Durable and Functional Metal Accessories for Cameras

By:Admin

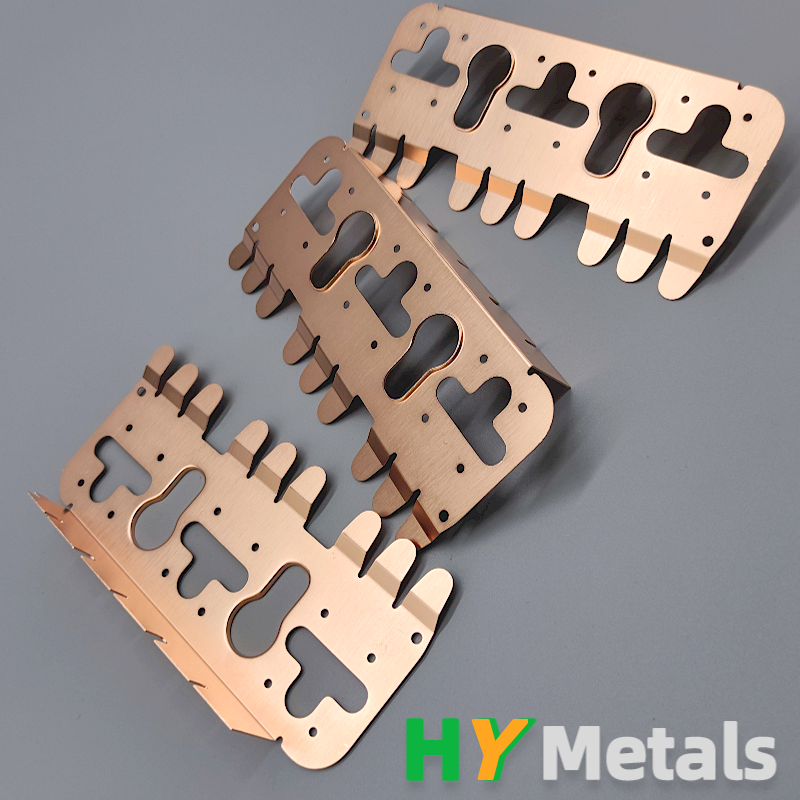

The new line of camera metal accessories includes a wide range of products designed to enhance the functionality and versatility of various camera models. From lens adapters and filter holders to quick release plates and camera brackets, the company's latest offerings are built to meet the diverse needs of modern photographers. Each accessory is meticulously designed and crafted using high-quality materials, ensuring durability and reliability in the field.

One of the standout products in the new line is the universal L-bracket, which provides a secure and stable mounting solution for cameras of all shapes and sizes. With its versatile design and sturdy construction, the L-bracket enables photographers to effortlessly switch between horizontal and vertical shooting positions, allowing for greater creative flexibility. Additionally, the company has also introduced a new range of lens hoods and filter holders, designed to optimize image quality and minimize glare and reflections in various shooting conditions.

As with all of Camera Metal Accessories' products, the new line of camera metal accessories is backed by the company's commitment to quality and customer satisfaction. By leveraging their extensive experience and expertise in the industry, the company continues to set the standard for excellence in camera accessories, providing photographers with the tools they need to capture stunning moments with ease and precision.

In addition to their innovative products, Camera Metal Accessories also takes pride in their dedication to environmental sustainability and social responsibility. The company's manufacturing processes are designed to minimize waste and energy consumption, and they actively support various environmental and social initiatives in their local community. By choosing Camera Metal Accessories, photographers can trust that they are supporting a company that prioritizes ethical business practices and strives to make a positive impact on the world.

"Our new line of camera metal accessories is the result of extensive research and development, as well as valuable feedback from our customers," said a spokesperson for Camera Metal Accessories. "We are thrilled to offer photographers even more options for enhancing their shooting experience and achieving their creative vision. With our commitment to quality and innovation, we are confident that our new products will exceed the expectations of our customers and empower them to push the boundaries of their craft."

