High-Quality Precision Machining Parts for Various Industries

By:Admin

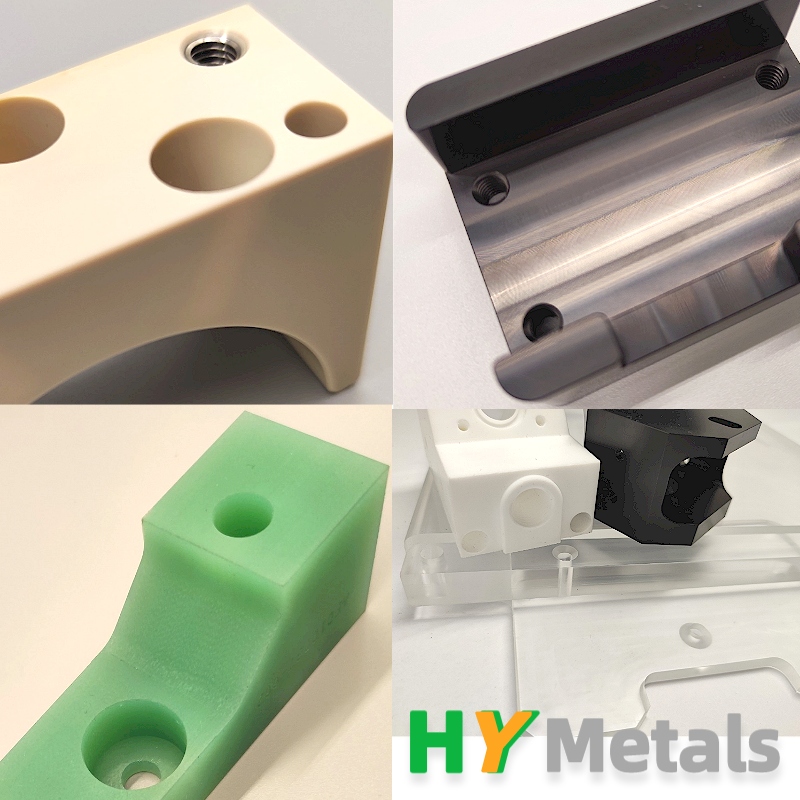

Specializing in the production of precision components for a wide range of industries, including aerospace, automotive, medical, and electronics, Precision Machining Parts has earned the trust and confidence of some of the biggest names in the industry. With a team of highly skilled engineers and technicians, the company is able to meet the unique and demanding needs of each of its customers, ensuring that they receive the highest quality products that are tailored to their specific requirements.

One of the key factors that sets Precision Machining Parts apart from its competitors is its dedication to innovation and continuous improvement. The company invests heavily in research and development, constantly looking for ways to improve its processes and technologies in order to deliver even better products to its customers. Additionally, Precision Machining Parts places a strong emphasis on the use of advanced manufacturing techniques and state-of-the-art equipment, ensuring that it is able to produce components with the highest level of precision and accuracy.

In addition to its commitment to quality and innovation, Precision Machining Parts is also renowned for its customer-centric approach. The company places a strong emphasis on building long-term partnerships with its clients, working closely with them to understand their unique needs and providing them with the support and expertise they need to succeed. This customer-focused approach has earned the company a loyal and satisfied customer base, many of whom have been working with Precision Machining Parts for years.

Precision Machining Parts is also committed to environmental sustainability and social responsibility. The company adheres to strict environmental standards in all of its operations, ensuring that its manufacturing processes have minimal impact on the environment. Additionally, Precision Machining Parts is dedicated to giving back to the community, regularly contributing to charitable causes and supporting local initiatives.

Looking ahead, Precision Machining Parts is poised for even greater success as it continues to expand its capabilities and reach new markets. The company's relentless focus on quality, innovation, and customer satisfaction has positioned it as a leader in the industry, and it is well-equipped to take advantage of new opportunities and challenges in the years to come.

