of all sizes. The potential applications of 3D printing are virtually limitless, with industries ranging from healthcare to consumer goods poised to benefit from its transformative capabilities.In conclusion, the rise of 3D printing and prototyping is revolutionizing the manufacturing industry, and [Company] is at the forefront of this revolution. With their advanced technology and commitment to innovation, they have been able to provide clients with high-quality 3D printing and prototyping services that are setting new standards for the industry. As the technology continues to evolve, [Company] is poised to continue leading the way, providing manufacturers with the tools they need to stay ahead in an ever-changing market.

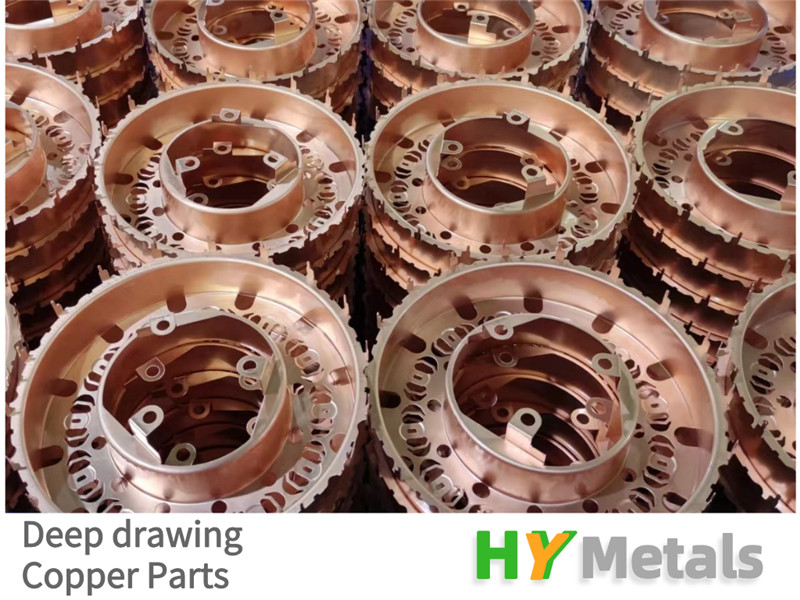

High-Quality Sheet Metal Copper Contacts Now Available

A leading company in the sheet metal industry, {}, has announced a groundbreaking development in the realm of copper contact. The company, known for its innovative solutions and high-quality products, has successfully designed and manufactured a new line of copper contacts that are set to revolutionize the industry.With a strong emphasis on research and development, {} has always been at the forefront of technological advancements within the sheet metal sector. The company's state-of-the-art manufacturing facilities and team of experienced engineers have enabled them to consistently deliver cutting-edge products that meet the evolving needs of their customers.The new copper contacts, which are designed to be used in a variety of electrical applications, boast a number of key features that set them apart from traditional contact materials. By leveraging their expertise in metallurgy and material science, {} has been able to enhance the conductivity and reliability of the contacts, while also ensuring that they meet the highest standards for quality and durability.In addition to their superior performance, the new copper contacts are also more environmentally friendly than alternative materials. As sustainability and energy efficiency become increasingly important considerations for businesses across all industries, {} is proud to offer a product that aligns with these values and helps their customers reduce their carbon footprint.The development of these copper contacts underscores {}'s commitment to staying ahead of the curve and anticipating the needs of their customers. By investing in research and development, the company is able to bring innovative solutions to market that enable their clients to achieve new levels of efficiency, performance, and reliability in their own products and operations.In response to the announcement, {}'s CEO expressed his excitement about the potential impact of the new copper contacts. "We are thrilled to introduce this game-changing product to the market," he said. "Our team has worked tirelessly to develop a solution that not only exceeds performance expectations, but also aligns with our commitment to sustainability. We believe that these copper contacts will enable our customers to achieve new heights of success in their own endeavors."The new copper contacts are now available for purchase, and {} is already seeing significant interest from a wide range of industries and applications. From automotive and aerospace to energy and telecommunications, businesses around the world are eager to take advantage of the enhanced performance and environmental benefits that these contacts offer.Looking ahead, {} remains dedicated to pushing the boundaries of what is possible in the sheet metal industry. By continuing to invest in research and development, as well as by leveraging their expertise in materials and manufacturing, the company is poised to deliver even more innovative solutions that will shape the future of the industry.As the demand for high-quality, sustainable materials continues to grow, {} is well-positioned to lead the way with their cutting-edge products and unwavering commitment to excellence. With the introduction of the new copper contacts, the company is once again demonstrating their dedication to driving progress and enabling their customers to thrive in an ever-changing world.