As photographers continue to push the boundaries of their creativity and technical capabilities, the demand for high-quality camera accessories will only continue to grow. With the launch of their new line of camera metal accessories, Camera Metal Accessories is poised to meet this demand and provide photographers with the tools they need to elevate their artistry. Whether capturing breathtaking landscapes, intimate portraits, or dynamic action shots, photographers can rely on Camera Metal Accessories to deliver the performance and reliability they need to bring their vision to life.

With their unwavering commitment to quality, innovation, and sustainability, Camera Metal Accessories is more than just a manufacturer of camera accessories – they are a trusted partner for photographers who demand nothing but the best. As the company continues to evolve and expand their product offerings, they remain dedicated to empowering photographers to capture the world in new and inspiring ways.

Company News & Blog

How to Bend Steel: Tips and Techniques for Shaping Metal

Steel Bending: A Competitive Edge for Steel bending is a critical process in the construction and manufacturing industries. It involves the manipulation of steel into various shapes and forms, providing structural integrity to a wide range of products and projects. In the competitive landscape of steel fabrication, the ability to bend steel with precision and efficiency is a crucial factor that sets companies apart from their rivals. This is where comes in, offering top-notch steel bending services that cater to the needs of its diverse clientele.Established in [], has built a solid reputation as a leading provider of steel bending solutions. With state-of-the-art equipment and a team of highly skilled technicians, the company has the capability to handle a wide range of steel bending projects, from small-scale components to large structural elements. Whether it's for architectural designs, industrial machinery, or construction applications, prides itself on delivering high-quality, custom-tailored bending solutions that meet the specific requirements of its customers.The company's comprehensive approach to steel bending encompasses a variety of techniques, including cold bending, hot bending, and induction bending. These techniques allow for the manipulation of steel with precision and control, ensuring that the end result meets the exact specifications of the customer. Additionally, through the use of advanced computer-aided design (CAD) software, is able to develop accurate bending profiles and simulations, further enhancing the efficiency and accuracy of its bending processes.One of the key differentiators for is its ability to work with a wide range of steel materials, including carbon steel, stainless steel, and alloy steel. This versatility allows the company to cater to the diverse needs of its clients across different industries. Whether it's for a high-strength application that requires alloy steel or a corrosion-resistant solution using stainless steel, has the expertise and resources to deliver bendable steel solutions that meet the highest standards of quality and performance.In addition to its technical capabilities, stands out for its commitment to customer satisfaction and project collaboration. The company takes a consultative approach to understand the unique requirements of each project and works closely with its clients to develop bending solutions that are both functional and cost-effective. By fostering open communication and maintaining a customer-centric focus, builds strong partnerships with its clients, often becoming the go-to provider for their steel bending needs.Furthermore, places a strong emphasis on quality control and efficiency in its operations. The company adheres to stringent quality standards and processes to ensure that every bent steel component meets the highest level of accuracy and consistency. Through continuous improvement initiatives and investment in the latest technologies, strives to optimize its production processes, reduce lead times, and minimize waste, ultimately delivering value to its customers in the form of high-quality, competitively priced bending solutions.Looking ahead, remains committed to staying at the forefront of the steel bending industry by continuously refining its capabilities and expanding its service offerings. The company invests in ongoing training and development for its staff, as well as the latest equipment and technologies, to ensure that it can effectively address the evolving needs of the market. By staying abreast of industry trends and advancements, is well-positioned to continue delivering innovative and reliable steel bending solutions to its clients.In conclusion, is a trusted industry leader in steel bending, offering a comprehensive range of services that cater to the diverse needs of its customers. With its advanced capabilities, commitment to quality, and customer-focused approach, has established itself as a go-to provider for steel bending solutions. As the company continues to grow and innovate, it is poised to maintain its competitive edge and contribute significantly to the success of its clients in the construction and manufacturing sectors.