With its unwavering commitment to excellence and its customer-centric approach, Precision Machining Parts is well-positioned to continue its success and remain a trusted partner for companies in need of high-quality precision components. As the company continues to grow and evolve, it will undoubtedly solidify its position as a top choice for companies looking for precision machining parts that exceed their expectations.

Company News & Blog

New Stamping Cut Process Streamlines Manufacturing Efficiency and Reduces Costs

[Company Name], a leading company in the manufacturing industry, has announced the implementation of stamping cut technology to enhance its production process. The company has been at the forefront of innovation, constantly seeking new and improved methods to increase efficiency and quality of their products.Stamping cut, also known as blanking or punching, is a method used to cut or shape metal sheets into a desired form. It is a widely used manufacturing process in various industries, including automotive, aerospace, electronics, and more. By introducing this technology into their production line, [Company Name] aims to further improve the precision and consistency of their products.With the implementation of stamping cut technology, [Company Name] will be able to streamline their manufacturing process and reduce lead times. This will not only help in meeting the growing demand for their products but also enable them to keep up with the ever-changing market trends. By reducing the time and effort required for manual cutting and shaping of metal sheets, [Company Name] can also significantly cut down on production costs, which could ultimately result in more competitive pricing for their customers.In addition to the improved efficiency, stamping cut technology will also enhance the quality of [Company Name]'s products. The precise and accurate cutting achieved through this method will ensure that each component meets the required specifications, ultimately leading to better performance and longevity of the final products. This, in turn, will further solidify the company's reputation for delivering high-quality and reliable products to their customers.[Company Name] has always been committed to investing in the latest technologies and equipment to stay ahead in the industry. The introduction of stamping cut technology is just one of the many steps the company has taken to achieve this goal. By continuously modernizing their production processes, [Company Name] is positioning itself as a leader in the manufacturing sector and is ready to meet the demands of the future.The company's dedication to innovation and quality has not gone unnoticed. [Company Name] has garnered a strong reputation for its commitment to excellence and has built enduring relationships with its customers and partners. The implementation of stamping cut technology is yet another testament to the company's unwavering dedication to providing the best products and services to the market.As [Company Name] moves forward with the integration of stamping cut technology into its production process, it is clear that the company is committed to driving progress and delivering value to its customers. The move is not only a significant step forward for the company but also signals its readiness to embrace new technologies and adapt to the evolving needs of the market.In conclusion, the implementation of stamping cut technology by [Company Name] is a testament to the company's commitment to innovation, efficiency, and quality. As the company continues to invest in advanced technologies, it is poised to maintain its position as a leading manufacturer in the industry and meet the demands of the market. With its strong focus on delivering value to its customers, [Company Name] is well-positioned to thrive in the ever-changing manufacturing landscape.

