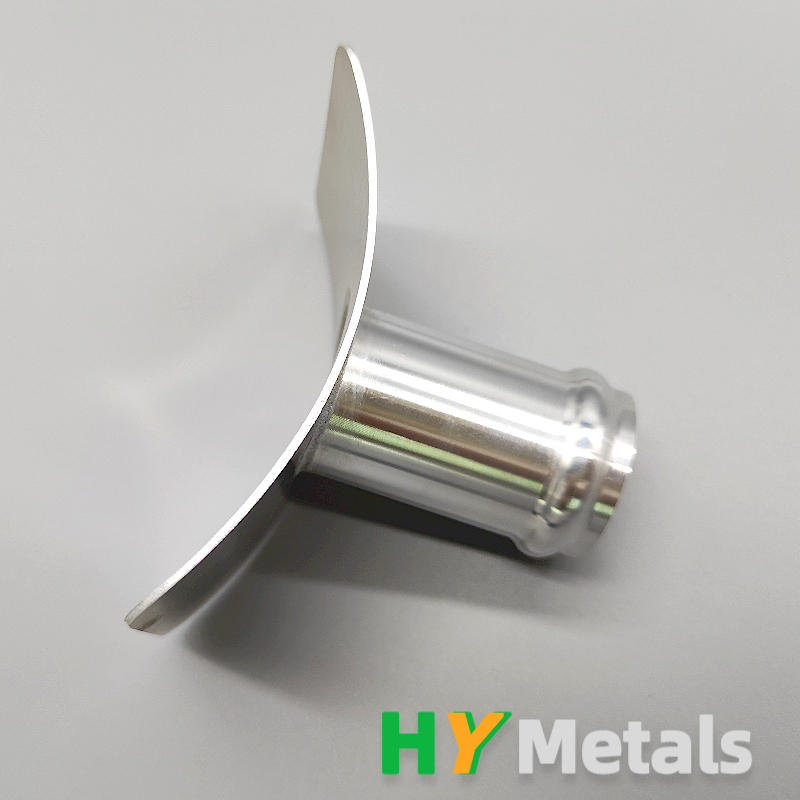

High Quality Anodized Aluminum Machined Parts for Precision Engineering

By:Admin

One company that has been at the forefront of producing high-quality Anodized Aluminum Machined Parts is {}. With years of experience in the precision machining industry, they have built a reputation for delivering top-notch products to their customers.

Specializing in custom machining services, they are able to produce an extensive range of Anodized Aluminum Machined Parts to meet the specific needs of their clients. From simple components to complex prototypes, they are equipped with state-of-the-art technology and a team of skilled professionals to ensure the highest level of precision and quality in their products.

Their dedication to providing exceptional customer service has made them a trusted partner for businesses in various industries, including aerospace, automotive, medical, and electronics. They understand the unique requirements of each industry and work closely with their clients to deliver tailor-made solutions that meet or exceed their expectations.

The anodization process used by {} involves immersing the aluminum parts in an electrolyte solution and passing an electrical current through it. This causes an oxidation reaction to occur, resulting in the formation of a thick, protective oxide layer on the surface of the parts. This layer can then be dyed using a variety of colors to achieve the desired finish.

The benefits of using Anodized Aluminum Machined Parts go beyond their aesthetic appeal. The anodized coating makes the parts resistant to corrosion, wear, and abrasion, thus extending their lifespan and reducing the need for maintenance. Additionally, the surface hardness of the anodized aluminum is significantly higher than untreated aluminum, making it suitable for applications that require a durable material.

Furthermore, the anodization process does not affect the dimensional accuracy of the parts, allowing them to maintain their precise measurements and tolerances. This is crucial for industries that demand high precision and reliability in their components.

The versatility of Anodized Aluminum Machined Parts also makes them suitable for a wide range of applications. They can be found in various products, such as electronics housings, automotive components, decorative fixtures, and medical devices. The ability to customize the color and finish of the parts makes them a popular choice for designers and manufacturers looking to add a unique touch to their products.

As the demand for Anodized Aluminum Machined Parts continues to grow, {} remains committed to staying at the forefront of the industry. They continuously invest in research and development to improve their manufacturing processes and expand their capabilities. This allows them to keep up with the evolving needs of their clients and deliver innovative solutions that set them apart from their competitors.