Sheet Metal: A Fundamental Form in Metalworking

Title: Sheet Metal Flat: Revolutionizing Industrial Fabrication ProcessesIntroduction:(sheet metal flat logo)Sheet Metal Flat is a renowned leader in the field of sheet metal fabrication. With a commitment to innovation and quality, the company continues to revolutionize the manufacturing industry. Their expertise lies in the production of thin, flat pieces of metal that can be easily cut and shaped into various forms. This article delves into the significance of sheet metal fabrication, explores the various applications, and highlights Sheet Metal Flat's contributions to this field.Importance of Sheet Metal Fabrication:Sheet metal fabrication plays a pivotal role in numerous industries, making it one of the fundamental forms used in metalworking. By utilizing industrial processes, sheet metal is transformed into thin, flat pieces which can then be molded into a variety of shapes. This versatility enables the creation of countless everyday objects that are an integral part of our lives.Applications of Sheet Metal:The applications of sheet metal fabrication are vast and diverse. From the automotive sector to construction, aerospace, and even household appliances, sheet metal is an essential component in the production of various products. It is widely used in the manufacturing of automobile parts, including body panels, chassis, and engine components due to its durability, strength, and resistance to corrosion.In the construction industry, sheet metal is utilized for roofing, facades, and structural elements due to its lightweight nature and high durability. The aerospace industry leverages sheet metal for aircraft structures, providing strength, stability, and resilience at high altitudes. In household appliances, sheet metal is employed in the manufacturing of refrigerators, stoves, and washing machines due to its ability to withstand high temperatures and repeated use.Sheet Metal Flat: Pioneers in Fabrication:Sheet Metal Flat has emerged as a reliable and innovative player in the sheet metal fabrication industry. The company's commitment to cutting-edge technology and exceptional quality has positioned them as a distinguished leader.Efficient Manufacturing Processes: Sheet Metal Flat employs state-of-the-art machinery and equipment to ensure precision and efficiency in their manufacturing processes. From laser cutting to stamping, bending, and welding, they have perfected every stage of fabrication. This enables them to deliver superior end products while ensuring timely production.Custom Solutions: Recognizing the unique requirements of each client, Sheet Metal Flat offers customized solutions tailored to suit their specific needs. Their team of experienced technicians works closely with customers, providing expert guidance and utilizing cutting-edge software to design and create flawless sheet metal components.Quality Assurance: Sheet Metal Flat is committed to delivering products of the highest quality. Rigorous quality control measures, including inspections at different stages of production, are in place to ensure that every piece meets the highest standards. By adhering to strict quality control protocols, Sheet Metal Flat has fostered long-lasting relationships with their clients.Environmental Responsibility: In an era of increasing environmental awareness, Sheet Metal Flat is committed to minimizing their carbon footprint. They have implemented eco-friendly practices such as recycling scrap metal, reducing waste generation, and incorporating energy-efficient machinery. By choosing Sheet Metal Flat, customers can align with their sustainability goals.Conclusion:Sheet Metal Flat's contribution to the sheet metal fabrication industry cannot be understated. With their innovative manufacturing processes, commitment to quality, and dedication to customer satisfaction, they have set new benchmarks in the field. As the demand for sheet metal continues to grow across various sectors, Sheet Metal Flat is poised to remain at the forefront, constantly pushing the boundaries of possibility and redefining the standards for industrial metalworking.

Exploring the Latest Trend: An In-Depth Look at Wire Cutting and Its Impact on Industries