Durable Stainless Steel Sheet Metal for Various Applications

Stainless Steel Sheet Metal is a popular material in the manufacturing industry due to its durability and versatility. It is widely used in various applications such as construction, automotive, and appliances. Its corrosion-resistant properties and high strength make it an ideal choice for many applications. With the constantly growing demand for stainless steel sheet metal, companies are continuously striving to improve their production processes to meet the market needs.One such company excelling in the production of stainless steel sheet metal is {}. With years of experience in the industry, they have become a leading manufacturer and supplier of high-quality stainless steel sheet metal products. Their state-of-the-art facilities and skilled workforce enable them to produce a wide range of stainless steel sheet metal products to meet the diverse needs of their clients.The company offers a variety of stainless steel sheet metal products in different grades, sizes, and finishes to cater to various industry requirements. Whether it is for architectural purposes, food processing equipment, or industrial machinery, they have the expertise to provide the right stainless steel sheet metal solutions. The company is committed to delivering superior quality products that meet international standards and exceed customer expectations.In addition to their extensive product range, the company also offers custom fabrication services to meet specific customer requirements. Their team of experienced engineers and technicians work closely with clients to understand their needs and provide tailored solutions. Whether it is cutting, bending, welding, or surface treatment, they have the capabilities to deliver precision-engineered stainless steel sheet metal components with high accuracy and consistency.With a strong emphasis on quality control, the company ensures that each stainless steel sheet metal product undergoes stringent testing and inspection processes to guarantee its reliability and performance. They have a well-established quality management system in place to monitor all stages of production, from raw material sourcing to the final product delivery. This commitment to quality has earned them a reputation for being a trusted and reliable supplier in the industry.In line with their dedication to sustainability, the company also promotes the use of recycled materials in their stainless steel sheet metal production. They recognize the importance of minimizing environmental impact and actively work towards reducing waste and energy consumption in their operations. By implementing eco-friendly practices, they strive to contribute to a cleaner and greener environment while serving the needs of their customers.Furthermore, the company places a strong focus on customer satisfaction by providing responsive and personalized service. Their team is readily available to address inquiries, provide technical support, and offer expert advice to ensure that clients have a seamless experience from initial consultation to product delivery. As a customer-centric organization, they are committed to building long-term partnerships based on trust, reliability, and mutual success.In conclusion, {} is a leading manufacturer and supplier of stainless steel sheet metal products, known for their commitment to quality, innovation, and customer satisfaction. With a comprehensive product range, custom fabrication capabilities, and a focus on sustainability, they continue to set a high standard in the industry. As the demand for stainless steel sheet metal continues to grow, the company remains dedicated to meeting the evolving needs of their clients and contributing to the advancement of various industries.

High-Quality Precision Machining Parts for Various Industries

Precision Machining Parts, a leading manufacturer of high-quality precision components, has been making waves in the industry with its commitment to quality, innovation, and customer satisfaction. The company, which was established in 2005, has quickly gained a reputation for its ability to deliver precision machining parts that meet the highest standards of excellence.Specializing in the production of precision components for a wide range of industries, including aerospace, automotive, medical, and electronics, Precision Machining Parts has earned the trust and confidence of some of the biggest names in the industry. With a team of highly skilled engineers and technicians, the company is able to meet the unique and demanding needs of each of its customers, ensuring that they receive the highest quality products that are tailored to their specific requirements.One of the key factors that sets Precision Machining Parts apart from its competitors is its dedication to innovation and continuous improvement. The company invests heavily in research and development, constantly looking for ways to improve its processes and technologies in order to deliver even better products to its customers. Additionally, Precision Machining Parts places a strong emphasis on the use of advanced manufacturing techniques and state-of-the-art equipment, ensuring that it is able to produce components with the highest level of precision and accuracy.In addition to its commitment to quality and innovation, Precision Machining Parts is also renowned for its customer-centric approach. The company places a strong emphasis on building long-term partnerships with its clients, working closely with them to understand their unique needs and providing them with the support and expertise they need to succeed. This customer-focused approach has earned the company a loyal and satisfied customer base, many of whom have been working with Precision Machining Parts for years.Precision Machining Parts is also committed to environmental sustainability and social responsibility. The company adheres to strict environmental standards in all of its operations, ensuring that its manufacturing processes have minimal impact on the environment. Additionally, Precision Machining Parts is dedicated to giving back to the community, regularly contributing to charitable causes and supporting local initiatives.Looking ahead, Precision Machining Parts is poised for even greater success as it continues to expand its capabilities and reach new markets. The company's relentless focus on quality, innovation, and customer satisfaction has positioned it as a leader in the industry, and it is well-equipped to take advantage of new opportunities and challenges in the years to come.With its unwavering commitment to excellence and its customer-centric approach, Precision Machining Parts is well-positioned to continue its success and remain a trusted partner for companies in need of high-quality precision components. As the company continues to grow and evolve, it will undoubtedly solidify its position as a top choice for companies looking for precision machining parts that exceed their expectations.

