Ultimate Guide to 3D Printing and Prototyping

By:Admin

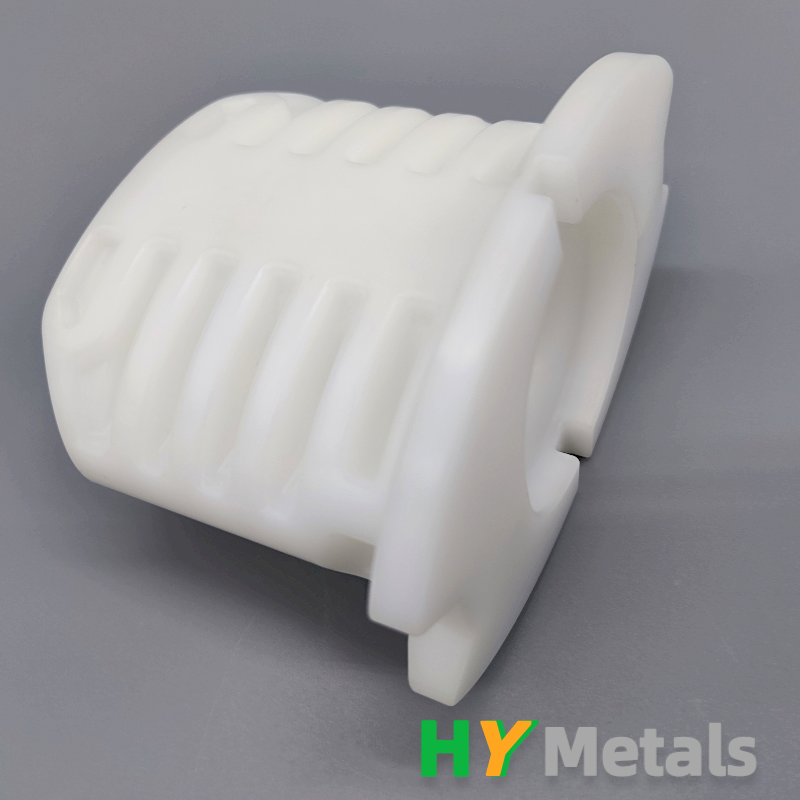

In recent years, the field of manufacturing has been revolutionized by the advent of 3D printing and prototyping. This innovative technology has allowed for the creation of complex and intricate designs, as well as rapid prototyping of products. One company that has been at the forefront of this revolution is {}.

{} is a leading provider of 3D printing and prototyping solutions, offering a wide range of services to meet the needs of various industries. With state-of-the-art technology and a team of skilled professionals, the company has positioned itself as a pioneer in the field of additive manufacturing.

3D printing, also known as additive manufacturing, involves creating three-dimensional objects by layering materials such as plastic, metal, or ceramics. This process allows for the production of intricate designs that would be impossible to achieve using traditional manufacturing methods. Rapid prototyping, on the other hand, enables companies to quickly develop and test new product designs, significantly reducing the time and cost involved in the product development cycle.

{} offers a comprehensive range of 3D printing and prototyping services, catering to industries such as aerospace, automotive, medical, and consumer goods. The company's advanced technology and expertise enable it to produce high-quality prototypes and end-use parts with precision and efficiency.

One of the key advantages of 3D printing and prototyping is the ability to create complex geometries and intricate designs that were previously unattainable. This has led to significant advancements in product innovation and design, allowing companies to push the boundaries of what is possible in their respective industries.

In addition to product design and development, 3D printing and prototyping also offer environmental benefits. Unlike traditional manufacturing methods, which often result in a large amount of waste material, additive manufacturing is a more sustainable option. By only using the necessary materials to create a product, 3D printing reduces material waste and energy consumption, making it a more environmentally friendly choice.

The potential applications of 3D printing and prototyping are vast, and {} is at the forefront of introducing this technology to a wide range of industries. From rapid prototyping of new product designs to the production of end-use parts, the company's innovative solutions have been embraced by businesses seeking to stay ahead in an increasingly competitive market.