With a strong focus on quality, precision, and customer satisfaction, {} is well-positioned to meet the increasing demand for Anodized Aluminum Machined Parts in the market. Their dedication to excellence and their ability to deliver reliable and high-quality products make them a trusted partner for businesses looking for custom machining solutions.

Company News & Blog

The Benefits of 3D Printing and Rapid Prototyping in Manufacturing

In recent years, 3D printing and rapid prototyping have revolutionized the manufacturing industry by allowing companies to quickly and cost-effectively create prototypes and products. With the advancement of technology, companies like {Company Name}, are leading the way in utilizing this innovative process to streamline their production and design processes.{Company Name} is a pioneering company that specializes in 3D printing and rapid prototyping services. By leveraging cutting-edge technology, they are able to provide their clients with high-quality prototypes and products in a fraction of the time compared to traditional manufacturing methods. Their expertise in additive manufacturing has enabled them to work with a wide range of industries, including aerospace, automotive, healthcare, and consumer goods.One of the key advantages of 3D printing and rapid prototyping is the ability to quickly iterate and refine designs. This allows companies like {Company Name} to work closely with their clients to bring their ideas to life and make necessary adjustments in a timely manner. Furthermore, this process significantly reduces the time and cost associated with traditional prototype development, ultimately giving companies a competitive edge in the market.Another benefit of 3D printing is the ability to create complex and intricate designs that would be nearly impossible with traditional manufacturing methods. {Company Name} has been able to push the boundaries of what is possible with their state-of-the-art 3D printers, producing highly detailed and functional prototypes for their clients. This level of precision and customization is unparalleled in the industry, making {Company Name} a go-to partner for companies looking to bring their innovative ideas to fruition.In addition to rapid prototyping, {Company Name} also offers end-to-end manufacturing solutions, including batch production and on-demand manufacturing. This full-service approach sets them apart from other 3D printing companies and allows their clients to seamlessly transition from prototype to production, all under one roof. By offering a comprehensive suite of services, {Company Name} is able to meet their clients' needs at every stage of their product development process.With the growing demand for customized and on-demand manufacturing, 3D printing and rapid prototyping are poised to play an even larger role in the future of the industry. {Company Name} is at the forefront of this movement, continually investing in new technologies and processes to stay ahead of the curve. They have recently expanded their production facilities and added new, cutting-edge 3D printers to their lineup, further solidifying their position as a leader in the industry.As the industry continues to evolve, {Company Name} remains committed to providing their clients with the highest quality 3D printed products and prototypes. Their dedication to innovation and customer satisfaction has earned them a reputation as a trusted partner for companies looking to leverage the power of 3D printing in their product development and manufacturing processes.In conclusion, the combination of {Company Name}'s expertise in 3D printing and rapid prototyping, along with their full-service approach to manufacturing, has positioned them as a driving force in the industry. With their commitment to innovation and excellence, {Company Name} is well-equipped to meet the diverse needs of their clients and lead the way in the exciting world of additive manufacturing.

High-Quality Sheet Metal Copper Contacts Now Available

A leading company in the sheet metal industry, {}, has announced a groundbreaking development in the realm of copper contact. The company, known for its innovative solutions and high-quality products, has successfully designed and manufactured a new line of copper contacts that are set to revolutionize the industry.With a strong emphasis on research and development, {} has always been at the forefront of technological advancements within the sheet metal sector. The company's state-of-the-art manufacturing facilities and team of experienced engineers have enabled them to consistently deliver cutting-edge products that meet the evolving needs of their customers.The new copper contacts, which are designed to be used in a variety of electrical applications, boast a number of key features that set them apart from traditional contact materials. By leveraging their expertise in metallurgy and material science, {} has been able to enhance the conductivity and reliability of the contacts, while also ensuring that they meet the highest standards for quality and durability.In addition to their superior performance, the new copper contacts are also more environmentally friendly than alternative materials. As sustainability and energy efficiency become increasingly important considerations for businesses across all industries, {} is proud to offer a product that aligns with these values and helps their customers reduce their carbon footprint.The development of these copper contacts underscores {}'s commitment to staying ahead of the curve and anticipating the needs of their customers. By investing in research and development, the company is able to bring innovative solutions to market that enable their clients to achieve new levels of efficiency, performance, and reliability in their own products and operations.In response to the announcement, {}'s CEO expressed his excitement about the potential impact of the new copper contacts. "We are thrilled to introduce this game-changing product to the market," he said. "Our team has worked tirelessly to develop a solution that not only exceeds performance expectations, but also aligns with our commitment to sustainability. We believe that these copper contacts will enable our customers to achieve new heights of success in their own endeavors."The new copper contacts are now available for purchase, and {} is already seeing significant interest from a wide range of industries and applications. From automotive and aerospace to energy and telecommunications, businesses around the world are eager to take advantage of the enhanced performance and environmental benefits that these contacts offer.Looking ahead, {} remains dedicated to pushing the boundaries of what is possible in the sheet metal industry. By continuing to invest in research and development, as well as by leveraging their expertise in materials and manufacturing, the company is poised to deliver even more innovative solutions that will shape the future of the industry.As the demand for high-quality, sustainable materials continues to grow, {} is well-positioned to lead the way with their cutting-edge products and unwavering commitment to excellence. With the introduction of the new copper contacts, the company is once again demonstrating their dedication to driving progress and enabling their customers to thrive in an ever-changing world.