MTConnect-Ready 3D Printer for Aerospace and Production Applications

, MTConnect, FDM, aerospace, production, 3D printing.Additive Manufacturing Magazine recently reported that the Stratasys Fortus 900 3D printer now features an MTConnect-ready interface. This is great news for those working in aerospace and other industries that require high-quality, production-grade 3D printing.The Stratasys Fortus 900 is a Fused Deposition Modeling (FDM) 3D printer designed for large, complex parts. With a build volume of 36 x 24 x 36 inches, it has the capability to produce parts that are larger than those typically produced with plastic extrusion machines. This makes it an ideal choice for aerospace applications, as well as for producing jigs, fixtures, and tooling.Incorporating the MTConnect protocol into the Stratasys Fortus 900 means that users can now monitor and control their 3D printing operations in real time. MTConnect is an open, royalty-free standard for machine tool communication that has become increasingly popular in the manufacturing industry. With MTConnect, users can easily connect machines and devices to a network, allowing them to monitor data and make informed decisions about their operations.For aerospace manufacturers, the Stratasys Fortus 900 with MTConnect-ready interface is ideal, as it provides the capability to produce production-grade parts with repeatable accuracy. Additionally, 3D printing allows for the production of complex geometries that cannot be produced with traditional manufacturing methods.Overall, the integration of MTConnect into the Stratasys Fortus 900 3D printer is a positive development for the additive manufacturing industry. By providing real-time monitoring and control, it enables users to optimize their operations, increase efficiency, and improve the quality of their products. This is especially important in industries such as aerospace, where high-quality, production-grade parts are essential.As the use of 3D printing continues to grow, we can expect to see further developments in this area, and the integration of other technologies into 3D printers. In the meantime, the Stratasys Fortus 900 with MTConnect-ready interface is a great option for those looking to produce high-quality, production-grade parts with 3D printing technology.

How to Create Tubes with Precise Forming Techniques for Industrial Applications

Innovation in Tube Forming ProcessTube forming is a well-known process in the manufacturing industry, serving as a cost-effective and efficient method of producing seamless tubes used in a variety of applications. However, in recent years, a new technological development has emerged - tube forming that promises to revolutionize the manufacturing industry. This innovative process uses advanced technology to deliver speed, accuracy and reliability in a way that older tube forming technologies simply cannot match. One such company leading the way in this area is {}.Founded in 2001 and headquartered in Germany, {} is a global leader in innovative tube processing solutions. The company has a range of unique and patented technologies and is continually investing in research and development to improve production efficiency. {} has a presence in over 50 countries, with clients in various industries such as automotive, aviation, energy and construction.One of the most significant achievements of {} is their innovative tube forming process that allows for simultaneous tube expansion and reduction in diameter. This process means that the tube's wall thickness can remain uniform throughout the tube's length, which is something that older traditional tube forming techniques could not achieve. Indeed, the older tube forming technology often resulted in decreased quality, imperfections that required additional shaping steps, and reduced production efficiency.However, {} has significantly changed this landscape. Their tube forming solution attains higher precision, and consistency in tube size with much less wastage of material. This cutting-edge technology generates seamless tubes that are produced in a single process, which is faster, less labor-intensive, and more cost-effective than traditional tube forming methods. The process also allows for a wide range of materials, including stainless steel, aluminum, copper, and nickel alloys, which further increases its application in various industries.Furthermore, the company has the expertise to design custom-made tube forming solutions. {} provides individualized solutions for their clients' specific production requirements. This service is only possible because of the digitization capabilities of their tube forming technology. The digitization of the tube forming process enhances accuracy and precision, leading to an exact match of the client's desired tube specifications. They also use advanced simulation software during the design process to identify potential issues before production, improving efficiency and cost-effectiveness.With {}'s innovative technology, cost-effectiveness is a significant advantage. The use of automated systems allows for minimal human intervention and increases production efficiency. The technology can operate at high speeds and produce a large volume of tubes within a short span of time, meaning that clients can enjoy reduced production costs and ultimately save on the bottom line.In conclusion, the innovative tube forming process presented by {} is proving to be a game-changer in the manufacturing industry. It offers speed, efficiency, cost-effectiveness, while simultaneously increasing accuracy and reducing waste. With the implementation of digitization, custo made solutions, and the use of advanced simulation software, {} is ultimately taking the production to the next level. The company is aptly positioned to lead the transformation of the tube forming industry, and it is exciting to see what is yet to come as they continue to innovate.

