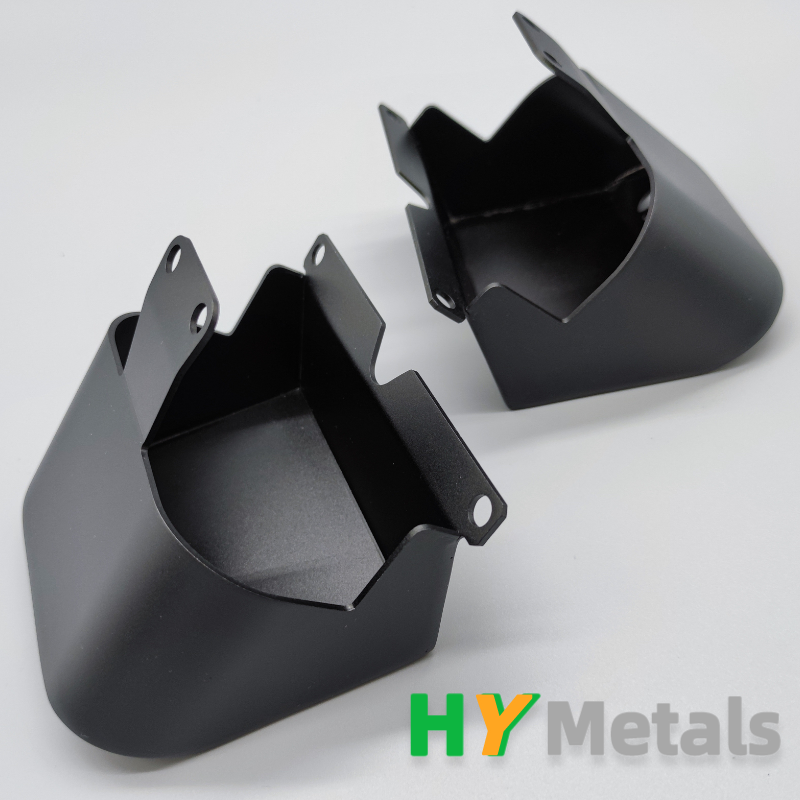

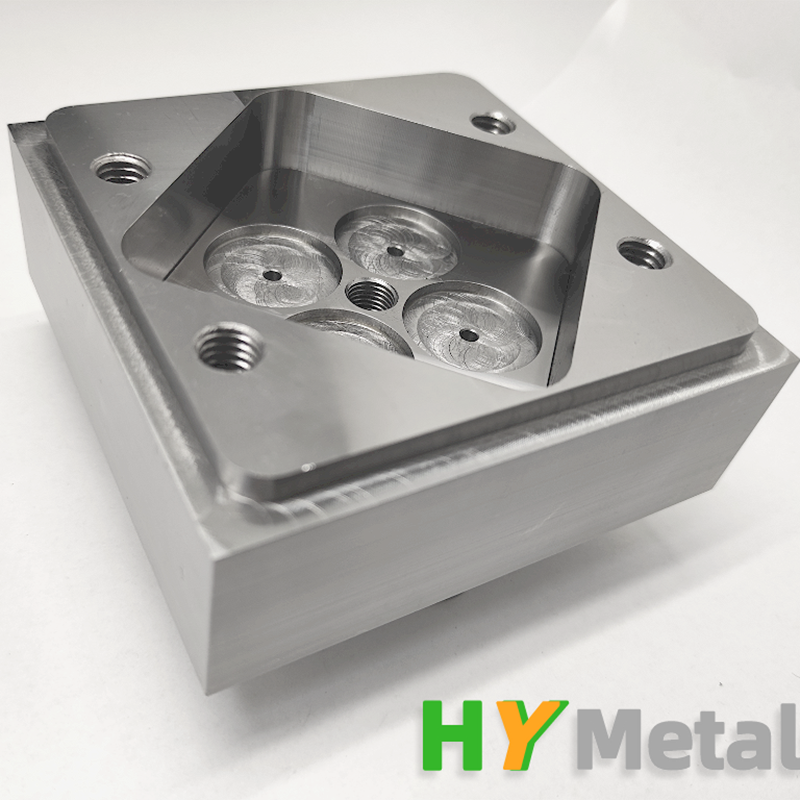

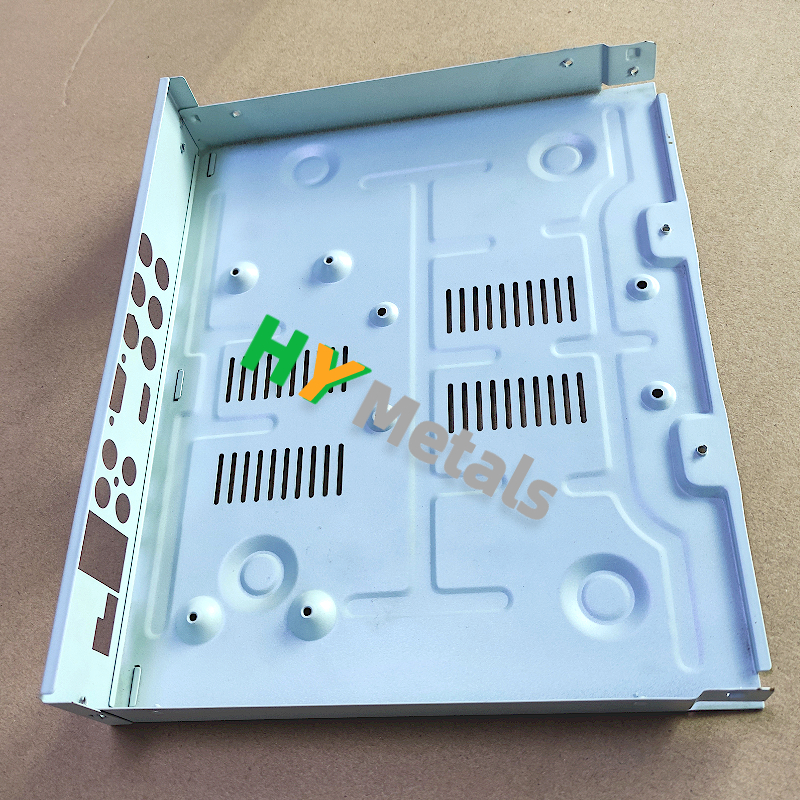

Powder coating is a kind of epoxy resin coating, its thickness always between 0.2-0.6mm,which is much thicker than plating layer. Powder Coat finish is suit for some outside sheet metal parts which are not sensitive to tolerance and want to get customized colors. Stainless steel has a better rust resistance ability, widely used in automation equipment, Medical device, kitchen wares and many kinds of outdoor brackets, shells. Stainless steel parts usually no need any finish, just keep the raw material with 2B finish or Brushed finish.HY metals is your best supplier of custom sheet metal parts and machining parts with more than 10 years of experience and ISO9001:2015 cert. We own 6 fully equipped factories including 4 sheet metal shops and 2 CNC machining shops. We provide professional custom metal and plastic prototyping and manufacturing solutions. HY Metals is a grouped company providing one-stop service from raw materials to end use products. We can handle all kinds of materials including Carbon Steel, Stainless steel, Tool steel, Brass, Aluminum, and all kinds of machinable plastic.The commonly used materials for CNC machining parts including Steel, Stainless steel, Aluminum, Brass, and all kinds of machinable plastic material. CNC parts usually required a tight tolerance, so the coating layer is not allowed too thick. Electroplating for steel and copper parts , anodizing for aluminum parts are the most popular finishes.