As the demand for streaming services continues to rise, many people are turning to wire cutting as a way to save money while still enjoying their favorite shows and movies. One of the companies at the forefront of this trend is [BRAND NAME REMOVED], a leading provider of streaming media players and smart TVs.Founded in [YEAR], [BRAND NAME REMOVED] has been a pioneer in the streaming media industry, offering a range of products that make it easy for consumers to access their favorite content from the comfort of their own homes. With its cutting-edge technology and intuitive user interface, the company has quickly become a go-to source for cord-cutters.Whether you're looking for a simple streaming media player or a smart TV with built-in streaming capabilities, [BRAND NAME REMOVED] has a product to meet your needs. Its streaming media players offer high-quality video and audio, as well as access to thousands of channels, apps, and games. They also come with a remote control that makes it easy to navigate through your favorite content.For those who want a more integrated experience, [BRAND NAME REMOVED] offers a range of smart TVs that come with built-in streaming capabilities. These TVs offer stunning picture quality and are designed to seamlessly integrate with popular streaming services like Netflix, Hulu, and Amazon Prime Video.One of the things that sets [BRAND NAME REMOVED] apart from its competitors is its commitment to innovation. The company is constantly researching and developing new technologies that make it easier for consumers to access and enjoy their favorite content. From voice controls to improved streaming quality, [BRAND NAME REMOVED] is always looking for ways to enhance the user experience.Of course, all of these features would mean very little if [BRAND NAME REMOVED] wasn't also committed to affordability. The company's products are priced competitively and are designed to offer the best value for the money. This has made [BRAND NAME REMOVED] a favorite among budget-conscious consumers who don't want to sacrifice quality for price.Wire cutting has become increasingly popular in recent years as people look for ways to save money on their entertainment expenses. For many, streaming services offer a viable alternative to expensive cable and satellite TV packages. With its range of high-quality streaming media players and smart TVs, [BRAND NAME REMOVED] is helping to lead this revolution.Whether you're a die-hard fan of Game of Thrones or just looking for a way to keep the kids entertained, [BRAND NAME REMOVED] has a product that can meet your needs. With its commitment to innovation, affordability, and quality, the company is shaping the future of streaming media, one viewer at a time.

Top Tips for Rapid Die And Molding in Manufacturing Industry

Rapid Die And Molding, a leading manufacturing company in the injection molding industry, has made significant advancements in their production processes to meet the growing demand for high-quality plastic parts.Established in 1998, Rapid Die And Molding has been at the forefront of innovation and technological advancements in injection molding. Since its inception, the company has continuously invested in state-of-the-art equipment, cutting-edge technology, and highly skilled employees to ensure the highest level of quality and efficiency in their manufacturing processes.With a strong emphasis on continuous improvement, Rapid Die And Molding has developed a reputation for delivering precision-engineered plastic parts to a wide range of industries, including automotive, aerospace, medical devices, and consumer goods.The company's commitment to excellence is evident in their dedication to providing exceptional customer service, innovative solutions, and a relentless pursuit of perfection in every aspect of their operations.Rapid Die And Molding recently announced a series of upgrades to their production facilities, including the acquisition of new injection molding machines with advanced automation capabilities. These state-of-the-art machines have significantly increased the company's production capacity, allowing them to fulfill larger orders with shorter lead times while maintaining the highest level of quality and consistency.Furthermore, Rapid Die And Molding has implemented the latest software for process monitoring and quality control, enabling real-time data analysis and predictive maintenance to minimize downtime and maximize efficiency. These technological advancements have resulted in improved product quality, reduced waste, and enhanced overall productivity.In addition to their investment in equipment and technology, Rapid Die And Molding has also focused on the development of their workforce. The company regularly provides specialized training and development programs for their employees, ensuring that they are equipped with the most up-to-date knowledge and skills to operate the new equipment and deliver the best results.Furthermore, Rapid Die And Molding places a strong emphasis on sustainability and environmental responsibility. The company has implemented eco-friendly manufacturing practices and continuously seeks ways to minimize their environmental impact through recycling and waste reduction initiatives.As a result of these investments and initiatives, Rapid Die And Molding has successfully elevated its position as a leading provider of precision plastic parts in the industry. The company's dedication to innovation and excellence has earned them a stellar reputation among their clients and partners, solidifying their position as a go-to partner for all injection molding needs.With their enhanced production capabilities and unwavering commitment to quality, Rapid Die And Molding is poised to continue its trajectory of growth and success in the injection molding industry. Their relentless pursuit of excellence, coupled with their investment in state-of-the-art technology and skilled workforce, sets them apart as an industry leader and ensures they remain at the forefront of innovation for years to come.