How to Choose Quality Hardware Parts for Your CNC Machine

Title: Industry-leading CNC Hardware Parts Manufacturer Introduces Cutting-edge SolutionsSubtitle: Driving Innovation and Precision with Unmatched Quality and Expertise[date][City, State] - [Company Name], a renowned leader in the CNC hardware parts industry, is proud to introduce its latest range of advanced solutions designed to revolutionize manufacturing processes across various sectors. With their unparalleled quality, precision, and relentless commitment to innovation, the company stands poised to provide customers with cutting-edge solutions that exceed expectations.[Company Name] has consistently upheld the highest standards, establishing itself as a trusted partner for businesses seeking top-quality CNC hardware parts. Leveraging state-of-the-art technology and an experienced team, the company has gained a reputation for delivering flawless performance, durability, and exceptional finish to their parts.Each CNC hardware part produced by [Company Name] undergoes rigorous quality control measures to ensure that they meet or exceed industry standards. Employing advanced software and machinery, the manufacturing process is optimized for precision and efficiency, resulting in parts that perfectly match clients' specifications. The company's commitment to investing in the latest technology guarantees the highest level of accuracy, consistency, and repeatability in every product.One of the key strengths of [Company Name] lies in its ability to tailor solutions to meet the unique needs of clients in diverse industries. Whether it is automotive, aerospace, electronics, medical, or any other industry requiring intricate parts, the company's expertise and flexibility enable them to deliver superior results. By collaborating closely with its clients, [Company Name] gains deeper insights into their specific requirements, ensuring a seamless integration of customized CNC hardware parts into their manufacturing processes.With the recognition that sustainability and environmental responsibility are paramount, [Company Name] places a strong emphasis on sustainable practices across its operations. The company follows strict guidelines to minimize waste, maximize energy efficiency, and reduce its overall carbon footprint. Their dedication to green manufacturing practices is exemplified by the utilization of eco-friendly materials as well as the implementation of recycling initiatives within their production facilities.Furthermore, [Company Name] boasts an exceptional team of highly skilled and knowledgeable professionals who are committed to delivering excellence. The company fosters an environment that encourages continuous learning and growth, ensuring that its workforce remains at the forefront of the industry's latest developments. This dedication to ongoing improvement enables [Company Name] to anticipate and meet the evolving needs of their clients, as well as maintain the company's position as a market leader.In an effort to expand their reach and increase accessibility to their products, [Company Name] offers efficient global shipping services. This allows businesses from around the world to benefit from their exceptional CNC hardware parts, further solidifying the company's position as a trusted international supplier.As [Company Name] continues to grow, their commitment to providing exceptional customer service remains unwavering. The company prides itself on building strong and long-lasting relationships with clients, guiding them at every step of the process - from initial inquiry through to post-purchase support. By offering comprehensive technical assistance and efficient after-sales service, [Company Name] ensures that customers receive a seamless experience and complete satisfaction with their products.In conclusion, [Company Name], a leading CNC hardware parts manufacturer, is revolutionizing the industry through their commitment to quality, precision, and innovation. With a focus on customization, sustainability, and exceptional customer support, the company is trusted by businesses around the world to provide cutting-edge solutions. As they continue to push the boundaries of technological advancements, [Company Name] leads the way in driving the future of CNC hardware parts manufacturing.For more information about [Company Name] and their range of CNC hardware parts, please visit their website or contact their knowledgeable team directly.About [Company Name]:[Company Name] is an industry-leading manufacturer specializing in CNC hardware parts. With years of expertise, advanced technology, and a commitment to innovation, the company delivers unmatched quality, precision, and customization to meet the unique needs of clients across various industries. Their dedication to sustainability, exceptional customer service, and global accessibility sets them apart as the go-to provider of cutting-edge CNC hardware parts.