Powder coating is a kind of epoxy resin coating, its thickness always between 0.2-0.6mm,which is much thicker than plating layer. Powder Coat finish is suit for some outside sheet metal parts which are not sensitive to tolerance and want to get customized colors. Stainless steel has a better rust resistance ability, widely used in automation equipment, Medical device, kitchen wares and many kinds of outdoor brackets, shells. Stainless steel parts usually no need any finish, just keep the raw material with 2B finish or Brushed finish.HY metals is your best supplier of custom sheet metal parts and machining parts with more than 10 years of experience and ISO9001:2015 cert. We own 6 fully equipped factories including 4 sheet metal shops and 2 CNC machining shops. We provide professional custom metal and plastic prototyping and manufacturing solutions. HY Metals is a grouped company providing one-stop service from raw materials to end use products. We can handle all kinds of materials including Carbon Steel, Stainless steel, Tool steel, Brass, Aluminum, and all kinds of machinable plastic.The commonly used materials for CNC machining parts including Steel, Stainless steel, Aluminum, Brass, and all kinds of machinable plastic material. CNC parts usually required a tight tolerance, so the coating layer is not allowed too thick. Electroplating for steel and copper parts , anodizing for aluminum parts are the most popular finishes.| Materials | Thickness | Finish | |

| Cold rolled steel | SPCC SGCC SECC SPTE Tin plated steel | 0.5-3.0mm | Powder coating (Custom colors are available) Wet painting (Custom colors are available) Silkscreen Zinc plating (Clear,Blue,Yellow) Nickel plating Chrome plating E-coating,QPQ |

| Hot rolled steel | SPHC | 3.0-6.5mm | |

| Other mild steel | Q235 | 0.5-12mm | |

| Stainless steel | SS304,SS301,SS316 | 0.2-8mm | 2B Finish raw material, Brushed raw material Brush, Polishing Electro-polish Passivate |

| Spring steel Suit for spring clips | SS301-H,1/2H,1/4H,3/4H |

| None |

| Mn65 |

| Heat treatment | |

| Aluminium | AL5052-H32, AL5052-H0 AL5052-H36 AL6061 AL7075 | 0.5-6.5mm | Clear chemical film Anodizing, Hard anodizing (Custom colors are available) Powder coating (Custom colors are available) Wet painting (Custom colors are available) Silkscreen Sandblasting Sandblast+ Anodize Electroless Nickel plating Brush, Polish |

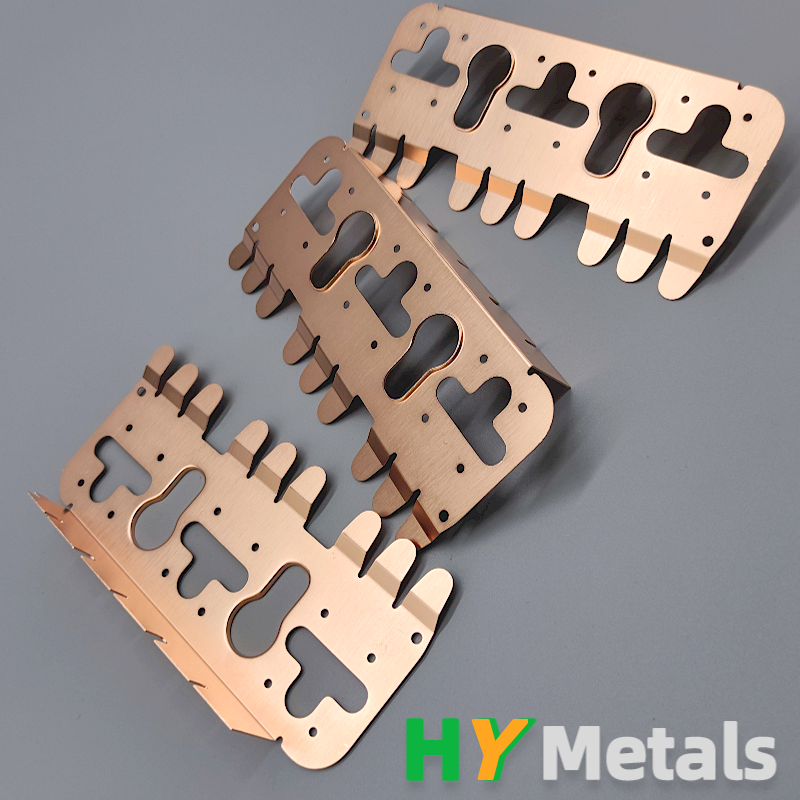

| Brass | Widely used in Electronic components, conductive connection parts | 0.2-6.0mm | Tin plating Nickel plating Gold plating Raw material finish |

| Copper | |||

| Beryllium Copper Phosphor copper | |||

| Nickel silver alloy | Electronic shielings | 0.2-2.0mm | Raw material |

Sometimes to get a cosmetic surface, we will do brushing finish on stainless steel sheet metal parts.