As the demand for 3D printing and prototyping continues to grow, {} remains committed to pushing the boundaries of what is possible in additive manufacturing. The company's dedication to innovation and excellence has earned it a reputation as a trusted partner for businesses looking to leverage the power of 3D printing in their operations.

In conclusion, 3D printing and prototyping have revolutionized the field of manufacturing, offering businesses the ability to create complex designs and prototypes with unprecedented speed and precision. {} is leading the way in this revolution, providing cutting-edge solutions to meet the diverse needs of industries around the world. As the technology continues to advance, the possibilities for 3D printing and prototyping are endless, and {} is poised to remain at the forefront of this exciting industry.

Company News & Blog

High-Quality Custom Radiator Parts for Your Car: A Comprehensive Guide

Custom Radiator Parts Company Continues to Lead the Industry in Innovation and QualityAs the automotive industry continues to evolve and advance, the demand for custom radiator parts has never been higher. One company that has been at the forefront of this industry is [Company Name]. With their commitment to innovation and quality, they have solidified their position as a leader in the market.[Company Name] has been in operation for over 20 years, serving customers with a wide range of custom radiator parts. Their dedication to providing high-quality products at competitive prices has earned them a reputation as a trusted and reliable supplier in the industry.One of the key factors that sets [Company Name] apart from its competitors is their focus on innovation. They understand the importance of staying ahead of the curve and meeting the ever-changing needs of their customers. This drive for innovation has led to the development of cutting-edge custom radiator parts that are designed to deliver superior performance and reliability.In addition to their commitment to innovation, [Company Name] is also known for their unwavering dedication to quality. They have implemented strict quality control measures throughout their manufacturing process to ensure that every part that leaves their facility meets the highest standards. This dedication to quality has earned them the trust and loyalty of their customers, who know that they can rely on [Company Name] for top-notch custom radiator parts.To further enhance their product offering, [Company Name] recently announced the release of a new line of custom radiator parts that are designed to meet the specific needs of modern vehicles. These parts have been developed using the latest technology and materials, ensuring that they are able to withstand the demands of today’s vehicles and deliver exceptional performance.One of the key advantages of choosing [Company Name] for custom radiator parts is their ability to work closely with their customers to develop parts that are tailored to their unique requirements. Their team of experts has the knowledge and experience to assist customers in designing and producing custom radiator parts that perfectly match their specifications. This personalized approach sets [Company Name] apart from other suppliers, as they are able to deliver parts that are truly customized to meet the needs of their customers.In addition to their focus on product innovation and quality, [Company Name] is also committed to providing exceptional customer service. They understand the importance of building strong relationships with their customers and are dedicated to providing the support and assistance that their customers need. This customer-centric approach has helped to solidify [Company Name]’s reputation as a trusted partner in the industry.Looking to the future, [Company Name] is poised to continue leading the industry in innovation and quality. With their ongoing commitment to developing cutting-edge custom radiator parts and providing exceptional customer service, they are well-positioned to meet the evolving needs of the automotive industry.As the demand for custom radiator parts continues to grow, [Company Name] remains dedicated to serving their customers with top-quality products and personalized service. With their focus on innovation, quality, and customer satisfaction, they are well-equipped to maintain their position as a leader in the industry for years to come.