Revolutionary Multi-Axis Turning: Unleashing New Possibilities in Precision Engineering

Multi-Axis Turning: Revolutionizing Precision MachiningPrecision machining has long been a staple in various industries, ensuring the production of high-quality components and products that meet the stringent demands of modern technology. In this regard, one technology has been making waves in the field - Multi-Axis Turning.Through its advanced capabilities and exceptional precision, Multi-Axis Turning has revolutionized the world of machining, providing numerous benefits to manufacturers, engineers, and ultimately, end-users. This cutting-edge technology combines state-of-the-art machinery with innovative software solutions to produce intricate designs and complex geometries with unmatched accuracy. By removing the constraints of traditional machining processes, Multi-Axis Turning sets new standards in terms of speed, versatility, and efficiency.One of the key features of Multi-Axis Turning is its ability to simultaneously move and rotate the component being machined, allowing for multi-directional cutting. This unique motion control enables the creation of complex shapes and contours that would otherwise be extremely difficult to achieve using conventional turning methods. By utilizing multiple cutting axes, manufacturers can perform intricate operations in a single machine setup, reducing production time and costs while ensuring exceptional precision.Moreover, Multi-Axis Turning minimizes the need for manual intervention, as much of the setup and tool positioning is automated. The integration of sophisticated software systems streamlines the machining process, eliminating human error and ensuring consistent results. This high degree of automation enhances productivity, increases throughput, and reduces the dependency on skilled labor, which ultimately translates into significant cost savings for manufacturers.One notable advantage of Multi-Axis Turning is its versatility. It can handle a wide range of materials, including metals, plastics, and composites, making it suitable for various industries such as aerospace, automotive, medical, and electronics. The ability to work with different materials expands the applications of Multi-Axis Turning, enabling manufacturers to produce intricate parts for diverse products with ease.Furthermore, Multi-Axis Turning excels in producing parts with exceptional surface finishes, a crucial aspect in industries where aesthetics, accuracy, and functionality go hand in hand. The simultaneous multi-axis movement allows for smoother tool paths, minimizing vibrations and enhancing surface quality. This capability is particularly important for critical components used in industries such as medical devices, where precision and superior finish are paramount.In recent years, a company at the forefront of Multi-Axis Turning technology has emerged - {}. With their cutting-edge machinery and industry-leading expertise, they have been instrumental in advancing the field of precision machining. Their state-of-the-art equipment boasts unmatched capabilities, offering multi-axis milling, turning, and drilling in a single setup. Moreover, their comprehensive software solutions enable seamless integration between design, simulation, and manufacturing processes, ensuring optimal results and increased efficiency.By pioneering Multi-Axis Turning, {} has revolutionized precision machining in terms of accuracy, speed, and versatility. Their commitment to innovation and continuous improvement has propelled the industry forward, enabling manufacturers to achieve new heights in manufacturing excellence. With their comprehensive range of machinery and software solutions, {} is poised to shape the future of precision machining, empowering industries worldwide.In conclusion, Multi-Axis Turning has emerged as a game-changer in the field of precision machining. Its ability to produce complex geometries, enhance surface finishes, and streamline the manufacturing process has made it indispensable for modern industries. With its wide range of applications and technological advancements, Multi-Axis Turning holds immense potential for transforming the way we manufacture and design components, setting new standards of precision and efficiency.

