In fact, HY Metals has more than 60 sets high precision lathes, which enables us to control tolerances within +/-0.005mm. This level of precision is critical to creating components such as those used in camera manufacturing, where even the slightest deviation can have a major impact on the quality of the final product. The camera's circular flange is just one of many parts that can be manufactured using CNC turning and milling. These machining processes are commonly used for finishing most mechanical parts as they provide precise and consistent results that meet the most demanding specifications. In addition to CNC machining, HY Metals offers a wide range of other fabrication services including sheet metal fabrication, prototyping, stamping, extrusion and more. This enables HY Metals to offer a comprehensive service suite that meets the needs of its clients. Whether you are looking for a supplier of high precision components or need a company that can help you deliver complex projects within tight deadlines, HY Metals is the perfect partner for your needs. Our team of experienced professionals can help you design and manufacture components to your exact specifications, no matter how challenging your project. Combining high precision with CNC turned parts is the hallmark of HY Metals CNC machining services. Camera circular flanges manufactured using CNC turning and milling are just one example of the many components that can be efficiently and accurately produced using these processes. HY Metals' commitment to quality and customer satisfaction has made us a preferred supplier to numerous industries and with our diverse services we are poised to continue delivering exceptional results for many years to come.

In fact, HY Metals has more than 60 sets high precision lathes, which enables us to control tolerances within +/-0.005mm. This level of precision is critical to creating components such as those used in camera manufacturing, where even the slightest deviation can have a major impact on the quality of the final product. The camera's circular flange is just one of many parts that can be manufactured using CNC turning and milling. These machining processes are commonly used for finishing most mechanical parts as they provide precise and consistent results that meet the most demanding specifications. In addition to CNC machining, HY Metals offers a wide range of other fabrication services including sheet metal fabrication, prototyping, stamping, extrusion and more. This enables HY Metals to offer a comprehensive service suite that meets the needs of its clients. Whether you are looking for a supplier of high precision components or need a company that can help you deliver complex projects within tight deadlines, HY Metals is the perfect partner for your needs. Our team of experienced professionals can help you design and manufacture components to your exact specifications, no matter how challenging your project. Combining high precision with CNC turned parts is the hallmark of HY Metals CNC machining services. Camera circular flanges manufactured using CNC turning and milling are just one example of the many components that can be efficiently and accurately produced using these processes. HY Metals' commitment to quality and customer satisfaction has made us a preferred supplier to numerous industries and with our diverse services we are poised to continue delivering exceptional results for many years to come.- Home