High-Quality Precision Machining Parts for Various Industries

Precision Machining Parts, a leading manufacturer of high-quality precision components, has been making waves in the industry with its commitment to quality, innovation, and customer satisfaction. The company, which was established in 2005, has quickly gained a reputation for its ability to deliver precision machining parts that meet the highest standards of excellence.Specializing in the production of precision components for a wide range of industries, including aerospace, automotive, medical, and electronics, Precision Machining Parts has earned the trust and confidence of some of the biggest names in the industry. With a team of highly skilled engineers and technicians, the company is able to meet the unique and demanding needs of each of its customers, ensuring that they receive the highest quality products that are tailored to their specific requirements.One of the key factors that sets Precision Machining Parts apart from its competitors is its dedication to innovation and continuous improvement. The company invests heavily in research and development, constantly looking for ways to improve its processes and technologies in order to deliver even better products to its customers. Additionally, Precision Machining Parts places a strong emphasis on the use of advanced manufacturing techniques and state-of-the-art equipment, ensuring that it is able to produce components with the highest level of precision and accuracy.In addition to its commitment to quality and innovation, Precision Machining Parts is also renowned for its customer-centric approach. The company places a strong emphasis on building long-term partnerships with its clients, working closely with them to understand their unique needs and providing them with the support and expertise they need to succeed. This customer-focused approach has earned the company a loyal and satisfied customer base, many of whom have been working with Precision Machining Parts for years.Precision Machining Parts is also committed to environmental sustainability and social responsibility. The company adheres to strict environmental standards in all of its operations, ensuring that its manufacturing processes have minimal impact on the environment. Additionally, Precision Machining Parts is dedicated to giving back to the community, regularly contributing to charitable causes and supporting local initiatives.Looking ahead, Precision Machining Parts is poised for even greater success as it continues to expand its capabilities and reach new markets. The company's relentless focus on quality, innovation, and customer satisfaction has positioned it as a leader in the industry, and it is well-equipped to take advantage of new opportunities and challenges in the years to come.With its unwavering commitment to excellence and its customer-centric approach, Precision Machining Parts is well-positioned to continue its success and remain a trusted partner for companies in need of high-quality precision components. As the company continues to grow and evolve, it will undoubtedly solidify its position as a top choice for companies looking for precision machining parts that exceed their expectations.

Download Softwares and Updates for Fieldbus Configuration and Diagnostic Programs

Software Download for Sheet Metalwork: Streamlining Your ProcessesIn today's fast-paced and highly technological era, software and technology have become integral parts of almost every industry, including sheet metalwork. Software can help automate complex processes, reduce costs, improve accuracy, and increase efficiency. With the availability of software downloads for sheet metalwork, you can take the first step towards streamlining your workflows and accelerating your productivity.But what exactly can software downloads offer to sheet metalwork fabricators? Let's take a closer look.Automating ProcessesSheet metalwork fabrication involves multiple complex processes, from designing and prototyping to cutting and forming the material. Software can automate many of these processes, saving time and reducing errors. For instance, CAD (Computer-Aided Design) software can help you create accurate and detailed 2D and 3D models with precise dimensions and tolerances. This eliminates the need for manual drawings, which can be time-consuming and prone to errors.Similarly, CAM (Computer-Aided Manufacturing) software can generate G-code for CNC machines, which can automate the cutting, drilling, and forming of sheet metal parts. It can also optimize the cutting paths, minimizing waste and reducing material costs. Additionally, software can generate BOMs (Bills of Materials) and track inventory levels, making it easier to manage and reorder materials.Enhancing CommunicationEffective communication is crucial in sheet metalwork, especially when dealing with complex geometries and tight tolerances. Software can enhance communication between design, manufacturing, and quality control teams, ensuring that everyone is working towards the same objectives. For example, PLM (Product Lifecycle Management) software can provide a single source of truth for all product-related data, including design files, BOMs, specifications, and quality records. This can help reduce delays, rework, and errors due to miscommunication or misunderstandings.Improving QualityQuality is one of the most critical aspects of sheet metalwork fabrication. Even small errors or deviations can compromise the performance, safety, or reliability of the final product. Software can help improve quality by automating inspections and tests, tracking defects, and analyzing data. For example, CMM (Coordinate Measuring Machine) software can compare the actual dimensions of a part with its design specifications and generate reports with detailed measurements and statistical analyses. This can help identify any deviations or trends that need to be addressed.Software can also integrate with quality standards and certifications, such as ISO 9001 or AS9100. This can help ensure that your products meet the required quality standards and that your processes are auditable and compliant.ConclusionIn summary, software downloads can offer numerous benefits to sheet metalwork fabricators, from automating processes and enhancing communication to improving quality and compliance. However, choosing the right software and implementing it effectively can be challenging. It is crucial to evaluate your needs, budget, and resources, and to seek expert advice from software providers or consultants. With the right software and approach, you can enhance your productivity, profitability, and competitiveness in the sheet metalwork industry.