Exploring the Latest Trends and Uses of Stainless Steel Sheet Metal

[News Title]: Company A Leads the Way in Stainless Steel Sheet Metal ManufacturingIntroduction:Company A, a leading player in the manufacturing industry, has gained significant attention for its superior quality stainless steel sheet metal products. With its commitment to innovation, advanced technology, and customer satisfaction, the company has established itself as a key player in the global market. This news article aims to delve deeper into the manufacturing process, product offerings, and the impact of Company A's stainless steel sheet metal on industries worldwide.Manufacturing Process: Company A follows a meticulous manufacturing process to ensure the production of high-quality stainless steel sheet metal. The process begins with the selection of premium raw materials sourced from reliable suppliers. These raw materials undergo rigorous quality control tests for strength, durability, and resistance to corrosion. Once approved, the materials move to the fabrication stage, where cutting-edge machines and advanced production techniques are employed to shape the stainless steel sheets according to precise dimensions and specifications.The manufacturing process at Company A also places a strong emphasis on environmental sustainability. The company adheres to strict industry standards, ensuring minimal waste generation and efficient energy consumption throughout the production cycle. By adopting sustainable practices, Company A not only safeguards the environment but also contributes positively to its corporate social responsibility.Product Offerings:Company A offers a diverse range of stainless steel sheet metal products suitable for various industries. The company produces sheets with different finishes, including brushed, mirror, and embossed, catering to the specific design requirements of its customers. Whether it be for architectural purposes, interior design, automotive applications, or industrial uses, Company A has a comprehensive array of stainless steel sheets to meet every need.Furthermore, the dimensional versatility of Company A's stainless steel sheet metal allows for customized solutions. The company possesses cutting-edge machinery capable of producing sheets in various thicknesses, widths, and lengths as per customer specifications. This flexibility has enabled Company A to establish itself as a preferred supplier for design professionals looking for tailored stainless steel sheet metal solutions.Global Impact:Company A's stainless steel sheet metal products have made a remarkable impact across various industries worldwide. Architects and interior designers appreciate the aesthetic appeal and durability that these sheets offer, leading to their extensive use in prestigious constructions and building projects. Additionally, within the automotive industry, Company A's stainless steel sheets find application in various components, such as exhaust systems, body panels, and trims, owing to their corrosion resistance and ability to withstand extreme conditions.The industrial sector also benefits from Company A's stainless steel sheet metal, with its applications in machinery manufacturing, food processing, and chemical plants. The high tensile strength, thermal resistance, and hygienic properties of these sheets make them ideal for industrial use, thereby ensuring safe and reliable operations.Conclusion:Through its unwavering commitment to excellence, Company A continues to lead the way in stainless steel sheet metal manufacturing. By embracing cutting-edge technologies, focusing on sustainability, and offering a diverse range of products, the company has become a trusted partner for industries across the globe. With a strong foothold in the market and unmatched product quality, Company A's stainless steel sheet metal continues to elevate the standard of quality and performance in various industrial applications.