High-Quality Precision Parts for CNC Lathes: Explore the Latest Options

Global Manufacturing Company Expands Precision Parts Production with State-of-the-Art CNC Lathe[Company Name], a leading manufacturer of precision parts for various industries, has recently made a significant investment in state-of-the-art CNC lathe technology to enhance its production capabilities. The company, known for its commitment to quality and innovation, continues to expand its capacity to meet the growing demand for high precision components in the global market.The new CNC lathe, which was recently installed at [Company Name]'s manufacturing facility, represents a significant advancement in the company's machining capabilities. With advanced features and precision controls, the CNC lathe allows for the efficient and accurate production of complex parts with tight tolerances. This new addition to the company's equipment lineup further solidifies [Company Name]'s position as a leading provider of high-quality precision parts for a wide range of industries, including aerospace, automotive, medical, and more."We are thrilled to introduce this state-of-the-art CNC lathe to our production floor," said [Spokesperson Name], [Title] at [Company Name]. "This investment reflects our ongoing commitment to providing our customers with the highest quality precision parts while also expanding our capacity to meet the increasing demand in the global market. With the advanced capabilities of the new CNC lathe, we are confident that we will be able to produce even more complex and intricate parts with the precision and efficiency that our customers have come to expect from us."The new CNC lathe is equipped with advanced technology and features that enable [Company Name] to achieve unparalleled levels of precision and consistency in its manufacturing processes. The machine's high-speed spindle and multi-axis control system allow for the efficient machining of a wide variety of materials, including aluminum, stainless steel, titanium, and more. In addition, the CNC lathe's automatic tool changer and advanced cutting strategies ensure optimal efficiency and productivity in the production of precision parts.With the installation of the new CNC lathe, [Company Name] is poised to take its precision parts production to the next level. The company's team of highly skilled engineers and machinists are eager to leverage the capabilities of the CNC lathe to produce intricate components that meet the exacting specifications and requirements of its clients. The investment in this cutting-edge technology reflects [Company Name]'s dedication to staying at the forefront of precision manufacturing and delivering innovative solutions to its customers.In addition to enhancing its production capabilities, [Company Name] remains committed to maintaining the highest standards of quality and excellence in every aspect of its operations. The company's strict quality control measures and rigorous inspection processes ensure that every precision part manufactured with the new CNC lathe meets the most demanding industry standards. Furthermore, [Company Name] is continuously investing in the training and development of its workforce to ensure that its team remains fully equipped to leverage the capabilities of the latest manufacturing technologies.As [Company Name] continues to expand its presence in the global market, the addition of the advanced CNC lathe to its manufacturing capabilities is poised to further strengthen the company's position as a premier provider of precision parts. With a focus on innovation, quality, and customer satisfaction, [Company Name] is poised to drive the advancement of precision manufacturing and provide its clients with the cutting-edge solutions they need to succeed in their respective industries.In conclusion, the introduction of the state-of-the-art CNC lathe at [Company Name]'s manufacturing facility represents a significant milestone in the company's commitment to excellence and innovation. With its advanced capabilities and precision controls, the CNC lathe will enable [Company Name] to produce complex and intricate precision parts with unmatched accuracy and efficiency. As the company continues to expand its global presence, this investment in advanced manufacturing technology reaffirms [Company Name]'s position as a leader in the production of high-quality precision parts for a diverse range of industries.