The Advantages of Die Casting in Manufacturing

Die Casting Company Expands Operations to Meet Growing DemandWith the global demand for high-quality die casting components on the rise, {Company Name}, a leading die casting company, has announced a significant expansion of its operations to meet the growing market demand.{Company Name} has a long-standing reputation for excellence in the die casting industry, with a strong focus on advanced technology, innovation, and quality. The company specializes in producing high-precision die cast components for a wide range of industries, including automotive, aerospace, electronics, and more.The expansion of {Company Name}'s operations comes as a result of increasing market demand for die casting components, driven by the growing need for lightweight, durable, and complex parts in various industries. By expanding its operations, the company aims to better serve its customers and meet the evolving needs of the market.The expansion includes the addition of new state-of-the-art die casting machines, advanced manufacturing technology, and an increase in production capacity. With these enhancements, {Company Name} will be able to offer a wider range of die casting solutions to its customers, while maintaining its high standards of quality and innovation.In addition to the expansion of its manufacturing capabilities, {Company Name} is also focusing on enhancing its research and development efforts to stay at the forefront of die casting technology. The company's team of engineers and technicians are constantly working on developing new and improved die casting processes and materials to meet the specific requirements of its customers.The expansion of {Company Name}'s operations is a testament to the company's commitment to continuous improvement and innovation. By investing in advanced technology and increasing its production capacity, {Company Name} is positioning itself to be a leading provider of die casting solutions in the global market."We are excited to announce the expansion of our operations to better serve our customers and meet the increasing demand for high-quality die casting components," said [Spokesperson's Name], [Title] at {Company Name}. "This expansion reflects our dedication to delivering innovative solutions and maintaining our position as a leader in the die casting industry."With the expansion of its operations, {Company Name} is also looking to create new job opportunities and contribute to the local economy. The company's growth is expected to have a positive impact on the community by providing employment opportunities and supporting related industries and businesses.As {Company Name} continues to expand its operations and enhance its capabilities, the company remains committed to upholding its core values of quality, integrity, and customer satisfaction. With a focus on continuous improvement and innovation, {Company Name} is well-positioned to meet the evolving needs of the market and maintain its leadership in the die casting industry.About {Company Name}:{Company Name} is a leading die casting company specializing in the production of high-precision die cast components for various industries. With a strong focus on advanced technology, innovation, and quality, the company is dedicated to delivering exceptional solutions to its customers. {Company Name} is committed to continuous improvement and staying at the forefront of die casting technology to meet the evolving needs of the market.