Durable and Versatile Aluminum Bending Bracket for Various Applications

Aluminum Bending Bracket Supplier Reaches New MilestoneIn the world of manufacturing, precision is key. Every detail matters, and every part must be crafted with care and expertise. This is especially true in the aerospace and automotive industries, where the demand for high-quality components is at an all-time high.One company that has been meeting and exceeding these demands is [Company Name]. With a proven track record of providing top-notch aluminum bending brackets to some of the biggest names in the industry, [Company Name] has recently reached a new milestone in their journey towards manufacturing excellence.Specializing in the production of aluminum bending brackets, [Company Name] has been a major player in the manufacturing industry for many years. Their parts are known for their precision, durability, and reliability, making them the go-to choice for companies in need of high-quality components.The team at [Company Name] is made up of dedicated professionals who are passionate about their work. With a commitment to delivering the best possible products to their customers, they have built a reputation for excellence and reliability. This has allowed them to forge strong partnerships with some of the most respected companies in the industry, cementing their status as a leading supplier of aluminum bending brackets.Their manufacturing process is second to none, with a focus on quality and precision at every step. From the initial design phase to the final inspection, every part is meticulously crafted to ensure that it meets the highest standards. This dedication to quality has set [Company Name] apart from the competition, making them a trusted name in the industry.Recently, [Company Name] announced that they have reached a new milestone in their production capabilities. Thanks to their continued investment in cutting-edge technology and their unwavering commitment to excellence, they have expanded their manufacturing capacity, allowing them to produce even more high-quality aluminum bending brackets than ever before.This milestone is a testament to [Company Name]'s dedication to innovation and progress. By investing in state-of-the-art equipment and staying ahead of the curve when it comes to manufacturing techniques, they have positioned themselves as a leader in the industry. This expanded capacity will allow them to better serve their customers and meet the growing demand for their products.In addition to their commitment to quality and innovation, [Company Name] also prioritizes sustainability in their manufacturing processes. They understand the importance of minimizing their environmental impact and have taken steps to ensure that their operations are as eco-friendly as possible. This dedication to sustainability has not gone unnoticed, and has further solidified [Company Name]'s reputation as a responsible and forward-thinking supplier.As the demand for high-quality aluminum bending brackets continues to grow, [Company Name] is well-positioned to meet and exceed the needs of their customers. With their expanded production capacity and unwavering commitment to excellence, they are ready to take on new challenges and continue to provide top-notch components to the aerospace and automotive industries.In conclusion, [Company Name] has reached a new milestone in their journey towards manufacturing excellence. With a focus on quality, innovation, and sustainability, they have solidified their position as a leading supplier of aluminum bending brackets. Their dedication to precision and their commitment to meeting the needs of their customers make them a trusted partner for companies in need of high-quality components. As they continue to invest in their capabilities and expand their production capacity, [Company Name] is poised to remain at the forefront of the industry for years to come.