What is Water-jet Technology? A Definition

Water-jet Technology Takes the Industrial World by StormWater-jet technology has been quietly revolutionizing the industrial world over the past decade. Driven by powerful streams of water and sometimes abrasive materials, water-jet cutting technology is quickly becoming the go-to cutting method for a variety of industries. From aerospace to the medical field, water-jet cutting is proving to be more precise and efficient than traditional cutting methods.A water-jet is a cutting tool that creates a high-velocity jet of water, usually mixed with an abrasive material. This creates a powerful cutting force that can cut through virtually any material with precision, including metal, stone, glass, and plastic. Water-jet cutting technology was developed in the 1950s, and since then, it has been continuously refined and improved, becoming one of the most versatile and effective cutting methods available today.One of the many benefits of water-jet cutting is its precision. Unlike traditional cutting methods that rely on brute force and sharp blades, water-jet cutting relies on a powerful stream of water to slice through materials with ease. This allows for incredibly intricate and precise cuts, even on difficult or complicated materials.Another benefit of water-jet cutting is its versatility. Water-jet cutters can handle a wide range of materials, from soft rubber to thick steel. This makes it an ideal choice for industries that require cutting precision on a variety of materials.The aerospace industry, for example, heavily relies on water-jet technology for the precision cutting of parts and components. With water-jet cutting, aerospace manufacturers can create intricate shapes out of tough materials such as titanium and composites, resulting in stronger, lighter-weight aircraft that perform better than ever before. Other industries, such as the medical field, also rely on water-jet cutting for precision cutting of surgical instruments and implantable devices.Water-jet cutting technology has also become more accessible in recent years, with more and more companies offering water-jet cutting services to a variety of industries. Companies like {} offer state-of-the-art water-jet cutting services that can handle large production runs or small, custom projects. By outsourcing their cutting needs, businesses can save time and money on equipment and maintenance costs while still enjoying the precision and versatility of water-jet cutting.Finally, water-jet cutting is also environmentally friendly. Unlike traditional cutting methods that produce harmful dust and debris, water-jet cutting creates minimal waste and leaves the material clean and untouched. This means less waste, fewer environmental hazards, and a safer workplace for employees.In conclusion, water-jet cutting technology is quickly becoming the go-to cutting method for businesses ranging from aerospace to medical manufacturing. With its precision, versatility, accessibility, and environmentally friendly benefits, water-jet cutting is the perfect solution for industries that require precise cutting of a variety of materials. As technology continues to improve, we can only expect to see water-jet cutting become even more essential to the industrial world.

Industry Innovates with New Stamping Cut Technology

Stamping cut technology has been a game-changer in the manufacturing industry, enabling companies to produce high-precision parts with speed and accuracy. However, the latest advancements in stamping cut technology have taken this process to a whole new level, allowing for even greater efficiency and cost-effectiveness.{Company name} is at the forefront of these developments, leveraging cutting-edge stamping cut technology to deliver superior parts and components to their clients. With a focus on innovation and continuous improvement, {Company name} has established itself as a leader in the industry, setting new standards for quality and performance.The key to {Company name}'s success lies in their state-of-the-art facilities and a team of highly skilled engineers and technicians. By investing in the latest stamping cut technology, {Company name} has been able to increase their production capacity and improve turnaround times, meeting the growing demands of their clients in various sectors, including automotive, aerospace, and electronics.One of the most significant advantages of the latest stamping cut technology is its ability to reduce material waste and improve overall efficiency. By utilizing advanced software and precision machinery, {Company name} is able to optimize the cutting process, minimizing errors and maximizing the utilization of raw materials. This not only leads to cost savings but also contributes to a more sustainable approach to manufacturing.Additionally, the high precision and accuracy achieved through stamping cut technology have enabled {Company name} to deliver parts that meet the most stringent quality standards. This has been particularly important for their clients in the automotive and aerospace industries, where safety and reliability are paramount. With the ability to produce intricate and complex parts with tight tolerances, {Company name} has become a trusted partner for companies looking for superior components.Innovation is also a key driver for {Company name}, as they continue to push the boundaries of stamping cut technology. By collaborating with research institutions and industry experts, {Company name} is constantly exploring new techniques and materials to further enhance their capabilities. This commitment to innovation has allowed {Company name} to stay ahead of the curve and offer their clients cutting-edge solutions for their manufacturing needs.Looking ahead, {Company name} is poised to further expand their capabilities in stamping cut technology, with plans to invest in even more advanced machinery and equipment. With an eye on the future, {Company name} aims to be at the forefront of the next generation of manufacturing, delivering even greater efficiency, precision, and cost-effectiveness to their clients.In conclusion, the latest advancements in stamping cut technology have revolutionized the manufacturing industry, and {Company name} has been a driving force behind this transformation. With a focus on innovation, quality, and continuous improvement, {Company name} has established itself as a leader in the field, setting new standards for excellence. As they continue to invest in the latest stamping cut technology, {Company name} is well-positioned to meet the evolving needs of their clients and drive the industry forward.