- Products

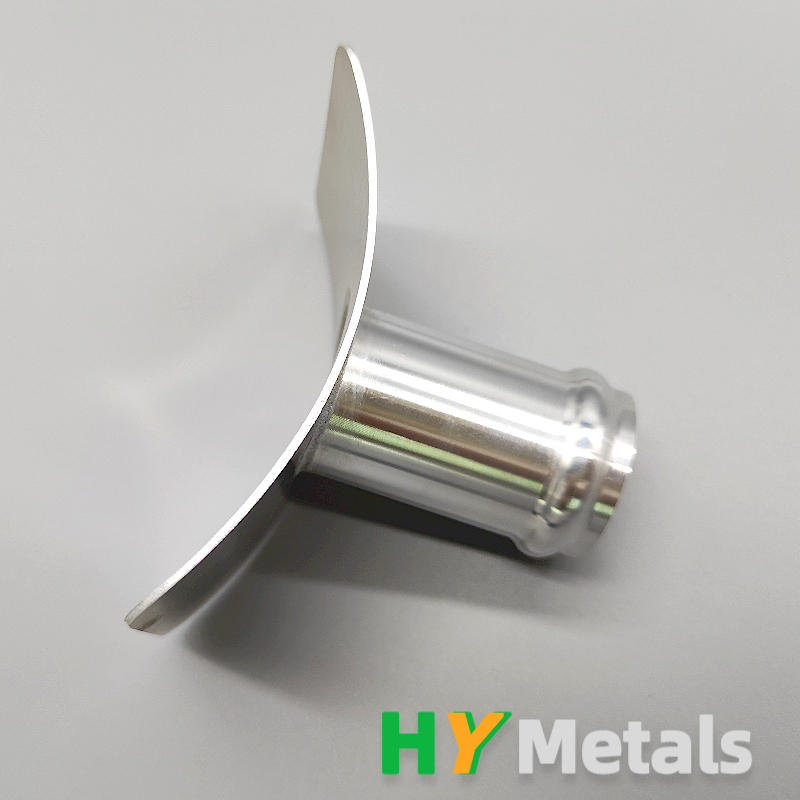

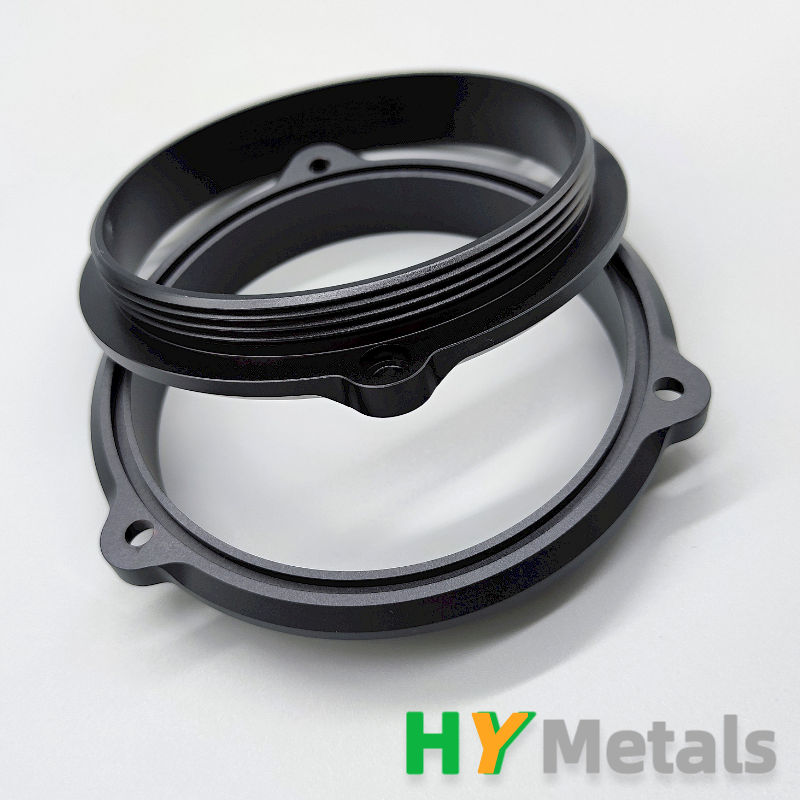

- High Precision CNC turned aluminum part with sandblasted and black anodized for camera prototypes

High Precision CNC turned aluminum part with sandblasted and black anodized for camera prototypes