Exploring Versatile and Efficient Options for Rapid Prototyping

Rapid Prototyping Options: Revolutionizing Prototyping ServicesIn today's competitive business environment, companies are constantly pushing the boundaries of innovation to stay ahead of the curve. One critical aspect of this innovation is rapid prototyping, which is essential for designing and testing new products. To remain competitive, companies need agile and efficient prototyping services that produce high-quality, functional prototypes at a rapid pace. That's where Rapid Prototyping Options (need to remove brand name) comes in.Rapid Prototyping Options (RPO) is a leading provider of rapid prototyping services that cater to a diverse range of industries, including aerospace, automotive, medical, and consumer products. With over a decade of experience in the industry, the company has consistently provided high-quality, cost-effective prototyping services that have helped clients accelerate innovation and bring products to market faster.At the heart of RPO's success is its commitment to using cutting-edge technology and advanced manufacturing techniques in its prototyping services. The company combines traditional manufacturing methods with innovative technologies like 3D printing, CNC machining, and injection molding to produce customized, high-quality prototypes that accurately represent the final product.RPO's 3D printing capabilities are among the most advanced in the industry. The company leverages a variety of 3D printing technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), to produce accurate, high-resolution prototypes. These prototypes can be made from a variety of materials, including plastic, metal, and even rubber, depending on the client's specific requirements.Another critical prototyping service offered by RPO is CNC machining. The company's state-of-the-art CNC machines can produce high-quality prototypes from a variety of materials, including metals, plastics, and composites. RPO's CNC machining capabilities allow clients to produce prototypes with precise dimensions and complex geometries, making it an ideal solution for industries like aerospace and automotive, where precision and accuracy are critical.For larger production runs, RPO offers injection molding services. The company's injection molding capabilities allow clients to produce high-quality, injection-molded parts quickly and efficiently. With RPO's injection molding services, clients can avoid the high startup costs associated with traditional injection molding and quickly produce functional, high-quality parts without sacrificing quality.One key aspect of RPO's prototyping services that sets it apart from competitors is its focus on customer service. The company's prototyping experts work closely with clients throughout the prototyping process to ensure that their needs are met and their expectations are exceeded. From initial consultations to prototyping design to final production, RPO is committed to providing world-class prototyping services that meet the highest standards of quality, accuracy, and reliability.RPO's prototyping services have been critical to its clients' success, allowing them to accelerate innovation, refine product designs, and reduce time-to-market. For example, RPO's prototyping services provided critical support to a medical device manufacturer that needed to produce functional prototypes for testing their devices' safety and effectiveness. RPO's 3D printing and CNC machining capabilities enabled the manufacturer to produce accurate, high-quality prototypes quickly and efficiently, helping to reduce product development timelines and costs.Overall, Rapid Prototyping Options is revolutionizing the prototyping landscape, providing efficient, cost-effective prototyping services that enable companies to innovate at a rapid pace. With a focus on cutting-edge technology, precision, and customer service, RPO is committed to helping companies accelerate innovation, optimize product design, and bring products to market faster. Whether you're in aerospace, automotive, medical, or any other industry, RPO's prototyping services can help you take your innovation to the next level.

Top Quality Auto Parts for Sale - Find the Best Deals Online

Auto Parts Company is a leading supplier of high-quality auto parts and accessories to the aftermarket industry. With a wide range of products and a commitment to customer satisfaction, Auto Parts Company has earned a reputation for excellence in the automotive industry.The company offers a comprehensive catalog of products, including engine parts, brake systems, suspension components, electrical systems, and much more. Their extensive inventory allows them to meet the needs of customers across the country, from individual car owners to professional mechanics and repair shops.In addition to their extensive product offering, Auto Parts Company is dedicated to providing exceptional customer service. Their knowledgeable staff is available to assist customers with finding the right parts for their specific needs and offer expert advice on installation and maintenance. With a focus on meeting and exceeding customer expectations, Auto Parts Company has built a loyal customer base that relies on them for all of their automotive needs.As a leader in the aftermarket auto parts industry, Auto Parts Company is constantly evolving to meet the changing needs of their customers. They are committed to staying ahead of the curve when it comes to new technology and innovations in the automotive industry, allowing them to offer the latest and most advanced products to their customers.Auto Parts Company also places a strong emphasis on quality and reliability. They work with top manufacturers to ensure that all of their products meet or exceed industry standards for performance and durability. This commitment to quality has earned Auto Parts Company a reputation for excellence in the industry and has helped them to build strong, long-lasting relationships with both customers and suppliers.In addition to their commitment to quality, Auto Parts Company is also dedicated to sustainability and environmental responsibility. They are constantly seeking out new ways to reduce their environmental impact, from reducing waste and emissions in their operations to sourcing eco-friendly products and materials. Their dedication to sustainability sets them apart as a company that not only cares about their customers but also the world around them.Auto Parts Company is also a leader in the community, actively participating in charitable initiatives and supporting local organizations. They believe in giving back to the communities that have supported them and are committed to making a positive impact wherever they can.Overall, Auto Parts Company is a company that is dedicated to excellence in every aspect of their business. From their extensive product offering and commitment to customer service to their focus on quality, innovation, and sustainability, Auto Parts Company sets the standard for excellence in the aftermarket auto parts industry. With a strong reputation and a loyal customer base, they are well-positioned for continued success and growth in the years to come.