Custom CNC Milling Metal Parts: Everything You Need to Know

The use of Computer Numerical Control (CNC) technology has revolutionized the manufacturing industry, particularly in the production of metal parts. With the ability to precisely and efficiently cut and shape metal materials, CNC milling has become an integral part of the production process for a wide range of industries. One company at the forefront of this cutting-edge technology is [Company Name].[Company Name] has established itself as a leading provider of CNC milling services for metal parts. With a state-of-the-art facility and a team of highly skilled engineers and technicians, the company has earned a reputation for delivering high-quality, precision-engineered components to its clients. The company's commitment to excellence and innovation has allowed it to stay ahead of the curve in an ever-evolving industry.The CNC milling process involves using computer-aided design (CAD) software to create a digital model of the desired part. This model is then translated into instructions for the CNC machine, which uses various cutting tools to shape the metal material according to the design specifications. The result is a finished metal part that meets the exact requirements of the client, with high levels of accuracy and consistency.One of the key advantages of CNC milling is its ability to produce complex and intricate parts that would be difficult or impossible to create using traditional manufacturing methods. This makes it an ideal solution for industries such as aerospace, automotive, medical devices, and electronics, where precision and reliability are paramount. With the ability to work with a wide range of metals, including aluminum, steel, titanium, and brass, CNC milling offers versatility in the production of metal parts.[Company Name] has made significant investments in CNC milling technology, ensuring that its facility is equipped with the latest machinery and software to provide cutting-edge solutions for its clients. The company's team of engineers and technicians are highly trained in the operation of these state-of-the-art machines, allowing them to achieve the highest levels of efficiency and accuracy in their work.In addition to its technical capabilities, [Company Name] prides itself on its commitment to customer satisfaction. The company works closely with its clients to understand their specific needs and requirements, providing tailored solutions that meet or exceed expectations. Whether it's a prototype for a new product or a large-scale production run, [Company Name] is dedicated to delivering metal parts of the highest quality, on time and within budget.As the demand for CNC-milled metal parts continues to grow, [Company Name] remains at the forefront of the industry, constantly pushing the boundaries of what is possible with this advanced technology. With a focus on innovation, quality, and customer service, the company is well-positioned to meet the evolving needs of its clients and continue to drive the manufacturing industry forward.In conclusion, CNC milling has become an indispensable tool for the production of metal parts, offering precision, efficiency, and versatility for a wide range of industries. Through its commitment to excellence and innovation, [Company Name] has established itself as a leader in the field, providing cutting-edge solutions for its clients and driving the industry forward. As the demand for high-quality, precision-engineered metal parts continues to grow, [Company Name] is well-equipped to meet and exceed the expectations of its clients, solidifying its position as a key player in the CNC milling industry.

Top 3-Axis Features and Benefits You Need to Know

3-Axis, a leading manufacturer of cutting-edge technology, has recently announced the launch of their latest product, the 3-Axis Advanced Motion Control System. This state-of-the-art system is designed to provide precise and accurate motion control for a wide range of applications, from industrial automation to robotics and beyond.The 3-Axis Advanced Motion Control System is a culmination of years of research and development, combining the latest advancements in motion control technology with the company's expertise in engineering and manufacturing. The system features a highly responsive 3-axis control unit, capable of delivering smooth and precise motion control across multiple axes. This allows for seamless integration into existing automation systems, as well as the ability to control complex motion sequences with ease.One of the key features of the 3-Axis Advanced Motion Control System is its user-friendly interface, which allows for easy setup and operation. Users can quickly configure the system to meet their specific requirements, using the intuitive interface to set motion parameters, control speed and acceleration, and monitor system performance in real-time. This level of flexibility and control makes the system well-suited for a wide range of applications, from advanced manufacturing processes to cutting-edge robotic systems.In addition to its advanced motion control capabilities, the 3-Axis system also offers a high level of precision and accuracy. This is achieved through the use of advanced servo motors and encoders, which provide real-time feedback and error correction to ensure that motion control is always precise and reliable. This level of precision is essential for many applications, particularly in industries where tight tolerances and high standards of quality are required.Furthermore, the 3-Axis Advanced Motion Control System is designed with scalability in mind, allowing for easy integration into existing automation and robotic systems. This makes it a versatile solution for companies looking to enhance their existing machinery with advanced motion control capabilities. Whether it's retrofitting older equipment or integrating the system into new production lines, the 3-Axis system offers a seamless and cost-effective solution for achieving better motion control performance.With the launch of the 3-Axis Advanced Motion Control System, 3-Axis has once again demonstrated its commitment to pushing the boundaries of motion control technology. The company has a long history of innovation and excellence in the field of automation and robotics, and the new system is a testament to their ongoing dedication to delivering cutting-edge solutions to their customers.In conclusion, the 3-Axis Advanced Motion Control System represents a significant advancement in the field of motion control technology. With its advanced capabilities, user-friendly interface, and high level of precision, the system is poised to make a significant impact in a wide range of industries. Whether it's improving the efficiency of manufacturing processes or enhancing the performance of robotic systems, the 3-Axis system offers a powerful and versatile solution for companies looking to take their motion control capabilities to the next level.