Effective Tips for Grinding and Polishing Your Metal Components

Grinding, a leading global supplier of grinding equipment and services, has recently announced a new product release that is set to revolutionize the industry. The company, with its headquarters in Germany, has been a major player in the grinding equipment market for over 100 years, and this latest innovation is designed to further solidify its position as an industry leader.The new product, which has been in development for the past several years, is a state-of-the-art grinding machine that offers unprecedented precision and efficiency. With a focus on sustainability and reducing environmental impact, Grinding's new machine utilizes the latest technology to minimize energy consumption while maximizing output.In addition to its impressive technical capabilities, the new machine also boasts a user-friendly interface and intuitive controls, making it accessible to operators of all experience levels. This focus on usability is a key part of Grinding's commitment to providing the best possible experience for its customers, ensuring that they can achieve the highest levels of productivity with minimal training or expertise.The company's dedication to innovation and customer satisfaction is reflected in its long-standing reputation for quality and reliability. With a global network of manufacturing and service facilities, Grinding is able to provide support to customers around the world, ensuring that their equipment is always performing at its best.In a statement regarding the new product release, a spokesperson for Grinding emphasized the company's commitment to pushing the boundaries of what is possible in the grinding industry. "We are thrilled to introduce this new machine to the market," the spokesperson said. "It represents a significant leap forward in terms of both technology and sustainability, and we are confident that it will set a new standard for grinding equipment worldwide."The spokesperson also highlighted Grinding's dedication to sustainability and environmental responsibility. "We understand the importance of minimizing our impact on the planet," they said. "That's why our new machine is designed to be as energy-efficient as possible, without compromising on performance. We believe that this commitment to sustainability is not only good for the environment, but also makes good business sense."Indeed, the release of this new product is a testament to Grinding's ongoing commitment to innovation and customer satisfaction. With a history of delivering high-quality, reliable equipment to the market, the company continues to be a trusted partner for companies in a wide range of industries, from automotive and aerospace to energy and medical devices.As the industry continues to evolve and adapt to new challenges, Grinding remains at the forefront, developing cutting-edge solutions that meet the needs of its customers. Whether it's through the introduction of new products like the one being announced today, or through its ongoing commitment to service and support, Grinding is dedicated to helping its customers succeed.In conclusion, the new product release from Grinding is an exciting development for the grinding industry. With its combination of advanced technology, user-friendly design, and commitment to sustainability, the new machine represents a significant step forward for the company and the industry as a whole. As Grinding continues to push the boundaries of what is possible in grinding equipment, customers can look forward to even greater levels of precision, efficiency, and reliability in their operations.

High-quality Sheet Metal Part for Precision Engineering Projects

Sheet Metal Part Company Provides High-Quality Components for Various IndustriesSince its establishment in 1998, Sheet Metal Part Company has been a leading manufacturer and supplier of precision sheet metal components for a wide range of industries. With a dedication to quality, innovation, and customer satisfaction, the company has built a solid reputation for producing high-quality parts that meet the specific requirements of its clients.The company's state-of-the-art manufacturing facility is equipped with advanced machinery and tools that enable the production of complex and precise sheet metal components. From intricate prototypes to large-scale production runs, Sheet Metal Part Company has the capabilities to handle diverse projects with efficiency and precision.One of the key strengths of Sheet Metal Part Company is its team of highly skilled engineers, technicians, and production staff. With years of experience and expertise in the field of sheet metal fabrication, the company's team members are committed to delivering top-notch solutions that exceed customer expectations. Whether it's custom enclosures for the electronics industry, precision components for the automotive sector, or specialized parts for the aerospace industry, the company's team is capable of meeting the unique demands of each customer.In addition to its commitment to quality and precision, Sheet Metal Part Company places a strong emphasis on innovation and continuous improvement. The company invests in research and development to stay at the forefront of technological advancements in the sheet metal fabrication industry. By embracing new techniques, processes, and materials, the company is able to offer innovative solutions that address the evolving needs of its customers.Furthermore, Sheet Metal Part Company takes pride in its strict adherence to industry standards and regulations. The company is certified to ISO 9001 standards, ensuring that its manufacturing processes and quality management systems are of the highest caliber. This dedication to quality and compliance has earned the company the trust and confidence of its customers, who rely on Sheet Metal Part Company for their most critical sheet metal component needs.With a strong focus on customer satisfaction, Sheet Metal Part Company works closely with its clients to understand their requirements and provide tailored solutions that meet their specific needs. The company's customer-centric approach, combined with its technical expertise and manufacturing capabilities, has resulted in long-term partnerships with a diverse range of customers across various industries.In recent news, Sheet Metal Part Company has introduced a new line of environmentally friendly sheet metal components that are designed to reduce waste and energy consumption in manufacturing processes. By utilizing sustainable materials and implementing eco-friendly production methods, the company aims to contribute to environmental conservation while meeting the needs of its customers.As Sheet Metal Part Company continues to expand its product offerings and reach new markets, the company remains committed to its founding principles of quality, innovation, and customer satisfaction. With a solid track record of delivering high-quality sheet metal components for diverse applications, the company is poised to remain a trusted partner for industries that require precision and reliability in their sheet metal parts.In conclusion, Sheet Metal Part Company stands as a leading provider of high-quality sheet metal components for a wide range of industries. With a focus on quality, innovation, and customer satisfaction, the company has established itself as a reliable partner for businesses seeking precision and reliability in their sheet metal parts. With a dedication to continuous improvement and environmental stewardship, Sheet Metal Part Company is well-positioned to meet the evolving needs of its customers and the market.