High-Quality Aluminum CNC Parts for Custom Projects

Custom CNC Aluminum Part Innovation Drives {} Growth{} is continuing to drive innovation in the manufacturing industry through the development of custom CNC aluminum parts. The company has become known for its expertise in precision machining and has established itself as a leader in the production of specialized components for a wide range of industries.The company's commitment to excellence and a customer-centric approach have been the driving forces behind its success. By leveraging advanced manufacturing technologies and a highly skilled workforce, {} has been able to meet the unique needs of its clients and deliver high-quality products that exceed expectations.One of the key factors that sets {} apart from its competitors is its investment in cutting-edge CNC machining capabilities. CNC (computer numerical control) machining allows for the precise and efficient production of complex parts, including those made from aluminum. With the ability to accurately shape and manufacture intricate components, {} has been able to provide its customers with tailored solutions that are essential for their operations.The custom CNC aluminum parts produced by {} are widely used in a variety of applications. From aerospace and automotive to medical and electronics, these components play a crucial role in ensuring the performance and reliability of different systems and machinery. By leveraging their expertise in CNC machining, {} has been able to cater to the diverse needs of these industries and contribute to their advancements.In addition to the exceptional quality of its products, {} has also earned a reputation for its ability to deliver on a wide range of specifications. The company's engineering team works closely with clients to understand their unique requirements and develop customized solutions that are tailored to their exact needs. This collaborative approach has allowed {} to establish strong partnerships with its customers and become a trusted provider of custom CNC aluminum parts.Furthermore, {}'s commitment to continuous improvement and investment in the latest manufacturing technologies has enabled the company to streamline its production processes. By utilizing state-of-the-art CNC machining equipment, {} has been able to increase efficiency, reduce lead times, and maintain cost-effectiveness for its clients. This has not only improved the company's overall performance but has also allowed it to stay at the forefront of the industry.Looking ahead, {} remains focused on further expanding its capabilities and enhancing its offerings. The company continues to explore new opportunities for growth and diversification, including the development of advanced CNC machining techniques and the expansion of its product portfolio. By staying ahead of the curve, {} aims to continue serving as a reliable partner for its clients and a driving force in the manufacturing sector.In conclusion, {}'s dedication to innovation and its expertise in custom CNC aluminum parts have been instrumental in its continued success. By prioritizing quality, precision, and customer satisfaction, the company has solidified its position as a leading provider of specialized components. With a strong foundation and a forward-looking mindset, {} is well-positioned to make a lasting impact in the industry and contribute to the advancement of manufacturing.