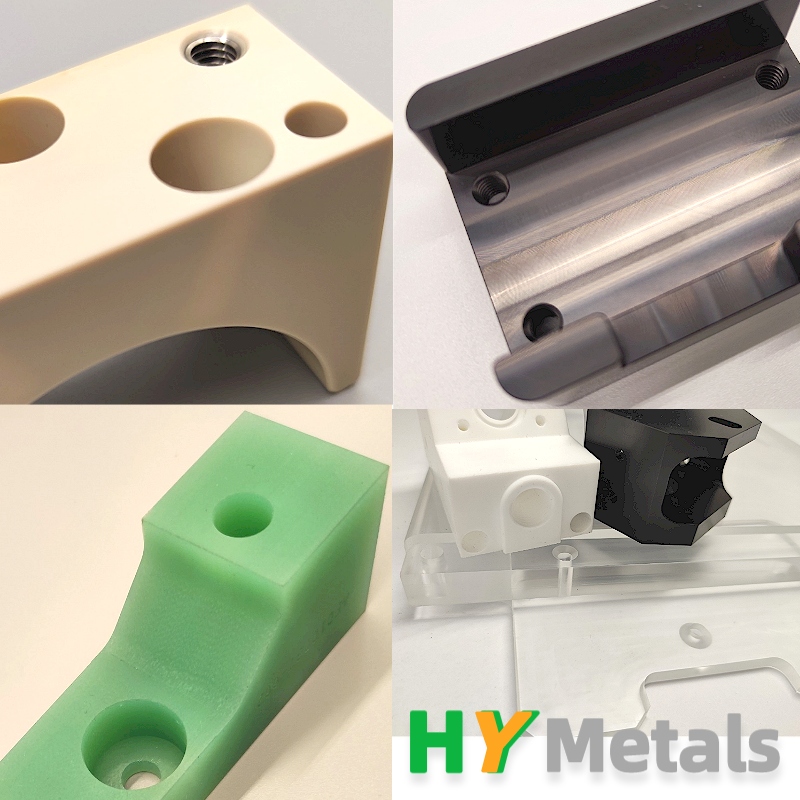

Looking for a high-quality CNC turned aluminum part for your camera prototypes? Look no further than our factory. Our sandblasted and black anodized part is precise, durable, and perfect for your needs. Order now and see the difference for yourself.

Request a QuotePRODUCTS DETAILS

In fact, HY Metals has more than 60 sets high precision lathes, which enables us to control tolerances within +/-0.005mm. This level of precision is critical to creating components such as those used in camera manufacturing, where even the slightest deviation can have a major impact on the quality of the final product. The camera's circular flange is just one of many parts that can be manufactured using CNC turning and milling. These machining processes are commonly used for finishing most mechanical parts as they provide precise and consistent results that meet the most demanding specifications. In addition to CNC machining, HY Metals offers a wide range of other fabrication services including sheet metal fabrication, prototyping, stamping, extrusion and more. This enables HY Metals to offer a comprehensive service suite that meets the needs of its clients. Whether you are looking for a supplier of high precision components or need a company that can help you deliver complex projects within tight deadlines, HY Metals is the perfect partner for your needs. Our team of experienced professionals can help you design and manufacture components to your exact specifications, no matter how challenging your project. Combining high precision with CNC turned parts is the hallmark of HY Metals CNC machining services. Camera circular flanges manufactured using CNC turning and milling are just one example of the many components that can be efficiently and accurately produced using these processes. HY Metals' commitment to quality and customer satisfaction has made us a preferred supplier to numerous industries and with our diverse services we are poised to continue delivering exceptional results for many years to come.

In fact, HY Metals has more than 60 sets high precision lathes, which enables us to control tolerances within +/-0.005mm. This level of precision is critical to creating components such as those used in camera manufacturing, where even the slightest deviation can have a major impact on the quality of the final product. The camera's circular flange is just one of many parts that can be manufactured using CNC turning and milling. These machining processes are commonly used for finishing most mechanical parts as they provide precise and consistent results that meet the most demanding specifications. In addition to CNC machining, HY Metals offers a wide range of other fabrication services including sheet metal fabrication, prototyping, stamping, extrusion and more. This enables HY Metals to offer a comprehensive service suite that meets the needs of its clients. Whether you are looking for a supplier of high precision components or need a company that can help you deliver complex projects within tight deadlines, HY Metals is the perfect partner for your needs. Our team of experienced professionals can help you design and manufacture components to your exact specifications, no matter how challenging your project. Combining high precision with CNC turned parts is the hallmark of HY Metals CNC machining services. Camera circular flanges manufactured using CNC turning and milling are just one example of the many components that can be efficiently and accurately produced using these processes. HY Metals' commitment to quality and customer satisfaction has made us a preferred supplier to numerous industries and with our diverse services we are poised to continue delivering exceptional results for many years to come.Hot Products

3D printing service for rapid prototype parts

High-quality sheet metal welded component Custom aluminum welding assembly

Urethane casting for rapid prototypes and low volume production

Customized metal parts which require no coating in specified areas

High Precision CNC turned aluminum part with sandblasted and black anodized for camera prototypes