High-Quality Lathe Parts for a Perfect Fit Every Time - Installation Guides and Manuals Available

Sears PartsDirect Now Offers Top-Quality Lathe Parts for All Major Lathe BrandsSears PartsDirect is excited to announce that we are now offering a wide selection of lathe parts for all major lathe brands, ensuring that our customers can find the best-quality parts they need to keep their lathes running smoothly. Our manufacturer-approved lathe parts are designed to provide a proper fit every time, giving our customers the assurance that their machines will be restored to optimal performance with ease.Lathe machines are an essential component of many industrial processes, and often need to be repaired and maintained in order to keep them functioning as designed. That’s where Sears PartsDirect comes in – we are committed to making it easy for our customers to find the parts they need to keep their machines running smoothly.We understand that different machines have different requirements, which is why we have a large selection of lathe parts available to suit all needs. Whether it is a specialized replacement part, an upgrade or a general maintenance part, our customers can be sure that they will find what they need.Our experienced team is dedicated to helping our customers find the right parts for their machines, and we are always on hand to answer any questions or concerns they may have. Our online catalogues are easy to navigate, and we provide detailed specifications and information about each part to make it easy for our customers to find what they need.In addition to our extensive selection of lathe parts, we also offer installation guides, diagrams, and manuals to help our customers along the way. Our guides and manuals are designed to provide a step-by-step approach to repairs and maintenance, ensuring that our customers can complete the job quickly and efficiently.At Sears PartsDirect, we are committed to providing our customers with the highest quality service and products possible. Our team of experts works diligently to ensure that our customers can find the parts they need, and our dedicated support team is always available to assist them with their needs.Our commitment to quality is reflected in our manufacturer-approved parts, which are designed to meet the highest standards for performance and reliability. We are proud to offer our customers the best in the industry, and we look forward to continuing to provide top-quality parts and support for all major lathe brands.In conclusion, Sears PartsDirect is excited to announce that we are now offering a wide selection of lathe parts for all major lathe brands. Our commitment to quality and service sets us apart from the competition, and we are dedicated to providing our customers with the best possible experience. With our extensive selection of parts, expert guidance, and exceptional customer support, we are confident that we can help our customers keep their lathes running smoothly and efficiently for years to come.