Durable and Versatile: The Advantages of Powder Coating

Powder Coating Revolutionizes the Industry: A Closer Look at {}'s Innovative ApproachIn today's fast-paced and ever-evolving manufacturing industry, companies are constantly seeking new and innovative ways to improve their products and processes. One such breakthrough has come in the form of powder coating, a cutting-edge technique that has revolutionized the way companies apply finishes to their products.Leading the way in this groundbreaking technology is {}. With a strong focus on research and development, {} has become a pioneer in the field of powder coating, setting new standards for quality and innovation. The company's commitment to excellence has not only propelled them to the forefront of the industry but has also earned them a reputation as a trusted leader in the market.So, what exactly is powder coating, and how is {} leveraging this technique to deliver exceptional results? Unlike traditional liquid paint, powder coating involves applying a dry powder to a surface, which is then cured under heat to form a smooth and durable finish. This process offers several advantages, including increased durability, enhanced corrosion resistance, and reduced environmental impact.With a state-of-the-art powder coating facility, {} has the capability to apply this advanced finish to a wide range of products, from automotive components and household appliances to industrial machinery and architectural elements. The company's expertise in powder coating extends to a variety of materials, including metal, plastic, and wood, allowing them to meet the diverse needs of their customers and deliver superior results across different industries.In addition to its technical prowess, {}'s approach to powder coating is characterized by a strong emphasis on customization and innovation. The company works closely with its clients to develop tailored solutions that meet their specific requirements, whether it's achieving a particular color, texture, or performance standard. Furthermore, {} is constantly exploring new techniques and formulations to further enhance the capabilities of powder coating and push the boundaries of what is possible in surface finishing.As a result of {}'s dedication to excellence, the company has earned the trust of leading brands and manufacturers, who rely on {} to deliver top-quality powder coating solutions that meet the highest standards of performance and aesthetics. By consistently exceeding customer expectations and delivering exceptional results, {} has solidified its position as a preferred partner for companies seeking cutting-edge surface finishing solutions.Looking ahead, {} is committed to continuing its investment in powder coating technology, with a focus on sustainability, efficiency, and versatility. With ongoing advancements in equipment, materials, and processes, {} is poised to further elevate the capabilities of powder coating and set new benchmarks for the industry.In conclusion, powder coating has undoubtedly changed the game in the world of surface finishing, offering a superior alternative to traditional paint and paving the way for new possibilities in product design and durability. Through its relentless pursuit of innovation and customer satisfaction, {} has emerged as a trailblazer in the field of powder coating, setting the bar for excellence and driving the industry forward. As the demand for high-quality, sustainable finishes continues to grow, {} is well-positioned to lead the charge and shape the future of surface coating technology.

Latest Updates: Important News on Masks Revealed for Maximum Protection

In a recent development, a leading company in the field of respiratory protection has launched a range of masks designed to combat the ongoing global pandemic. With the demand for masks surging in recent months, the company has sought to provide a product that offers reliable and effective protection to wearers.Founded in [year], {} is a [industry] that specializes in [product/service]. With a focus on innovation and product development, the company has established itself as a leader in its field, providing high-quality products to customers around the world. The latest addition to its portfolio is a range of masks designed to meet the needs of customers during the COVID-19 pandemic.The new masks are made from high-quality materials, including [insert materials], to provide maximum protection to wearers. Each mask features [insert features], ensuring that they are comfortable and easy to wear for extended periods. The masks have also been rigorously tested to ensure that they meet the highest standards of safety and efficacy.Speaking about the launch of the new product, a spokesperson for the company said: "We are proud to be launching these masks in response to the ongoing pandemic. Our team has worked hard to develop a product that provides reliable and effective protection to wearers, and we believe that our masks will make a real difference to people's lives."The spokesperson added: "We have received a lot of interest in our masks from customers around the world, and we believe that they will be especially popular in high-risk environments such as hospitals, care homes, and other settings where people are at increased risk of exposure to the virus."The company's commitment to innovation and product development has been a key factor in its success, and it has invested heavily in research and development to ensure that its products are at the forefront of their field. With the launch of these new masks, the company is once again demonstrating its commitment to its customers and to providing innovative solutions to the challenges of the modern world.In addition to providing reliable protection to wearers, the company's masks are also designed to be environmentally friendly. They are made from materials that are recyclable, and the company has implemented a range of measures to minimize its environmental impact throughout the production process.The spokesperson said: "We understand the importance of sustainability and environmental responsibility, and we have taken steps to ensure that our masks are as eco-friendly as possible. We believe that it is important to consider the long-term impact of the products that we create, and we are committed to doing our part to protect the environment."Overall, the launch of {}'s new range of masks marks an important step in the response to the ongoing pandemic. With a focus on quality, reliability, and sustainability, the company has developed a product that is both effective and environmentally friendly. As the world continues to grapple with the challenges posed by COVID-19, products like these will play an important role in keeping people safe and protecting public health.