Expert Aircraft Sheet Metal Fabrication Services for Precision and Durability

Aircraft Sheet Metal Fabrication is a critical aspect of the aerospace industry, as it involves the manufacturing and assembly of metal components for aircraft structures. These components must be fabricated with precision and accuracy to ensure the safety and performance of the aircraft. One company that specializes in this field is {}, which has been a leading provider of aircraft sheet metal fabrication for over two decades.{} is equipped with state-of-the-art technology and a team of highly skilled engineers and fabricators who are dedicated to delivering top-quality products. The company's commitment to excellence has earned them a reputation as a trusted supplier in the aerospace industry.The process of aircraft sheet metal fabrication involves cutting, bending, and assembling various types of metal, such as aluminum, steel, and titanium. These metal components are used in the construction of aircraft fuselages, wings, and other structural elements. Precision is key in this process, as even the smallest error can have serious consequences for the aircraft's performance and safety.One of the key factors that sets {} apart from other manufacturers is their stringent quality control measures. Every phase of the fabrication process is carefully monitored to ensure that each component meets the highest standards. This dedication to quality has made {} a preferred supplier for many major aerospace companies.In addition to their commitment to quality, {} also strives to be a leader in innovation and efficiency. The company continues to invest in the latest technology and equipment to streamline their manufacturing processes and reduce lead times. This not only benefits their customers by providing quicker turnaround times, but also contributes to the overall advancement of the aerospace industry.Furthermore, {} is dedicated to sustainability and environmental responsibility. They have implemented eco-friendly practices in their manufacturing processes, such as waste reduction and energy-efficient operations. By prioritizing sustainability, {} is not only contributing to a greener planet, but also fulfilling the increasing demand for environmentally conscious manufacturing practices in the aerospace industry.As a testament to their expertise and dedication, {} has been recognized with several industry certifications and awards. These accolades further demonstrate their commitment to excellence and their position as a leader in the field of aircraft sheet metal fabrication.With the aerospace industry constantly evolving and demanding higher standards, {} remains at the forefront of innovation and advancement. The company's ongoing investment in technology, commitment to quality, and dedication to sustainability make them an invaluable partner for aerospace companies around the world.In summary, {} is a leading provider of aircraft sheet metal fabrication, with a reputation for excellence, innovation, and sustainability. With their state-of-the-art facilities and highly skilled team, {} continues to set the standard for quality and reliability in the aerospace industry. Their commitment to excellence and dedication to advancing the field of aircraft sheet metal fabrication make them a trusted partner for aerospace companies seeking top-quality components for their aircraft structures.