Ultimate Guide to Designing and Developing an Industry-Specific Solution

Industry Design And Development Part, a leading design and development company in the industry, is proud to announce its latest collaboration with a renowned technology company. The partnership aims to revolutionize the way consumers interact with technology and create innovative, user-friendly products that will shape the future of the industry.With over a decade of experience in the design and development field, Industry Design And Development Part has established itself as a pioneer in the industry. The company is known for its cutting-edge approach to product design and its ability to deliver high-quality, innovative solutions to its clients. With a team of experts in industrial design, engineering, and user experience, Industry Design And Development Part has consistently pushed the boundaries of what is possible in product development.The latest collaboration with the technology company is an exciting opportunity for Industry Design And Development Part to showcase its expertise in creating groundbreaking products. The partnership will leverage the strengths of both companies, combining the technology company's advanced technology with Industry Design And Development Part's design and development capabilities. This collaboration is expected to result in the creation of products that will not only meet the needs of consumers but also exceed their expectations.One of Industry Design And Development Part's key strengths is its focus on user-centered design. The company understands the importance of creating products that are intuitive and easy to use, and it has a proven track record of designing products that resonate with consumers. By working closely with the technology company, Industry Design And Development Part will be able to apply its user-centered design approach to the creation of innovative products that will set new industry standards.In addition to its design expertise, Industry Design And Development Part is also known for its commitment to sustainability and environmental responsibility. The company is dedicated to minimizing the environmental impact of its products and processes, and it actively seeks out sustainable materials and manufacturing methods. This commitment to sustainability aligns with the values of the technology company, making the collaboration a perfect fit for both parties."We are thrilled to be partnering with a company as esteemed as the technology company," said [spokesperson], [title] at Industry Design And Development Part. "This collaboration presents a unique opportunity for us to showcase our expertise in design and development and create products that will truly make a difference in the industry. We are excited to combine our strengths and work together to push the boundaries of innovation."As the collaboration between Industry Design And Development Part and the technology company continues to unfold, industry insiders and consumers alike are eager to see the products that will emerge from this partnership. With a shared commitment to innovation, user-centered design, and sustainability, the collaboration is poised to make a significant impact on the industry and set new benchmarks for product excellence.About Industry Design And Development PartIndustry Design And Development Part is a [remove brand name] design and development company with a mission to create innovative, user-centered products that push the boundaries of what is possible. With a team of experts in industrial design, engineering, and user experience, Industry Design And Development Part has established itself as a leader in the industry, known for its cutting-edge approach to product development and its commitment to sustainability. Whether working with startups or Fortune 500 companies, Industry Design And Development Part is dedicated to delivering high-quality, innovative solutions that exceed client expectations.

3-Axis Milling Machine for Versatile Applications in Die and Mold Construction

Milling Precision Parts: Achieving Unparalleled Accuracy and Versatility with Universal Milling MachinesMilling machines are used extensively in a wide range of industrial applications to create precision parts with high accuracy and efficiency. With the advent of advanced technology and innovative engineering, milling machines have become much more versatile and capable of performing a wide range of functions. Among the most versatile of all milling machines in the market today are the 3-axis universal milling machines.Here, we will highlight the Milling machine | 3 axis | MILL E Series – a universal application offered by GF Machining Solutions. The range of HEM vertical machining center sets standards in the VMC category, and the VCE range is ideally suited for die and mold construction using a round-head cutter.The Mill E series milling machines are highly sophisticated and versatile machines capable of performing a diverse range of functions. They can create precision parts of various sizes to meet the demands of different industries, from aerospace and defense to automotive and medical.What sets the Mill E series apart from other milling machines in the market is its unique design and engineering. It features a 3-axis system that offers unparalleled accuracy and versatility, making it perfect for a range of applications. Additionally, the Mill E series is built to withstand the rigors of industrial use, ensuring reliable and precise performance.One of the main benefits of using the Mill E series milling machines is their ability to reduce production time while increasing output. The fast and precise movement of the spindle head enables them to create complex parts with high accuracy, reducing the need for manual labor and enhancing overall productivity.Moreover, the Mill E series machines are designed with user-friendliness in mind, with intuitive software and user interfaces that enable easy operation of the machines. With these machines, operators can create complex parts with ease, and the machines can be easily customized to suit the demands of different applications.The VCE range of milling machines also makes use of advanced technology and innovative engineering to offer unparalleled performance. These machines are designed to work exclusively with round head cutters, making them ideal for die and mold construction. They are built to provide high precision and repeatability during the machining process, ensuring consistent results every time.One of the main advantages of the VCE range of milling machines is their ability to perform smoothing operations on complex surfaces of molds and dies. Smoothing the surfaces of molds and dies is a critical part of the manufacturing process, as it ensures high-quality parts that are free of blemishes and imperfections.In conclusion, milling precision parts requires high accuracy, precision, and versatility, which is why the Mill E series and VCE range milling machines are ideal for any industrial application. With their ability to create complex parts with precision and accuracy, these machines are the perfect choice for industries that require high-quality parts with tight tolerances. The use of these machines not only enhances productivity but also helps to reduce production costs, making them a valuable addition to any manufacturing facility. If you are searching for a reliable and efficient milling machine to create precision parts, look no further than the Mill E series and VCE range of milling machines.