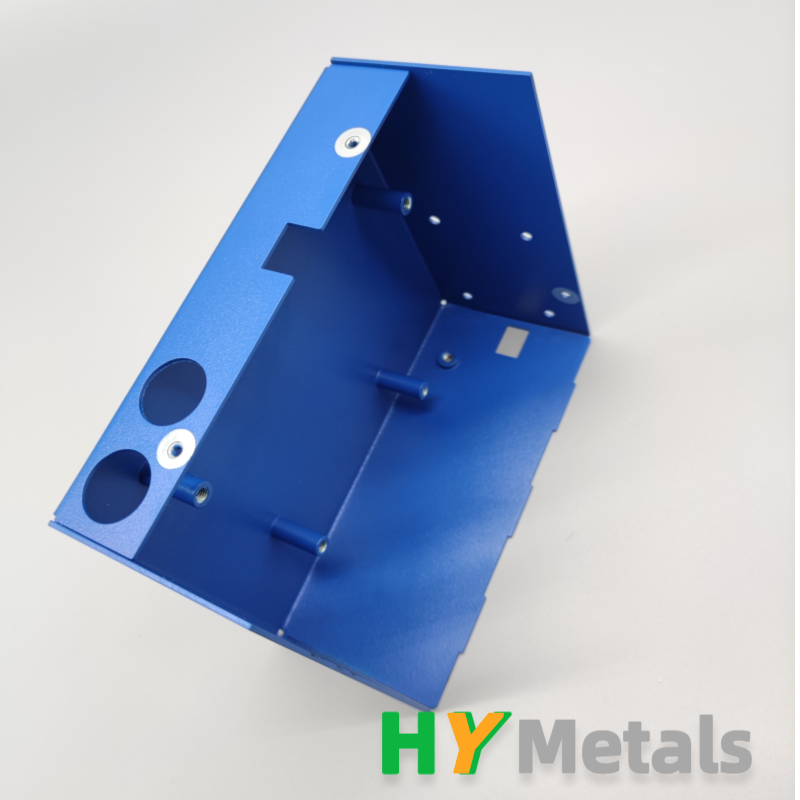

Sometimes to get a cosmetic surface, we will do brushing finish on stainless steel sheet metal parts. Aluminum alloy is widely used in aerospace and shells of some equipment to reduce weight and get good rust protection. At the same time, aluminum alloy also has a very good coloring ability when anodizing. You can get any beautiful color you want on your aluminum sheet metal parts.

Aluminum alloy is widely used in aerospace and shells of some equipment to reduce weight and get good rust protection. At the same time, aluminum alloy also has a very good coloring ability when anodizing. You can get any beautiful color you want on your aluminum sheet metal parts.

Sandblasting and anodizing finishes on aluminum extruded tubes. Sandblast finish can cover the material defects or tooling marks of machined parts. Anodizing can get the anti-corrosion ability and same time get the ideal color for aluminum parts. So sandblasting+ anodizing is a very perfect finish option for almost all the cosmetic aluminum parts.

Sandblasting and anodizing finishes on aluminum extruded tubes. Sandblast finish can cover the material defects or tooling marks of machined parts. Anodizing can get the anti-corrosion ability and same time get the ideal color for aluminum parts. So sandblasting+ anodizing is a very perfect finish option for almost all the cosmetic aluminum parts.

Sandblasting and anodizing finishes on aluminum extruded tubes.