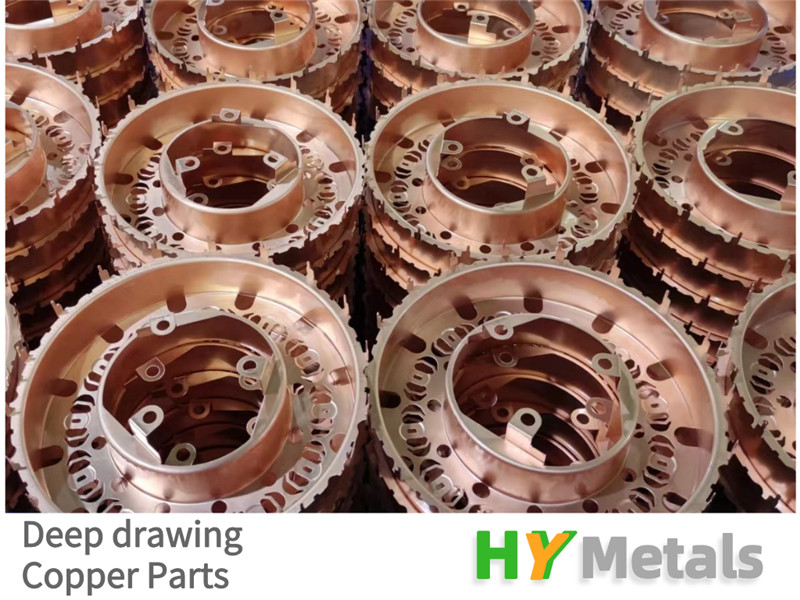

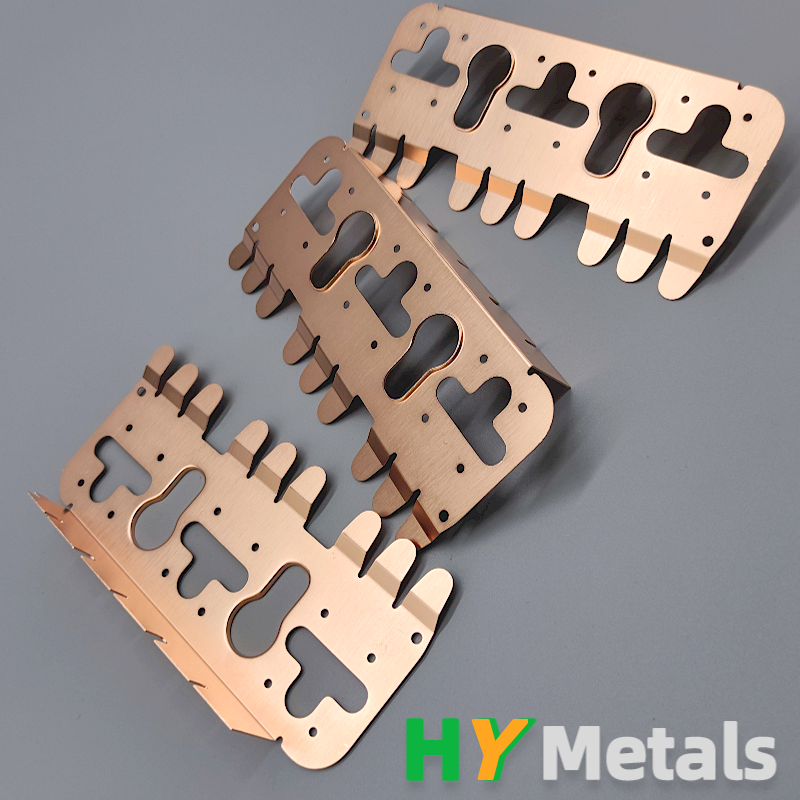

High precision metal stamping work include Stamping, Punching and Deep-Drawing

High Precision Plastic Parts custom machined plastic parts

Stainless steel sheet metal bracket with black powder coating custom sheet metal parts

High precision sheet metal parts copper contactors sheet metal copper connectors

OEM High Precision CNC Machining Services for Custom CNC Machining Aluminum Parts

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours