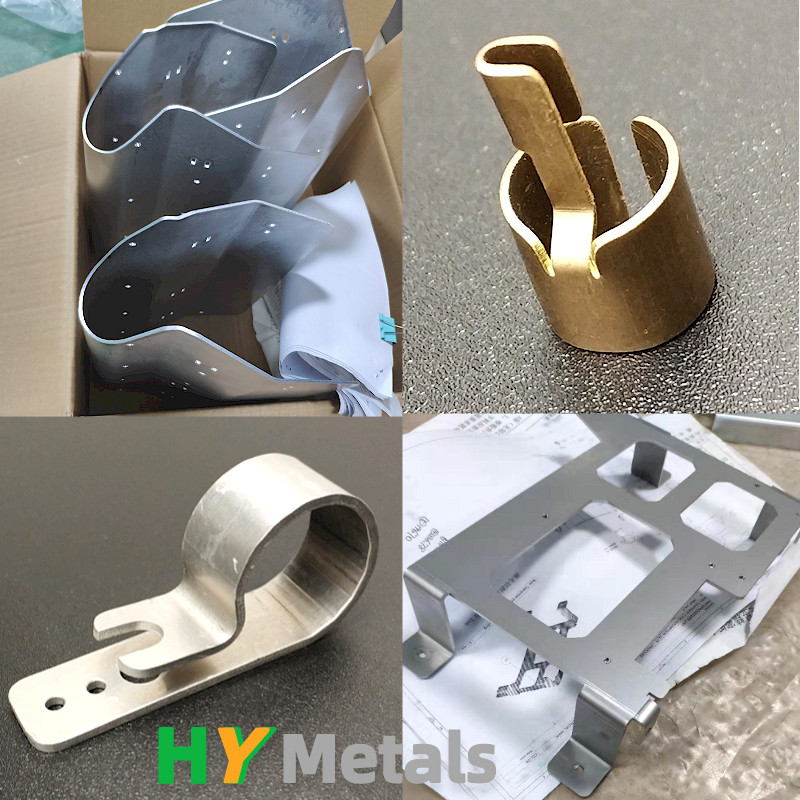

High Quality Aerospace Sheet Metal Parts for Precision Engineering

By:Admin

Aerospace sheet metal parts are an essential component in the aviation industry and play a crucial role in the manufacturing of aircraft. These parts are used in the construction of various aircraft components, including fuselages, wings, and engine components. The demand for aerospace sheet metal parts has been steadily growing as the aviation industry continues to expand and modernize its fleet of aircraft.

{Company Name} is a leading manufacturer of aerospace sheet metal parts, specializing in the production of high-quality components for the aviation industry. With a strong reputation for superior quality and precision engineering, {Company Name} has established itself as a trusted supplier to some of the world's leading aerospace companies.

The company utilizes advanced manufacturing techniques and state-of-the-art equipment to produce aerospace sheet metal parts that meet the highest industry standards. Their team of highly skilled engineers and technicians work closely with clients to develop custom solutions for their specific aerospace sheet metal part requirements. This commitment to innovation and customer satisfaction has earned {Company Name} a solid reputation for delivering top-quality products that meet the stringent requirements of the aerospace industry.

In response to the increasing demand for aerospace sheet metal parts, {Company Name} has continually invested in expanding its manufacturing capabilities and adopting the latest technologies. This commitment to staying at the forefront of industry advancements has allowed the company to meet the evolving needs of its customers and to deliver innovative solutions for the aerospace industry.

The aerospace industry is constantly evolving, with a growing emphasis on lightweight materials and advanced manufacturing techniques. As a result, {Company Name} has continued to invest in research and development to ensure that its aerospace sheet metal parts meet the industry's evolving needs.

In addition to its dedication to producing high-quality aerospace sheet metal parts, {Company Name} places a strong emphasis on sustainability and minimizing the environmental impact of its manufacturing processes. The company follows strict regulations and industry best practices to ensure that its operations are environmentally responsible and sustainable.

{Company Name} is committed to maintaining the highest standards of safety and quality in all aspects of its operations. The company has achieved various certifications and accreditations, demonstrating its dedication to delivering aerospace sheet metal parts that meet the most demanding industry requirements.

As the demand for aerospace sheet metal parts continues to grow, {Company Name} is well-positioned to meet the needs of its customers. With a strong focus on innovation, quality, and customer satisfaction, {Company Name} is poised to remain a leading supplier of aerospace sheet metal parts for the aviation industry.

In conclusion, the demand for aerospace sheet metal parts is steadily increasing as the aviation industry continues to modernize and expand. {Company Name} is a trusted manufacturer of high-quality aerospace sheet metal parts, known for its commitment to innovation, quality, and customer satisfaction. With a focus on sustainability and advanced manufacturing techniques, {Company Name} is well-positioned to meet the evolving needs of the aerospace industry and to continue delivering top-quality products for its customers.

Company News & Blog

Precision CNC Machined Parts for Corn and Grain Agriculture Products – Manufacturer in China

CNC machining is a widely-used technology in various industries, including agriculture. Specifically, CNC machined parts are essential in corn and grain harvesting and processing activities. In Senorok.com, we offer precision CNC machined parts that provide outstanding performance and optimal efficiency. Our expert manufacturing team uses the latest technology and an extensive range of raw materials to produce high-quality machined parts for different industries.One of our most popular CNC machined parts is the SS-03,05 model, which is made of high-quality steel. Steel is a durable and robust material that can withstand extreme conditions, making it ideal for use in agricultural machinery. With our precise CAD/CAM techniques and cutting-edge CNC technology, we can manufacture highly accurate and precise machined parts that meet our clients' unique demands.Our CNC machined parts are available at a reasonable price, and we offer competitive rates that make us a reliable partner for different types of businesses. Our team has years of experience in delivering top-quality CNC machined parts, and we understand the importance of delivering products that match our clients' expectations.Apart from steel, we can also manufacture CNC milled plastic parts that are highly effective in various applications. Plastic parts are preferred in some cases because they are lightweight, affordable, and can be quickly produced in large volumes. Our CNC machines are optimized to work with different types of plastics, and we can provide custom-made solutions that suit our clients' requirements.In conclusion, CNC machining is an essential technology that contributes significantly to the agricultural sector. At Senorok.com, we are committed to delivering top-quality CNC machined parts that provide superior performance and durability. Our products are reliable, competitively priced, and manufactured with precision to meet our clients' unique needs. Please contact us today to learn more about our CNC machining services and how we can help your business succeed.

Precision Grinding of CNC Machined Parts for Increased Durability and Performance

Title: Advancements in CNC Machined Parts Grinding: Delivering Precision and EfficiencyIntroduction (approx. 80 words):In the fast-paced world of manufacturing, the demand for precision-engineered components is at an all-time high. Addressing this need, a leading company in the field has made significant breakthroughs in CNC Machined Parts Grinding. By combining cutting-edge technology and industry expertise, they are revolutionizing the production of machined parts, offering unparalleled precision, efficiency, and reliability. With the ability to remove imperfections with remarkable accuracy, their advanced grinding techniques enhance product quality, reduce production time, and maximize cost-effectiveness.Innovation in CNC Machined Parts Grinding (approx. 200 words):Building on decades of experience and a commitment to continuous innovation, the company has introduced state-of-the-art advancements in CNC Machined Parts Grinding. By leveraging advanced robotic systems, high-precision tools, and computer numerical control (CNC) technology, they have transformed the grinding process, setting new standards in the industry.The integration of robotic systems has enabled precise handling and positioning of components, ensuring consistent grinding quality. This automation enhances productivity, eliminates human error, and optimizes production throughput. Additionally, it allows for multitasking capabilities, enabling simultaneous grinding of multiple parts, saving valuable time without compromising precision.Furthermore, the utilization of high-precision tools and cutting-edge abrasives guarantees the removal of imperfections with exceptional accuracy. By employing a combination of grinding wheels, belts, and discs designed for specific applications, the company ensures the highest level of precision, ensuring superior surface finishes and dimensional accuracy.To enhance the grinding process's efficiency, the company has incorporated CNC technology into their machining centers. This allows for seamless coordination between various machining operations, eliminating the need for multiple setups and tool changes. The result is faster cycle times, reduced downtime, and improved overall productivity.Benefits and Applications (approx. 250 words):The advancements in CNC Machined Parts Grinding have numerous benefits that make them indispensable for various manufacturing industries. The precision achieved through these techniques ensures the exact dimensions and tolerances required, eliminating the risk of errors and rework. By improving product quality and reducing rejects, manufacturers can establish a reputation for delivering superior components consistently.Moreover, these advancements have considerably reduced production time. With increased automation, multitasking capabilities, and efficient integration of CNC technology, companies can significantly improve throughput. This accelerates the delivery of finished parts, enabling manufacturers to meet tight deadlines without compromising quality.The cost-effectiveness of CNC Machined Parts Grinding is another crucial advantage. By streamlining processes and minimizing waste, manufacturers can optimize resource utilization and reduce production costs. In addition, the ability to complete complex grinding operations in a single setup reduces labor costs and machine downtime.The applications for CNC Machined Parts Grinding span various industries, including aerospace, automotive, robotics, medical, and more. In the aerospace sector, for instance, the precision grinding techniques are indispensable for creating intricate components that withstand the extreme demands of aircraft engines. Similarly, in the medical field, these advancements enable the production of high-precision parts for surgical instruments and prosthetics, ensuring utmost reliability and patient safety.Conclusion (approx. 70 words):Through their relentless pursuit of innovation, the company has transformed CNC Machined Parts Grinding, positioning themselves as industry leaders. With a focus on precision, efficiency, and cost-effectiveness, their advanced grinding techniques have revolutionized the manufacturing sector. By embracing these advancements, manufacturers can forge a path towards increased productivity, improved quality, and enhanced competitiveness in the global market.

The Advantages of Die Casting in Manufacturing

Die Casting Company Expands Operations to Meet Growing DemandWith the global demand for high-quality die casting components on the rise, {Company Name}, a leading die casting company, has announced a significant expansion of its operations to meet the growing market demand.{Company Name} has a long-standing reputation for excellence in the die casting industry, with a strong focus on advanced technology, innovation, and quality. The company specializes in producing high-precision die cast components for a wide range of industries, including automotive, aerospace, electronics, and more.The expansion of {Company Name}'s operations comes as a result of increasing market demand for die casting components, driven by the growing need for lightweight, durable, and complex parts in various industries. By expanding its operations, the company aims to better serve its customers and meet the evolving needs of the market.The expansion includes the addition of new state-of-the-art die casting machines, advanced manufacturing technology, and an increase in production capacity. With these enhancements, {Company Name} will be able to offer a wider range of die casting solutions to its customers, while maintaining its high standards of quality and innovation.In addition to the expansion of its manufacturing capabilities, {Company Name} is also focusing on enhancing its research and development efforts to stay at the forefront of die casting technology. The company's team of engineers and technicians are constantly working on developing new and improved die casting processes and materials to meet the specific requirements of its customers.The expansion of {Company Name}'s operations is a testament to the company's commitment to continuous improvement and innovation. By investing in advanced technology and increasing its production capacity, {Company Name} is positioning itself to be a leading provider of die casting solutions in the global market."We are excited to announce the expansion of our operations to better serve our customers and meet the increasing demand for high-quality die casting components," said [Spokesperson's Name], [Title] at {Company Name}. "This expansion reflects our dedication to delivering innovative solutions and maintaining our position as a leader in the die casting industry."With the expansion of its operations, {Company Name} is also looking to create new job opportunities and contribute to the local economy. The company's growth is expected to have a positive impact on the community by providing employment opportunities and supporting related industries and businesses.As {Company Name} continues to expand its operations and enhance its capabilities, the company remains committed to upholding its core values of quality, integrity, and customer satisfaction. With a focus on continuous improvement and innovation, {Company Name} is well-positioned to meet the evolving needs of the market and maintain its leadership in the die casting industry.About {Company Name}:{Company Name} is a leading die casting company specializing in the production of high-precision die cast components for various industries. With a strong focus on advanced technology, innovation, and quality, the company is dedicated to delivering exceptional solutions to its customers. {Company Name} is committed to continuous improvement and staying at the forefront of die casting technology to meet the evolving needs of the market.

Expert Aircraft Sheet Metal Fabrication Services for Precision and Durability

Aircraft Sheet Metal Fabrication is a critical aspect of the aerospace industry, as it involves the manufacturing and assembly of metal components for aircraft structures. These components must be fabricated with precision and accuracy to ensure the safety and performance of the aircraft. One company that specializes in this field is {}, which has been a leading provider of aircraft sheet metal fabrication for over two decades.{} is equipped with state-of-the-art technology and a team of highly skilled engineers and fabricators who are dedicated to delivering top-quality products. The company's commitment to excellence has earned them a reputation as a trusted supplier in the aerospace industry.The process of aircraft sheet metal fabrication involves cutting, bending, and assembling various types of metal, such as aluminum, steel, and titanium. These metal components are used in the construction of aircraft fuselages, wings, and other structural elements. Precision is key in this process, as even the smallest error can have serious consequences for the aircraft's performance and safety.One of the key factors that sets {} apart from other manufacturers is their stringent quality control measures. Every phase of the fabrication process is carefully monitored to ensure that each component meets the highest standards. This dedication to quality has made {} a preferred supplier for many major aerospace companies.In addition to their commitment to quality, {} also strives to be a leader in innovation and efficiency. The company continues to invest in the latest technology and equipment to streamline their manufacturing processes and reduce lead times. This not only benefits their customers by providing quicker turnaround times, but also contributes to the overall advancement of the aerospace industry.Furthermore, {} is dedicated to sustainability and environmental responsibility. They have implemented eco-friendly practices in their manufacturing processes, such as waste reduction and energy-efficient operations. By prioritizing sustainability, {} is not only contributing to a greener planet, but also fulfilling the increasing demand for environmentally conscious manufacturing practices in the aerospace industry.As a testament to their expertise and dedication, {} has been recognized with several industry certifications and awards. These accolades further demonstrate their commitment to excellence and their position as a leader in the field of aircraft sheet metal fabrication.With the aerospace industry constantly evolving and demanding higher standards, {} remains at the forefront of innovation and advancement. The company's ongoing investment in technology, commitment to quality, and dedication to sustainability make them an invaluable partner for aerospace companies around the world.In summary, {} is a leading provider of aircraft sheet metal fabrication, with a reputation for excellence, innovation, and sustainability. With their state-of-the-art facilities and highly skilled team, {} continues to set the standard for quality and reliability in the aerospace industry. Their commitment to excellence and dedication to advancing the field of aircraft sheet metal fabrication make them a trusted partner for aerospace companies seeking top-quality components for their aircraft structures.

Custom CNC Machining Services for Prototypes and Production Parts

Prototype CNC Machining Invests in State-of-the-Art Equipment to Further Expand OperationsIn a bid to enhance its manufacturing capabilities and meet the growing demand for precision components, Prototype CNC Machining has made a significant investment in new equipment. The company, known for its expertise in producing high-quality machined parts for various industries, has acquired cutting-edge CNC machines to further expand its operations and increase production capacity.As a leading provider of precision machining services, Prototype CNC Machining has built a solid reputation for delivering top-notch components that meet the most stringent specifications. With a focus on quality, reliability, and efficiency, the company has become a preferred partner for a wide range of customers seeking precision parts for their applications.The recent investment in state-of-the-art CNC equipment underscores Prototype CNC Machining's commitment to staying at the forefront of technological advancements in the manufacturing industry. By incorporating the latest machining technologies into its operations, the company aims to improve efficiency, reduce lead times, and maintain its high standards of quality.The new CNC machines feature advanced capabilities such as multi-axis machining, high-speed cutting, and automated tool changing, allowing Prototype CNC Machining to take on more complex and intricate projects. With enhanced precision and repeatability, these machines will enable the company to produce components with tight tolerances and intricate geometries, catering to the evolving needs of its diverse customer base.Furthermore, the acquisition of the latest CNC equipment aligns with Prototype CNC Machining's strategic vision to expand its market reach and diversify its product offerings. By bolstering its manufacturing capabilities, the company is poised to take on a wider range of projects across industries such as aerospace, automotive, medical devices, and electronics."We are excited to announce the addition of new CNC machines to our facility, as this investment represents a significant milestone in our journey to offer cutting-edge manufacturing solutions to our customers," said the spokesperson for Prototype CNC Machining. "With these state-of-the-art machines, we are poised to elevate our production capabilities and take on more challenging projects, solidifying our position as a trusted partner for precision machining."The company's dedication to investing in advanced manufacturing technologies reflects its long-term commitment to delivering exceptional value to its customers. By continuously upgrading its equipment and capabilities, Prototype CNC Machining seeks to ensure that it can effectively meet the evolving needs of industries that rely on high-precision machined components.Additionally, Prototype CNC Machining's investment in new CNC machines aligns with its environmental stewardship goals, as the latest equipment offers improved energy efficiency and sustainable manufacturing practices. This demonstrates the company's holistic approach to modernizing its operations while minimizing its environmental footprint.With the installation of the new CNC machines, Prototype CNC Machining is well-positioned to take on larger production volumes, handle more intricate designs, and deliver superior quality components to its customers. The company's investment in cutting-edge equipment is a testament to its unwavering dedication to innovation, excellence, and customer satisfaction.Moving forward, Prototype CNC Machining is set to leverage its enhanced manufacturing capabilities to drive growth, expand its market presence, and solidify its standing as a leader in the precision machining industry. By staying at the forefront of technology and investing in the future, the company is poised to unlock new opportunities and exceed the expectations of its customers.

Precision CNC Machining for Small Parts: What You Need to Know

In today's fast-paced manufacturing industry, precision and efficiency are crucial elements for success. This is where CNC machining comes into play, providing the capability to produce small parts with a high degree of accuracy and repeatability. One company that has been at the forefront of this technology is {Company Name}, a leading provider of precision machining services.{Company Name} is a world-class precision machining company that has been in the business for over 20 years. With state-of-the-art facilities and a team of highly skilled machinists, they have built a reputation for delivering high-quality products to a wide range of industries, including aerospace, automotive, medical, and more.One of the key services offered by {Company Name} is CNC machining of small parts. This process involves using computer-controlled machines to remove material from a workpiece, resulting in the production of intricate and precise components. With their advanced CNC equipment and expertise, {Company Name} has the capability to machine a wide variety of small parts, from prototypes to high-volume production runs.The company's CNC machining capabilities are particularly well-suited for producing small parts that require tight tolerances and complex geometries. This includes components such as gears, bushings, connectors, and many others. Their ability to work with a wide range of materials, including metals, plastics, and composites, further expands the possibilities for small part machining.In addition to their technical capabilities, {Company Name} also focuses on providing exceptional customer service. They work closely with their clients to understand their specific needs and requirements, ensuring that the machined parts meet the highest standards of quality and accuracy. This collaborative approach has allowed them to build long-standing relationships with their customers, who rely on {Company Name} for their precision machining needs.With the increasing demand for small, intricate parts across various industries, {Company Name} continues to invest in the latest CNC machining technologies to stay ahead of the curve. Their commitment to innovation and continuous improvement has made them a trusted partner for companies seeking high-quality small parts for their products.In a recent development, {Company Name} has made significant investments in their CNC machining capabilities, including the acquisition of new equipment and the implementation of advanced software solutions. This has further enhanced their ability to produce small parts with unmatched precision and efficiency, reinforcing their position as a leader in the precision machining industry.One of the key advantages of working with {Company Name} for CNC machining of small parts is their ability to handle complex projects with quick turnaround times. Their advanced equipment and experienced machinists allow them to optimize production processes, minimizing lead times and ensuring timely delivery of machined parts to their customers.Overall, {Company Name} has solidified its position as a top-tier provider of CNC machining services for small parts, catering to the diverse needs of industries that demand precision and reliability. With their unwavering commitment to quality and customer satisfaction, they continue to be the go-to choice for businesses looking for a trusted partner in precision machining.As the manufacturing industry continues to evolve, the demand for high-quality small parts will only increase. With {Company Name}'s dedication to excellence and continuous investment in CNC machining technologies, they are well-positioned to meet the evolving needs of their customers and maintain their leadership in the precision machining sector.

Best Tips for Aluminum Welding: Techniques, Tools, and Safety Precautions

Aluminum welding is a crucial process in various industries, such as automotive, aerospace, and manufacturing. The ability to efficiently and effectively weld aluminum is essential for creating strong and durable products. One company that has gained recognition for its expertise in aluminum welding is {}.{} is a leading manufacturer of welding equipment and solutions. With over 50 years of experience in the industry, the company has established itself as a reliable and innovative provider of welding technology. {} offers a wide range of welding equipment, including advanced machines for aluminum welding, as well as comprehensive training and support services.The company's advanced aluminum welding equipment is designed to meet the specific needs of various industries. Whether it's automotive components, aerospace parts, or architectural structures, {}'s welding solutions are capable of delivering high-quality welds on aluminum materials. The company's commitment to research and development has led to the creation of cutting-edge welding technology that ensures precision and efficiency in aluminum welding processes.One of the key advantages of {}'s aluminum welding equipment is its ability to produce welds with superior strength and integrity. Aluminum is known for its lightweight and corrosion-resistant properties, making it a preferred material in many applications. However, welding aluminum can be challenging due to its high thermal conductivity and low melting point. {}'s welding technology is specially designed to overcome these challenges and produce high-quality welds that meet industry standards.In addition to its advanced equipment, {} also provides comprehensive training and support services to ensure that customers are able to maximize the potential of their welding technology. The company's team of experts offers training programs and workshops on aluminum welding techniques, as well as on-site support for troubleshooting and optimization of welding processes. This level of support is crucial for industries that rely on aluminum welding for the production of critical components and structures.Furthermore, {} is dedicated to sustainability and environmental responsibility. The company's aluminum welding technology is designed to minimize energy consumption and waste generation, contributing to a more sustainable manufacturing process. By investing in {}'s welding solutions, companies can reduce their environmental impact while maintaining high standards of quality and efficiency.{}'s commitment to excellence in aluminum welding has earned the company a strong reputation in the industry. Its innovative technology, comprehensive support services, and dedication to sustainability make {} a trusted partner for businesses seeking reliable aluminum welding solutions. With a focus on continuous improvement and customer satisfaction, {} is well-positioned to meet the evolving needs of the welding industry.As the demand for aluminum welding continues to grow across various sectors, {} remains at the forefront of innovation, offering state-of-the-art solutions for the most challenging welding applications. The company's dedication to quality, reliability, and sustainability makes {} a go-to provider for businesses looking to elevate their aluminum welding capabilities.In conclusion, {}'s expertise in aluminum welding, combined with its advanced technology and comprehensive support services, makes it a key player in the welding industry. With a focus on innovation, sustainability, and customer satisfaction, {} is well-equipped to address the diverse needs of industries that rely on aluminum welding for their manufacturing processes. By choosing {} as a partner, businesses can ensure that their aluminum welding operations are efficient, cost-effective, and of the highest quality.

New Stamping Cut Process Streamlines Manufacturing Efficiency and Reduces Costs

[Company Name], a leading company in the manufacturing industry, has announced the implementation of stamping cut technology to enhance its production process. The company has been at the forefront of innovation, constantly seeking new and improved methods to increase efficiency and quality of their products.Stamping cut, also known as blanking or punching, is a method used to cut or shape metal sheets into a desired form. It is a widely used manufacturing process in various industries, including automotive, aerospace, electronics, and more. By introducing this technology into their production line, [Company Name] aims to further improve the precision and consistency of their products.With the implementation of stamping cut technology, [Company Name] will be able to streamline their manufacturing process and reduce lead times. This will not only help in meeting the growing demand for their products but also enable them to keep up with the ever-changing market trends. By reducing the time and effort required for manual cutting and shaping of metal sheets, [Company Name] can also significantly cut down on production costs, which could ultimately result in more competitive pricing for their customers.In addition to the improved efficiency, stamping cut technology will also enhance the quality of [Company Name]'s products. The precise and accurate cutting achieved through this method will ensure that each component meets the required specifications, ultimately leading to better performance and longevity of the final products. This, in turn, will further solidify the company's reputation for delivering high-quality and reliable products to their customers.[Company Name] has always been committed to investing in the latest technologies and equipment to stay ahead in the industry. The introduction of stamping cut technology is just one of the many steps the company has taken to achieve this goal. By continuously modernizing their production processes, [Company Name] is positioning itself as a leader in the manufacturing sector and is ready to meet the demands of the future.The company's dedication to innovation and quality has not gone unnoticed. [Company Name] has garnered a strong reputation for its commitment to excellence and has built enduring relationships with its customers and partners. The implementation of stamping cut technology is yet another testament to the company's unwavering dedication to providing the best products and services to the market.As [Company Name] moves forward with the integration of stamping cut technology into its production process, it is clear that the company is committed to driving progress and delivering value to its customers. The move is not only a significant step forward for the company but also signals its readiness to embrace new technologies and adapt to the evolving needs of the market.In conclusion, the implementation of stamping cut technology by [Company Name] is a testament to the company's commitment to innovation, efficiency, and quality. As the company continues to invest in advanced technologies, it is poised to maintain its position as a leading manufacturer in the industry and meet the demands of the market. With its strong focus on delivering value to its customers, [Company Name] is well-positioned to thrive in the ever-changing manufacturing landscape.

Discover the Latest Trends in Aluminum Extrusion Technology

Aluminum Extrusion Company Leads the Industry in Innovation and SustainabilityWith a commitment to innovation and sustainability, [Aluminum Extrusion Company] is leading the way in the aluminum extrusion industry. Their dedication to excellence has positioned them as a premier provider of high-quality aluminum extrusions for a wide range of applications.Founded in [year], [Aluminum Extrusion Company] has established itself as a leader in the industry, constantly pushing the boundaries of what is possible with aluminum extrusion. Their state-of-the-art manufacturing facilities and cutting-edge technology allow them to produce extrusions that meet the most stringent requirements and specifications.One of the key factors that set [Aluminum Extrusion Company] apart is their focus on sustainability. They are committed to reducing their environmental impact through the use of recycled materials and energy-efficient processes. This dedication to sustainability has not only earned them a reputation as an environmentally conscious company but has also opened up new business opportunities as more and more customers prioritize sustainable sourcing.In addition to their commitment to sustainability, [Aluminum Extrusion Company] is also at the forefront of innovation in the industry. They continuously invest in research and development to improve their products and processes, driving efficiency and creating new possibilities for their customers. This commitment to innovation has led to the creation of unique extrusion designs and the ability to produce custom extrusions that meet precise specifications.Another key area of focus for [Aluminum Extrusion Company] is their dedication to customer service. They work closely with their clients to understand their needs and provide tailored solutions that meet and exceed their expectations. Whether it's a custom extrusion for a specific application or a high-volume order for a specific industry, [Aluminum Extrusion Company] has the expertise and capabilities to deliver.As a testament to their commitment to excellence, [Aluminum Extrusion Company] has earned numerous certifications and accolades for their quality and performance. They adhere to strict industry standards and undergo regular audits to ensure that their products meet the highest levels of quality and consistency.With a proven track record of success and a strong reputation in the industry, [Aluminum Extrusion Company] continues to grow and expand its reach. Their dedication to innovation, sustainability, and customer service has allowed them to forge strong relationships with customers and partners, positioning them for continued success in the years to come.In an industry that is constantly evolving, [Aluminum Extrusion Company] has demonstrated a commitment to staying ahead of the curve and leading the way in the aluminum extrusion market. With a focus on sustainability, innovation, and customer service, they are well-positioned to continue setting the standard for excellence in the industry.In conclusion, [Aluminum Extrusion Company] is a company that is making a significant impact in the aluminum extrusion industry. Their commitment to sustainability, innovation, and customer service sets them apart as a leader in the field. With a dedication to excellence and a track record of success, [Aluminum Extrusion Company] is poised for continued growth and continued success in the years to come.

High-Quality Steel Machined Parts for Various Applications

Steel Machined Parts is a leading manufacturer of precision machined components for a wide range of industries. With a reputation for delivering high quality products and exceptional customer service, the company has established itself as a trusted partner for businesses in need of reliable and efficient manufacturing solutions.Founded in 1998, Steel Machined Parts has grown from a small workshop into a state-of-the-art manufacturing facility, equipped with the latest CNC machining technology and a team of highly skilled engineers and machinists. Over the years, the company has continued to invest in new equipment and training to ensure that they can meet the evolving needs of their customers and maintain their position as a leader in the industry.Steel Machined Parts serves a diverse customer base, including companies in the automotive, aerospace, defense, and medical industries. Their ability to produce complex components with tight tolerances has made them a trusted supplier for manufacturers producing critical parts for various applications. Whether it's precision gears for aircraft engines or specialized medical implants, Steel Machined Parts has the expertise and capabilities to deliver the highest quality machined parts.One of the key factors that sets Steel Machined Parts apart from their competitors is their commitment to continuous improvement and innovation. The company has a strong focus on research and development, constantly exploring new techniques and materials to enhance their manufacturing processes. This dedication to innovation has allowed Steel Machined Parts to stay ahead of the curve and provide their customers with cutting-edge solutions to their machining needs.In addition to their technical expertise, Steel Machined Parts is also known for their dedication to customer satisfaction. The company works closely with each client to understand their specific requirements and provide tailored solutions to meet their needs. From prototype development to full-scale production, Steel Machined Parts offers a comprehensive suite of services to support their customers at every stage of the manufacturing process.Most recently, Steel Machined Parts has announced the launch of a new line of steel machined parts that will further expand their product offerings. This expansion is expected to provide customers with even more options for their machining needs, further solidifying Steel Machined Parts' position as a leading provider of precision machined components."We are excited to introduce our new line of steel machined parts to the market," said [Company Spokesperson]. "With our state-of-the-art manufacturing capabilities and commitment to excellence, we are confident that these new products will meet the needs of a wide range of industries and continue to uphold our reputation for quality and reliability."The new steel machined parts are designed to offer the same level of precision and performance that customers have come to expect from Steel Machined Parts. Whether it's hardened steel shafts, precision milled components, or custom steel fittings, the company's expanded product line will provide businesses with a wider range of options for their machining needs.As Steel Machined Parts continues to grow and evolve, they remain dedicated to upholding the highest standards of quality and service for their customers. With their focus on innovation, dedication to customer satisfaction, and the launch of new products, the company is poised to remain a leader in the precision machining industry for years to come.