Custom CNC Machining Services for Prototypes and Manufacturing

Prototype CNC Machining is a leading company in the field of precision manufacturing and prototyping. The company specializes in providing high-quality CNC machining services for a wide range of industries including aerospace, automotive, medical, and defense. With state-of-the-art facilities and a highly skilled team of engineers and technicians, Prototype CNC Machining has earned a reputation for delivering top-notch precision parts and prototypes to its clients.The company prides itself on its ability to deliver complex and intricate parts with the highest level of precision and accuracy. Using the latest CNC machining technology and advanced software, Prototype CNC Machining is able to produce parts with tight tolerances and intricate geometries. This has made them a preferred choice for businesses looking for reliable and high-quality CNC machining services.Prototype CNC Machining offers a wide range of CNC machining capabilities including 3-axis, 4-axis, and 5-axis machining, as well as turning and milling services. This allows the company to fulfill a variety of manufacturing needs and produce parts of varying complexities and sizes.One of the key strengths of Prototype CNC Machining is its ability to work closely with its clients to understand their specific requirements and provide customized solutions. The company's team of engineers and technicians work closely with clients throughout the entire process, from initial design and prototyping to final production. This collaborative approach ensures that the final product meets the exact specifications and quality standards of the client.In addition to its precision machining capabilities, Prototype CNC Machining also offers value-added services such as finishing, assembly, and quality inspection. This allows the company to provide a complete manufacturing solution to its clients, from initial concept to final product.The company's commitment to quality and customer satisfaction is evident in its ISO 9001 certification, which ensures that all processes and procedures meet the highest standards of quality. This commitment to quality has earned Prototype CNC Machining the trust and confidence of its clients, who rely on the company to deliver precision parts and prototypes that meet their exact requirements.Prototype CNC Machining has also invested in the latest manufacturing technology and equipment to further enhance its capabilities and provide even more efficient and cost-effective solutions to its clients. This includes the latest CNC machining centers, advanced inspection equipment, and cutting-edge software for design and production.With its dedication to excellence, cutting-edge technology, and a customer-centric approach, Prototype CNC Machining has positioned itself as a leader in the precision manufacturing and prototyping industry. The company's ability to deliver high-quality, precision parts and prototypes has made it a trusted partner for businesses seeking reliable and customized CNC machining solutions.As Prototype CNC Machining continues to grow and expand its capabilities, it remains committed to providing the highest level of quality and service to its clients. With a focus on innovation and continuous improvement, the company is well-positioned to meet the evolving needs of the manufacturing industry and exceed the expectations of its clients.

High-Quality CNC Aluminium Extrusion: What You Need to Know

CNC Aluminium Extrusion Company Leading the Industry with Innovation and QualityWith the increasing demand for high-quality aluminium extrusion products, the CNC Aluminium Extrusion Company has emerged as a leader in the industry. The company, founded in 1995, has established a strong reputation for delivering precision-engineered aluminium extrusion profiles to meet the diverse needs of its customers.The CNC Aluminium Extrusion Company has become known for its commitment to innovation, quality, and customer satisfaction. With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, the company has the capability to produce a wide range of custom aluminium extrusion profiles to meet the exact specifications of its customers.One of the key factors that sets the CNC Aluminium Extrusion Company apart from its competitors is its advanced CNC machining capabilities. The company has invested heavily in the latest CNC machining technology to ensure that its products are manufactured with the highest levels of accuracy and precision. This investment in technology has allowed the company to consistently deliver products that meet the most demanding requirements of its customers.In addition to its advanced manufacturing capabilities, the CNC Aluminium Extrusion Company places a strong emphasis on quality control. The company's quality assurance team ensures that every product that leaves its facility meets stringent quality standards. This commitment to quality has earned the company a reputation for reliability and consistency in the industry.Furthermore, the CNC Aluminium Extrusion Company is committed to sustainability and environmental responsibility. The company has implemented eco-friendly manufacturing processes and is dedicated to minimizing its environmental impact. By using recycled aluminium and reducing waste, the company is contributing to a more sustainable future for the industry.The CNC Aluminium Extrusion Company's dedication to innovation and quality has led to its continued success in the industry. With a focus on continuous improvement and a dedication to meeting the needs of its customers, the company has built a loyal customer base and has earned the trust of industry professionals.In recent news, the CNC Aluminium Extrusion Company has announced the launch of a new range of aluminium extrusion profiles that are designed to meet the evolving needs of its customers. These new profiles are the result of extensive research and development, and are engineered to deliver superior performance and durability. The company's investment in innovation has positioned it as a pioneer in the industry, and it continues to set the standard for excellence in aluminium extrusion manufacturing.The CNC Aluminium Extrusion Company's commitment to innovation and quality has not gone unnoticed. The company has received numerous awards and accolades for its outstanding products and services. These accolades serve as a testament to the company's dedication to excellence and its leadership in the industry.Looking ahead, the CNC Aluminium Extrusion Company is poised for continued success and growth. With a relentless focus on innovation, quality, and customer satisfaction, the company is well-positioned to meet the evolving needs of the industry and to remain a leader in aluminium extrusion manufacturing.In conclusion, the CNC Aluminium Extrusion Company has established itself as a leader in the industry through its commitment to innovation, quality, and customer satisfaction. With advanced manufacturing capabilities, a focus on sustainability, and a dedication to continuous improvement, the company has earned a reputation for excellence and reliability. As the company continues to innovate and meet the evolving needs of its customers, it is well-positioned for continued success and leadership in the industry.