For copper alloy parts, the most commonly used surface treatment is tin plating and nickel plating.| Plastic and Finish | Metal alloy | Finish | |

| ABS | Aluminum alloy | Al6061-T6,AL6061-T651 | Deburr, Polish, Brush |

| Nylon | AL6063-T6, AL6063-T651 | Anodize,Hard anodize | |

| PC | AL7075 | Sandblast | |

| POM(Delrin) | AL1060,AL1100 | Electroless nickel plate | |

| Acetal | AL6082 | Chromate/chrome chemical film | |

| PEEK | Stainless steel | SUS303,SUS304,SUS304L | Passivate |

| PPSU(Radel® R-5000) | SUS316,SUS316L | As machined | |

| PSU | 17-7 PH, 18-8 PH | As machined | |

| PS | Tool steel | A2,#45,other tooling steel | Heat treatment |

| PEI(Ultem2300) | Mild steel | Steel 12L14 | Nickel/chrome plating |

| HDPE | Brass | As machined | |

| PTFE (Teflon) | Copper | C36000 | Nickel/Gold/Tin plating |

| PMMA(Acrylic) | Zinc alloy | As machined | |

| PVC | Titanium | 6Al-4V | As machined |

Sandblasting and anodizing finishes on aluminum extruded tubes.Sandblast finish can cover the material defects or tooling marks of machined parts. Anodizing can get the anti-corrosion ability and same time get the ideal color for aluminum parts. So sandblasting+ anodizing is a very perfect finish option for almost all the cosmetic aluminum parts.

Sandblasting and anodizing finishes on aluminum extruded tubes.Sandblast finish can cover the material defects or tooling marks of machined parts. Anodizing can get the anti-corrosion ability and same time get the ideal color for aluminum parts. So sandblasting+ anodizing is a very perfect finish option for almost all the cosmetic aluminum parts.Custom CNC machined parts with different finishes

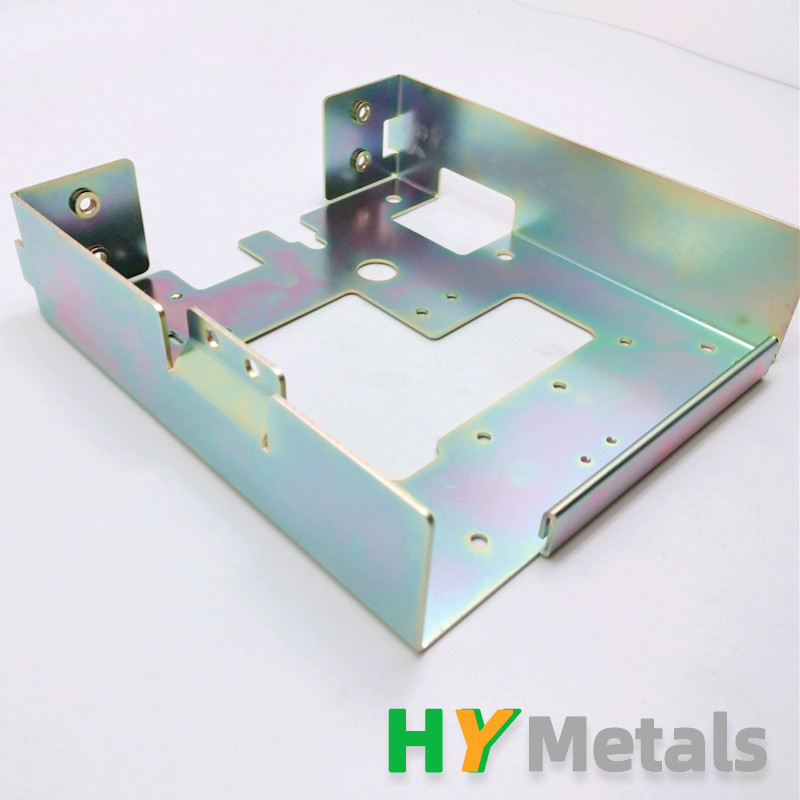

Custom sheet metal parts with different finish