What is Water-jet Technology? A Definition

Water-jet Technology Takes the Industrial World by StormWater-jet technology has been quietly revolutionizing the industrial world over the past decade. Driven by powerful streams of water and sometimes abrasive materials, water-jet cutting technology is quickly becoming the go-to cutting method for a variety of industries. From aerospace to the medical field, water-jet cutting is proving to be more precise and efficient than traditional cutting methods.A water-jet is a cutting tool that creates a high-velocity jet of water, usually mixed with an abrasive material. This creates a powerful cutting force that can cut through virtually any material with precision, including metal, stone, glass, and plastic. Water-jet cutting technology was developed in the 1950s, and since then, it has been continuously refined and improved, becoming one of the most versatile and effective cutting methods available today.One of the many benefits of water-jet cutting is its precision. Unlike traditional cutting methods that rely on brute force and sharp blades, water-jet cutting relies on a powerful stream of water to slice through materials with ease. This allows for incredibly intricate and precise cuts, even on difficult or complicated materials.Another benefit of water-jet cutting is its versatility. Water-jet cutters can handle a wide range of materials, from soft rubber to thick steel. This makes it an ideal choice for industries that require cutting precision on a variety of materials.The aerospace industry, for example, heavily relies on water-jet technology for the precision cutting of parts and components. With water-jet cutting, aerospace manufacturers can create intricate shapes out of tough materials such as titanium and composites, resulting in stronger, lighter-weight aircraft that perform better than ever before. Other industries, such as the medical field, also rely on water-jet cutting for precision cutting of surgical instruments and implantable devices.Water-jet cutting technology has also become more accessible in recent years, with more and more companies offering water-jet cutting services to a variety of industries. Companies like {} offer state-of-the-art water-jet cutting services that can handle large production runs or small, custom projects. By outsourcing their cutting needs, businesses can save time and money on equipment and maintenance costs while still enjoying the precision and versatility of water-jet cutting.Finally, water-jet cutting is also environmentally friendly. Unlike traditional cutting methods that produce harmful dust and debris, water-jet cutting creates minimal waste and leaves the material clean and untouched. This means less waste, fewer environmental hazards, and a safer workplace for employees.In conclusion, water-jet cutting technology is quickly becoming the go-to cutting method for businesses ranging from aerospace to medical manufacturing. With its precision, versatility, accessibility, and environmentally friendly benefits, water-jet cutting is the perfect solution for industries that require precise cutting of a variety of materials. As technology continues to improve, we can only expect to see water-jet cutting become even more essential to the industrial world.

Top Metal Brackets for Dental Braces: A Buyer's Guide

Metal Brackets Advancements to Revolutionize Orthodontic TreatmentOrthodontic treatment has come a long way in recent years, and one of the major advancements that has contributed to this progress is the development of metal brackets. These innovative brackets, manufactured by the leading orthodontic product company, {}, have quickly gained popularity among orthodontists and patients alike for their exceptional performance and reliability.Metal brackets have been a staple in orthodontic treatment for decades, but recent advancements in technology and materials have led to significant improvements in their design and functionality. The metal brackets developed by {} are made from high-quality, durable materials that provide excellent strength and stability, ensuring optimal performance throughout the course of treatment.One of the key advantages of metal brackets is their ability to deliver precise and effective tooth movement, resulting in more efficient and predictable treatment outcomes. The superior mechanical properties of these brackets, combined with their low friction design, allow for greater control and accuracy in tooth alignment, reducing the overall treatment time and enhancing patient comfort.Another important benefit of metal brackets is their versatility and adaptability to a wide range of malocclusions and treatment complexities. Whether it's correcting misaligned teeth, closing gaps, or addressing bite issues, these brackets offer orthodontists the flexibility to customize treatment plans to meet the unique needs of each patient, ultimately leading to more satisfactory results.In addition to their outstanding performance, metal brackets from {} are renowned for their aesthetic appeal. With a sleek and low-profile design, these brackets offer a more discreet and appealing alternative to traditional metal braces, making them a popular choice among adult patients and teenagers who may be self-conscious about wearing braces.The implementation of advanced technology in the manufacturing process of these brackets also ensures a precise fit and consistent quality, contributing to an overall positive treatment experience for both patients and clinicians. The brackets are carefully engineered to minimize discomfort and irritation, while their durable construction minimizes the risk of breakage or damage during the course of treatment.Furthermore, {} as a pioneering company in the orthodontic industry, is committed to continuous research and development, constantly seeking new ways to enhance the performance and functionality of their metal brackets. This dedication to innovation and excellence has solidified {}'s position as a trusted leader in the orthodontic product market, providing clinicians with the tools they need to deliver exceptional care to their patients.The impact of metal brackets on orthodontic treatment cannot be overstated. Their unmatched performance, combined with their aesthetic appeal and adaptability, have set a new standard for orthodontic appliances, ultimately reshaping the landscape of modern orthodontic care.In conclusion, metal brackets have emerged as a game-changing advancement in orthodontic treatment, offering unparalleled performance, versatility, and aesthetic appeal. With {} leading the way in innovation and quality, orthodontists and patients can look forward to a future of more efficient, effective, and satisfactory orthodontic treatment outcomes.