Discover the Latest Aluminum Extrusion Profiles

Aluminum Extrusion Profiles are an essential component in various industries such as construction, automotive, aerospace, and manufacturing. These profiles are manufactured using a process called aluminum extrusion, wherein the aluminum is forced through a die to create a specific cross-sectional profile.One of the leading manufacturers of aluminum extrusion profiles is {company name}. With over 20 years of experience in the industry, {company name} has established itself as a trusted supplier of high-quality aluminum extrusion profiles to a wide range of customers worldwide.{Company name} offers a diverse range of aluminum extrusion profiles, including standard profiles, custom profiles, and specialty profiles for specific applications. These profiles are available in various alloys, including 6061, 6063, and 7075, with different surface finishes such as anodized, powder-coated, and mill finish.One of the key advantages of aluminum extrusion profiles is their lightweight yet strong characteristics, making them ideal for structural applications in the construction and automotive industries. The versatility of aluminum extrusion profiles also allows for complex shapes and designs, making them suitable for architectural and decorative purposes.In addition to standard profiles, {company name} also specializes in custom aluminum extrusion profiles, tailored to meet the unique requirements of their customers. With a team of experienced engineers and designers, {company name} can assist customers in developing custom profiles to exact specifications, ensuring a perfect fit for their specific needs.Furthermore, {company name} is committed to sustainability and environmental responsibility in their manufacturing processes. Aluminum is a highly recyclable material, and the extrusion process itself generates minimal waste, making it a sustainable choice for customers seeking eco-friendly solutions.With a state-of-the-art manufacturing facility and a dedicated team of experts, {company name} has the capability to produce high-volume orders with precision and efficiency, ensuring on-time delivery to their customers.The quality of {company name}’s aluminum extrusion profiles is upheld through stringent quality control measures and rigorous testing procedures, ensuring that each profile meets the highest standards for performance and durability.Having established a strong reputation for reliability and excellence, {company name} has built long-standing relationships with customers across various industries, serving as a trusted partner in providing top-quality aluminum extrusion profiles.As the demand for aluminum extrusion profiles continues to grow, {company name} remains poised to meet the evolving needs of the market, leveraging their expertise and capabilities to deliver innovative solutions to their customers.In conclusion, {company name} is a leading manufacturer of aluminum extrusion profiles, offering a comprehensive range of standard, custom, and specialty profiles to a diverse customer base. With a focus on quality, sustainability, and customer satisfaction, {company name} continues to set the benchmark for excellence in the industry, solidifying its position as a preferred supplier of aluminum extrusion profiles globally.

How Water Jet Technology is Revolutionizing the Industrial Sector

Water Jet Technology Combined with Cutting Edge Innovation Brings Efficiency and Precision to Manufacturing IndustryIn today’s fast-paced and competitive manufacturing industry, the need for precise and efficient cutting solutions has never been greater. The demand for high-quality and accurate products has led to the development of advanced machining techniques, and one such innovation is the use of water jet technology.Water jet technology is a cutting method that utilizes a high-pressure stream of water to cut through various materials with precision and accuracy. This technology has been in use for decades and has continued to evolve and improve, thanks to continuous research and development efforts. The addition of abrasive materials to the water jet stream has significantly enhanced its cutting capabilities, enabling it to cut through even the hardest and thickest materials with ease.One company that has been at the forefront of the development and advancement of water jet technology is {}. With a strong focus on innovation, precision, and customer satisfaction, {} has established itself as a leading provider of water jet cutting solutions for a wide range of industries.Established in {}, {} has grown to become a global leader in the water jet cutting industry, with a strong reputation for delivering cutting-edge cutting solutions that meet the unique needs of its customers. The company’s commitment to innovation and technological advancement has enabled it to stay ahead of the curve, offering state-of-the-art water jet cutting systems that deliver unmatched performance and efficiency.{}’s water jet cutting systems are equipped with the latest technological advancements, including advanced motion control systems, high-pressure pumps, and cutting-edge software. This allows for precise and accurate cutting of a wide range of materials, including metals, composites, stone, glass, and more. With the ability to cut through materials of varying thickness and hardness, {}’s water jet cutting systems are ideal for a diverse range of applications, from aerospace and automotive manufacturing, to architectural and artistic projects.The use of water jet technology offers several advantages over traditional cutting methods. Unlike laser or plasma cutting, water jet cutting does not produce heat-affected zones, ensuring that the integrity of the material remains intact. This makes it ideal for cutting materials that are sensitive to heat, such as plastics and composites. In addition, water jet cutting is a clean and environmentally friendly process, as it does not produce harmful fumes or dust. This makes it a preferred choice for manufacturers looking to reduce their environmental impact.In addition to its cutting-edge water jet cutting systems, {} also offers a range of ancillary equipment and accessories to complement its cutting solutions. This includes abrasive delivery systems, abrasive recycling systems, and precision cutting heads, all of which are designed to further enhance the performance and efficiency of the water jet cutting process.With a strong focus on customer satisfaction, {} also provides comprehensive training and support services to ensure that its customers are able to maximize the potential of their water jet cutting systems. From installation and setup, to ongoing maintenance and support, {} is committed to providing its customers with the tools and resources they need to succeed.As the manufacturing industry continues to evolve and demand for high-quality, precise products grows, the use of water jet technology is expected to become even more prevalent. With {}’s cutting-edge water jet cutting solutions, manufacturers can benefit from increased efficiency, precision, and cost savings, making it an essential tool for the modern manufacturing industry.

An Overview of Custom Metal Parts: Latest Trends and Applications

Custom Metal Part, a leading manufacturer in the metal fabrication industry, has recently announced the launch of their newest product line. With their state-of-the-art facility and dedicated team of skilled professionals, Custom Metal Part continues to be a top choice for businesses seeking high-quality metal parts.Established in 1995, Custom Metal Part has built a reputation for providing custom metal parts for a wide range of industries, including automotive, aerospace, and electronics. The company takes pride in their ability to deliver precision-engineered metal parts that meet the specific needs of their clients.The new product line from Custom Metal Part includes a variety of metal parts designed to meet the needs of their diverse customer base. From precision machined components to custom metal stampings, the company is committed to delivering high-quality products that meet the highest industry standards.One of the key features of Custom Metal Part's new product line is their ability to provide custom solutions for their clients. With their team of experienced engineers and designers, the company is able to work closely with their customers to develop custom metal parts that meet their unique specifications. This level of customization sets Custom Metal Part apart from other metal fabrication companies and allows them to offer a truly tailored solution for their clients.In addition to their custom capabilities, Custom Metal Part also emphasizes the importance of quality and precision in their manufacturing processes. The company utilizes advanced technology and cutting-edge equipment to ensure that each metal part they produce meets the highest standards of quality and accuracy. This commitment to excellence is reflected in the company's ISO 9001 certification, which demonstrates their dedication to maintaining the highest level of quality control in all aspects of their operation.As part of their new product line, Custom Metal Part is also introducing a range of eco-friendly metal parts that are designed to minimize environmental impact. With a growing focus on sustainability in the manufacturing industry, Custom Metal Part is committed to offering solutions that not only meet the needs of their clients but also align with their environmental values.The launch of their new product line represents an important milestone for Custom Metal Part, as it demonstrates their ongoing commitment to innovation and excellence in the metal fabrication industry. By continually evolving and expanding their product offerings, Custom Metal Part is positioned to remain a leader in the industry for years to come.With their dedication to quality, customization, and sustainability, Custom Metal Part is well-positioned to meet the needs of their diverse customer base and continue to provide value-added solutions for businesses in a wide range of industries. As the company looks to the future, they remain focused on staying at the forefront of the metal fabrication industry and delivering the highest standard of products and service to their clients.In conclusion, the introduction of Custom Metal Part's new product line is an exciting development for the company and the metal fabrication industry as a whole. With their focus on quality, customization, and sustainability, Custom Metal Part is well-positioned to remain a top choice for businesses seeking high-quality metal parts. The company's commitment to innovation and excellence ensures that they will continue to be a leader in the industry for years to come.

Precision Grinding of CNC Machined Parts for Increased Durability and Performance

Title: Advancements in CNC Machined Parts Grinding: Delivering Precision and EfficiencyIntroduction (approx. 80 words):In the fast-paced world of manufacturing, the demand for precision-engineered components is at an all-time high. Addressing this need, a leading company in the field has made significant breakthroughs in CNC Machined Parts Grinding. By combining cutting-edge technology and industry expertise, they are revolutionizing the production of machined parts, offering unparalleled precision, efficiency, and reliability. With the ability to remove imperfections with remarkable accuracy, their advanced grinding techniques enhance product quality, reduce production time, and maximize cost-effectiveness.Innovation in CNC Machined Parts Grinding (approx. 200 words):Building on decades of experience and a commitment to continuous innovation, the company has introduced state-of-the-art advancements in CNC Machined Parts Grinding. By leveraging advanced robotic systems, high-precision tools, and computer numerical control (CNC) technology, they have transformed the grinding process, setting new standards in the industry.The integration of robotic systems has enabled precise handling and positioning of components, ensuring consistent grinding quality. This automation enhances productivity, eliminates human error, and optimizes production throughput. Additionally, it allows for multitasking capabilities, enabling simultaneous grinding of multiple parts, saving valuable time without compromising precision.Furthermore, the utilization of high-precision tools and cutting-edge abrasives guarantees the removal of imperfections with exceptional accuracy. By employing a combination of grinding wheels, belts, and discs designed for specific applications, the company ensures the highest level of precision, ensuring superior surface finishes and dimensional accuracy.To enhance the grinding process's efficiency, the company has incorporated CNC technology into their machining centers. This allows for seamless coordination between various machining operations, eliminating the need for multiple setups and tool changes. The result is faster cycle times, reduced downtime, and improved overall productivity.Benefits and Applications (approx. 250 words):The advancements in CNC Machined Parts Grinding have numerous benefits that make them indispensable for various manufacturing industries. The precision achieved through these techniques ensures the exact dimensions and tolerances required, eliminating the risk of errors and rework. By improving product quality and reducing rejects, manufacturers can establish a reputation for delivering superior components consistently.Moreover, these advancements have considerably reduced production time. With increased automation, multitasking capabilities, and efficient integration of CNC technology, companies can significantly improve throughput. This accelerates the delivery of finished parts, enabling manufacturers to meet tight deadlines without compromising quality.The cost-effectiveness of CNC Machined Parts Grinding is another crucial advantage. By streamlining processes and minimizing waste, manufacturers can optimize resource utilization and reduce production costs. In addition, the ability to complete complex grinding operations in a single setup reduces labor costs and machine downtime.The applications for CNC Machined Parts Grinding span various industries, including aerospace, automotive, robotics, medical, and more. In the aerospace sector, for instance, the precision grinding techniques are indispensable for creating intricate components that withstand the extreme demands of aircraft engines. Similarly, in the medical field, these advancements enable the production of high-precision parts for surgical instruments and prosthetics, ensuring utmost reliability and patient safety.Conclusion (approx. 70 words):Through their relentless pursuit of innovation, the company has transformed CNC Machined Parts Grinding, positioning themselves as industry leaders. With a focus on precision, efficiency, and cost-effectiveness, their advanced grinding techniques have revolutionized the manufacturing sector. By embracing these advancements, manufacturers can forge a path towards increased productivity, improved quality, and enhanced competitiveness in the global market.